Introduction

Are you searching for the best laser cleaning machine manufacturers that are likely to lead in 2025? You’re in the right place. Find out the industry’s leading manufacturers, supported by their exemplary history and vast range of laser products, with our company review guide!

Top 10 Laser Cleaning Manufacturers and Suppliers in the World: At a Glance

Here’s a quick preview of the companies we’ll discuss.

| Position | Company Name | Year Established | Location (City) | Employee Size | No. of Patents | R&D Size | Strengths/Focus Areas | Price Range / Star Rating | Notable Details |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Baison Laser | 2004 | China | 500+ | 300+ | 50+ R&D Staff.Significant in-house R&D and manufacturing | Custom fiber laser cutting, welding, cleaning, marking solutions | $$-$$$ / 4.9¡ï | Over 20 years experience, global dealer network, full in-house production |

| 2 | Trumpf | 1967 | Farmington, CT (USA) | 1,000+ | 1,000+ patents | Large R&D investment | Industrial lasers, sheet metal fabrication, global reach | $$$ / 4.7¡ï | Leading global supplier, diverse laser machinery |

| 3 | IPG Photonics | 1990 | Marlborough, MA (USA) | 4,740 | 1,500+ patents | Extensive R&D | High-performance fiber lasers, OEM, automation, medical | $$$ / 4.7¡ï | Broad application spectrum, advanced fiber laser technology |

| 4 | Coherent | 1971 | Saxonburg, PA (USA) | Not specified | 500+ patents | Strong R&D focus | Industrial, medical, communications, electronics lasers | $$$ / 4.6¡ï | Innovation-driven, 50+ years in lasers |

| 5 | Laserax | Not specified | Quebec City (Canada) | Not specified | Not specified | Moderate R&D | Automated laser cleaning, marking, battery welding | $$ / 4.5¡ï | Focus on automation, battery manufacturing solutions |

| 6 | Laser Photonics | 1981 | Orlando, FL (USA) | 51-200 | Not specified | Moderate R&D | Cleaning, marking, cutting, engraving, 3D printing | $$ / 4.5¡ï | Robust industrial solutions, public company |

| 7 | SCANLAB | 1990 | Puchheim (Germany) | 51-100 | Not specified | Moderate R&D | Galvanometer scanners, scan solutions, precision tools | $$ / 4.4¡ï | Global support, laser/measurement labs |

| 8 | Anilox | Not specified | Not specified | Not specified | Not specified | Not specified | Laser cleaning for print rollers, specialty cleaning | $$ / 4.3¡ï | Known for niche in printing industry cleaning |

| 9 | TLM-Laser | Not specified | Bromsgrove (UK) | Not specified | Not specified | Not specified | Laser cleaning, marking, welding, cutting | $$ / 4.3¡ï | UK-based, broad industrial laser applications |

| 10 | P-Laser | Not specified | Hamont-Achel (Belgium) | Not specified | Not specified | Not specified | Portable and industrial laser cleaning systems | $$ / 4.2¡ï | Specializes in portable laser cleaning, global presence |

The following subsection briefly describes the Top 10 Laser Cleaning Machine Manufacturers. These companies have long held the international market with various products and services in this sector.

1. Baison Laser

Baison Laser is a leading laser machine manufacturer known for its low-cost laser system solutions. It is also the best laser equipment manufacturer in the region.

This company produces various types of products involving laser technology. Its specialties include Laser Cutting Machines, Laser Welding Machines, Laser Cleaning Machines, Laser Marking Machines, and C02 Laser Cutting Machines.

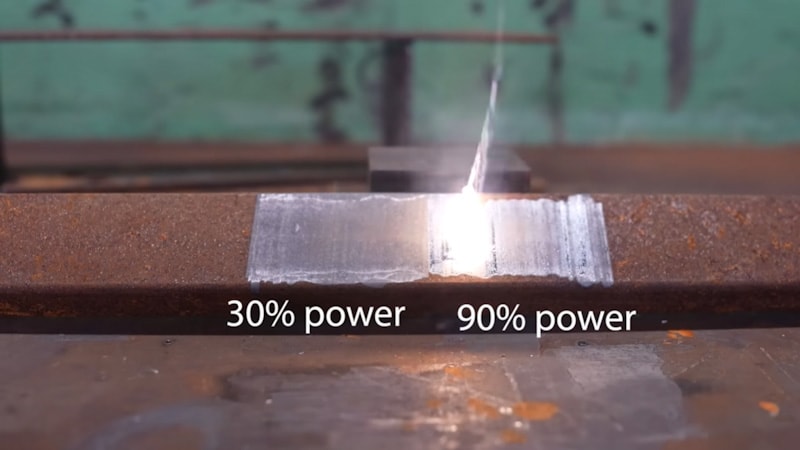

This company has many laser cleaning machines, and Pulse Laser Cleaning Machines is its most iconic product. This product easily removes rust, surface paint, deposited oxide layers, and other contaminants from metal surfaces. The machine doesn’t harm the environment or its surface and parts in this process.

In addition, these machines can remove oil and grease from the surface and add roughness when installing accessories. Baison has been manufacturing laser machines with cutting-edge technology. It’s a global leader for ergonomic design and precision engineering.

Main Products and Services:

- Fiber Laser Sources

- Laser Marking Machine

- Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

Advantages

- Cleans surfaces with pinpoint accuracy without touching or damaging the underlying material, making it ideal for delicate or complex parts.

- Uses no chemicals, abrasives, or water-resulting in a safe, pollution-free, and environmentally friendly process with minimal secondary waste.

- Delivers extremely fast cleaning, especially on large surfaces, and reduces downtime in industrial settings.

- Designed for reliability and minimal maintenance, leading to lower long-term operating costs and high ROI.

- Easy to use with intuitive controls; systems are available in both portable and industrial-scale models, suitable for many industries (automotive, shipbuilding, oil & gas, manufacturing, etc.).

- Effectively removes rust, paint, oxides, oil, and coatings from a wide range of surfaces; parameters can be adjusted for different contaminants and materials.

- Reduces the risk of hearing damage and exposure to hazardous chemicals compared to traditional methods.

- Can be integrated into robotic or automated production lines for even greater efficiency and consistency.

2. TRUMPF

Among international manufacturers, TRUMPF differentiates itself by its superior laser technology solutions. As a crown jewel of German manufacturers, TRUMPF produces high-quality products for laser cutting, welding, marking, and cleaning. Their machines are geared to serve various industrial sectors, including automotive, aerospace, and electronics.

TRUMPF’s laser cleaning systems are designed to remove dirt, oxidation, and coatings from all types of metal surfaces. These machines are highly efficient and do not damage the substrate, environment, or equipment.

Main Products and Services:

- Laser cleaning systems

- Fiber lasers

- Laser Cutting

- Laser Welding

- Marking Systems

- Laser Consumables

- Automation Solutions

Advantages

- No need for additional abrasives or cleaning agents

- High throughput and fast cycle times

- Direct removal of ablated layers

- Premium, high-quality equipment

- Versatile machines (can also do laser marking)

- Wide range of wavelengths and power for different applications

- Global supply chain and support

3. IPG Photonics

IPG Photonics is a well-known leader in manufacturing high-performance fibre lasers and amplifiers. This company is located in the United States and is an expert in producing trustworthy and effective industrial lasers. The high-power fibre lasers in IPG’s catalogue focus on CNC machines, welding, marking, and additive manufacturing applications.

IPG’s laser rust removal machines are well known for their high precision and low environmental impact on resources.

Main Products and Services:

- Fiber lasers

- Laser cleaning systems

- Laser cutting

- Welding marking

- Additive manufacturing solutions

Advantages

- No need for chemicals or abrasives; eco-friendly and zero waste

- High-speed cleaning can process hundreds of square inches per second

- Highly precise and selective; minimizes substrate damage

- Easily automated and scalable for industrial production

- Consistent, repeatable quality and minimal maintenance

- Reduced noise and exposure to hazardous dust or vapors

4. Coherent

Coherent is a worldwide leader in laser technology with a strong specialty. This organization produces a wide range of laser systems, including fiber lasers, CO2 lasers, and ultrafast lasers. Coherent’s products enable applications like laser cleaning, cutting, welding, and marking in global industries.

Coherent offers modular and scalable laser systems designed for simple inclusion into manufacturing workflows. Its laser cleaning equipment facilitates accurate, contact-free, safe, and environmentally friendly cleaning processes.

Main Products and Services:

- Fiber lasers

- CO2 lasers

- Ultrafast lasers

- Laser cleaning machines

- Cutting

- Welding

- Marking equipment

Advantages

- Non-contact cleaning: avoids mechanical wear and chemical corrosion

- No need for chemicals or abrasives: environmentally friendly and zero waste

- High cleaning speed and efficiency

- Precise removal: minimal or no damage to the substrate, suitable for precision parts

- Multiple cleaning modes and adjustable parameters for different applications

- Suitable for a wide range of materials and industries

5. Laserax

Laserax is a leading player in the industrial sector, specializing in laser cleaning technology. They design laser cleaning systems to harmonize with automated and robotic processes, providing precise, non-contact cleaning that merges effortlessly with automated and robotic processes for rust removal, paint, and contaminants without affecting the substrate.

Laserax technology is widely used in various industrial sectors for surface preparation, paint elimination, and rust removal. Its comprehensive solutions, embedded with remote monitoring and diagnostics, enable efficient performance and maintenance without interruptions.

Main Products and Services:

- Industrial laser cleaning systems

- Robotic integration

- Turnkey cleaning solutions

- Remote diagnostics

Advantages

- Non-contact cleaning: avoids mechanical wear and chemical use

- Highly efficient and fast: quickly removes contaminants and coatings

- Precise and selective: removes layers without damaging the substrate

- Environmentally friendly: no chemicals or secondary waste

- Advanced technology and sophisticated control for reliable, repeatable results

- Suitable for a wide range of industrial applications (rust, paint, oxide, coating removal, surface texturing, hardening)

6. Laser Photonics

Laser Photonics is known for its knowledge of laser cleaning technology. It provides portable, stationary laser cleaning machines that guarantee maximum precision and performance.

Laser Photonics provides laser marking, engraving, welding, and cutting equipment for several industrial purposes. It is keen to use friendly-to-the-environment practices that exclude secondary waste, ensuring that operations occur safely and economically.

Laser Photonics offers exact systems that are easy to use, built to last, and versatile enough for various surfaces and industries.

Main Products and Services:

- Portable and stationary laser cleaning machines

- Marking

- Engraving

- Welding

- Cutting equipment

Advantages

- Non-contact, precise, and controlled cleaning process

- No need for chemicals or abrasives

- Consistent, high-quality results that surpass traditional cleaning methods

- Versatile and effective on metals, thermoplastics, composites, stone, wood, concrete, and more

- Suitable for a wide range of contaminants (rust, paint, oil, carbon, epoxy, powder coating, radioactive particles, rubber, etc.)

- Offers handheld and stationary systems, plus turnkey and custom solutions

- Portable and easy to use, with models designed for both delicate and industrial-strength cleaning

- Multiple operational modes and adjustable parameters for various cleaning tasks

- Long-term cost savings due to low maintenance and no consumables

7. SCANLAB

SCANLAB is a world-class player in laser scanning technology, offering fast and precise beam delivery systems. Due to their compatibility with various laser sources, SCANLAB aims to create modular scanning systems that are flexible and can be integrated into diverse industrial environments.

SCANLAB provides galvanometer scanners and control software customized to enhance efficiencies in laser-related cleaning, cutting, and welding processes. Their technology directly helps in automation and increased manufacturing efficiency, offering reliable, scalable, and customizable laser beam control.

Main Products and Services:

- Laser scanning solutions

- beam delivery systems

- modular scanning systems

- Laser process integration software

Advantages

- Non-contact, chemical-free cleaning

- High precision and speed

- Versatile for many materials and applications

- Flexible, easy automation and integration

- Minimal maintenance and no secondary waste

8. Anilox Roll Cleaning Systems

Anilox Roll Cleaning Systems is a celebrated firm that specializes in creating laser cleaning solutions that meet the requirements of the printing industry. The meticulously designed Anilox Roll Cleaning Systems laser cleaning machines effectively and gently clean ink, debris, and contaminants from anilox rolls and printing cylinders, protecting the roll surface.

The systems employ efficient energy use and are operator-safe, leading to a cleaner and safer operating environment. Anilox laser works on its machines’ innovation and reliability to develop customized cleaning products tailored for the industry’s current production methods and to become a dependable partner to its customers.

Main Products and Services:

- Laser cleaning systems for the printing industry

- Anilox roll cleaning machine

Advantages

- Fast and efficient cleaning (often 10–30 minutes per cycle)

- Consistent, thorough cleaning improves print quality and roll lifespan

- Reduces the need for harsh chemicals (especially ultrasonic and powder-based methods)

- Minimal wear and tear on anilox rolls (ultrasonic/liquid methods)

- Automated systems reduce labor and downtime, easy to operate

- Environmentally friendly options available (less chemical use, eco-friendly cleaning agents)

- Extends roll life and reduces maintenance/repair costs

9. TLM Laser

Headquartered in the United Kingdom, TLM Laser offers a comprehensive range of laser cleaning systems tailored to suit unique industries. Their line of products includes portable and industrial laser cleaning devices that are convenient, safe, and green for undertaking procedures for surface preparation, rust removal, and paint removal.

TLM Laser highlights customization of solutions to cater to the specific needs of individual customers, namely the installation, educational training, and maintenance services to ensure that its systems run at the best level.

Main Products and Services:

- Portable and industrial laser cleaning systems

- custom solutions installation

- training

- maintenance

Advantages

- Non-contact, precise, and gentle cleaning

- Fast, efficient, and eco-friendly process

- No chemicals, abrasives, or consumables needed

- Minimal waste and low maintenance

- Suitable for various contaminants and surfaces

10. P-Laser

P-Laser is the leading European firm that is fully focused on laser cleaning technology. Its products offer a combination of portability and industrial standards that guarantee maximum cleaning output, quiet operation, and reduced user fatigue.

The company’s systems are designed to accommodate fragile surfaces, reducing the probability of substrate damage during clean-up. Modular elements and distant assistance are the tenets that P-Laser exploits to enhance user satisfaction and simplify maintenance.

P-Laser: Advantages And Disadvantages

- Non-contact, precise, and controlled cleaning minimizes substrate damage

- No chemicals or abrasives- environmentally friendly, minimal secondary waste

- Fast, efficient, and high-quality cleaning, even for sub-micron contaminants

- Advanced pulsed laser technology tailored for sensitive and industrial applications

- User-friendly and portable models are available

- Inline sensor technology for real-time process control and efficiency

How to Quickly Choose the Best Laser Cleaning Company?

To quickly choose the best laser cleaning company, follow these key tips:

- Define Your Cleaning Requirements: Identify the type of contaminants, surface materials, cleaning precision, and application scope you need. Narrow down companies that specialize in your specific cleaning tasks.

- Evaluate Laser Power and System Type: Based on your operational environment, match your cleaning needs with appropriate laser power (low, medium, or high) and decide between portable or fixed systems.

- Check Supplier Reliability and Capacity: Choose companies with strong production capacity, proven track records, and decent after-sales support to ensure timely delivery and long-term service.

- Consider Safety and Environmental Features: Ensure the company’s systems comply with safety standards and offer eco-friendly cleaning without harmful chemicals or waste.

- Assess Efficiency, Speed, and ROI: To maximize your investment, look for solutions that offer fast cleaning cycles, low maintenance, and long-term cost savings.

- Seek Customization and Support: Prefer suppliers who provide tailored solutions, operator training, and ongoing technical support to fit your unique operational needs.

You can quickly identify a laser cleaning company by systematically evaluating these factors.

Conclusion

This is a saturated field, and many companies compete in it. Most companies described here have top-notch technology, but their demographic location doesn’t allow them to sell their products at reasonable prices.

Now, what should you do? After reviewing all of these companies’ websites, I have concluded that you should go with Baison Laser. Although it has the same top technologies as other companies, it offers its products and services at a much lower price.

Follow our complete guide if you’re a B2B buyer.

FAQ Section

Why Is a Laser Cleaning Machine Expensive?

Laser cleaning machines are expensive due to high-power lasers and advanced technology, costly optical and material components, and custom engineering for specific industrial needs. Automation features like robotics add complexity and price. Limited production scale and import tariffs also increase costs.

Can I Make Money With a Laser Cleaner Machine?

A laser cleaning machine is in high demand in the automotive, aerospace, shipyards, and construction sectors. Find out more from our detailed guide!

Service charges range between $100 and $300 an hour, and service commissions are usually more than 40–60 percent due to minimal operating expenses.

How Much Does a Laser Cleaning Machine Cost?

Prices for laser cleaning help in choosing the right machine.

- A 1500W handheld laser cleaner costs approximately $3800, priced at entry-level rates.

- Medium power 2000W systems start at about $5,500

- A 3000W high-power portable machine consumer will pay up to $8000.

High end industrial or specialized laser cleaning systems can begin at $10,000 and range as high as $35,000 or more, depending on the model’s effectiveness and capacity.