The laser cutting technology has been a gift for both large as well as small businesses. This technology has become one of the most widely used techniques to cut and engrave materials.

Many manufacturing industries use laser cutting machines or engraving machines for their manufacturing processes.

The laser cutting process is a fairly simple and easy one. It helps business owners efficiently produce products.

The high efficiency of laser-cutting machines can boost productivity and profits. Due to this laser technology, many businesses have seen exponential growth in their profit rates.

Read ahead to understand how production and profits are increased with the help of laser-cutting technology.

What Is a Laser Engraving or Cutting Machine?

Laser-cutting machines are used in many factories and industries. Their high precision cutting and mass production attributes make them one of the ideal cutting tools.

The laser cutting services include various processes such as heating, melting, burning, and even vaporizing.

Currently, CNC machines are widely utilized in the laser-cutting process. The CNC machines receive instructions after converting digital drawings into computer code.

The cutter uses a high-power laser beam. The strong laser power of the laser cutters offers high power for a smooth thermal cutting process.

Simultaneously, the high precision, fast engraving speed, and cutting speed offer better production of finished parts than traditional methods. The laser cutter produces the highest quality products. It also enables you to cut a variety of materials whilst producing less waste.

Laser cutting allows you to create custom and intricate designs on different materials. Unlike other machines, the production process is quite smooth and cost-effective.

Different Types of Laser Cutters

A laser cutting machine depends on the type and kind of laser being used in it.

The type shall ultimately decide the cutting metals and various materials that that machine can cut.

There are 3 main types of laser engraving and cutting machines. These are explained as follows.

CO2 Laser Cutters

This cutter is one of the most popular types. This laser technology machine involves different gases such as CO2, helium, and nitrogen.

The gas mixture is charged by an electric discharge. This then generates a 10.6mm laser beam.

Compared to other cutting tools, these cutters are widely recognized for their cost-effectiveness and high-precision cutting.

A range of materials can be cut by this cutter. These include:

- Glass

- Plastic

- Leather

- Wood

- Acrylic

Crystal Laser Cutters

The laser beam is produced by Neodymium-doped yttrium ortho vanadate in this crystal cutter.

Unlike CO2 cutters, these cutters can effectively penetrate thicker materials. This is due to their small wavelengths.

The small wavelength of the laser beam allows many materials to be accurately cut. The production quality of the laser cut is unmatched.

However, there is a drawback to this laser-cutting machine. Their parts tend to experience wear and tear due to their strong power functionality.

The following materials can be cut by this cutter.

- Plastic

- Metal

- Ceramic

Fiber Laser Cutters

The fiber laser cutter is also known as the solid-state laser cutting machine. It originates from a seed laser that amplifies and magnifies through specialized optical fibers.

The laser cutter brings remarkable benefits to the table. Firstly, it can easily be cut through reflective and conductive metals of different metal thicknesses. Secondly, it exhibits three times the efficiency compared to CO2 cutters. Lastly, one notable advantage is the absence of movable parts in its design.

Fiber lasers are quite versatile. They are capable of processing both metals and organic materials.

Despite their similarities to crystal lasers, fiber laser cutters outperform them. Both, in terms of efficiency as well as they require less maintenance.

Different materials are cut by this laser cutter. These include:

- Metals

- Organic substances

Different Materials that a Laser Cutter Can Cut

Laser cutters are a very versatile tool. They are known to cut or engrave a variety of materials with high accuracy.

Here are the different metal materials laser cutters can cut. A laser cutting machine can cut many different types of metals. Some examples of the types of metals that are commonly cut are given below.

- Stainless steel

- Mild steel

- Carbon steel

- Aluminium

- Copper

- Iron

- Brass

- Titanium

- Nickel alloys

- Inconel

The size of the laser cutting machine shall denote the thickness of the metal being cut. Kerf width can also be maintained accurately throughout the process.

Advantages of Laser Technology

There are many laser-cutting advantages that make this process a very popular one. Some of these laser-cutting advantages are as follows.

Highly Precise and Accurate Products

The laser cutting machine offers high precision. This is because the material is being cut using a sharp and focused laser beam.

The beam is very strong and has great power and cutting speed. Therefore, it is able to cut any material precisely and accurately.

Cost-effectual

The laser cutting equipment is quite cost-effectual. It is affordable compared to other cutting technologies that are available in the market.

This is because you do not have to spend extra on tooling costs. No extra tools for cutting or engraving are needed separately. Hence, further money is saved.

All you need to pay is the upfront costs while purchasing the machines. After that, you can create as many products as you want.

The upfront costs would be the only major investment required. Maintenance of the machine is also quite reasonable since it is less subject to wear and tear.

Highly-complexed Tasks

Tasks that are way too complicated for other cutting technologies are very easy for laser cutting ones.

This technology can operate on very thick as well as very thin material. The cutting speed and quality can be easily maintained throughout the process. This unifies the entire manufacturing process, which is a high advantage, especially for large businesses.

Great Quality

This technology ensures that all products that are manufactured have great quality standards. This enhances productivity as well as increases the profit rate for businesses.

Avoiding Damages

The strong laser power ensures minimum waste material is produced throughout the process. This prevents any major losses, even when production is in bulk.

Very Safe

Safety is an outstanding feature of this technology. There are little to no risks for those who are manufacturing the products. This is because all the cutting work is done by the laser.

Many machines also have an additional safety feature in them. This enables the machine to produce harmful gases at a much lower rate. This is not only beneficial for those who are working with the machine but also for the overall environment.

Top Laser Cutters for Large Businesses

You will find numerous brands of laser cutters in the market. So many options are available that it is easy to get overwhelmed at times.

Here are the top 4 laser cutters that are perfect for large business owners.

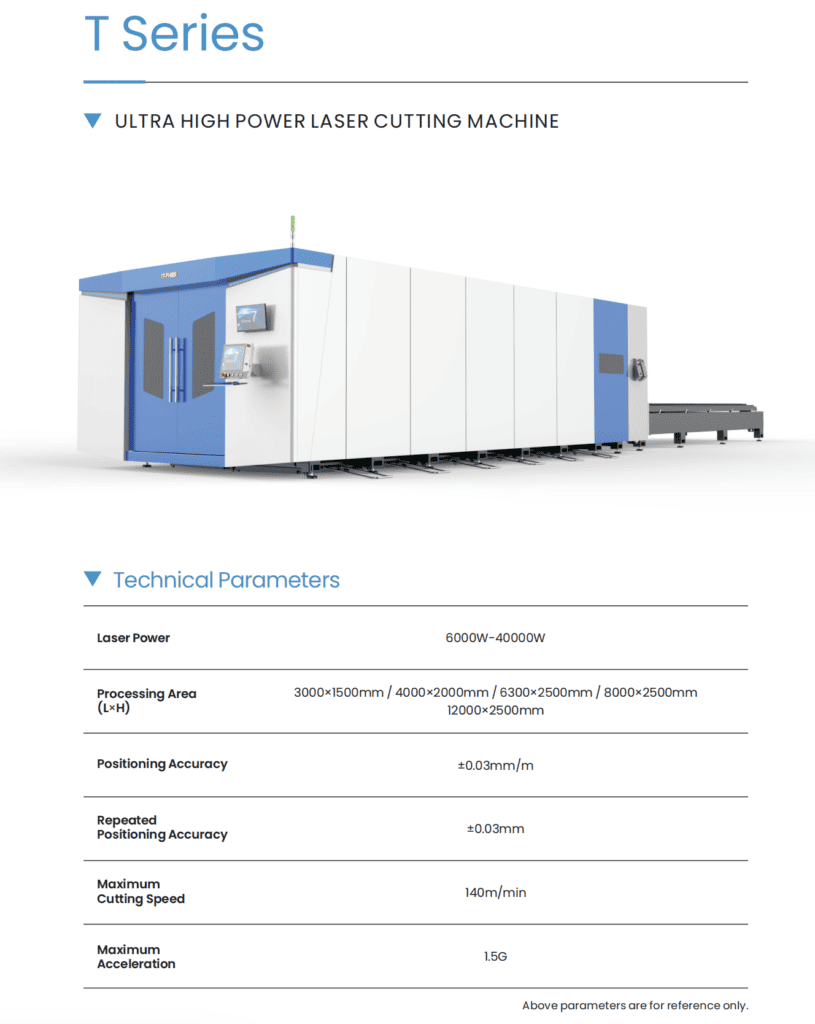

T Series

The T series laser cutting machine is a very popular choice. It has a light path system as well as a control system in its mechanics.

Original fiber lasers are imported. They are very strong, powerful, and highly stable machines. Their overall lifespan exceeds more than 1000000 hours.

The cutting speed of this machine is around 85 m/min. Hence, the process is carried out smoothly and is not time-consuming at all.

The cutting quality is quite remarkable. The overall product is finished with beauty.

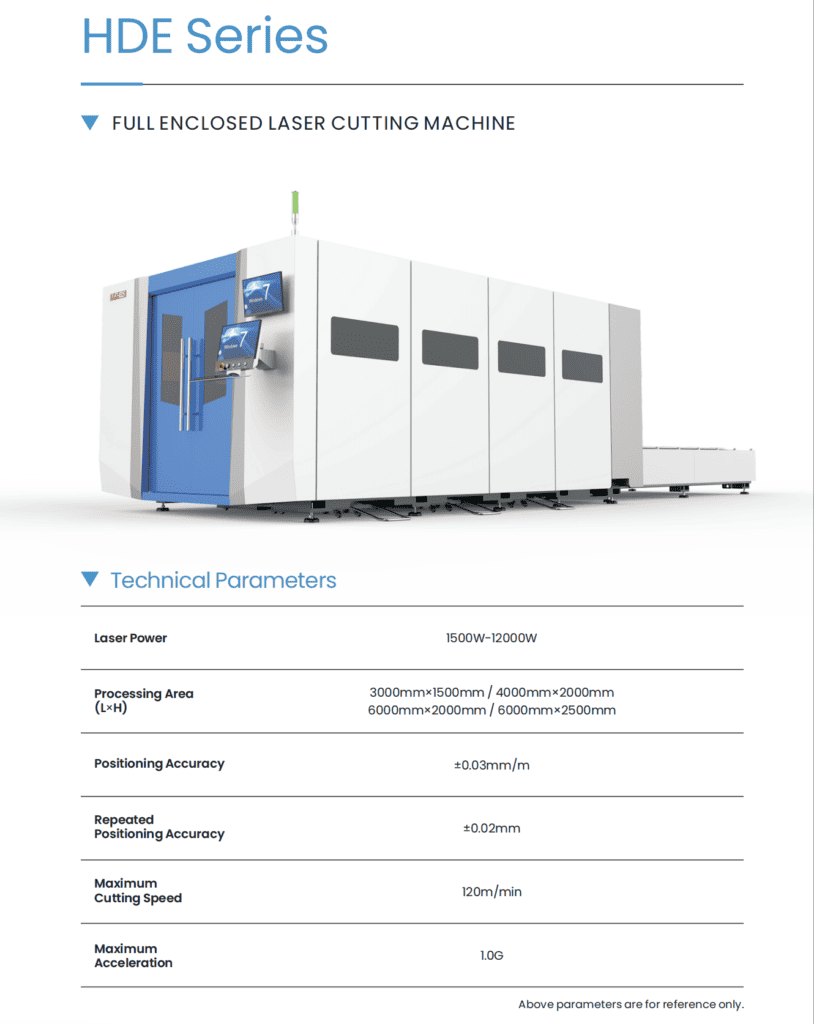

HDE Series (Dual Platforms Laser Cutter)

The HDE series is a completely enclosed laser cutter. Being fully enclosed, it helps to keep the operator safe from the laser beam. It also protects them from any flying debris or other threats. Therefore, it eliminates the risk of any accidents or injuries which may be possible.

This machine can be used in a variety of environments. This is because all the fumes, dust, and wastes are kept enclosed within.

The machine’s climbing exchange method is of great advantage. It allows you to switch platforms within seconds.

The beam is of a very strong power strength. Therefore, the cut precision is greatly improved.

The laser head of the machine can focus automatically. This not only speeds up the entire process but makes it more efficient and smooth.

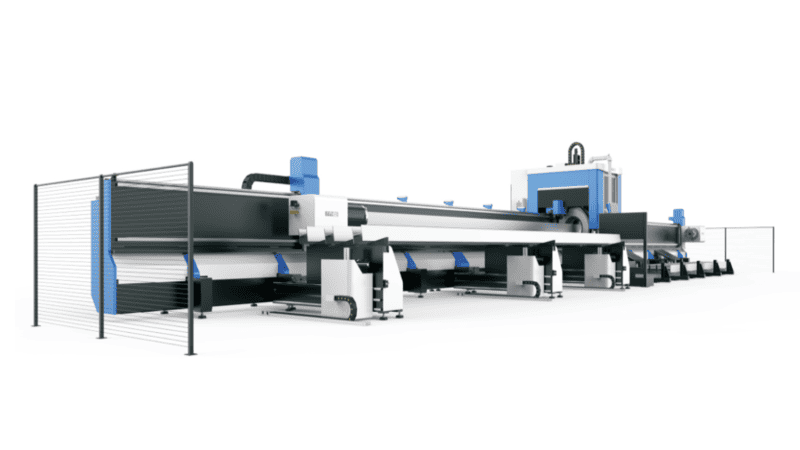

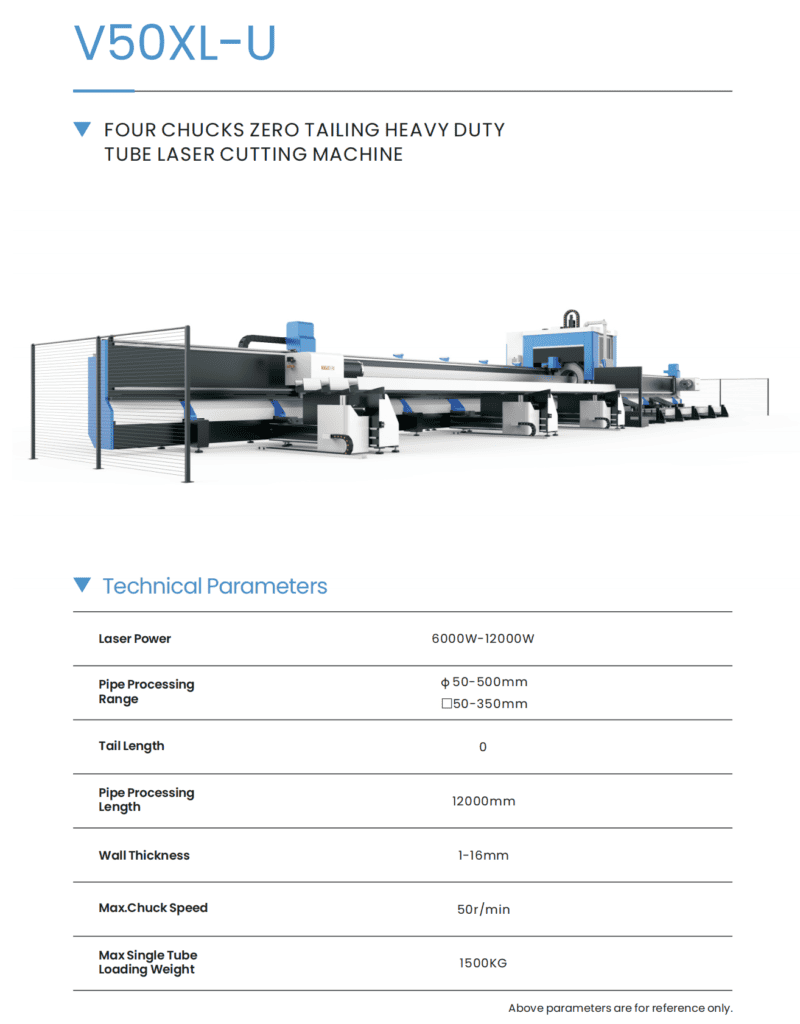

V50XL-U (Four Chucks Heavy Duty Tube Laser Cutter)

The V50XL-U is another model of a laser cutter. It is a heavy-duty machine that can process and cut round, square, rectangular, L, U, and H pipes.

This model uses a CNC bus system. It is a very modern and advanced software system that makes the process quite efficient.

Materials like carbon steel, aluminum, brass, silicon steel, electrolytic steel, titanium alloys, etc., can be processed.

This heavy-duty equipment is mainly used in aerospace, metal fabrication, railway transport lines, food machinery, etc.

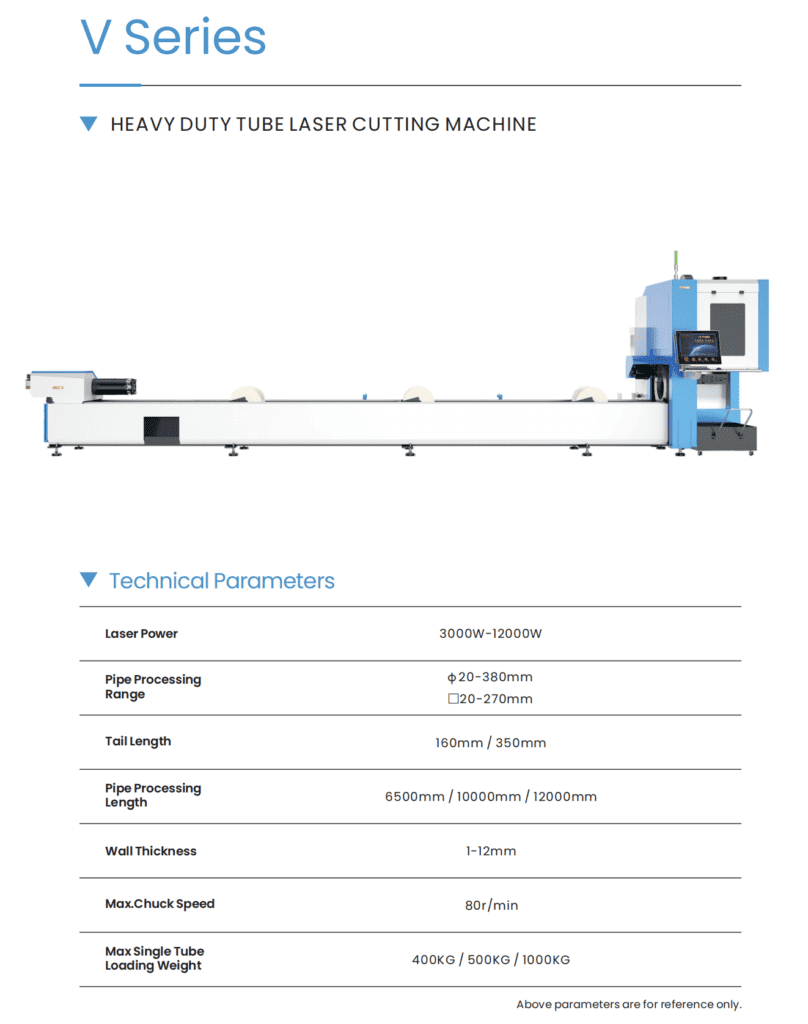

V-Series

The V series laser cutters are also great for large business owners. They are used for manufacturing large, heavy pipes. These pipes can withstand a weight of around 1000 kg.

The machine is quite safe to use as well. It prevents any metal, dust, and debris from splashing back. The body of the equipment is also rust-resistant and is quite heavy-duty in nature.

The bed frame is very strong and highly durable. It goes through a 12-step manufacturing process. Therefore, you can rest assured of its strong quality and durability.

The CNC software system is incorporated into the laser cutter. It is an intelligent control system that shall ensure high-precision cutting.

If you are interested in Heavy Duty Tube Laser Cutting Machine, Watch the video to learn about another machine model.

Reasons to Choose Baison Laser as Your Partner

Partnering up with an experienced and reliable laser cutter supplier is crucial for a successful business. Therefore, you must partner with a brand like Baison Laser to ensure a value-for-money deal.

Here are some of the reasons to choose Baison Laser as your partner.

Great Expertise

Baison is well-known for its great expertise. We have the best fiber laser experts and specialists you shall come across. They are all well-versed in the field of laser cutting and can help you find the perfect machine for your business.

Outstanding Reputation

We have the best reputation when it comes to laser cutting systems. We make sure all our customers are fully satisfied with our products, staff, and after-sales service. We make sure to deliver only the best and never compromise on quality.

Continued Innovation

Baison does not just stop at the basic kinds of machines. We make sure to bring innovations for our clients continuously. Be it our laser cutting machines, welding machines, cleaning machines, or marking machines, we only ensure advanced and top-grade products.

You shall find various laser cutting machines and handheld welding machines. Thus, no matter what you want, you will find something interesting here.

Competitive Pricing

Despite the inflation and economic instability, we ensure to provide our clients with the best rates.

Our pricings are not just competitive; they are also quite affordable, especially when you compare them with the kind of quality we deliver.

Best Customer Service

We are there for our customers every step of the way. Our work does not end with you making a purchase. In fact, we make sure to provide the best customer service to our clients.

No matter what help you require, the Baison team will be at your service throughout. Therefore, we ensure you do not have to worry about anything when working with us.

Final Thoughts

All successful businesses have shifted their manufacturing methods towards laser cutting. This has proved to be more efficient and allows manufacturers to produce better-quality products.

Laser-cutting machines increase the production rate to an unmatched level. They also help large businesses manufacture innovative and stylish designs. This helps them gain a large fan-following from their customers. All this then results in the business getting more fame and success, leading to higher profits.

Discover the Perfect Solution for Your Business with Baison

Here at Baison, we prioritize our customers above everything. We know that our clients deserve to get the best items at the best possible rates. Therefore, we will try our best to get this fulfilled.

Be it any laser cutting machines or handheld welding machines you want, be sure to contact us immediately. You will be able to find something of your need from our wide range of products.

We offer the best rates for our laser cutting equipment compared to the market. You can easily do your survey and ask us for a quotation.

Click the button below to get more information about Baison Laser!