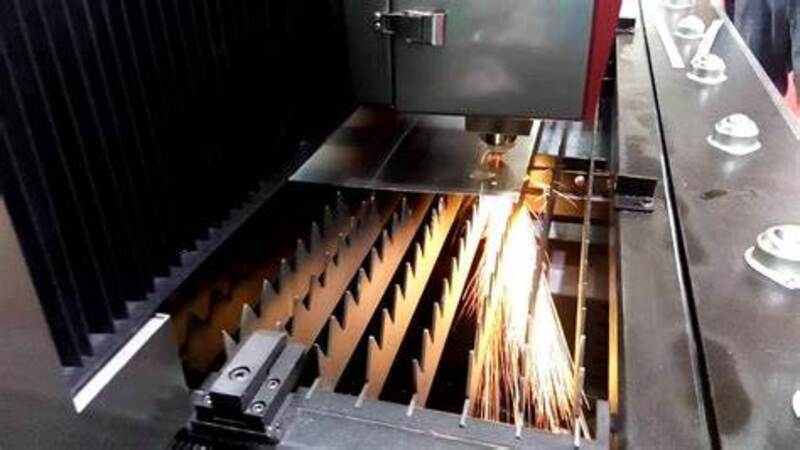

In this blog post, we’ll explore how you can optimize your laser cutting machine’s power to improve performance and help your business succeed. So, let’s get started!

What Is Laser-Cutting Machine Power

Laser-cutting machine power refers to the amount of energy that a laser beam can deliver to the material being cut. This energy is measured in watts and determines the cutting speed and thickness that the laser can handle. The power output of laser-cutting machines can range from a few watts to several kilowatts, depending on the type and size of the machine.

The higher the power of the laser cutting machine, the faster it can cut through the material and the thicker the material it can handle. However, higher power also means higher costs in terms of the initial investment and ongoing operating expenses.

Therefore, it is essential to optimize the power of your laser-cutting machine to balance speed and precision with cost-effectiveness.

How to Measure Laser-Cutting Machine Power?

Measuring laser-cutting machine power is crucial to maintaining optimal performance and achieving accurate and consistent results. The most common method of measuring power is by using a power meter. This device measures the amount of energy the laser beam delivers per unit of time, displaying the result in watts.

By regularly measuring the power output of your laser cutting machine, you can ensure that it’s operating at optimal levels.

In addition to using a power meter, you can also refer to the machine’s documentation or user manual to check its power output.

However, it’s essential to keep in mind that the power output indicated by the manufacturer may not be the same as the actual power output of the machine. This is because several factors, such as age, maintenance, and wear and tear, can affect the machine’s performance.

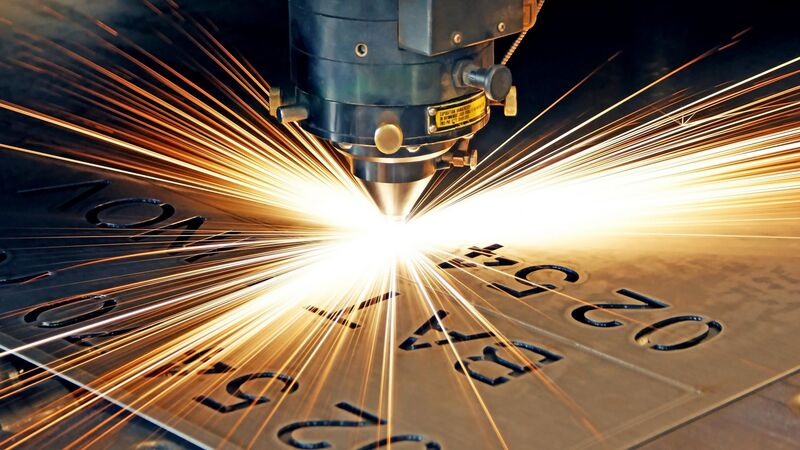

The Relationship between Laser Power and Cutting Speed

Here is a table highlighting the different power levels available for laser cutting machines and their recommended use cases:

| Laser Power | Recommended Use Cases |

| 40W | Engraving, marking, and cutting thin materials up to 1/8″ |

| 60W | Cutting and engraving thin to medium-thickness materials up to 1/4″ |

| 80W | Cutting and engraving medium to thick materials up to 1/2″ |

| 100W | Cutting and engraving thick materials up to 3/4″ |

It’s important to note that the recommended use cases may vary depending on the specific machine and material being used.

Higher laser power generally allows for faster cutting speeds and the ability to cut through thicker materials. However, finding the right balance between power and speed is important to achieve optimal results. Using too much power can lead to overheating, distortion of the material, and other issues that can affect the quality of the cut.

On the other hand, using less power can result in slow cutting speeds, uneven cuts, and other issues that can impact productivity and efficiency.

Material thickness also plays a role in determining the appropriate laser power for cutting. Harder and thicker materials require more power to cut through, while softer and thinner materials require less power. Additionally, different materials have varying degrees of reflectivity, which can affect the machine’s power needs.

In summary, the relationship between laser power and cutting speed is vital for achieving optimal results in laser cutting. The appropriate laser power depends on the material thickness and type, and finding the right balance between power and speed is crucial for achieving high-quality cuts while maximizing productivity and efficiency.

What Are the Factors Affecting Laser-Cutting Machine Power?

- Material type and thickness: Different materials require different laser power levels to cut through. Harder and thicker materials require more power to cut through, while softer and thinner materials require less power. Additionally, the material’s reflectivity can also affect the machine’s power needs. Highly reflective materials like copper or aluminum require higher power levels than less reflective materials like wood or plastic.

- Cutting speed: The laser’s speed across the material also affects the power requirements. Faster cutting speeds require more laser power to maintain the same cutting quality and accuracy level. Operators should consult the machine’s user manual for recommended power levels at different cutting speeds.

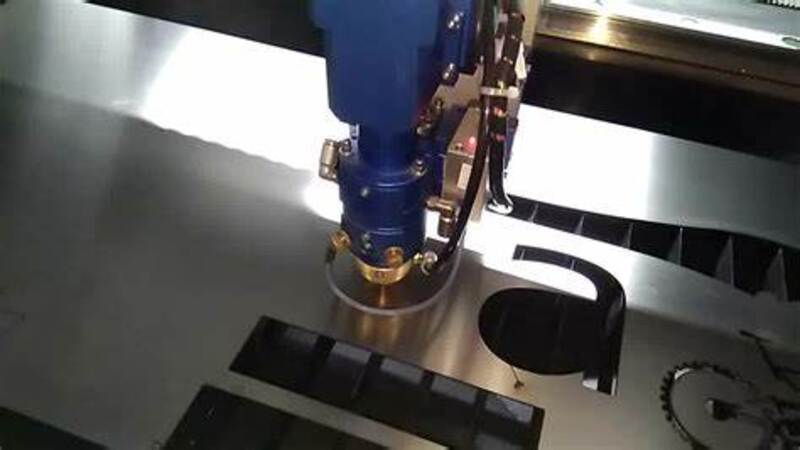

- Nozzle size: The size of the nozzle used for the cutting process can also impact the machine’s power requirements. Larger nozzles require higher power levels to maintain the same cutting speed and quality as smaller nozzles. Therefore, selecting and matching the appropriate nozzle with the right power level is important for achieving optimal results.

- Gas pressure: The pressure of the gas used during the cutting process can also affect the machine’s power needs. Higher gas pressure requires higher power levels to maintain the same cutting speed and quality. Operators should consult the machine’s user manual for recommended power levels at different gas pressures, and choose the right auxiliary gas.

Tips for Choosing the Optimal Power Level

- Refer to the machine’s documentation and user manual for recommended power levels.

- Conduct test cuts to determine the optimal power level for different materials and thicknesses

- Consider the tradeoff between speed, precision, and cost when selecting the power level.

Recommendations for Adjusting Laser Power During Cutting

- Monitor the cut quality and adjust the power level as needed to maintain accuracy and precision

- Increase power for thicker or more rigid materials, and decrease power for thinner or softer materials

- Adjust power levels based on the cutting speed and desired results.

The Benefits of Optimizing Laser-Cutting Machine Power

Optimizing laser-cutting machine power can provide numerous benefits for your business. By ensuring that your machine operates optimally, you can achieve improved cutting speed, accuracy, and consistency, resulting in higher-quality cuts and reduced material waste.

In addition, properly calibrated power levels can help extend the lifespan of your machine by reducing wear and tear.

Here are some of the benefits of optimizing laser-cutting machine power:

- Improved Cutting Speed and Accuracy: Optimizing the power level of your laser cutting machine can help you achieve faster and more accurate cuts, leading to increased productivity and efficiency. Proper calibration of the power levels ensures that the machine can cut through the material effectively and efficiently, reducing the need for re-cuts and minimizing the overall cutting time. The result is a higher-quality finished product with improved accuracy, which can help reduce the need for post-processing and finishing, saving time and resources.

- Reduced Material Waste: When laser cutting machines operate at optimal power levels, they produce fewer errors and higher-quality cuts, reducing material waste and cost savings. Proper calibration of power levels ensures that the machine can cut through materials effectively without causing damage or wasting materials. This reduces the number of re-cuts and the amount of scrap material generated during the cutting process, resulting in cost savings.

- Extended Machine Lifespan: Optimizing the power settings of your laser cutting machine can also help extend its lifespan. Properly calibrated power levels can help prevent overheating, which can damage the machine’s optics and other components over time. By reducing the stress on the machine’s components, you can increase its lifespan and reduce the need for repairs or replacements, resulting in cost savings in the long run.

Tips for Optimizing Laser-Cutting Machine Power

Optimizing laser-cutting machine power can improve cutting speed, accuracy, and consistency, as well as reduce material waste and extend the lifespan of your machine. Here are some tips for optimizing laser-cutting machine power:

Prepare Your Materials:

It is important to prepare the materials to be cut properly. This includes cleaning the surface of the material and securing it properly to prevent movement during the cutting process. Additionally, consider the thickness and type of material, as these factors will influence the power settings required for cutting.

Set Up the Machine

To optimize your machine’s performance, it is important to ensure that the machine is properly calibrated and maintained. This includes cleaning the optics and checking the gas pressure and flow. Referring to the machine’s documentation and user manual for recommended power settings based on the material type and thickness is also helpful.

Adjust Power Settings

Start by using the recommended power settings and conduct test cuts to determine the optimal power level for the specific material and thickness. Monitor the cuts’ quality and adjust the power settings as needed. Consider the tradeoff between speed, precision, and cost when selecting the power level.

Optimize Cutting Speed

Once the optimal power level has been determined, adjust the cutting speed to maximize efficiency while maintaining quality. Monitor the quality of the cuts and adjust the power and speed settings as needed to maintain accuracy and consistency.

Regularly Maintain and Monitor the Machine:

Maintaining and cleaning the machine is important to ensure optimal performance and longevity. Regularly monitor the power settings and cutting quality to identify any issues or adjustments that may be needed. This includes cleaning the optics, checking the gas pressure and flow, and making any necessary repairs or replacements.

How to Avoid Common Mistakes?

Common Mistakes Businesses Make When Optimizing Laser Cutting Machine Power:

- Using incorrect power settings for specific materials and thicknesses

- Failing to maintain and clean the machine properly

- Not conducting regular checks and calibrations

- Overlooking the importance of the nozzle size and gas pressure

Tips for Avoiding These Mistakes and Achieving Optimal Performance:

- Follow the machine’s documentation and user manual for recommended power settings

- Conduct test cuts to determine the optimal power level for each specific material and thickness

- Regularly clean and maintain the machine to ensure optimal performance

- Conduct regular checks and calibrations to identify and address any issues early on

- Consider the importance of nozzle size and gas pressure in achieving optimal results

- Train operators on proper machine use and maintenance to prevent errors and improve performance

Conclusion

In conclusion, optimizing laser-cutting machine power is essential for achieving faster cutting speeds, improved accuracy, reduced material waste, and extended machine lifespan. The power level required for cutting varies based on the material type, thickness, cutting speed, nozzle size, and gas pressure.

It is important to refer to the machine’s documentation and user manual for recommended power settings and to conduct test cuts to determine the optimal power level for specific materials and thicknesses.

You can achieve optimal performance and efficiency in your laser cutting operations by properly calibrating the power level, adjusting the cutting speed, and regularly maintaining the machine.

Upgrade Your Cutting Game with Baison Laser Cutting Machines Today!

At Baison, we not only offer high-quality laser cutting machines with customizable options, but we also provide cost-effective and excellent after-sales service to ensure customer satisfaction.

Our experienced technicians are available to provide timely and effective support for any issues that may arise. Additionally, we offer regular maintenance and training programs to keep your machine operating at optimal performance.

With Baison, you can trust that you will invest long-term in your business with a reliable and efficient laser-cutting machine. Contact us today!