What is a laser cutter?

A laser cutter is a machine equipped with a powerful and focused laser beam. And it is capable of cutting and engraving different materials through burning, melting, or vaporizing.

These machines also require a laser-cutting file containing details about the design. Using this information, the laser cutter can make the required cuts or engravings on the provided material.

Due to the high power and precision of laser cutters, they work well on a variety of different materials. This includes wood, metal, plastic, and so on. Furthermore, this is also a non-contact process that requires very little input from the operator once started.

An additional benefit of a laser cutter is that it is very easy to use. The process becomes easier when you understand the basics of using this machine. You must place the required material with the design’s laser-cutting file. Once started, these machines can continue to cut independently with very little supervision.

That’s why whenever there is a need to make high-precision repeated cuts or engravings, the preferred choice is always the laser cutting machines!

Applications of laser cutters

With the advancement in laser-cutting technology, the applications of laser-cutting machines have also expanded. Let’s take a look at some of the common and popular applications of laser cutters:

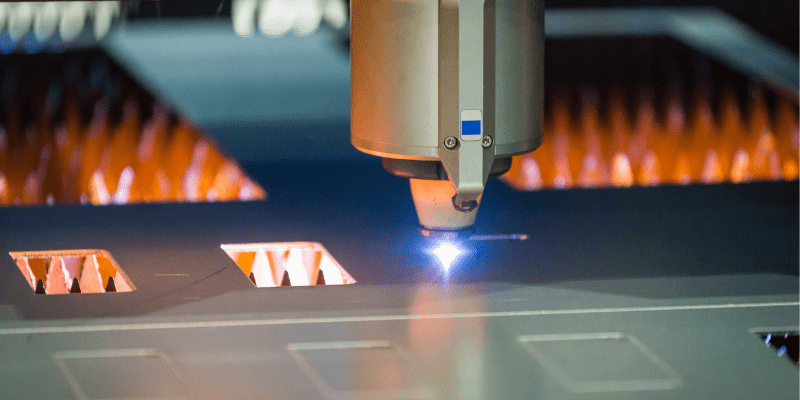

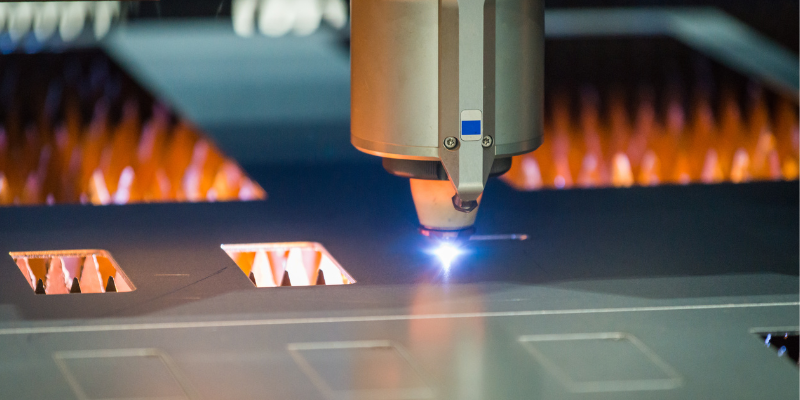

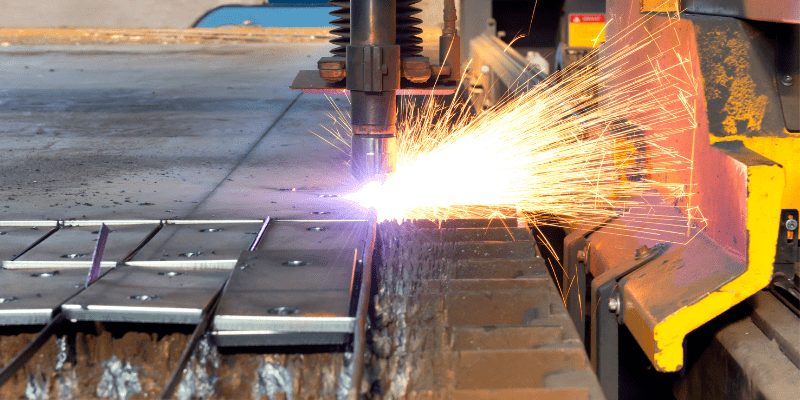

Metals

The laser technology used in the laser cutters makes it possible to use different metals. Cutting metal through mechanical means can lead to rough and unrefined cutting edges. However, laser cutting can quickly produce tight, smooth, and precise metal cuts.

With laser-cutting machines, the metallic parts of computers, cars, and even airplanes can be easily made. That’s why you will notice that the use of laser cutters in the auto and aerospace industries is widespread.

Even reflective metals can be cut with the help of a laser beam. Many assume it could cause problems if a laser beam is directed at a reflective material. We all know that this could reflect the laser and destroy the machine!

That’s why when it comes to working with reflective metals, the use of fiber laser cutters is common. In this type of laser cutting, the fiber optic cable transmits the light (laser beam). As a result, the reflected light doesn’t cause any damage to the fiber optic cable.

So, in short, you can use laser cutting for all types of metals, including non-reflective and reflective. Some popular reflective metals you can use in laser cutting include copper, silver, aluminum, and gold.

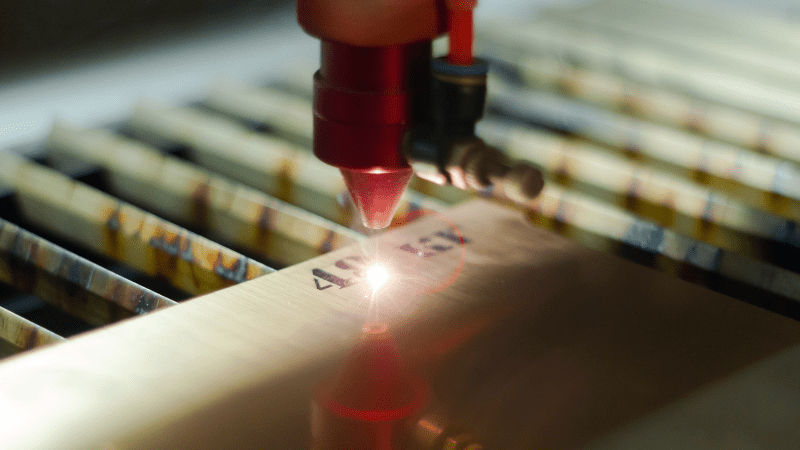

Engraving

Another popular application of laser machines is in engraving and marking. These machines have become the go-to choice in the mainstream market for engraving.

These machines can produce numerous items like key rings, insignias, metal signs, visiting cards, jewelry, etc.

Furthermore, laser-cutters can engrave on various materials without any problem, such as metal, wood, or plastic!

Medical Science

The medical industry is also a major application area of laser technology. In this industry, there’s always high volume demand. Therefore, it requires a technology that can replicate designs quickly and accurately.

Many medical devices can be made with laser-cutting machines, from orthopedic devices to surgical implants to cardiovascular devices.

Silicon Cutting

Silicon has become a key component in pretty much all the items related to electronics and computers. Furthermore, it is also the main component of solar panels, allowing us to harness solar energy.

And when talking about cutting silicon, we can’t ignore the importance of these laser beam-powered machines! Currently, one of the best and most cost-effective ways to cut small silicon pieces is only possible through laser cutters!

We have already discussed how one can use these laser beam-powered cutters with metal and silicon. But you’d be surprised to know that laser beams are also used to cut and engrave many other materials, such as:

- Textiles

- Papers

- Plastics

- Films

- Foils

- Rubber

- Foam

- Abrasive materials

- Mats

And so on…

The different types of laser cutters available on the market

Since the invention of laser cutters in the 1960s, these machines have undergone huge technological upgrades. Today, different types of laser cutters are available in the market utilizing different types of laser technology.

Let’s look at three main types of laser cutters to understand how they work:

CO2 Lasers

This laser cutter uses a gas mixture of carbon dioxide, hydrogen, helium, & nitrogen enclosed in a tube. When electricity passes through these gases, it produces a light beam (laser).

A reflective mirror is present on one end of the tube, and a partial mirror is present on the other. As a result, some of the light passes through the tube – This light produced by CO2 is invisible and belongs to the light spectrum’s infrared range.

Since this type of laser-cutter uses CO2 gas, it is also known as a CO2 (carbon dioxide) laser-cutters.

On average, these machines offer laser power of 25 – 100 watts and a wavelength of around 10.6 μm. However, some of the CO2 lasers used in the industry can also have laser power of several Kilowatts.

Fiber Lasers

These laser machines use seed lasers and belong to the solid-state laser group. In these machines, glass fibers amplify the laser beam & can provide a wavelength of 1.064 μm. Compared with CO2 cutters, the price of fiber laser cutters is usually higher.

However, the higher price tag also comes with many benefits. Fiber lasers have a long service life and are also maintenance-free. On average, a fiber laser cutter can last 25,000 operational hours at the minimum. Another benefit is that the laser produced by fiber laser machines is more stable and strong than other types of laser cutters.

There are different types of fiber laser machines in the market with different functions. One particular type of fiber laser is the MOPA, which allows you to adjust the pulse durations. This flexibility allows the application of MOPA fiber laser machines in many different fields.

And if we look at the uses of fiber lasers, they’re mostly used in metal engraving, annealing, and marking. Moreover, fiber lasers are also suitable for metals and their alloys, which is usually impossible with CO2 lasers. As a result, you can use these machines for wood, glass, plastic, and all types of metals.

An extra benefit of fiber lasers is their ability to work with thin materials with high precision.

So, in short, fiber laser machines are more expensive but can work with a variety of different materials with longer service life. Especially when it comes to working with metals and alloys, then fiber lasers are the obvious choice.

Nd: YAG or Nd: YVO Lasers

Another type of laser-cutting machine utilizes a crystal that can be Nd: YVO or Nd: YAG. The term Nd: YVO refers to crystals of neodymium-doped yttrium ortho-vanadate and YVO4. Similarly, the term nd: YAG is commonly used to refer to neodymium-doped yttrium aluminum garnet crystals.

The Nd: YAG or Nd: YVO Lasers offer high cutting power compared with other laser cutters. But with a high cutting power also comes a higher price tag. That’s why Nd: YAG or Nd: YVO Lasers are more expensive. On average, the life span of Nd: YAG or Nd: YVO Lasers is around 8000 – 15000 hours.

You can use Nd: YAG or Nd: YVO Lasers with various materials, including non-metals and metals. You can use these laser machines for working with ceramics as well.

The crystals used in these machines allow them to shift the frequency output from infrared to UV, green, or blue. As a result, crystal laser machines offer many different functions compared with other types.

How to choose the right laser cutter for your needs

Now that we understand the different types of laser cutters let’s see how to choose the right type for your needs. A simple answer is that it depends on the material, laser power, budget, maintenance, bed size, etc.

Let’s look at each of these factors in more detail:

Power

The first factor to consider is the output power of the laser machines. Generally, a higher output power machine can cut through thick materials. Whereas a machine with lower power can only cut thin materials.

So after you decide on the thickness of the material you want, get a machine that offers sufficient cutting power.

Budget

Your budget will play an important role in deciding the right type of laser cutters for your needs. As it goes with everything, a higher price tag can get you the best machine available in the market.

However, your goal should be getting a machine that packs the required cutting power and is within your budget. You shouldn’t break the bank just to get a high-power laser cutter if you don’t need it.

Bed Size

The bed size refers to the working area where the intended material can be placed for cutting and engraving. The cutting area depends on the material (metals or non-metals) and the specific industry. For example, cutting machines used in the acrylic industry require a large work area to cut the acrylic sheets.

On the other hand, you will not need a bigger bed if you plan to engrave small objects such as key rings or visiting cards.

Floor Space

If you only have limited floor space in your factory or workshop. Then, the only viable choice would be to get a machine that can fit in the available floor space.

Similarly, if you have enough floor space and the required budget, then getting a bigger machine will help you get more work done quickly.

Maintenance

Different machines have different maintenance requirements and eventually add to the running costs. That’s why when you think of the right laser-cutting machine for your needs, always consider the maintenance costs.

The benefits of using a laser cutter in your business

What are the benefits of using cutters powered by high-power lasers? Let’s take a quick look at some of the benefits:

Speed

You can’t rely on mechanical or slow-cutting processes when the business requires a lot of cutting or engravings within a short period. An average laser-cutting machine can cut up to 8m/minute using a high-power laser beam. And by using a more powerful laser cutting machine (1000w), the cutting speed increases to 17m/minute.

High Precision

Laser-powered cutting can deliver high precision, whether a simple cutting job or metal engraving.

It is normal to see rough edges in other cutting processes, which usually require additional smoothing. But with laser cutting machines, you can make the cuts with high precision and smooth edges.

These machines can deliver up to 10 μm positioning accuracy and around 5 μm repeatability precision.

Complex Designs

You do not have to limit yourself to simple designs with laser cutters. These machines allow you to easily produce highly complex designs on various materials.

Normally, it is difficult to do metal engraving with mechanical processes, and it can easily take several days. But when you do metal engraving with a laser cutter, you can make even complex designs within a few seconds to a few minutes at best.

The same is true when working with other materials as well – As long as you can make a design, the machine can get the job done!

Energy Savings

Laser cutters consume up to 5x – 8x less energy than standard operations. So although these machines might come as expensive, they can easily save you money in energy consumption!

Tips for getting the most out of your laser cutter

Follow these tips to ensure that you get the most out of your laser-cutting device:

- Test Cuts – Always make a test cut or engraving to ensure that the machine produces the correct designs.

- Correct Settings – Different materials require different settings on your machine, such as output power, cutting speed, etc. So before starting the actual cutting process, always ensure that you are using the correct settings.

- Vector Files – Although a laser-cutter can work with raster images (jpg, .png, etc.) – It is preferable to use vector images since it is not limited to pixels.

- Multiple Objects – One of the major benefits of laser cutters is repeatability. So it is always a good idea to engrave/cut multiple objects in one go to save time and increase efficiency.

Conclusion

Choosing the right laser cutter for your business depends on many factors. This includes price, materials, thickness…, etc. The best choice is to always assess your needs first and then decide on the right type that meets your needs.

You wouldn’t want to buy a machine that is too expensive and offers features that you aren’t going to use. Similarly, you wouldn’t want a machine that is cheap but can’t cut through the materials you are working with!

So before making a decision, it is best to educate yourself about the different types of laser cutters – (we have explained the three popular types) to make a more informed decision.

Looking For A Reliable Manufacturer Of Laser Cutters?

So you have decided what type of laser cutter the right choice for your business is? Then we have some good news for you: Baison Laser is a trusted name for buying laser cutters and has been around for years.

You can request a quote to get the pricing of different machines and models. You can even get free sample proofing from our expert team to better understand the different available machines. And for any relevant query or request for additional information, feel free to contact us today!