Laser cutting is the most accurate and efficient way to cut material. A crossbeam is a structural part of a laser cutting machine and supports the laser head and other components. It can directly influence accuracy. Quality crossbeam directs the laser beam and can affect the laser cutting accuracy.

This article will discuss how we can achieve precision and accuracy with laser-cutting machines. We will examine the crossbeam and how it can affect the overall cutting process and results. Before we dig deep, let’s understand what a crossbeam is.

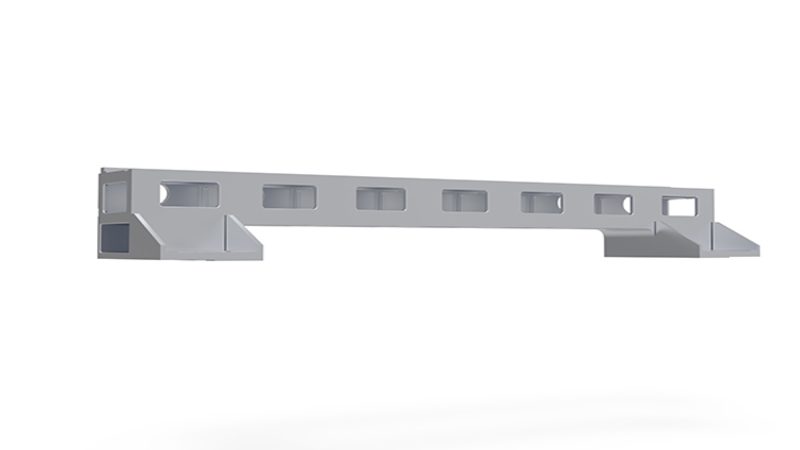

What Is a Crossbeam of a Laser Cutter?

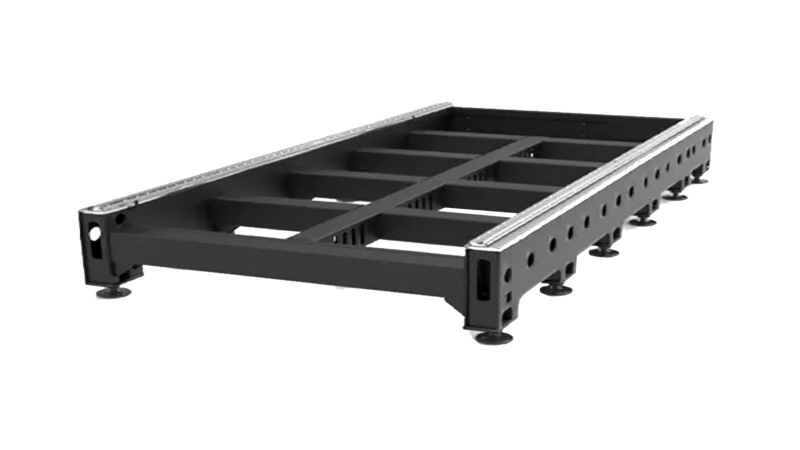

A crossbeam is a structural part of a laser cutting machine. It is an integral part of the machine control system. A horizontal beam is attached to the cutting area, supporting the laser head and other associated components.

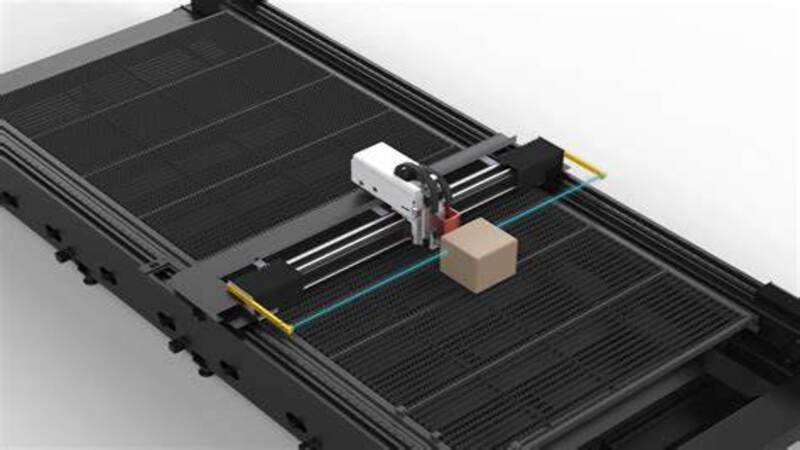

The primary purpose of the crossbeam is to stabilize the laser beam while the cutting process. It prevents movements or vibrations to ensure precise and accurate cutting during laser cutting. The laser head is mounted on a crossbeam and moves along the beam’s length.

Automatic laser cutter produces high-precision cuts, and crossbeam plays an essential role in it. The major function of a crossbeam is to prevent vibration and other movements during the cutting process.

It is lightweight and minimizes deflections or vibrations for accurate cutting results. So they should be secure, stable, rigid, and still light in weight. Crossbeam is also attached to the auto-focus laser head.

Usually, aluminum is used for making s. It is lightweight and still provides the stability and rigidity required for cutting.

Different Types of Crossbeams Available in the Market

Different types of crossbeams are available in the market; let’s take a look at each:

Steel Crossbeams

Steel is a rigid material that gives the stability and rigidity required by a crossbeam. However, steel is a heavy material with high thermal conductivity. It can also be less vibration-dampening, especially when working on delicate cuts.

Aluminum

Aluminium is the widely used material for crossbeams. Lightweight and rigid aluminum is used that maintains the stability of laser-cutting equipment. They reduce the machine’s overall weight and provide stability and rigidity required for laser cutting.

Composite Laser Beam

It is made of composite material. Carbon fiber-reinforced polymer material is widely used in industries as it has low weight, better vibration absorption, and less thermal conductivity.

Factors that Affect the Performance of a Crossbeam

Here are some factors that can affect the performance of crossbeams.

Material

The choice of material can affect the performance of the crossbeam. Several materials, like steel, aluminum, brass, and composites, are used to make crossbeams. However, each material has properties that can affect the machine’s performance. Like steel can be too heavy with high thermal conductivity.

Crossbeam Design

The structural design of a crossbeam can affect its overall performance. Its shape, dimensions, and structural reinforcement can affect its overall performance. How it is attached to the laser head and other components also affects its movement and performance.

Alignment and Calibration

Proper crossbeam alignment and correct calibration are essential for achieving perfect cutting results. That’s why the maintenance of machines is essential. Any misalignment of the crossbeam can affect its overall performance.

Stability and Vibration Dampening

The main purpose of the crossbeams is to provide stability and dampen the vibration. It fails its purpose if it is flexible enough and can dampen the vibration.

Thermal Conductivity

The thermal conductivity of the crossbeam is important. Laer beam produces heat while cutting. If the crossbeam absorbs too much heat, it can affect its performance. This means adequate thermal management measures such as ventilation and cooling can dissipate heat and prevent material overheating, expansion, or distortion.

Load-Bearing Ability

The crossbeam should be light in weight, but it should be stable and hard enough to support the laser head and its components. The load-bearing ability of the crossbeam should be considered while selecting the material and type of crossbeam.

Advantages of Using a Quality Crossbeam

Here are a few advantages of using a quality crossbeam:

Precision in Cutting

The crossbeam supports the laser head and moves along to provide support and rigidity. Quality crossbeam keeps the laser head secure and helps the laser beam follow the pattern while cutting. It ensures the laser beam follows the pattern and gives desired cuts and shapes.

Rigid and Durable

A good crossbeam can withstand opposing forces like heat and stress and still perform. Good material and calibration provide it strength and long-lasting performance.

What are the Manufacturing Methods of Crossbeams?

Here are different methods of manufacturing crossbeams:

Welding

Welding is the process of joining two metal pieces together by heating them. The edges of metal pieces are fused to make a crossbeam. It gives a strong and durable crossbeam, and the method can be used to manufacture crossbeams of different materials. However, certain disadvantages of this method are:

Pros

- If welded properly, it can make a secure and rigid crossbeam.

- Welding can be used to manufacture crossbeams of several metals.

- It’s a cost-effective way to manufacture crossbeams, so small workshops or medium to small-scale businesses still use it.

Cons

- You need skilled labor that is proficient in different types of welding.

- Crossbeam quality is not consistent.

- Poor rigidity and welding flaws can affect the quality of the crossbeam.

- An expensive method as lots of electricity is used for welding.

- There can be potential weak joints due to air bubbles that can affect the structural quality of the crossbeam.

- Welding can only work for metal-made crossbeams and not for composite materials.

Casting

Casting is the process of melting metal and pouring it into a mold to form a shape once solidified. It is commonly used for making crossbeams of aluminum or steel. We at Baison’s use the casting of aircraft-quality aluminum to manufacture crossbeams.

Here are several pros and cons:

Pros

- Gives design flexibility

- The casting method gives a lot of flexibility, and you can structure crossbeams according to special needs for intricate patterns, shapes, and designs,

- Though aluminum is used to manufacture crossbeams, other metals like steel can also be used in the cost method.

Cons

- Casting requires liquid material to be poured into casts. The air in the cavity will fuse with molten metal and may cause bubbles, holes, or rough surfaces.

- When liquid flows through the casting, there is no guarantee that wall thickness remains. The same from each side can cause edge breaking or cracking.

- Many process conditions can cause imperfect results.

- Suitable for large-sized and bulkier crossbeams.

Extrusion Film Drawing Process

It is the most accurate way of manufacturing crossbeams in high-tech industries. Extrusion is making a crossbeam with a constant cross-sectional shape. In extrusion, melted material is forced through a die, which gives it a specific shape. The material is cooled down and cuts to get the desired length.

Pros

- It allows manufacturers to create custom designs and make I-beam T-beams or any custom-required shape and size.

- Less material is wasted in this process as the process makes crossbeams with less scrap and offcuts.

- Extrusion makes a strong yet lightweight crossbeam. They are suitable for applications where strength and reduced weight are important.

- A cost-effective method is suitable for high production volume.

- The extrusion process gives consistent quality every time.

Cons

- Limitation of size and shapes

- Set-up cost is high as it requires dies and extrusion cases.

- Less surface finish and require more post-process steps.

Some Common Challenges with Crossbeam for Laser Cutting

Here are a few challenges that may arise with crossbeams and tips for solving them.

Alignment

Proper alignment of the crossbeam is crucial for precise and accurate laser cutting. The crossbeams may become misaligned from time to time. It can be due to wear and tear, improper maintenance, accidental damages, or simply loading and unloading materials.

It is essential to check the calibration and proper alignment of the crossbeam before the cutting process starts. Regular maintenance can also keep the crossbeam well-aligned.

Wrapping and Distortion

Crossbeams are usually made of aluminum, and overheating may cause wrapping and distortion in their material. Mechanical stress can also affect the performance of crossbeams.

Monitoring the crossbeam from time to time will help you address the issue. Wrapping or distortion may cause uneven cuts and inaccurate cutting results. Make sure you inspect the crossbeam before the laser cutting process, and if there are any signs of distortion or wrapping,

Wear and Fatigue

Continuous use of the crossbeam will wear out the part over a while. Repetitive stress and thermal cycling can also cause wear and tear in the material.

Again, inspect the crossbeam regularly to notice any wear and fatigue. Regular maintenance and timely repair will increase the life span of the Crossbeam.

Vibration and Resonance

Too much vibration can be caused by high speed on certain materials. Excessive vibration can lead to inaccurate cutting results.

Make sure the operating staff is skilled enough to adjust the parameters according to the properties of each type of material. Proper damping and vibration control measurements can solve the issue.

Corrosion

Crossbeam may be exposed to environmental conditions like moisture, chemical exposure, or corrosive agents. Several environmental factors can cause corrosion as well. Corrosion can degrade crossbeams’ quality, performance, and lifespans.

Here are some tips:

- Keep the temperature under control.

- Inspect the crossbeam regularly to look for signs of corrosion.

- Coating of corrosion resistance chemicals can help to control the corrosion.

How Baison Makes Crossbeam for our Laser Cutting machines

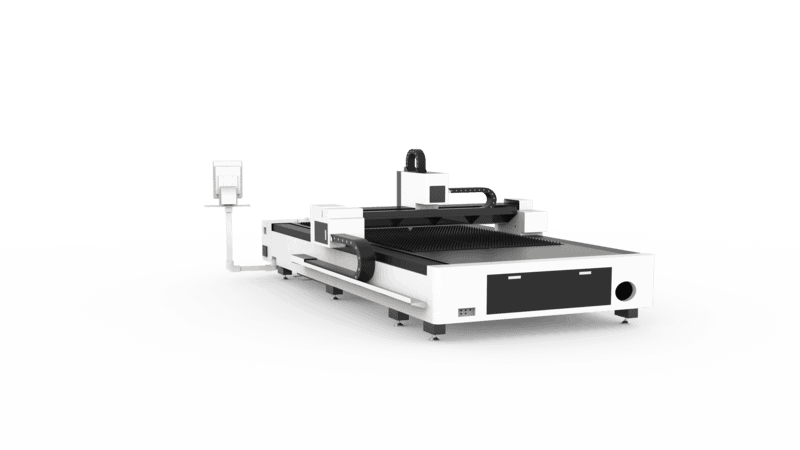

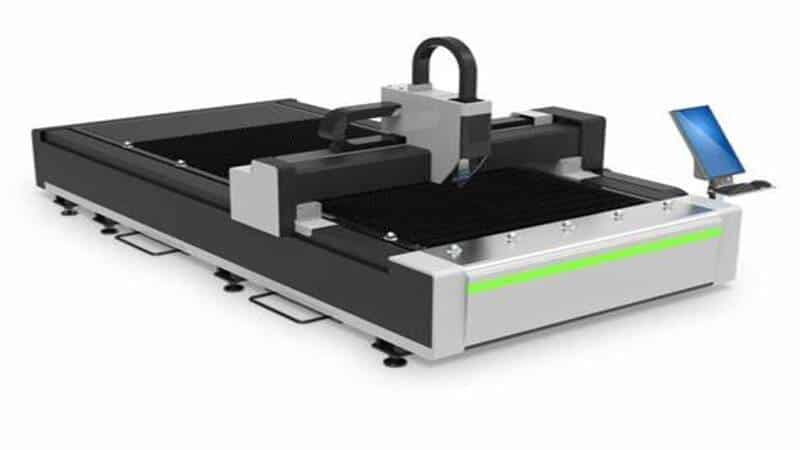

Baison offers high-tech laser machines for small to big industries. Our laser machines are built on modern and innovative designs that make them efficient, user-friendly, and highly capable in all industries.

Baison manufactures high-quality crossbeams using an extrusion film drawing process. We use the seventh series of aircraft-grade aluminum, considered the best in industries for laser machine crossbeam manufacturing.

Our manufacturing method, crossbeam, is foul[-proof that it gives consistent quality and accuracy. We melt the aluminum ingot to 500℃, which softens the material rather than melting it.

Softened materials are put into extrusion equipment, and ensure the material has the right thickness from all sides. As the material is not melted, there is no risk of any bubbles or air fusion into the material. The crossbeam has the consistency of shape and density.

Conclusion

Baison stays forefront of technological advancement and offers high-quality laser cutting, welding, and engraving machines. Our laser systems are built are equipped with industry-leading technology and are efficient. These machines can be fully automated and help industries to increase their production quality and volume.

We offer free application evaluation, and our friendly staff is always there to help you guide us through our laser machines. Contact us today!