Industrial marking applications usually come down to laser marking and inkjet printing. This article aims to help you understand the difference between the two. This is important, especially if you are in an industry with marking application needs. Some of which are in the pharmaceutical industry as well as the automotive and even the aerospace industry.

You will read about the advantages and challenges of each marking application. We will also cover some of the distinct advantages of laser marking and why most people in several industries prefer it. On top of this, you will also come across 3 absolute reasons why laser marking is a cut above the competition.

What is laser marking?

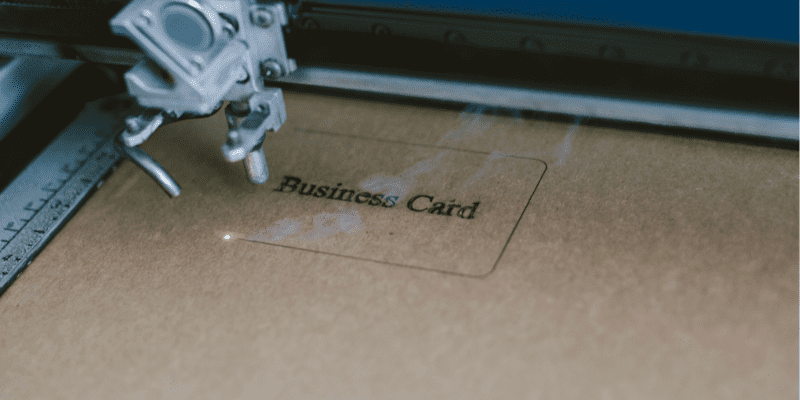

Laser marking is making a permanent marking on a material using a beam of concentrated light. This lasting mark on a surface is usually accomplished with a continuous wave, pulsed wave, or UV laser machine. As soon as the beam interacts with the material’s surface, it alters its appearance.

There is no question that the laser marking system is increasingly becoming the go-to marking application for several industries. One of the biggest reasons for this is its ability to mark without needing too many materials like ink and chemicals. On top of this, laser marking can work not only with all metals but most composites, plastics, and even semiconductors with precision.

Do not confuse laser marking with laser etching and even engraving. Etching and engraving can mark a surface, but it physically removes a portion of the material. Laser etching melts the surface, while engraving is more invasive, with deeper indents on the surface. The light beam discolors the material’s surface when you choose laser marking. This is why some people refer to laser marking as laser coloration and even laser dark marking.

What are its benefits over inkjet printing?

When it comes to the benefits of laser marking over ink jet printing, here are 3 reasons why laser marking is better.

- Fewer consumables – laser marking can be done with electricity as your main consumable. Inkjet printing requires several consumables like ink, tape, and even chemicals. This makes it a lot more expensive option over time.

- Permanence – laser marking is hard to take off compared with inkjet printing. Since it marks by using a laser to discolor the surface area, you cannot easily take it off. Ink, on the other hand, is easier to rub off. If you printed on paper, getting it wet could render the printing unusable. This is also one of the reasons why laser marking is preferred when you need permanent marking for materials in harsh weather conditions.

- Versatility – laser marking is much more flexible compared with inkjet printing. The reason for this is your ability to make fine adjustments. Power, wavelength, and even the diameter of the laser beam are just some of the adjustments you can make when marking with a laser.

Now that you know what laser marking is and the top 3 reasons it comes out better than inkjet printers, let’s look at the technologies behind it. There is 2 most common technology used when it comes to laser marking.

- Fiber laser is a recent technology that uses light or optical amplification to achieve marking results on a material’s surface.

- Gas laser – this makes use of gas, where light passes through to mark the surface. The most common gas used behind this technology is CO2.

How does laser marking work, and what materials can it be used on?

Laser marking works by using a laser beam and moving it across the surface of a material. As a result, this leads to discoloration on the surface, essentially marking it. Another way of looking at it is when the laser heats the surface, it leads to oxidation and changes the color and marking it. This high-contrast mark on the surface is achieved without disrupting or damaging the materials.

Laser marking is ideal for use across several industries. One of the reasons for this is the fact that lasers can work on several materials. Although the biggest upside is being able to work with most metal materials, here are some specific uses of laser marking:

- Laser marking can be used in titanium and stainless steel parts of medical devices

- The aerospace industry uses a laser to mark raw materials like stainless steel, titanium, and aluminum.

- Composite hybrid hose assemblies in the automotive industry use laser marking.

- Bakery tags in the food industry can use laser marking to show food product information.

- Agriculture products such as tube assemblies benefit from laser marking, especially when they use black adhesive labels.

- Stainless steel exhaust systems and other automotive OEM parts also use laser markings.

What is the cost difference between laser marking and inkjet printing?

Laser marking has a higher upfront cost, but consumable and maintenance costs are much lower than inkjet printing. Inkjet is the opposite – it has a lower upfront cost, but its maintenance and consumable expenses are higher than laser marking.

The main reason for the high upfront cost of laser marking is purchasing the machine at the onset. This can range anywhere from $10,000-$80,000. The technology behind the machine you will purchase and the power output are some variables to consider. But it is also important to remember that high-powered laser machines that lead to better efficiency can also lead to higher electricity costs.

But once you buy the laser machine, expenses start to become manageable. Unlike the inkjet printing system, lasers do not have continuous solvent or ink refills, as well as expensive maintenance costs and daily care.

Factors to consider when choosing between laser marking and inkjet printing methods?

The top factors to consider when choosing between laser marking and inkjet printing are the costs for each marking technique, the materials you can use them on, and the marking quality. These three factors will make you realize how much better laser marking is when compared with inkjet printing.

Laser marking offers much less maintenance cost on your operations and can work with several materials spanning several industries. The marking is also much more permanent compared with the inkjet method.

On top of these, versatility is another factor you need to consider, and again, laser marking comes out on top. This is because inkjet has a lower resolution printing, especially when making small markings. Laser marking has the ability to make high-quality small marks due to the small size of the laser beam. This makes it the marking technique for small and intricate marking designs.

- Ongoing maintenance needs – Yes, inkjet printing machines cost less, allowing you to start your printing business or marking needs quickly. But soon, you will come across the constant need to replace toners, inks, or solvents to keep on printing. The machine also needs a lot more maintenance and daily care. There is no way around it. If you need to print, it would be best to refill those ink or solvent cartridges continuously.

- Production line compatibility – the versatility of inkjet printing is limited in material and even size. Ink would have a tough time marking metal materials. This is something laser marking can easily accomplish. The size of the print is also an obstacle for inkjet marking. The smaller the printing gets, the lower the resolution inkjet makes it. On the other hand, the quality of laser marking does not diminish as the design to be marked gets smaller.

Conclusion

Laser marking is a cut above the rest, especially when compared with inkjet printing. It comes off with flying colors when you look at cost, material compatibility, versatility of use, and even the quality of the print. Although inkjet printing is still widely used across several industries, laser markings seem to be the technique of choice for the more demanding marking projects.

Baison is a leading fiber laser system manufacturer in China. If you are looking for high-precision fiber laser marking machines for your business, then Baison will be your best option. Contact us to find a suitable product now.