The article aims to help you understand 3D laser cutting technology and its benefits for your business. It also gives you the latest 3D laser cutting machines in Baison and the way to get them.

Working Principle of 3D Laser Cutting

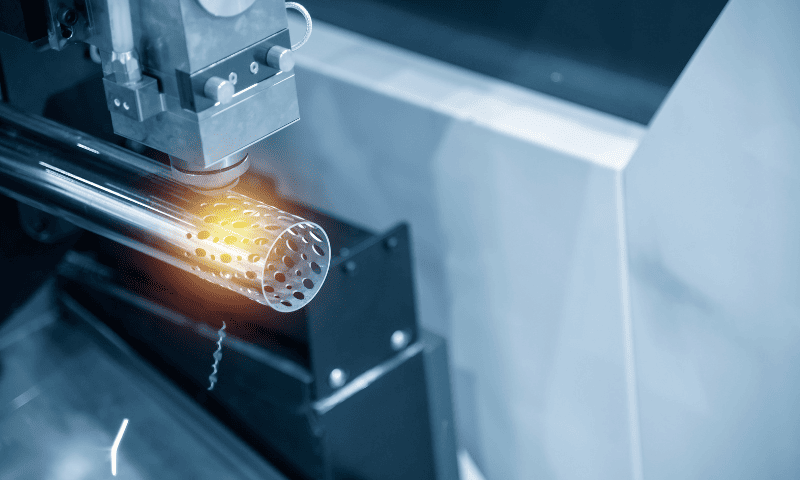

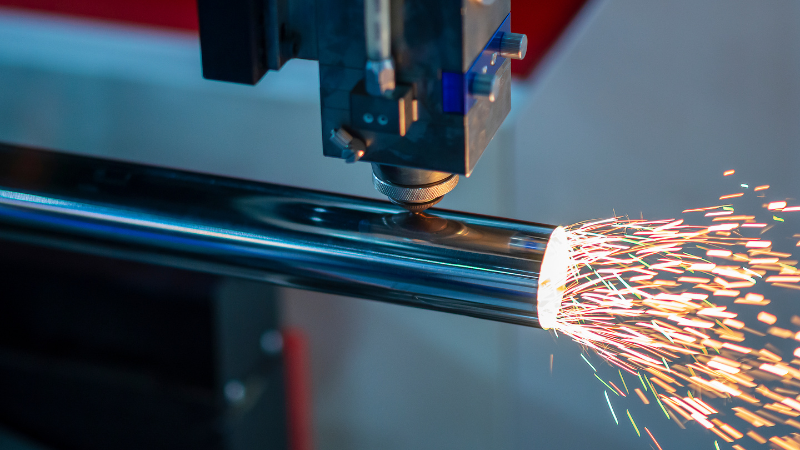

Utilizing a high-powered laser beam emitted from the cutting head focused through a lens to melt or vaporize material to form a desired shape, the 3D laser cutting process offers an efficient and precise method for various cutting applications. This advanced technology involves computer-controlled mirrors that guide the laser beam along the desired cutting path.

The laser beam from the cutting head, with its immense power, generates intense heat when it interacts with the material. This heat effectively melts or vaporizes the material, resulting in a clean and accurate cut. They have the flexibility to adjust rapidly to the cutting functions required for workpieces of various shapes and sizes. From complex parts to large-scale productions, 3D laser cutting technology has taken manufacturing to a whole new level.

This innovative system revolutionizes the traditional various processes of metal cutting by offering greater precision and faster results. With its ability to handle diverse materials and intricate designs effortlessly, 3D laser cutting has become an indispensable tool across industries ranging from metal processing to artistry.

The Difference Between 2D and 3D Laser Cutting

2D laser cutting operates on a two-dimensional plane while 3D laser cutting works in three dimensions. In 2D cutting, only flat surfaces can be processed, whereas 3D cutting allows for curved and complex shapes.

While both methods use lasers for cutting, their applications differ significantly. 3D laser cutting offers greater design flexibility compared to its two-dimensional counterpart. It enables the creation of round shapes and a variety of intricate designs that would be challenging or impossible with 2D cutting.

In addition to the ability to work with curved surfaces, 3D laser cutting also allows for the processing of various three dimensional components. This opens up possibilities for creating unique and customized products in industries such as automotive, medical equipment, and jewelry.

The production process of 3D laser cutting is highly versatile, making it suitable for cutting various materials such as metals, plastics, wood, and more. Its precision and accuracy ensure high-quality results even when dealing with intricate designs.

In contrast, 2D laser cutting is primarily used for simpler projects that involve flat materials like sheet metal or acrylic sheets. It remains an efficient method for producing components that don’t require the complexity offered by three-dimensional capabilities.

To summarize:

- 2D Laser Cutting: Operates on a two-dimensional plane; limited to flat surfaces; suitable for simpler laser cutting projects involving flat materials.

- 3D Laser Cutting: Works in three dimensional cutting; allows curved and complex shapes; offers greater design flexibility; is suitable for creating round shapes, pipe cutting, and a variety of intricate designs.

What Materials Can 3D Laser Cut?

3D laser cutting technology offers an ideal solution for cutting various materials. Here are some examples of materials that can be cut using this advanced technique.

Metals

This includes various types of metals such as stainless steel, carbon steel, alloy steel, aluminum alloy, silicon steel, copper, titanium, and more. These metals can be cut in different thicknesses and are commonly used in industries like automotive, aerospace, electronics, and elevator manufacturing that require laser processes.

Plastics

3D laser cutters can cut different types of plastics, including acrylic (PMMA), polycarbonate (PC), polyethylene (PE), polypropylene (PP), polyvinyl chloride(PVC), and more. Plastics are often used in signage, displays, packaging, and various consumer products.

Wood

Laser cutters can cut and engrave different types of wood, such as plywood, MDF (medium-density fiberboard), solid wood, veneer, and more. Wood cutting is popular in industries like furniture, cabinetry, model making, and crafts.

Composites

Composites are materials made by combining two or more different materials to create enhanced properties. 3D laser cutters can cut composite materials like carbon fiber, fiberglass, and laminates used in industries such as aerospace, advertising production, and sports equipment.

Fabrics and Textiles

Laser cutters can cut fabrics and textiles, including cotton, silk, polyester, nylon, and more. This is commonly used in the fashion industry, textile manufacturing, and for creating intricate designs on fabrics.

Leather

Laser cutters can cut and engrave leather materials, such as genuine leather, synthetic leather, suede, and more. Leather cutting is used in industries like fashion, footwear, upholstery, and accessories.

It’s important to note that the specific cutting capabilities may vary depending on the power, precision, and features of the 3D laser cutter. Different materials may require specific laser settings and cutting techniques to achieve optimal results.

Advantages of 3D Laser Cutting Technology

- Provides high precision with minimal material wastage: 3D laser cutting technology offers exceptional precision, ensuring that each cut is made with utmost accuracy. This not only enhances the quality of the final product but also minimizes material wastage, resulting in cost savings.

- Allows for intricate designs that are difficult or impossible to achieve with traditional methods: With lasers, complex and intricate designs can be achieved effortlessly. Unlike traditional cutting methods, laser technology enables the creation of intricate patterns and shapes on various materials such as stainless steel. This opens up a world of possibilities for designers and manufacturers.

- Reduces production time due to faster processing speeds: The efficiency and speed of laser cutting technology significantly reduce production time compared to conventional methods. Lasers can cut through materials swiftly and precisely, allowing for quicker fabrication processes. For an example of this, you can refer to the manufacturing process of the 3d map.

- Eliminates the need for additional machining processes: One of the key advantages of 3D laser cutting technology is its ability to perform multiple tasks in a single process. Unlike other techniques that may require additional machining steps, lasers can handle various operations like cutting, engraving, and etching all at once. This streamlines production workflows and saves both time and costs.

FAQs

Is 3D laser cutting cost-effective?

Yes! Despite its advanced capabilities, 3D laser cutting is a cost-effective solution due to reduced material waste and increased efficiency in production processes.

How precise is 3D laser cutting?

With its high level of precision down to micrometer scales (0.001 mm), 3D laser cutting ensures accurate results with minimal error margins.

Can 3D laser cutting technology be used for rapid prototyping?

Absolutely! The ability to create complex three-dimensional shapes quickly makes 3D laser cutting an ideal choice for rapid prototyping and product development.

Conclusion

As the demand for intricate and complex designs continues to grow, 3D laser cutting technology will undoubtedly play a crucial role in shaping the future of manufacturing. Its ability to deliver precise and efficient results makes it a game-changer, enabling businesses to stay competitive in an ever-evolving market. By embracing this advanced technology, you can enhance productivity while achieving superior results.

Baison Offers the Latest 3D Equipment

Baison Laser offers higher performance and complex designs in shorter lead times. If you want your business to enjoy the benefits of 3D laser cutting, we can help you. Baison’s Coil-fed Laser Blanking System is a solution with high flexibility for any size manufacturing business, providing you with full spectrum automated cutting.

In addition, we also have a plate laser cutting machine, welding machine and other equipment, and provide excellent customer training free of charge, to help you improve efficiency. What are you waiting for? Contact us today for a free quote.