Different manufacturing industries incorporate cutting operations in their day-to-day running. And it’s one of the core aspects of sheet metal fabrication in the sectors it’s applied. One of the techniques used is sheet metal laser cutting.

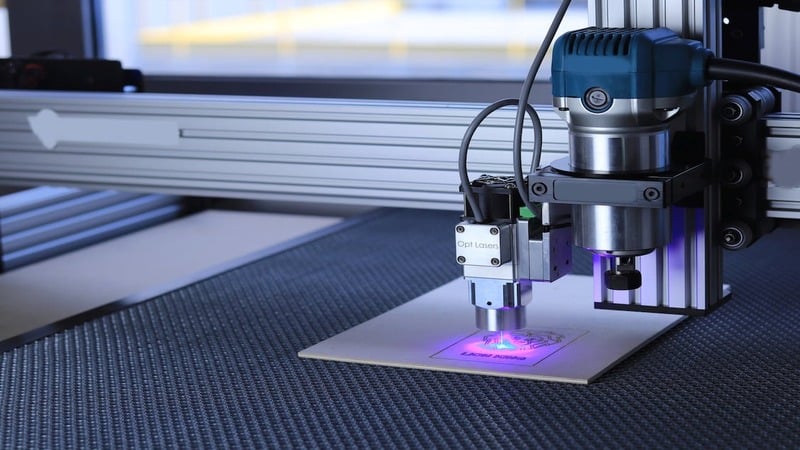

The laser cutting technique uses a laser beam to cut through materials. This can be applied to various materials, including metal, plastic, glass, and paper. It is mainly used for industrial applications but can also be used by hobbyists and in art projects.

As a business, you might have come across many instances where you need to cut a sheet of aluminum. The question is what is the best way to do it? Well, fiber laser cutting aluminum sheets and tubes is one of the most effective and efficient methods.

This article will provide you with all the information that you need to know about laser-cutting aluminum sheets and tubes.

What Is Laser Cutting?

Laser cutting is a process that uses laser beams to cut reflective materials like metals. It is one of the most precise and efficient ways to cut metal, and it is being used more often by companies all around the world.

With laser cutting, you can cut out intricate shapes or designs on your thick aluminum material with the laser cutter. This is without having to use any other tools or equipment besides the laser itself.

You can also customize your material by adding text or patterns to it. This makes it easy for companies to create unique products based on their needs.

There are several different types of lasers that can be used in laser cutting equipment, including CO2 lasers and fiber lasers. Each type has its own benefits and drawbacks when compared with one other.

For example, fiber laser cutting tends to be more accurate than CO2 laser cutting. But they require more maintenance time because they have more moving parts than other laser cutting machines. If you want to learn about the difference between fiber laser and CO2 laser technology in detail, click here.

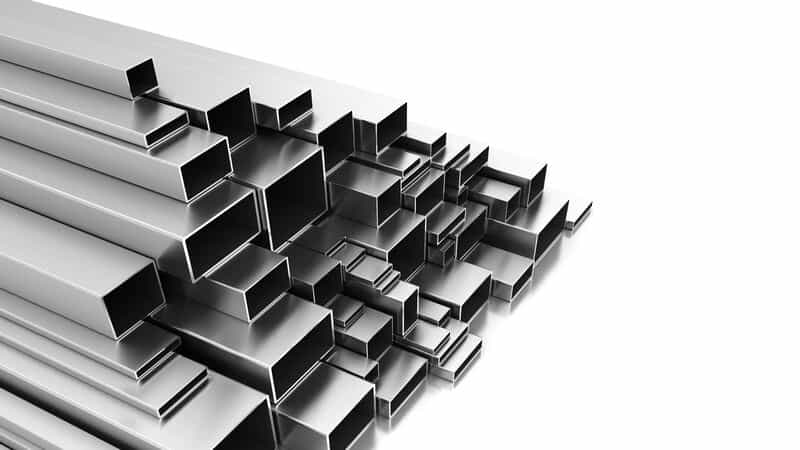

What Are the Properties of Aluminum Sheets and Tubes?

Aluminum is a lightweight, corrosion-resistant metal that can be used to make all kinds of things, including sheets and tubes.

But before you start fiber laser cutting your engraving aluminum, here are a few things you should know:

- Lightweight: Aluminum is light and easy to work with because it has low density (weight per unit volume). This makes it easy to transport and cut into thin sheets and tubes without damaging the material itself.

- Corrosion resistance: Aluminum has excellent corrosion resistance, which means it doesn’t corrode easily or crack when exposed to water or other chemicals. This makes it ideal for many industrial applications where water is present, for example, in manufacturing, automotive manufacturing, or construction.

- Ductile: Aluminum’s ductile nature makes it easy to work with when you’re cutting out shapes or forming new ones. It bends easily without breaking.

- Good thermal and electrical conductivity: Aluminum has high thermal conductivity; it can be used to make electrical components function efficiently at higher temperatures. Or, in more extreme environments than other materials would allow.

- Reflectivity: Aluminum has a high reflectivity value, meaning that it reflects light very well. It can also be used as an indicator for light levels in dark places like inside your car.

- Non-magnetic: It’s also non-magnetic, which means it won’t interfere with magnetic fields like iron does.

- Recyclable: Aluminum sheets and tubes can be recycled because they’re made from recycled aluminum cans. The recycling process also removes any excess zinc and other impurities from the metal itself.

What Are the Different Types of Lasers Used for Cutting Aluminum?

Laser cutting is a very popular technique in the manufacturing process today, and it’s used to cut almost any type of material.

The most common types of lasers with reflected laser beams include:

- Fiber lasers

A fiber laser cutting machine uses light beams to cut through metal. As Baison’s primary product, they can cut through metal faster than other types of lasers. This is because they don’t need to heat up the metal as much before they start cutting it.

- CO2 lasers

A CO2 laser cutting machine uses carbon dioxide gas as an energy source, so it can work in environments where other types of lasers cannot (like in outer space). They also tend to be more powerful than other types of lasers and can cut through thicker metals than other types of lasers.

- Nd: YAG lasers

Nd: YAG laser machines use nitrogen dioxide gas as an energy source. They’re not as powerful as CO2 lasers but can still easily cut through thick metals like aluminum sheets and tubes.

- Excimer lasers

Excimer lasers use an energy ray that is generated by a gas in the laser’s chamber, which is then focused onto the material being cut.

They’re usually used on thinner materials like plastic or paper. They have a very short wavelength that allows them to cut through surfaces at high speeds without heating them up too much.

- Disk lasers

These work just like fiber and excimer lasers do—they use powerful rays of light to cut through materials quickly and efficiently.

How Does Laser Cutting Work on Aluminum Sheets and Tubes?

Laser cutting is a process that uses an intense beam of light to cut through metal. The laser’s wavelength is between 1064 nm and 1065 nm, which is the same range as red light but with a shorter wavelength (between 656 nm and 663 nm).

At this laser wavelength, any material can absorb laser light for energy. When the light interacts with the material, it heats up that material, causing it to vaporize. This vaporization then causes a chemical reaction that cuts through the metal.

There are two types of lasers: continuous and pulsed lasers. A continuous laser emits pulses at regular intervals and can cut through materials continuously for long periods without overheating or damaging it.

A pulsed laser emits one pulse of energy at a time, which allows for faster processing times because it does not require constant heating from the laser itself.

What Are the Advantages of Laser Cutting Aluminum?

In a world where technology is constantly changing, this is more important than ever.

If you want to make sure your business stays on top of the latest trends and developments, then you need to account for this in your marketing strategies.

Here are the benefits of laser-cutting aluminum sheets:

1. High-Precision and Accuracy

Laser cutting aluminum sheets and tubes is a high-precision process that can produce precise cuts of up to 0.1mm.

The laser equipment machine is designed to support any length of sheet metal, with an adjustable laser head, and can cut through up to 25mm of material at once.

Laser cutting is a solid choice for cutting metals because it is extremely precise and accurate. It can easily cut materials such as aluminum, carbon steel, and other metals.

2. Automated Process

Laser cutting is an automated process that uses lasers to cut the material you want in the shape you want it to be cut into.

This makes it easier than manual methods because there are no moving parts or tools needed to get the job done correctly. All you need is a computer screen and some patience.

3. Damage Prevention

One of the best things about laser cutting is its ability to prevent damage from occurring. More so when working with lightweight metal materials like aluminum sheeting or tubing.

If you’re going to be working with metal materials on a regular basis, then this will come in handy. You won’t have any accidents while using the laser machine as part of your business plan.

4. Compatible with Most Materials

In addition to being able to reduce your costs, laser-cutting aluminum sheets and tubes also allow for a high degree of versatility in terms of material compatibility.

You can use this method with a variety of materials including steel, copper, brass, and aluminum plates all at once while keeping costs low due to its relatively low energy consumption.

5. Relatively Low-cost

The cost of laser cutting aluminum sheets and tubes is relatively low compared with other methods, such as grinding or drilling.

It uses little energy and produces fewer emissions than conventional processes. This makes it suitable for a range of applications, including small-batch production of parts for consumer electronics and aerospace industries.

6. High Versatility

Another benefit of using sheet metal laser cutting is its high versatility. This means that businesses will have more options when selecting materials for manufacturing products like parts for cars or motorcycles.

This is because they can use different metals instead of just one type of material like steel or aluminum. For example, businesses could choose between stainless steel and titanium instead of just one type of metal if needed.

7. Low Energy Consumption

The laser-cutting process uses high-powered lasers to cut through metal by causing heat that melts the material and pushes it along a path determined by the laser’s operator.

This cutting process requires less energy than other types of metal cutting because lasers use infrared light instead of visible light, which requires more power to produce intense heat levels needed for sheet metal cutting projects.

Factors Affecting Laser-Cutting Aluminum

There are a number of factors that affect your ability to successfully laser cut aluminum sheets and tubes.

Before beginning the laser cutting process, you need to prepare your material. You should ensure it’s clean, free of dirt or dust, and well-ventilated.

If you’re using a metal shear or other type of sawmill tool on the surface of your aluminum surface material, be sure to wear safety glasses and gloves at all times during the cutting process.

Next, you’ll need to select the right grade for your project. The higher the quality grade, the more expensive it will be because it will cost more time and money in terms of setup time and equipment.

In addition to grade, another important thing to consider is surface preparation for your aluminum sheet or tube. You’ll need to remove any rough spots on the metal with a wire brush or sandpaper before you start cutting into it.

Besides, you should always apply lubricant when using any type of metal. It helps prevent any unnecessary friction during laser cutter operation so there aren’t any unnecessary breaks or cracks.

How to Prepare Aluminum Sheets and Tubes for Laser Cutting?

To prepare aluminum sheets, you need to do some preparation before laser cutting aluminum sheets and tubes.

You should always clean your metal before using it in order to ensure that there are no impurities on the surface. These could cause problems later on down the line when it comes time to laser cutting something into it.

In addition, you should always apply lubricant when using any type of metal. It helps prevent any unnecessary friction during laser cutting operations, so there aren’t any unnecessary breaks or cracks.

Besides, the material used to make your machine will determine what grade of aluminum you should use. For best results, you should use a low-carbon grade of aluminum, as this will result in a cleaner cut and less distortion.

If you are looking for a harder material that is ideal for laser cutting thicker pieces, then you should use an alloy with a higher carbon content.

Applications of Laser Cutting Aluminum

1. Medical Equipment

Laser cutting is the most reliable method to create medical parts. Medical equipment can be cut by laser cutters from aluminum sheets and tubes, such as crutches, braces, splints, and prosthetics.

The parts are durable and lightweight, which makes them ideal for patients who need a helping hand. Also, laser cutting is safer than traditional methods such as injection molding or casting.

2. Interior Design

Interior designers use laser cutters for their work because it allows them to create unique designs. These designs could be impossible using other cutting methods, such as carving wood or creating leather goods using hand tools only.

Laser cutting using laser beams allows designers to design furniture pieces that would otherwise be impossible due to their size or shape.

3. Jewelry Production

In the jewelry industry, laser cutting aluminum sheets and tubes is a cost-effective way to make custom designs. You can use laser cutters to create intricate parts like bezels or flowers that are difficult to create using other methods.

Laser cutting can also be used to make accessories such as rings, necklaces, bracelets, and earrings that are typically made from precious metals like gold or silver.

4. Aerospace Industries

The aerospace industry is the largest customer for laser cutting aluminum sheets and tubes. It has a huge demand for these products due to the fact that most of the parts are stressed and have to withstand high temperatures and pressure.

The aerospace industry also demands precision, durability, and longevity in the laser cutting parts of the airplane, like metal detectors, conveyors, and trolleys, when undergoing fiber laser cutting operations during manufacturing.

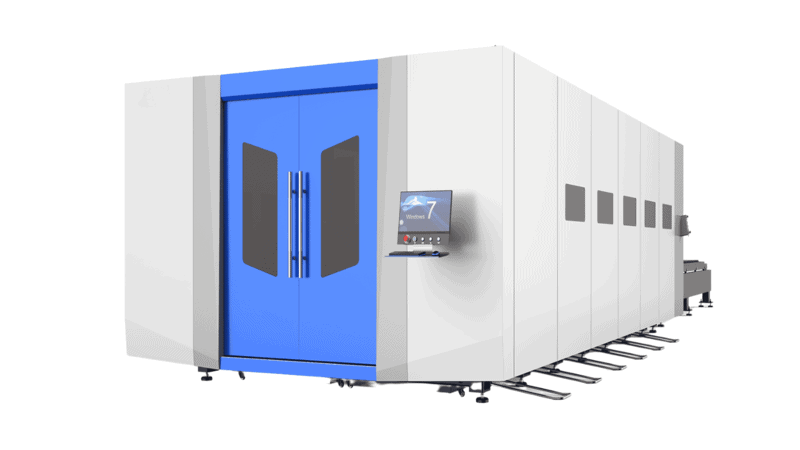

The Importance of a Quality Laser Cutter to Get the Desired Results

A quality laser cutter is necessary for any business looking to cut aluminum sheets and tubes.

You’ll need one if you want to get the best possible results from your cutting job. But also want to make sure that your machine is safe for your employees and the surrounding environment.

You may be wondering why you should invest in a quality laser cutter. The answer is simple: You’ll get great results with less effort.

When you use a quality laser beam machine, you can cut sheets and tubes far faster than on any other machine out there.

Cutting fewer materials at once will save you time and money. This means less time spent cleaning up after each cut, making it easier for everyone involved.

Tips for Getting Perfect Cuts with the Help of a Laser Cutter

If you’re looking to cut aluminum sheets and tubes, it’s important to choose the right machine for your needs.

Here’s what you need to know before you start:

Choose the Right Type of Laser Cutter for Your Project

To get the most out of your laser cutting project, we recommend choosing the right type of laser cutter for your project.

There are different types of cutting machines on the market, and they each come with unique features that can be useful in different situations.

You should also consider what material will be used in your project. Thick or thin materials require different settings so that they don’t get damaged while being cut by the laser beam.

First, check out our guide on how to choose the right type of laser cutter for your project. Depending on your needs and budget, there are different types of laser cutters available that will be able to help you create exactly what you want.

Select the Right Materials

The type of material you’re cutting determines which machine is best for your needs.

For example, a large-capacity laser cutter is probably your best bet if you’re cutting through heavy steel or even titanium.

On the other hand, if you need something more specialized—like cutting through the wood—you might want a smaller machine with less power.

If not, just make sure whichever machine you choose has enough power and very high cutting speed for whatever task comes your way!

Price

When picking out a laser cutting machine, price should definitely be a factor—but not all expensive machines are worth the cost!

You want something that will last through years of use without breaking down or malfunctioning (and also doesn’t break the bank!). The best way to find out if something is worth investing in is by researching reviews online.

If you know ahead of time which type of material(s) you want to cut with your laser cutter and how many pieces per hour (PPH) will be needed for each type of material, then this can help narrow down your search.

Available Space

Another important consideration when choosing a suitable laser-cutting machine is its available space.

You need to make sure that your room has enough space for the machine’s components and accessories. Such as computer monitors, keyboards, and printers will be needed to operate the machine.

Power Requirements and Cost.

The last thing you should consider when buying an aluminum laser-cutting machine is power requirements and cost.

Make sure that whatever machine you choose has enough power for whatever type of work you plan on doing with it before making your purchase decision!

Conclusion

In conclusion, you need to have a thorough understanding of sheet metal laser cutting technology.

It is a cutting-edge manufacturing method for producing huge quantities of fabrication and parts with strict dimensional tolerances. You can choose whether or not to use the approach for your manufacturing requirements.

Baison’s laser sheet metal cutting service is what you want for your fabrication if you want to work with a business that guarantees high-quality laser cutting services. Contact us today!