A laser welding machine is a good gear in a gym due to the range of metal products: training equipment racks and other metal gears. A laser welding machine can not only repair the existing equipment but may also help you to make custom equipment or prototypes.

This article will discuss how a laser machine can be useful in the gym. We will discuss laser welding and how to utilize it in the fitness industry. Let’s take a look at what laser welding is.

What is Laser Welding?

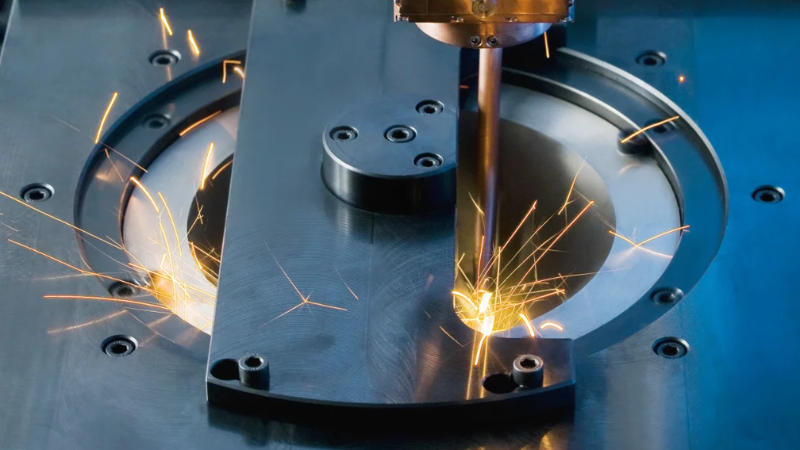

Laser welding is the process of joining metal pieces together. Instead of using electricity or a plasma jet to create an arc, laser welding uses laser power to create a heated source that melts the base metal allowing it to join with minimum damage. The heat-affected zone with a laser machine is very small, so it heats only the localized area to perform precise weld. The laser welders join pieces without distorting the surrounding material. This on-spot welding gives accurate results.

How Laser Welding Works?

Laser welding uses a focused laser beam to melt the metals as a concentrated heat source. Melted materials fuse on cooling. It works like any other welding device but uses laser power to melt material. It can weld both thin and thick materials with equal precision.

The programmable system has advanced optics that send the laser beam to the targeted spot.

Here is how it works:

Preparing the Material

Clean the metal surface to make sure there is no paint, debris, or rust on its surface. Remove also any coating of paint or protective film.

Position the Materials

Align both materials that need to be joined. Make sure they are clamped securely in place before starting the laser welding. Wrong placement or alignment can give poor welding results.

Adjust the Laser Setting

Before starting the laser welding, adjust the laser parameters, such as power, pulse duration, and beam shape. They can be adjusted according to the desired welding results, metal type, and thickness.

Activate the Laser System

Each laser machine has specific instructions. Activating the laser machine laser beam will melt the material forming the weld pool. The melted material solidifies as the laser beam moves along, making a weld bead.

Post Welding Process

After the metal is joined, the welded are also need some treatment. You can grind or polish the material to remove rough edges.

How to Use Laser Welding Machine In the Fitness Field

Here are some ways welding machines can be used in the fitness Industry:

Manufacturing Fitness Equipment

Producing high-quality fitness equipment is the most obvious use of laser welding in the fitness industry. All of this fitness equipment require metal frames. This equipment requires a lot of pipes, tubes, and sheet processing.

Fitness equipment like weight lifting machines and treadmills can be welded with this equipment. The use of force on this equipment is obvious as they are used in strenuous training. Laser welding machine gives them durable and strong bond.

Resistance Band and Cables

Resistance bands are generally made with rubber or other stretchable material but may have metal endings or holders. Using metal handles can handle high tension.

Dumbbells, Barbels, and Kettlebells.

These small handheld fitness equipment have metal parts. The laser welding machines can add weight plates, handles, and other metal parts to the handles of dumbbells and barbells, creating a strong bond that can withstand repeated drops and impacts.

Cardio machine components:

Expensive cardio machines require metal brackets, frames, and other components. So do the stationary bikes and rowing machines, creating a secure and stable platform for users.

Gym Decor

Besides making fitness gear and equipment, a laser machine makes it easy to weld different racks, metal shelves, and decor pieces in the fitness industry.

Creating Custom Metal Products for Training

Laser welding machines can help you customize your equipment to meet individual needs. You can make or customize gears to suit your individual needs. A laser welding machine helps you create custom metal products for your gym. You can create custom logos.

Repairing Gym Equipment

Besides creating equipment, a laser machine helps you to give instant repair if any joints or frames need quick fixes.

Advantages of Laser Welding Machines

Laser welding machines have their advantages. Here are a few advantages of laser welding machines

Precision and Accuracy

The most obvious benefit of laser welding is that it creates precise designs. It joins two pieces to target a very small spot through a laser beam. The heat affects only the target spot. It gives better precision and superior welding results.

Speed

Regarding the welding speed, laser welding surpasses any other traditional welding method. Laser light moves faster, continuously moving across the material and melting it.

The laser welders create a strong bond between the metal pieces. It offers deep penetration welding. Due to the high energy density of the laser beam, it penetrates deeper into the material.

Versatile

Laser welding machines come with modern technology with too many useful features. It allows the welding of a range of materials. It works with precision on both thick and thin materials.

Less Distortion

As the laser beam targets a small spot and only sends concentrated heat to that area, it does not distort the metal. Especially when working with thin and smaller pieces, it does not damage the material.

Fully Automated Machines

Laser machines come in handheld ad fully automated machine types. You can automate it, requiring less manual intervention and thus saving labor costs.

Safety

These are high-end machines that come with maximum safety features. There is no need for direct human contact with the weld pool. The technicians can control the machine from a safe distance.

Saves Labor Costs

Especially the laser welding robots are fully automated machines and require very little to no manual intervention. It can save a lot of labor costs and speed up the production level as well.

Safety Tips for Handling Laser Welding Machines

Here are a few safety tips for laser welding machines:

- Wear protective gear, including face shields, eye goggles, and gloves, to protect yourself from laser radiation

- Check the power levels to make sure you have adjusted all the parameters according to the need

- Use a machine enclosure to protect other people around from exposure to the laser beam

- Ensure the workshop or the area is well-ventilated with plenty of airflows so fumes and gases cannot build-up

- Shut down the machine with an emergency stop button in case of an emergency.

- Make sure the staff operating the laser machines are trained.

- Regular maintenance of laser welding machines can help you identify potential hazards.

- Control the laser power to ensure no accidental exposure to high-intensity radiation occurs.

Why Specialized Training and Certificates are important for Handling Laser Welding?

Laser welding is a highly technical process that requires expertise and knowledge to operate the machine safely and effectively. Laser welding machines use high-powered lasers and, if not used correctly, can pose serious safety hazards to the operator and the surrounding environment.

Proper training gives the knowledge and skills required to operate the machine. It is also essential to understand the different types of lasers and welding processes to identify and fix any issues that may arise during operation. Proper training is also needed to maintain the machine’s longevity and prevent any potential breakdowns or malfunctions.

Baison’s Fiber Laser Welder

Baison is your one-stop to get all laser cutting machines and welders. We offer handheld laser welding machines and Laser Welding Robots that suit both big and small industrial use. Handheld laser machines are easy to use and portable. They provide better welding results with low power consumption and noise. Laser Welding robots are fully automatic machines that boost industrial production with unmatched precision.

Final Words

Laser welding machines have revolutionized the manufacturing industry by providing a fast, precise, cost-effective solution for welding various materials. With their ability to produce high-quality welds with minimal distortion, they have become an indispensable tool for various applications, from automotive and aerospace to medical and electronics. As technology advances and more industries adopt laser welding, we can expect to see even greater improvements in efficiency, accuracy, and versatility. Laser welding machines have truly transformed the way we manufacture and build, and their impact on the industry will continue to be felt for years.

Get a Free Evaluation of Fiber Laser Welders for Your Business

Are you seeking the most efficient and effective welding solutions for your business? Baison’s laser welding machines have been designed to deliver precise and high-quality welding results in a fraction of the time it takes traditional welding methods.

Take a look at our laser welding machines and choose the one that suits your needs the most. We offer a free evaluation service to ensure you get the most out of our machines.

Enhance productivity and production quality with our handheld and fully automated laser welding machines.