In this blog post, we’ll take a closer look at lenses for fiber laser cutters, their role in protecting the cutting head from damage, and why it’s essential to use high-quality lenses to ensure the highest precision and accuracy of your laser cutting and laser welding process. So, let’s dive in and learn more about this vital consumable accessory for your fiber laser cutter.

What Is a Fiber Laser Cutter?

A fiber laser cutter is an industrial cutting machine that uses a fiber laser beam to cut various suitable materials, including metals, plastics, and composites.

Unlike traditional CO2 laser cutters, which use a gas laser beam, fiber laser cutters use a solid-state laser beam generated by a series of diodes to produce a high-energy beam that is focused on the material being cut.

Fiber laser cutters offer several advantages over other cutting technologies, including faster cutting speeds, lower operating costs, and higher accuracy and precision. They are commonly used in manufacturing and fabrication applications to produce parts and components for a wide range of industries, including automotive, aerospace, and electronics.

What Are Protective Lenses of Laser Cutters?

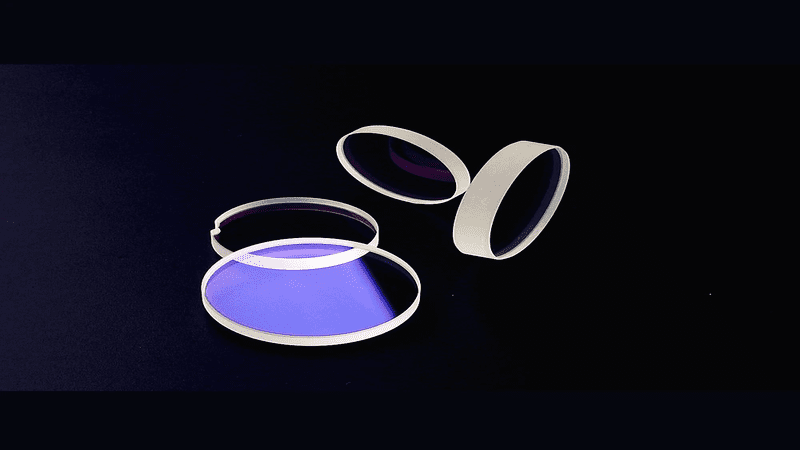

Lenses play a critical role in protecting the cutting head of fiber laser cutters during the laser cutting process. These lenses, such as fused silica or sapphire, are constructed with high-quality materials and are engineered to withstand the high-intensity laser beam without degrading or distorting.

Protective lenses protect debris, splatter, and other contaminants from damaging essential components of the cutting head by serving as a barrier between the laser beam and the cutting head. In addition, the lenses maintain the quality and accuracy of the laser beam by reducing distortion and preventing the formation of hot spots.

It’s important to remember that lenses are consumable accessories that will eventually wear out and require replacement. The frequency of replacement varies based on several factors, including the intensity of the laser beam, the material being cut, and the quality of the lens. Regular replacement of high-quality lenses is critical for achieving optimal performance and longevity of your fiber laser cutter.

Choosing the right protective lens involves considering material compatibility, thickness and diameter, focal length, beam diameter, and quality and durability. Proper maintenance techniques, such as regular cleaning and careful handling, are also crucial to ensuring the longevity and optimal performance of the protective lens.

By following these guidelines, you can maximize the lifespan and effectiveness of your lenses and, ultimately, your fiber laser cutter.

What Are the Types of Protective Lenses?

In the realm of fiber laser cutters, protective lenses come in various types, each of which uniquely ensures efficient, precise, and accurate laser cutting. Here are the most common types of lenses and their respective functions:

- Focusing Lenses: As the name suggests, these lenses focus the laser beam onto the cutting material, providing optimal accuracy and precision. They work by creating a tiny and intense focus point on the material, ensuring minimal distortion and clean cuts.

- Collimating Lenses: These lenses ensure the laser beam is parallel before reaching the focusing lens. This type of lens helps improve the quality and consistency of the laser beam, resulting in accurate cuts.

- Beam Expander Lenses: When cutting thick materials or creating larger cuts, beam expander lenses come in handy as they increase the size of the laser beam before it reaches the focusing lens.

- Reflective Lenses: These lenses are utilized to direct the laser beam to a particular location by reflecting it at a specific angle. Reflective lenses are particularly useful in 3D laser cutting applications, where the laser beam must be directed at an angle.

Using the right protective lens for your fiber laser cutter is vital for achieving optimal performance and accuracy. It’s critical to choose high-quality lenses specifically designed to withstand the intensity of the laser beam and provide long-lasting service.

Why Are Protective Lenses Crucial to Fiber Laser Cutters?

Protective lenses are integral components of fiber laser cutters that are vital for optimal cutting performance and machine longevity. There are several reasons why protective lenses are essential for fiber laser cutters, including:

- Protection of the Laser: lenses act as a shield between the laser beam and debris, splatter, and other contaminants that can damage the laser itself. Using high-quality lenses can help extend the laser’s lifespan and prevent costly repairs.

- Protection of the Machine: In addition to protecting the laser, lenses also safeguard other critical components of the laser cutting head, including the nozzle and focusing lens. This protection helps reduce maintenance and repair costs and prolong the machine’s life.

- Protection of the Operator: lenses are crucial in protecting operators from harmful laser radiation. By filtering out harmful wavelengths of light, they help to make the laser-cutting process safer for operators.

- Reduction in Operating Costs: Regular replacement of protective lenses can help to reduce operating costs by preventing damage to the laser and other critical components. This can minimize downtime and maintenance costs, ultimately increasing productivity and profitability.

- Impact on Cutting Quality: The quality and accuracy of the laser cutting and laser welding process depend heavily on the quality of the protective lenses used. High-quality lenses can help to maintain the integrity of the laser beam, resulting in cleaner, more precise cuts and improved cutting performance overall.

How to Choose the Right Protective Lens?

When it comes to selecting the right protective lens for your fiber laser cutter, several critical factors must be considered to ensure optimal performance and durability. As such, it’s important to approach the selection process with care and attention to detail. Here are some key considerations to keep in mind:

- Material Compatibility: It’s important to select a protective lens compatible with the material being cut. This means choosing a lens that is specifically designed for the material you plan to cut, as different materials may require different types of lenses to achieve different laser power.

- Thickness and Diameter: The thickness and diameter of the lens are also important factors to consider. The lens must be thick enough to withstand the intensity of the laser beam without cracking or shattering, and the diameter of the lens should be appropriate for the size of the cutting head and the desired cutting area.

- Focal Length: The lens’s focal length determines the focus point of the laser beam and is crucial for achieving precise cuts. It’s important to select a lens with the correct focal length for your specific cutting needs, considering the thickness and type of material being cut and the desired cutting quality and precision.

- Beam Diameter: The diameter of the laser beam is another important consideration when selecting a protective lens. The lens must be able to accommodate the size of the laser beam without causing distortion or other issues that could affect cutting quality.

- Quality and Durability: The quality and durability of the protective lens are also crucial factors to consider. High-quality lenses are designed to withstand the intensity of the laser beam and resist damage from debris and other contaminants. Choosing a lens from a reputable supplier with a proven track record of producing high-quality and durable protective lenses can help ensure optimal performance and longevity of your fiber laser cutting machine.

Maintenance of Protective Lenses

Maintaining your laser machine lenses is critical to achieving maximum cutting efficiency and prolonging the lifespan of your equipment. Here are some key maintenance tips to keep in mind to ensure your lenses operate at their best:

- Gentle Handling and Proper Cleaning: Proper handling and cleaning techniques are crucial to protect the protective lens from damage and maintain its integrity. Always use a soft, lint-free cloth and a mild cleaning solution specifically designed for laser lenses when cleaning the lens. Avoid using abrasive materials or cleaning solutions that could scratch or damage the lens. With gentle handling and proper cleaning, your protective lens will be in top condition to perform its task.

- Timely Replacement: Regularly replacing lenses is essential to ensure optimal cutting performance and prevent damage to the cutting head. The replacement schedule may vary depending on usage frequency, intensity, and the type of materials being cut. Therefore, it’s necessary to monitor the condition of the lens regularly and replace it as needed to achieve optimal cutting performance and durability.

- Consistent Maintenance is Key: Regular maintenance of lenses is critical to keep your laser cutting machine running smoothly, prevent unnecessary downtime, and avoid costly repairs or replacements. Lack of proper maintenance can lead to reduced cutting quality, increased operating costs, and the possibility of damaging the lens due to debris, contaminants, or other factors that affect cutting performance. Consistent maintenance, on the other hand, will ensure your lenses perform at their best and maintain optimal cutting quality.

Conclusion

In conclusion, protective lenses are critical components of fiber laser cutters that significantly ensure optimal cutting performance and durability. Selecting the right protective lens, maintaining it properly, and replacing it regularly are all essential factors to consider for achieving high-quality, precise cuts and prolonging the lifespan of your cutting machine.

By following these key considerations and maintenance tips, businesses can maximize their productivity and profitability while ensuring the safety of their operators and equipment.

Invest In a High-Quality Laser Cutting Machine Today

At Baison, we take pride in our extensive experience and expertise in the laser cutting industry. Our team of professionals is dedicated to providing exceptional customer service and support to our clients, ensuring that they get the most out of their investments.

We understand that each business has unique requirements and challenges, which is why we offer customized solutions to meet those needs. Whether you’re a small business or a large corporation, our fiber laser machines are designed to provide precision cutting that meets your specific requirements. Get Free Sample Proofing.