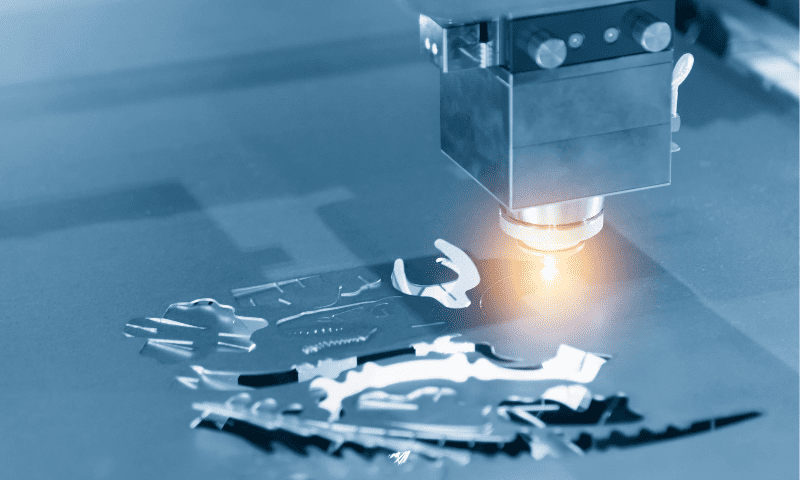

What is Fiber Laser Metal Cutting?

If you’re wondering about the future of metal cutting, look no further than prime fiber laser technology. It’s revolutionizing the way we shape and mold metals. But what exactly is fiber laser metal cutting?

Basics of Fiber Laser Technology

Fiber laser technology uses optical fibers doped with rare-earth elements as the gain medium to generate laser light for industrial processes. The core component is an optical fiber that is equipped with elements such as erbium, thulium, and dysprosium. When used with inert gases like nitrogen, oxygen, or compressed air, the fiber lasers can slice through a wide variety of metals with a high degree of precision.

Fiber lasers operate in a single transverse mode, producing a high-quality laser beam. Traditional methods often left rough edge quality or required extensive post-processing. With fiber lasers, you can achieve immaculate cuts in record time. They are highly efficient, can emit light at different wavelengths, and find applications in materials processing, telecommunications, medicine, research, and military sectors.

So why settle for outdated techniques when you can embrace the future? Let’s delve deeper into the fascinating world of fiber laser cutting metals and explore its incredible capabilities.

Application in Metal Cutting

Fiber laser cutting technology has revolutionized the future of metal cutting, finding widespread applications across various industries such as automotive, aerospace, and electronics. Its versatility and precision make it an ideal choice for intricate designs and complex shapes.

Manufacturing sector: Fiber laser cutter technology has significantly improved the metal cutting process. With its high power density, it efficiently cuts through different materials including carbon steel, stainless steel, aluminum, and more. This technology enables cost-effective production processes by reducing material waste and minimizing the need for secondary operations.

Medical device industry: Fiber lasers are used for cutting metal components in the medical device industry, including surgical instruments, implants, and medical equipment. The high precision and cleanliness of high power fiber laser cutting are crucial in ensuring the quality and safety of medical devices.

Energy industry: High power fiber lasers are used in the energy industry for cutting metal components in power generation systems, renewable energy equipment, and oil and gas infrastructure. The ability of fiber lasers to cut thick metal sheets and withstand harsh environments makes them suitable for this industry.

Defense and military industry: Fiber lasers are used in the defense and military sector for cutting metal components in weapons, vehicles, and equipment. The high speed and precision of high power fiber laser cutting are essential for meeting the stringent requirements of this industry.

These are just a few examples of industries that benefit from fiber laser cutting metals. The versatility, precision, and efficiency of fiber lasers make them a valuable tool in various sectors that require accurate and efficient metal cutting.

Benefits of Using Fiber Laser for Metal Cutting

Fiber laser cutting machine offers numerous benefits for metal cutting in the CNC machines market. Let’s explore some of the advantages of this high power technology in the region.

Precision and Efficiency

Fiber lasers provide exceptional precision in metal cutting operations. The concentrated beam allows for accurate cuts, ensuring minimal material wastage. This precision also contributes to increased cutting efficiency, as it reduces the need for rework or additional processing. With high power output capabilities, fiber lasers enable fast cutting speeds without compromising on quality.

Versatility and Material Compatibility

Fiber lasers are highly versatile and compatible with a wide range of materials. Whether it’s cutting stainless steel, aluminum, brass, or even exotic alloys, fiber lasers can effectively cut through them all.

Fiber lasers can handle a wide range of materials and thicknesses, making them suitable for diverse applications. From thin sheet metals to thick plates, this technology adapts to various cutting requirements. This versatility makes fiber lasers an ideal choice for various industries such as automotive, aerospace, and manufacturing.

Fiber Laser Metal Cutting Machines

Fiber laser cutting technology is revolutionizing the future of metal cutting. With its advanced capabilities and superior cutting accuracy, fiber laser cutting machine is becoming increasingly popular in the market. These CNC fiber laser cutting machines offer a range of benefits that make them an ideal choice for various cutting needs.

The growing demand for fiber lasers has led to significant advancements in the market. There are multiple fiber laser cutting machine options available to cater to diverse manufacturing requirements.

Features to Look for in a Machine

To ensure the future of metal cutting is efficient and precise, it’s essential to consider the right features when selecting a laser cutter. Here are some key points to keep in mind.

- Automatic Focusing System: Look for CNC fiber laser machines equipped with an automatic focusing system. This feature guarantees consistent cutting quality across the entire workpiece surface, eliminating variations that may affect the final product. With the power of fiber technology and the precision of a prime fiber laser, this automatic focusing system ensures optimal performance.

- Integrated Cooling System: Prolonged operation can lead to overheating, affecting both the machine and the quality of cuts. Therefore, prioritize machines with an integrated cooling system. This ensures optimal temperature regulation, enhancing performance and preventing any potential issues.

- Power and Cutting Capacity: Determine the power output and cutting capacity of the machine, which should align with your specific metal cutting needs. Higher power allows for faster and thicker metal cutting, while larger cutting capacity ensures compatibility with various sheet sizes.

- Precision and Accuracy: When considering CNC fiber laser cutting machines, it is important to check the machine’s positioning accuracy and repeatability. These factors play a crucial role in determining the precision and accuracy of the cuts.Therefore, it is recommended to look for machines equipped with advanced motion control systems and high-resolution linear guides for optimal precision. The power laser cutting head and the prime fiber laser power are key components that contribute to achieving precise and accurate cuts.

By focusing on these essential features, you can find a machine that combines automation, efficiency, precision, and advanced technology for improved metal cutting processes in various industries.

Overview of Baison Laser’s Fiber Laser Metal Cutting Machines

One notable feature of Baison Laser’s machines is our customizable options. These options allow customers to tailor our solutions based on specific requirements, making it possible to achieve optimal results for different projects. Whether it’s adjusting power levels, beam quality, or cutting speed, Baison Laser provides the flexibility needed to meet unique manufacturing needs.

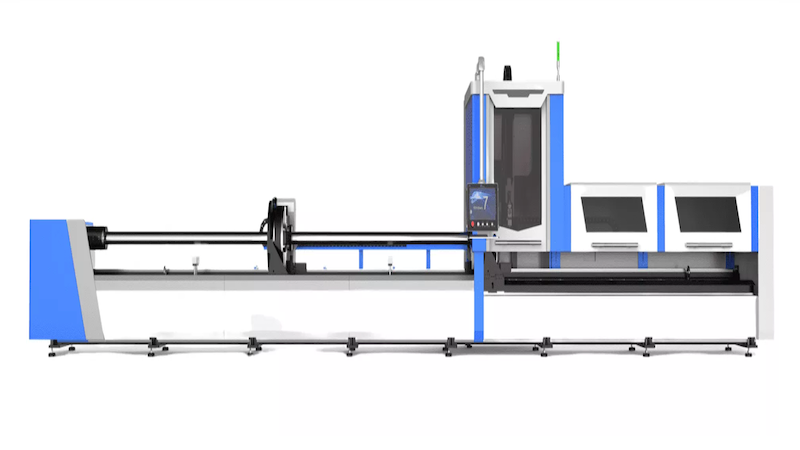

All-round Tube Laser Cutting Machine

The all-around tube laser cutting machine has been a breakthrough in the industry. It uses solid-state lasers that allow for short processing times and high-volume production, even on heavier tubes or thicker materials, to ensure you can always afford excellent quality!

It can meet the diameter of 10-220mm in the range of a variety of metal materials cutting. The dynamic combination of full-travel professional pneumatic chuck and laser head makes cutting more flexible. On the cost side, the machine offers a cost-effective way to improve business operations

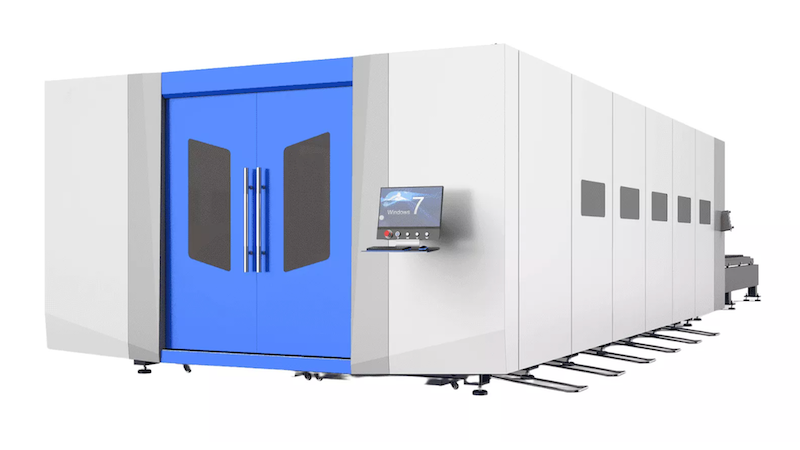

High Power Sheet Metal Laser Cutting Machine

Become a leader in your industry with our high-power sheet metal laser cutting machines that combine innovation, premium technology and fiber transmission. Whether in shipbuilding, steel construction, towers or any other field, our machines are fully productive, flexible and lower cost.

Thanks to the high power and long service life of our diodes, our equipment offers superior reliability in the market over traditional technology production operations in your business. The Sheet Metal Laser Cutting Machine, with its built-in dust removal system, provides better air quality and improves the working environment for employees.

Dual Platforms Sheet Metal & Tube Laser Cutting Machine

The new dual platforms sheet metal and tube laser cutting machine are more than a powerful upgrade. It takes advantage of the strengths prevalent in both platforms: short processing times for large ranges or possible tubes, as well as cutting through thick materials with an increased power level for sheet metal fabrication!

This machine produces more accurate results because it allows the laser cutting head to cut without changing the z-axis. It provides an energy-efficient and stable cutting production method that can reduce energy consumption by 15-20% compared to similar products.

The Future of Metal Cutting with Fiber Lasers

Continuous advancements in fiber laser technology are revolutionizing the metal cutting industry. With the global fiber laser market projected to grow rapidly, the future looks promising for this innovative technology. Let’s explore some key trends and developments shaping the future of metal cutting with fiber lasers.

Trends and Developments in the Field

- Increasing Power and Cutting Speed: Fiber laser technology continues to evolve, with ongoing efforts to increase power levels and improve cutting speeds. Higher power fiber lasers enable faster and more efficient metal cutting, reducing production time and increasing productivity. As power levels continue to rise, we can expect even greater cutting speeds and the ability to process thicker materials.

- Integration of Automation and Industry 4.0: Automation and Industry 4.0 concepts are being integrated into fiber laser metal cutting systems. This includes the use of robotics, material handling systems, and advanced software for automated loading, unloading, and part sorting.

Real-time monitoring, data analytics, and connectivity enable improved process control, predictive maintenance, and overall efficiency. The future of metal cutting with fiber lasers will see increased integration of these technologies, leading to higher levels of automation and productivity.

Real-time monitoring, data analytics, and connectivity enable improved process control, predictive maintenance, and overall efficiency. The future of metal cutting with fiber lasers will see increased integration of these technologies, leading to higher levels of automation and productivity. - The development of hybrid laser cutting systems that combine laser technology with other technologies like cutting methods, such as waterjet cutting or plasma cutting, is gaining traction. These hybrid systems offer the advantages of multiple cutting technologies, allowing for increased versatility and the ability to handle a wider range of materials and thicknesses.

The future trend of metal cutting with fiber lasers holds tremendous potential for growth and innovation. With continuous advancements in technology, we can expect even faster cutting speeds and improved efficiency. Furthermore, the integration of automation systems will revolutionize manufacturing processes by reducing errors and enhancing productivity. As costs decrease over time, smaller businesses will have the opportunity to leverage this transformative technology.

FAQs

How does fiber laser technology improve metal cutting?

Fiber laser technology improves metal cutting by delivering higher precision cuts at faster speeds compared to traditional methods. It also offers cost savings through reduced energy consumption and maintenance requirements.

What makes Baison Laser’s fiber laser machines stand out?

Baison Laser’s fiber laser machines are highly sought after in the market due to their advanced features. These machines offer power output options whether low power,medium power or high power, excellent beam quality for superior cut quality, and automation capabilities that streamline production processes.

What can we expect from the future development of fiber laser technology?

The future development of fiber laser technology holds great promise. We can anticipate even high speed cutting, higher precision, improved energy efficiency, and expanded applications across various industries. The continuous advancements will drive further growth and innovation in metal cutting processes.

Concluding Thoughts

In conclusion, fiber laser technology has revolutionized the metal cutting industry. Its applications in various industries have proven to be highly effective and efficient. The benefits of using fiber lasers for metal cutting are numerous, including higher precision, faster cutting speeds, and higher productivity.

Looking ahead, the future of metal cutting lies in the continued advancement of fiber lasers. As technology evolves, we can expect even greater breakthroughs in terms of higher speeds, high accuracy, and versatility. Fiber lasers will continue to play a pivotal role in shaping the manufacturing landscape.

To stay ahead in this rapidly evolving industry, it is crucial to embrace the potential of fiber laser cutting machine. Investing in state-of-the-art equipment can significantly enhance productivity and competitiveness. What potential applications do you see for fiber laser technology in your operations? Please share your thoughts in the comments below. Don’t miss out on the opportunity to leverage this game-changing technology for your business.

Choose Baison, Embrace the Future of Metal Cutting

Baison Laser offers a wide range of fiber laser metal cutting machines that are designed to shape the future of metal cutting. These advanced machines cater to diverse industrial applications, providing efficient and precise solutions for various needs. What are you waiting for? Contact us for a one-to-one application evaluation from our experts to improve laser cutting efficiency today!