We saw a significant and remarkable evolution in the arena of manufacturing when fiber laser cutting technology emerged in 2008. Until now, we are reaping the revolutionary advantages of this ingenious machine that help ease the process of cutting through metal. As years pass, its applications, performance, and capabilities continue to improve and become more diverse.

It is amazing to know how much the metal fabrication industry benefits from laser-cutting, which also serves as an aid to the progress of industrial technology. To this date, it is still a huge deal. However, just like any technology, there will always be limitations.

What type of materials can a fiber laser machine cut? What type of materials can it not?

In this article, we will explore the material type limitations of fiber laser cutting machines, the factors affecting these restrictions, and also provide you with proper techniques to overcome them. This discussion aims to help you optimize and unleash the full potential of your cutting machine for a more lucrative and thriving business.

What Is Fiber Laser Cutting?

Before we jump right into the material type limitations of fiber laser cutting, let us first define the technology.

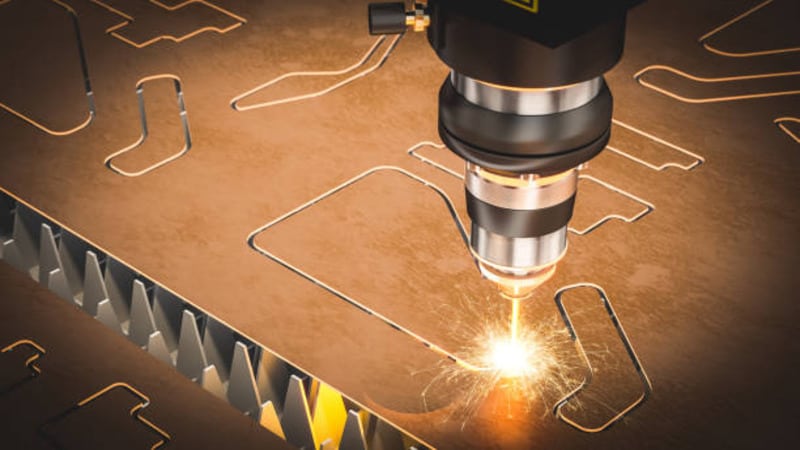

Fiber laser cutting utilizes a high-powered fiber-optic cable to create a laser beam that can cut through various materials, especially tough-to-cut ones like metal. The beam allows the material to vaporize and melt, allowing for a more meticulous and precise cutting, which is common knowledge when we talk about lasers.

Precision in manufacturing is of paramount value, and fiber laser-cutting machines can deliver just that. This cutting-edge tool is popular for metal fabrication due to its speed, efficiency, and accuracy.

Unlike traditional cutting methods, this technique no longer requires physical contact. Many industries use this technology to improve the scale of their business operations, including the medical, automotive, aerospace, and electronics industries.

How Does a Fiber Laser Cutting Machine Work?

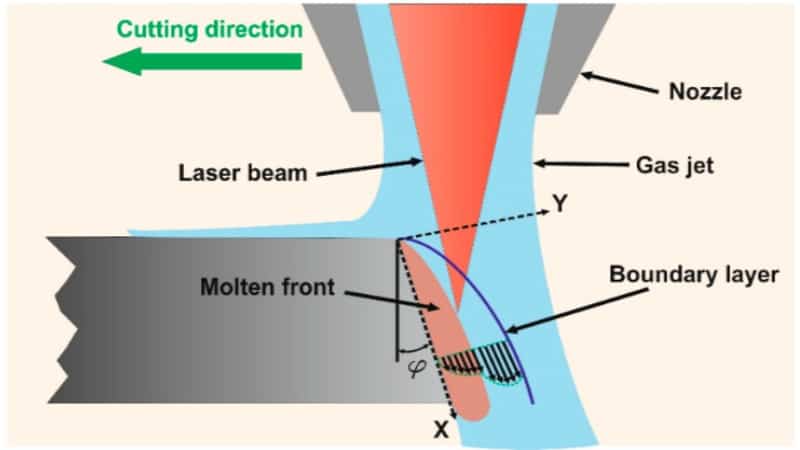

Thermal cutting is a term you can alternatively use to describe how it works, and it has the same principle as the sun and magnifying glass. There is a narrow but highly localized area or a dot light that goes through the lens resulting in high temperatures that can ignite a fire.

Providing exceptional cutting effects and results, a fiber laser-cutting machine works wonders. At the very core of this machine is a revolutionary and specialized device that produces high-quality, precise cuts to a vast array of materials.

The main component of the fiber laser cutting machine is its focused fiber-optic laser beam that melts the material instantaneously with speed and high accuracy. The movement is controlled by a mechanical and numerical system (like that of a 3D printer) where you can set, adjust, and redirect the fine points or parameters of the laser to match your design and preference.

A high-speed airflow removes the molten lava to make the precise cut in a specific area.

The Advantages & Disadvantages of a Fiber Laser Cutting Machine

Let us take a look at the advantages and disadvantages of a fiber laser cutting machine. Do the pros outweigh the cons?

Advantages:

- Fiber laser cutting machines offer a truly remarkable level of precision. They are a perfect choice for those who need to create complex designs for decorative architectural projects, jewelry making, automotive parts, etc.

- It works at high speeds, and if you want to improve your business operations, make better use of your extra hours instead of wasting hours just to make mediocre cuts, and would love to finish more and boost your profitability, get one for your business.

- A fiber laser cutting machine is more cost-effective in the long run than traditional cutting methods. How? Simple because you can now maximize your materials. With spatial skills, you can make intricate designs while all while preventing large amounts of materials from going to waste. The cost of production therefore decreases.

- Damage prevention is among the most sought-after advantages of using a fiber laser cutting machine. Unlike other ways of cutting, this tool can protect your materials from warping and getting distorted due to small focal heat exposure.

- Since this machine can cut at high speeds, you can also conserve electricity.

- It is compatible with a wide range of materials, making it a truly versatile machine to have for your business.

- It is the most advanced form of cutting today.

- Fiber laser cutting machines come in different sizes and varying strengths too. There are different types of machines; two of the most popular types are made for sheet and tube cutting. Whether you need a small, an all-around, or a heavy-duty high-powered machine, you can avail of all of them at Baison to improve your metal fabrication processes.

Disadvantages:

Despite the advancement of fiber laser cutting machines, they also come with imperfections.

- Although this tool is considered a metal-cutting machine and is often deemed to have the power to cut anything, it also has limitations. A fiber laser cutter is perfect for cutting thin to medium-thickness metal sheets but won’t be able to cut through thicker and highly-reflective materials.

- The initial cost, as expected, would be very expensive as opposed to other types of cutting machines. This can be a cause for concern for small and medium-sized businesses that do not have that big of a budget for a high-end cutting tool. Their components are also expensive if you are going to need repair and replacement. It would help if you also prepared for maintenance costs.

- Like all cutting methods, this machine poses health risks, too, especially with improper use and lack of protection while operating the tool. Its high-energy laser beam can cause serious burns or eye injuries. It is logical that those who must operate the machine should have proper training and follow safety procedures.

- As the laser beam and auxiliary gas work to make a precise cut, they will leave residues, fumes, and particles that can harm the operators and the environment. Utilizing the machine in a well-ventilated area is necessary to reduce exposure to hazards.

What Materials Can Not Be Cut by Fiber Laser Cutting Machines?

There are limitations to what a fiber laser cutter can do. Despite these challenges that we are about to discuss, the technology’s overall quality is still immeasurable.

So, what materials can a fiber laser cutting machine not cut?

Wood

Imagine a high-powered laser cutting machine that produces a great beam of heat directed to any wood material. Combust, ignite, spark, fire – words that will instantly pop up in your mind.

It is true that fiberglass cutters can cut through wood, but there is a risk because they are flammable, especially for fiberboard, wood fiber, and plant fiber. The result is also oftentimes inefficient.

Composites

Composite materials with reinforced carbon nanofibers are also unsuitable for laser cutting. The fibers will easily absorb the beam’s high energy and may result in ineffective cutting or material waste.

MDF, for example, contains excessive iron debris, impurities, and soil that could directly affect the cutting precision and even catch fire. This material is not dense enough.

Glass & Acrylic

What exactly are these transparent materials? They are basically glass, acrylic, and polycarbonate. These materials are common among builders, the automotive industry, consumer electronics, and more.

They are, unfortunately, also not applicable for fiber laser cutting. Though these cutters can still cut through, the result will not be as efficient and can contribute to critical industrial situations.

Glass, specifically, will absorb only a very small amount of laser energy because the range of the laser-cutting machines is not within the material’s absorption range.

Highly-reflective materials can lead to poor-quality cutting and can even damage your machine’s laser system, which can be detrimental to your business.

Certain ceramics and plastics are also not good for fiber laser cutting.

List of Common Material Types that Fiber Laser Cutting Machines Can Cut

A fiber laser cutter can get through metal sheets such as:

- Carbon steel

- Stainless steel

- Copper

- Brass

- Aluminum

- Titanium

Factors that Affect Material Type Limitations

The Thickness of Material

The simplest explanation is that the higher the power is needed, the thicker the material.

The math is simple: The thicker the material, the more laser power is required. This factor significantly impacts the functionality of a laser-cutting machine. Fiber laser cutters are designed mainly to cut thinner to medium-sized materials with remarkable speed and accuracy.

500W-powered fiber laser cutting machine can cut a maximum of 6mm carbon steel, 3mm stainless steel, and 2mm for aluminum plate and copper. This is the lowest power estimate but for a higher one with 3000W power, it can cut a maximum thickness of about 20mm carbon steel, 10mm stainless steel, and 8mm for copper and aluminum plate.

The Reflectivity of the Material

It is important to consider the reflective power of the materials you are using when laser cutting. Some of them include copper, aluminum, gold, and silver. They can still be cut through. However, the problem with reflective materials is that they can resist the laser due to their reflection. This can lead to damage to the laser source and waste of materials.

Chemical Composition

Laser-cutting quality can also be affected by the material’s chemical composition. They can even pose a risk to the safety of the operator. Polyvinyl Chloride (PVC), polyurethane, and other types of plastics release hazardous, corrosive, and toxic gases when dealt with high-powered heat.

Another example is cork. It contains a significant amount of adhesives, and though it is a safe material to cut, the cut will be of poor quality.

Techniques to Overcome Material Type Limitations

Gladly, there are ways to overcome these challenges and limitations.

Changing Laser Parameters

A study on the influence of fiber laser cutting parameters on aluminum alloy, a reflective material with high thermal conductivity, presents that processing parameters can contribute positively to the quality of the aluminum alloy fiber laser cutting process.

Laser power, gas assist, and cutting speed are the parameters that can deal with fatigue strength, surface roughness, static mechanical properties, striation angle, wavelength, and HAZ extension. These are the mechanical and surface characteristics that the aerospace industry requires.

Gas Assist Pressure

A review published in the National Center for Biotechnology Information regarding the influence of gas assist pressure on the performance of fiber lasers for industrial applications presented that it is highly relevant in quality cutting.

The nozzle design also has something to do with its performance. Conical nozzles are considered the highest class in the industry. You can learn about how to choose an ideal nozzle for your machine.

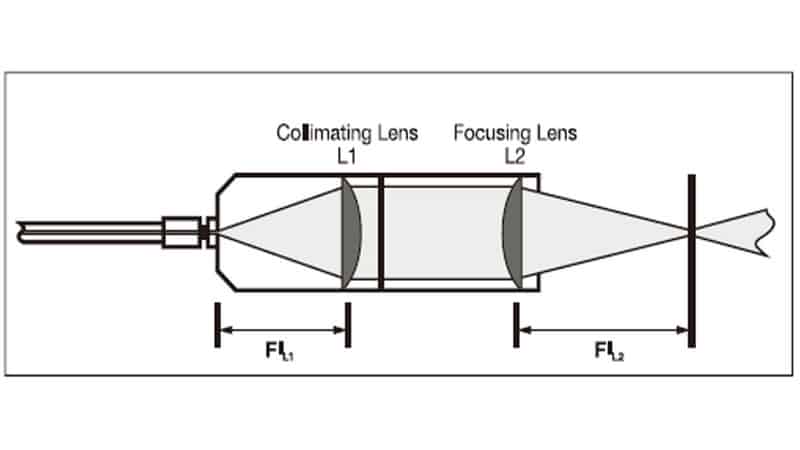

Use of Special Lenses

Using special lenses for your fiber laser cutters can help with focal depth and at the same time, minimize the laser spot size to narrow down the beam efficiently. This can be very helpful when you have to deal with reflective materials. Special protective lenses reduce the amount of energy that can bounce off the material back to the laser system.

Applications of Fiber Laser Cutting Machines

Widely used in different industries, fiber laser-cutting machines are popular in the following applications.

- Aerospace

- Automotive

- Electronics

- Medical

- Jewelry

- Metal Fabrication

- Home Appliances

- Advertising Products (Billboards, promotional products, and more)

- Fitness Industry

- Elevators

- Sheet Metal Industry

Conclusion

Fiber laser cutting machines are used in various fields and are considered a convenient tool in industrial development. Since its emergence, the machine remains to be an indispensable item in manufacturing.

Despite its limitations in material thickness, reflectivity, and chemical compositions, there are ways to configure the performance of a fiber laser cutter through parameter setting.

Discover the Perfect Solution for Your Business with Baison

Fiber laser cutting machines are already configured to perform high-quality cutting and overcome these material limitations. You can request an instant quote at Baison and get free sample proofing too. Baison is one of the top-trusted fiber laser cutting technology providers with a long-standing reputation in the welding, laser cutting, and automation industry.