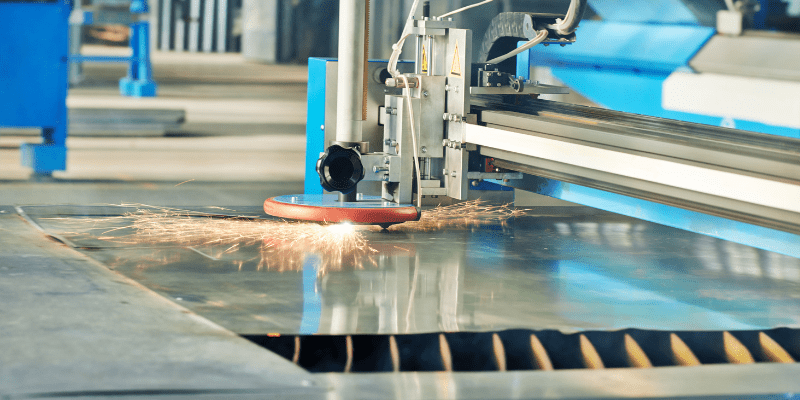

Understand the Coil-Fed Laser Cutting Process

A coil-fed laser cutting machine is going to be a machine that can process materials into programmed designs from coils of sheet materials that you place into the machine. You can create the design you want with the necessary software and when you are ready, lasers will print it off onto the material that you would like.

When used industrially, the coil of sheet material will be placed into the machine. It can then unwind and cut through the coil of material into different designs and patterns. The fiber laser is perfect for this because it provides enough power to go through several types of material, no matter the thickness.

The coil-cutting process occurs through the following steps:

- The coil roll of material is placed into the opening of the machine.

- The transverse axis of the machine pushes the material through.

- The necessary software is placed inside the machine to tell where all cuts should be made.

- Material-cutting lasers will follow the instructions to create the final product.

- The machine outputs a semi-finished or finished item.

Coil-fed laser cutting is unique in that it utilizes a laser to cut through a variety of different materials. While other similar processes will have limits on the material type and thickness you can use, this is not the case with coil-fed laser cutting. This machine can cut through a variety of materials including mild steel, fabric, brass, stainless steel, titanium, and copper.

Core Components of Coil-Fed Laser Cutting Machines

When you choose a coil-fed laser cutting machine, there are a few core components that are available to provide you with the final product you are looking for. Some of these include:

Coil Feed Equipment

A coil feeder is the device responsible for unwinding and delivering the material through the machine. The feeder may have a frame, an unwinding device, and a delivery device to make the process as smooth as possible. The frame will support the other two parts and is often mounted on a stand or a table. The unwinding device will prevent tangles in the material while the laser cuts it. The user can adjust the unwinding device to set the proper tension on the material too. The delivery device helps guide the material at the right speed through the working area.

Laser Source and Variations

The laser source will depend on what you want to do with your product. However, robot programming will allow you to reach all of your high-volume serial production needs without material waste. The laser beam here can be adjusted to get through different materials and thicknesses of material.

Optics and Lenses in Coil-Feed Machine

Optics and lenses in this machine will help you to get the light amplification that you need. Whether you are working with blank stacks, variable-length lasers, or something else, you will find that this machine provides the answers you need.

Software and Control Systems

Most industries that utilize this type of machine will choose to implement software and control systems. This saves time. The employees can just place the right software and all the products will be made exactly the same. This helps reduce waste and human error when someone manually adds the information in themselves.

Decoiler

This helps to untangle the material you want to cut into. You can set the tension and the speed at which it uncoils the material.

Blanking Machine

There are many differences between coil-fed blanking and die-based blanking systems. The coil-fed laser blanking machine helps you pull through all the material and provides support to the process. You can use this to hold onto the material and get accurate cuts with the laser beam. You need this component to get the cuts done.

Automatic Stacking Device

When you need to make more than one product at the same time, the automatic stacking component will help you stack and organize products or materials on pallets or for storage. This can help automate the process more and keep the product organized along the way.

Benefits of Using Coil-Fed Systems

Now that we know a bit more about these coil-fed laser cutting machines, it is time to look at the benefits of choosing this machine over some of the others. Why would you go with coil-fed laser cutting rather than some of the other similar machines on the market? A few benefits of these coil-fed systems include:

High productivity: These machines can improve your productivity. When you have the machine loaded, it will cut with interaction, which helps it get more done in less time. You can cut through and create the necessary parts and components in a fraction of the time. In addition to speeding up the process, these machines can reduce the waste of materials to zero, saving your company a lot of money.

Multifunctional: A coil-fed laser beam machine can be used on a wide range of materials, including metals, rubber, and plastics. It can also handle different widths and thicknesses of sheet metal, which allows your business to use it for much more than you can with other machines.

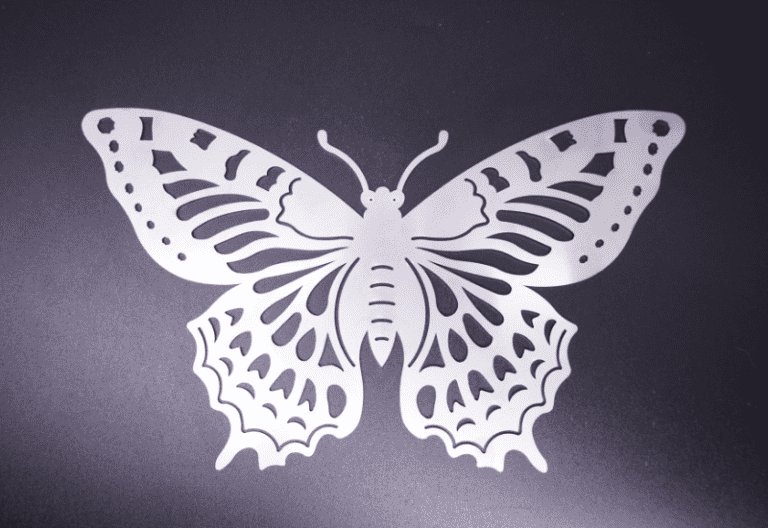

Precision: When accuracy and precision are important to you, the coil-fed laser cutting machine is the best option. When used properly, this machine makes the cutting operation as smooth as possible, giving you the exact specifications each time. When cutting quality is important, this machine can help.

Automation: These machines can be integrated into an automated production line to make life a bit easier for your business. Take some time to set everything up, and you can have a quick and precise automated process. Automated systems can work for any type of business you want to run.

Best Practices for Optimal Coil-Fed Laser Cutting

It doesn’t take long to find out that the coil-fed laser cutting machine can provide you with some of the best quality products possible. But it can seem a bit overwhelming when you first look at the machine. The process and best practice for coil-fed laser cutting you should use include:

Choose the right material: While the laser technology is able to handle a wide range of different materials, you need to choose the right one for your project. Compare the materials available, as well as the thickness and width, to see which one is right for you.

Calibrate the system: Always take the time to calibrate the coil-fed laser cutting machine before you decide to use it. This will help make sure the laser works correctly and that nothing has been moved around or ruined along the way. The laser blanking technology works best when you calibrate after each use.

Effective use of software for pattern optimization: The best way to get the most out of this fiber laser is to effectively use the software. Our team will help you choose the necessary software for your business, or you can work with your own team to create something specialized to get the work done. The right software will get the product created perfectly each time.

Regular maintenance; This machine is not something you can just set up in your business and ignore. It needs routine maintenance by a professional to make sure nothing breaks and all the parts work properly for many years to come.

Common Mistakes and How to Avoid Them

There are a lot of great features that come with this coil-fed laser cutting machine, but many business owners will choose this machine and find that it just doesn’t work well for them. The final product doesn’t come out just right or they run into other problems. Some of the common mistakes and how to avoid them include:

Coil feed issues: There is the potential that someone doesn’t place the coil feed the right way. It is hard to complete sheet metal processing if the coil feed is not placed into the machine well. When you have very high material utilization, you want to make sure you place the material in properly from the very beginning.

Using the wrong laser parameters: You need to choose the right laser cutting parameters to help the machine know how to cut. If your software is off or you aren’t certain about your parameters, the final product will not come out well.

Overlooking material surface conditions: These machines can do a lot of amazing things. But if the surface of the material you plan to use is imperfect, it will appear in the final product. Laser blanking lines eliminate some defects but not all of them.

Applications of Coil-Fed Laser Cutting

There are so many industries that can use this coil-fed laser cutting to help them improve their production process and see amazing results. Some examples include:

Textile Industry

The textile industry will use these fiber lasers and cutting machines. These machines can be used to help handle some of the more complex designs in textiles, synthetic materials, and fabrics. While this may not be the bulky materials typically seen with laser cutting, it can speed up the processes used in textiles.

Automotive Industry

The automotive industry needs the technology of these coil-fed laser cutting machines. There are a ton of parts in cars and other vehicles and they must meet exact specifications and be precise, and durable. These lasers will be able to provide some of the best parts for all types of vehicles.

Construction and Infrastructure

Whether it is a part of a big piece of machinery or the nuts and bolts that help create a new building, the construction industry needs high-quality parts to get the work done. A coil-fed machine can handle the work and make sure the parts are made perfectly each time. The machine can help produce the beams for skyscrapers, drill bits for machinery, and even some of the automotive components on bulldozers and other major pieces of equipment.

Medical Equipment

Whether it is a thermometer or something more complex for surgery and analysis, the medical industry needs components through the coil-fed machine. A coil-fed laser cutting machine can make the exact parts out of all necessary materials for the medical industry.

Filtration Systems

This coil machine is great at creating filters of all types. Thanks to the coil laser’s ability to make precise cuts and changes, it can be done quickly. It can also create cutting gaskets from foam, rubber, and fiber that can be used in a variety of different filtration systems.

If you are not sure what kind of coil-fed laser cutting machine is required in your industry, please get in touch with us for a free application evaluation.

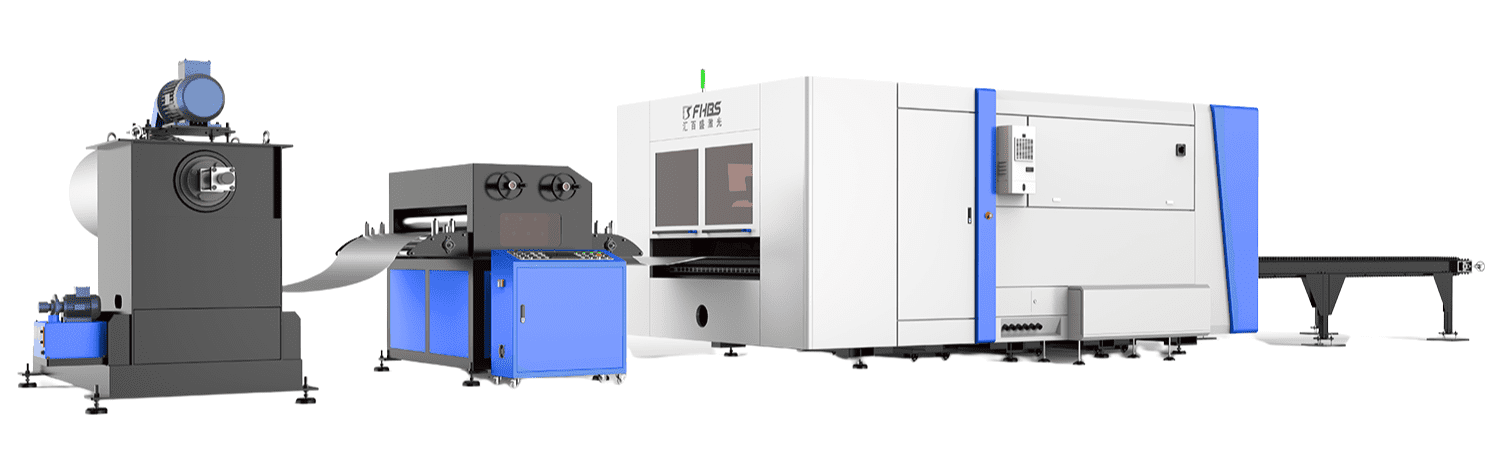

Why Choose Baison Coil-Fed Laser Cutting Machines?

You have a lot of choices on the market when it is time to pick a coil-fed laser cutting machine to get the work done. But when high quality and a personal guarantee are important, you need a Baison coil-fed laser cutting machine. Why are our machines better than the rest?

4 Types of Coil Can be Simultaneously Installed

The Baison coil-fed laser cutting machine can take four types of coil at the same time. This speeds up the process and saves you the hassle of having to change up materials all the time.

While other laser cutting machines can just take one coil at a time, the Baison model can take four at the same time, saving you the hassle and speeding up the process. Whether you need to get the same part done quickly, or you have several components to work on at the same time, this feature will simplify things and provide the efficiency and productivity you need.

High Material Utilization Rate

Baison coil-fed laser cutting machines have large processing sizes and the ability to accurately repeat positioning, which will reduce the waste of all materials being cut. This helps reduce waste and improve efficiency for your production.

High Cutting Quality

Many applications of the coil-fed laser machine will require a high-quality cut to make the product look perfect. Baison coil-fed laser cutting machines will create some of the best cuts on the market, ensuring the product looks amazing each time.

The Baison Coil-Fed Laser Cutting machine’s chuck has a good load-bearing capacity and it can pull materials weighing up to 800kg using a pneumatic cylinder, helping it bring the strength and speed you need for all types of production needs.

Baison coil-fed laser cutting machines can provide you with the high volume production you need, without the high material costs or capital equipment investment of other companies. With all the many advantages of this machine, you will find it is one of the most cost-effective options you can make.

Conclusion

When traditional sheet-fed processes no longer get the work done and you need sheet metal processing that can create high-quality products meant to last for a long time, then check out these amazing coil-fed machines.

They work quickly, provide a good deal of accuracy, and can last for a long time, giving you the amazing results your business needs. No matter the parts you need to create, Baison can be here to provide you with the high-quality machines you need to get it done.

Get the Best Coil-fed Laser Cutting Machine from Baison!

Ready to elevate your production with efficient coil-fed laser cutting. Our team at Baison Laser is here to provide industry-leading solutions that are tailored to the needs of your business. Don’t choose someone else and compromise on efficiency and precision. Contact Baison Laser today and let us bring your projects to life with the best laser technology.