In this article, we will highlight all the benefits of automatic laser machinery and how it can benefit your business to stay in the spotlight. Read on to learn more!

What Is an Automatic Laser Machine?

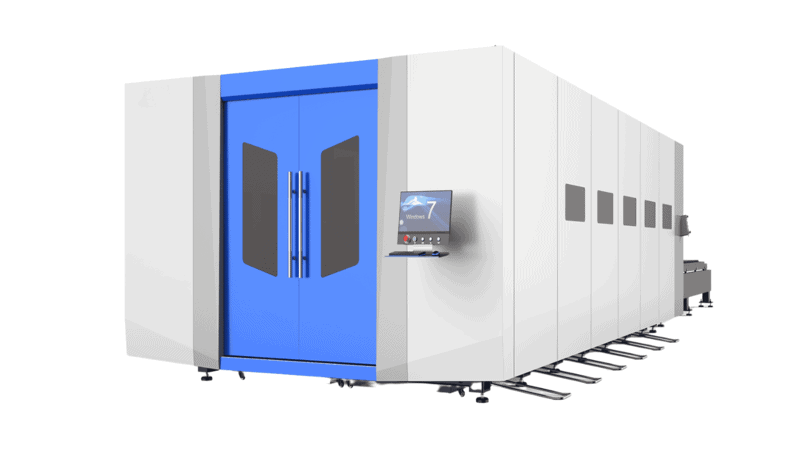

An automatic laser cutting machine has all the components found in a regular laser machine. However, the only difference is that it has software automation and additional components such as robotic arms. This helps improve work efficiency and reduce the labor, time, and cost required for a task.

As a result, many laser cutting, welding, and engraving businesses benefit from automatic laser machines to meet high customer demands. It helps them produce quicker and deliver even faster.

Hence, they are always ahead of the competition thanks to laser automation’s cost and time effectiveness. On top of it, laser automation also eradicates the room for human error leading to excellent and accurate precision cutting.

What Are the Different Types of Automatic Laser Machines?

Currently, the industry offers a wide range of automatic laser machines. Each type of machine serves a specific purpose for businesses. Here are the most common ones:

- CO2 Laser Machines: manufacturers popularly use CO2 laser cutting machines to cut and engrave non-metallic substances. These include wood, fabrics, and even plastics.

- UV Laser Machines: this type of automatic laser cutting machine is highly compatible with materials such as polymers, glass, and ceramics.

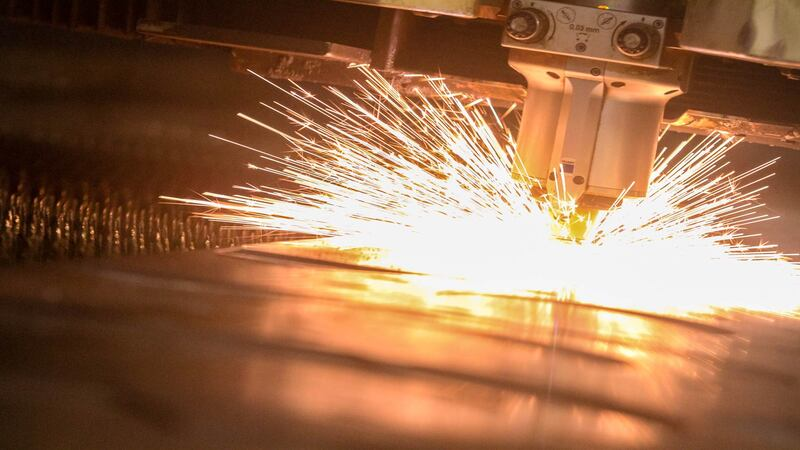

- Fiber Laser Machines: the most common materials cut and engraved using high-precision fiber laser cutting include metals such as brass, stainless steel, carbon steel, copper, etc.

- Nd:YAG: precision drilling and welding require a solid-state laser to melt and connect metals. Hence, an Nd: YAG automatic laser machine is equipped with a solid-state laser.

10 Benefits of Using Automatic Laser Machine

Here are ten ways an automatic laser-cutting machine benefits businesses:

Enhanced Precision

Some industries, such as aircraft and ship manufacturers, require highly precise laser cutters. They have little room for any mistakes. As a result, having a high-precision automatic laser machine comes in really handy to cut through and engrave complex aircraft and ship components. Typical parts include fuselage sections and engines.

Significantly Efficient

Automatic laser machines help manufacturers save time, effort, and costs. All of this combined makes them highly efficient for production, especially for businesses that need to produce in bulk.

A good example is the automotive industry, where vehicle parts are always in high demand. Automation leads to faster production rates without the need for manual labor.

Flexible and Versatile

Automatic laser cutting machines are highly customizable. This means they have software and integrations which allow them to work with a variety of materials in a variety of different ways. As a result, it eradicates any limitations for a manufacturer to work with versatile materials increasing their scope of business.

Precision Customizations

Another area where automatic laser cutting machines stand out includes customizations. These highly accurate and precise laser cutters allow manufacturers to easily produce unique patterns and designs.

For instance, the rapid manufacturing industry requires quick custom parts with intricate logos and designs. Automatic laser-cutting machines make the cutting process a lot easier and faster.

Improved Safety

Safety is a big concern when working around laser cutting and welding machinery. However, as automation is taking over, safety concerns are decreasing. How come? For starters, automatic laser-cutting machines require minimal labor intervention.

As a result, the short interaction reduces the risk of worker injury. On top of it, more automation also comes with more safety features with touch controls and software inputs.

Low Production Cost

Being highly efficient not only means that automatic laser cutting machines produce fast results. It also means that they bring down the cost of production in two ways: one, by producing more in less time to generate more significant revenue, and secondly, by reducing labor costs by automating the whole process.

For instance, the transport industry readily needs large-scale components. Relying on manual labor can cost a lot, whereas shifting to an automatic laser-cutting machine can significantly reduce costs.

Environmentally Friendly

As mentioned above, automatic laser cutting machines are highly efficient. On top of it, they do precision cutting with 100% accuracy if given the right inputs. As a result, all of this helps reduce waste products as manufacturers don’t have to redo products.

Moreover, they can be used on a variety of materials, including recycled metals, which helps with sustainability.

Competitive Advantage

We have already talked about how businesses that haven’t equipped their production lines with automatic laser-cutting machines are missing out. This is because these efficient machines offer a competitive advantage to businesses that use them.

As a result, businesses that are still using traditional laser cutting machines are at a disadvantage due to slower production rates and higher labor costs, paving the way for competition to stay ten steps ahead.

Improved Traceability

This has more to do with product quality, as some industries require intricate attention to detail. A good example is the aircraft industry, where manufacturers cannot make any mistakes with aircraft components. Here, the excellent traceability of automatic laser cutting machines is useful as it reduces the risk of component failure.

Long Term Investment

While the initial investment in an automatic laser-cutting machine may seem like a lot, it pays off in the long run. In fact, the initial high cost is one reason why so many businesses hesitate to invest in one. However, automatic laser-cutting machines have a much higher ROI, leading to greater profits and market share in the long run.

Applications of Automatic Laser Machine

Here is how different industries make use of automatic laser-cutting machines to speed up their production processes:

- Rapid Manufacturing: this industry often comes across orders which require small batches of prototype products for new clients. As a result, they need automatic laser-cutting machines for quick and precise customized designs.

- Automotive: brake rotors, vehicle exhausts, and gear and engine components need precise laser-cutting automation. On top of it, it needs to be done quickly, given the high demand for automotive parts. Hence, the industry widely uses automatic laser cutting machines for their quick response and accurate cutting.

- Construction: This industry often has to cut, engrave, and weld through pipes, steel beams, and metal sheets. In most cases, these cuts are complex and need a precisely focused laser engraver to do the job. On top of it, having manual labor do the work can also threaten the workers’ safety. As a result, they use automatic laser machines to do the work safely and efficiently.

- Shipbuilding and Aviation are two industries that produce large-scale industrial and commercial vehicles for air and sea travel. As a result, they need an excellent automatic laser-cutting machine for component production. These help them weld parts, cut through components, and engrave sheets precisely, so there are no failure risks.

- Oil and Gas: this industry readily uses extraction and drilling equipment to source oil and gas. However, the required equipment isn’t easy to produce, given the complexities. Here again, automatic laser cutters, with their reliable computer software inputs and precise cutting and welding, allow for robust equipment production that aids oil and gas mining.

What Should You Consider When Choosing an Automatic Laser Machine?

Automatic laser cutting machines are a big investment for a business of any size. Even enterprise-level businesses have to make sure they are investing in the right size, capacity, and model of the machine for efficient results in the long run. Here are some vital factors that you must keep in mind while out shopping for an automatic laser-cutting machine:

- Automation Level: interestingly, automatic laser cutting machines come with varying levels of automation. While some machines are fully automatic, others might require labor intervention to keep everything in order. As a business, you must know your automation solutions needs and invest in the right machine. Investing in a fully automated laser machine only makes sense if you want to keep labor intervention and costs at a minimum.

- Material Compatibility: manufacturers that sell automatic laser cutting machine has various of them. These different types of machines are compatible with varying materials. For instance, some machines cut or weld through glass better than others, whereas some are specifically designed for metal cutting. Hence, you must know the material compatibility requirements of your business before investing.

- Machine Size: for this, you must scope out your production space and production needs. Get a machine that can cater to both because an automatic laser-cutting machine can take up a lot of space. However, the larger the machine, the larger the output. So, it would be best if you also kept future expansion plans in mind.

- Service and Support: a critical consideration because post-purchase service and support from the manufacturer are essential for an automatic laser cutting machine. Why? These highly complex machines require proper instructions and assistance from the manufacturer for smooth operation. As a result, only purchase from a manufacturer with good credibility in the market for customer support.

Conclusion

Automatic laser cutting machines are efficient, cost-effective, accurate, and versatile. All of these help businesses boost their production and bring down costs while keeping waste at a minimum and worker safety at a maximum. You can learn more about how highly powerful automatic fiber laser cutters help businesses make great profits here!

At Baison Laser, we have dedicated our efforts to producing highly advanced automatic laser-cutting and welding machines for businesses of all sizes. Our goal is to equip you with the best-in-class automated laser equipment that helps increase revenue and stand out among a massive competition pool. Get an instant quote today!