Copper is a highly used metal with worldwide reserves over the past 10 years, increasing from a whopping 630 million metric tons to 870 million tons. It’s also the third most popular, following iron and aluminum, in terms of usage worldwide. If you operate in the construction, electronics, transport, plumbing, or home appliance industry, you should carefully consider the cutting process.

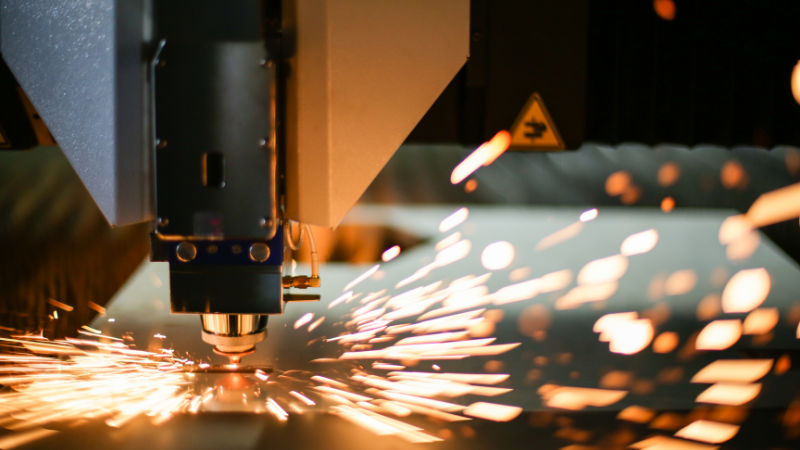

Laser-cutting copper can be a bit more complex than other metals, as it tends to reflect light as opposed to absorbing it. But don’t worry; in this article, we’ll explain more about how to laser cut copper and get the best outcomes using laser cutters.

What are the advantages of cutting copper using laser cutters?

A fiber laser cutter has many advantages and disadvantages. Compared to other types of cutting styles, there are many benefits for cutting copper. Here are some of the main advantages of using fiber laser cutters for copper:

Accuracy

There’s a higher chance of a precise cut when using fiber lasers for copper. This is because the laser beam creates immaculate sides and edges with no jagged edges. The smooth cut it creates saves you from polishing, as there’s no debris on the metal. Therefore, laser cutting can cut complex metals because of its high accuracy.

Fast speed

Laser cutters are known to have a fast speed. If you have a small sheet of copper, a laser cutter can cut through quickly. While cutting through may take slightly longer for other thicker materials, it’s still much quicker than other cutting methods. Its quick speed can enhance your production process.

Consistent cuts

The cuts laser cut copper provides close to identical. The consistency from a laser cut machine causes little difference in the shape and size of the final outcome.

Part of the reason there’s high process reliability is that the machine uses a computer program to save a pattern and cut around that. If you want to achieve the same cut again, you only need to reload the pattern from the computer. The machine’s memory can allow previous patterns to be reloaded quickly and produced nearly identical to previous ones.

Benefits the environment

A good thing about using a laser to cut copper is that the machine is highly energy efficient. Even though the machine uses high temperates for cutting, only a concentrated amount of heat is applied to the metal. Therefore, the power setting is low due to the less energy used on the machine compared to other ones. This is a good solution for your business as you can save money due to the little energy required to operate the machine.

Less waste

When cutting copper using a fiber laser, there’s a lower chance of waste. Due to the machine’s high precision and accuracy, it’s only likely to discard a small number of materials. As a result, you’re less likely to spend on production costs, saving your business money in the long term.

It’s an automated process

While cutting copper can be tricky, it’s a lot easier with fiber laser cutters. As a laser cutter uses a Computer Numerical Control (CNC), it automates the process following the instructions you input into the system and saves previous patterns and cuts, reducing the need for additional manpower.

Can help with other tasks

In addition to cutting copper, a fiber laser can help with other processes, such as engraving, drilling, and marking metals. A laser beam’s multiple functions can save you expenses and efficiency by purchasing new machines or switching between other ones.

Why is it difficult to laser cut copper?

The cutting process for copper can be quite tedious and complex compared to other metals. Part of this is that it can conduct heat quite easily, and the laser light emitted is highly reflective on the copper. To give you an idea, pure copper reflects around 95% of close to IR radiation in the solid state.

So when you try to laser cut metal like copper, the efficiency is reduced as the laser is reflected, making infrared lasers difficult to absorb. Because of this, the material removes the heat from the cut area, restricting efficiency.

A large amount of power required to cut the metal makes it difficult to get a good quality cut. The high power volume often makes the edges look rough, almost like they’re chewed, and shows slight discoloration around the edge.

How to get the best outcomes when laser cutting metal like copper?

When using fiber lasers to cut through copper, there are a few things you may wish to consider, such as:

Laser Power

When using a fiber laser for cutting, you must consider the power. It’s one of the essential factors in cutting through copper. The more power fiber lasers have, the easier it will be to provide a clean cut through the copper. To give you an idea, here is a breakdown of the typical strengths of different laser cutters:

While looking at these figures, you’ll probably notice that pulsed CO2 lasers have a dramatically higher power density. However, when cutting highly reflective materials like copper, the fiber laser is the best as it can absorb more energy quickly.

Power Setting

Ideally, try and use the highest power peak you can to reduce the amount of time the material is in its biggest reflective condition. To give you an idea of this, check out this chart:

Cutting Speed

To utilize fiber lasers and ensure an excellent copper cut, you must consider the machine’s speed. To optimize the speed, you must consider the thickness and power. If you invest in a high-power laser, you can cut through complex, thick metals like copper at a good pace.

It would help if you always opted for fiber lasers instead of a co2 laser, as they can cut through thicker metals faster. Moreover, try to avoid the maximum feed rate and begin at a slower pace that you know the machine can easily support. It’s always good to start at around 10-15% at a slower rate to ensure you can move the laser through the piercing hole before beginning laser cutting.

Auxiliary Gas

One of the major factors when cutting copper or any other metal is auxiliary gas. Auxiliary gas plays a vital role as it moves compressed gas toward the area of the copper you’re cutting. This gas also protects the lens when the metal is melting, keeping the temperature controlled. It also helps enhance the quality, productivity, and how quickly you can cut into the metal. So you should choose the best auxiliary gas for laser cutting.

Reflection Detector

When laser cutting metals like cope, you should pay careful attention to its laser beam. If too much light is reflected from laser-cut copper, it could damage the machine. One way to reduce this risk is to ensure that the laser machine you choose comes with a reflection detector.

A reflection detector monitors infrared laser light emitted from a fiber laser and the radiation produced from it. If the lens of the fiber laser has too much radiation, the detector triggers the machine to shut down. Therefore, if the copper sheet’s reflective condition is set up correctly and the machine works slowly, it will be easier to cut through the metal.

Position to focus

When cutting and piercing copper, you should aim to set the laser beam to a position of focus. You’ll want to do it as near to the top of the surface as possible. Doing this will reduce the amount of the material that comes into contact with the bean, increasing the power density and causing molten metal to happen quicker.

Conclusion

Overall, laser cutting copper is possible but a lot more difficult to undergo than other metals. Part of this is because copper falls under the category of highly reflective materials. Copper’s reflective qualities make it difficult for the infrared laser light to be absorbed, slowing down the cutting process.

To make the most out of laser-cutting copper, you should always consider the speed, power setting, reflection detector, and focus position. All of these factors help make metal penetration easier for metals like copper.

If you take these into account when laser cutting, you’ll reap enormous benefits for your business. For instance, you’ll have less waste, be able to cut copper at a quicker pace, have more accurate cuts, and more.

To start seeking these benefits, you might want to check out our range. Biason Laser has many laser cutting machines that hold some, if not all, of these qualities to cut copper effectively. Contact us today to learn more about the types of laser cutting machines we offer.