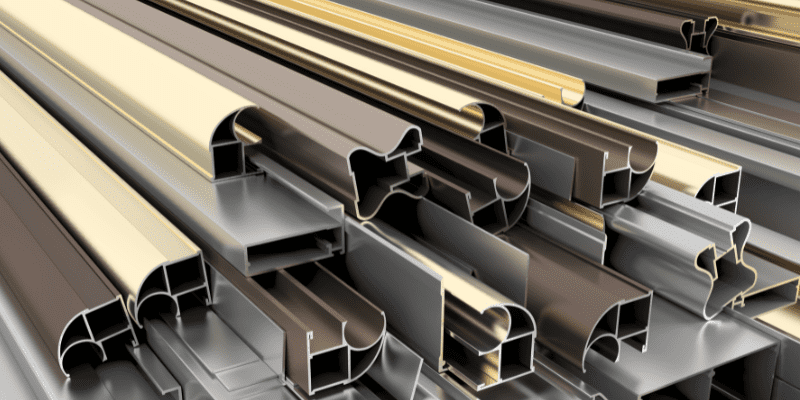

Aluminum is a lightweight and pliable material that offers corrosion resistance and extreme flexibility. It is also non-ferrous and has high thermal conductivity. These unique properties make it the perfect material for the manufacturing industry.

However, although aluminum is soft and lightweight, laser cutting it is not easy. Many manufacturers avoid cutting it through laser cutters because of this. Yet, with the right process and tools, the laser can cut aluminum effectively!

So today, we will examine everything you need to know about laser cutting aluminum. This will help you understand the process behind cutting aluminum and how to get the best results.

The Benefits of Laser Cutting Aluminum

Aluminum is widely used in the manufacturing industry to make many things, including cans, foils, airplane parts, and window frames.

So much usage means a big market for cutting aluminum sheets into the desired shapes. There are many tools for cutting aluminum. For instance, people use metal shears, jigsaws, circular saws, CNC machines, and laser cutters.

Laser-cutting remains the most suitable and beneficial of all these different tools and methods.

So without wasting time, let’s look at some of the benefits of cutting aluminum with laser cutting machines:

Precision Cutting

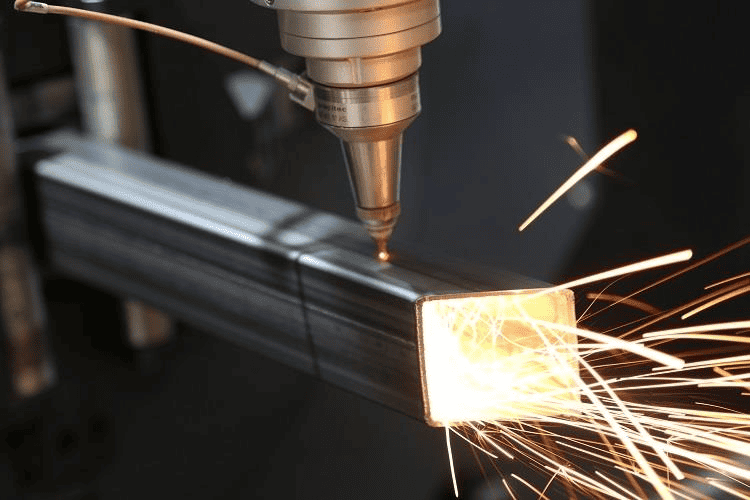

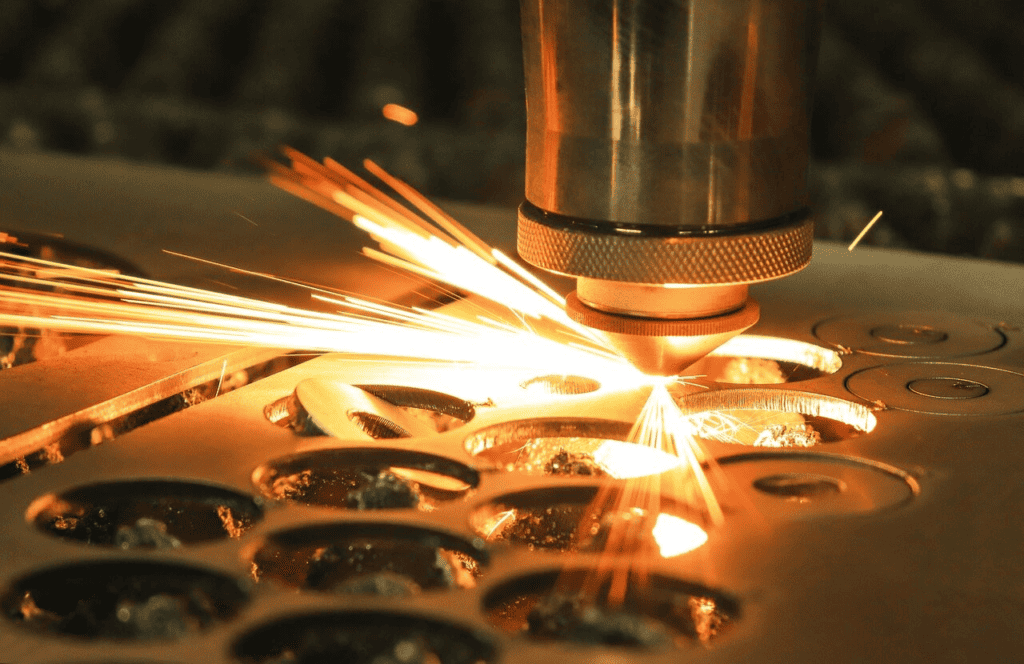

The first benefit of laser cutting aluminum is that it allows for precision cutting. A standard laser-cutting machine utilizes a laser beam to cut through the aluminum sheets. Thus, it can make small holes, sharp cuts, and high-quality edge quality.

When comparing it with alternative cutting processes, it becomes evident that those processes can’t come anywhere near the preciseness of a laser cutter. De facto, these machines hit an accuracy of is ± 0.0005 inches.

Moreover, the mirrors and optical path Lose beam quality and cause significant power drop-off (Around 1/4th of the width of a human’s hair).

Less Expensive

Compared with other cutting processes, such as chemical etching, a laser cutting process is more affordable for aluminum sheets.

Furthermore, the tools are not worn down since they are a no-contact process and use a laser beam. And this is yet another aspect through which a laser-cutting machine can be cost-effective in the long run.

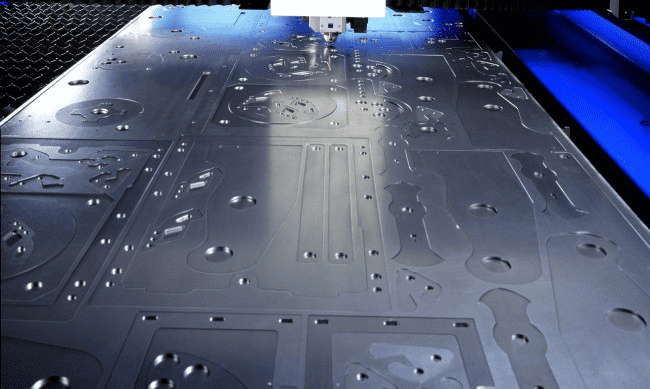

Custom Jobs

Cutting aluminum plates through laser cutting machines allows for highly customized jobs without tooling charges or up-front costs. All you need is to add the laser cutting file to the machine containing the details of the cutting/engraving. The machine does the rest, no matter how complex the design or shape is!

On the contrary, other cutting processes are not designed to handle custom jobs and usually require up-front costs and additional tools.

Fast & Repeatable

Metal shears, Circular Saws, or any other cutting tool can’t compete with the speed of laser cutters. So an additional benefit of relying on laser cutting services is that it can get the job done quickly, within seconds.

In addition, the entire process is also highly repeatable. All you need is to add the cutting file and adjust your laser cutting machine settings. Then, it will cut your desired number of aluminum designs/shapes with minimum human input.

Speed

Given the non-contact nature of the process, laser cutting is typically faster than traditional cutting techniques, especially for thin aluminum.

Flexibility

From prototypes to large batch production, laser cutting meets various needs, effectively handling simple to complex designs.

Why Is The Process of Laser Cutting Aluminum Challenging?

Earlier, we discussed how cutting aluminum with a laser cutting machine can be challenging. This invites us to ask about the factors that make this process tricky.

To answer this question, we have shared some of the challenges:

Reflective Material

Aluminum is a reflective metal, so the laser beam can reflect from its surface. This reflection can be dangerous since it can enter the laser head and damage the machine parts.

However, this problem can be easily solved by covering the aluminum surface with masking tape or paint. This will remove the reflection of the aluminum sheets and thus make it possible to cut easily.

Another way to deal with this problem is to mix aluminum with other elements such as zinc, magnesium, etc. These are known as alloy elements and can reduce aluminum’s reflectiveness, making it safe for use in the cutting process.

However, the easiest way to solve this problem is to use a fiber laser cutting machine. Fiber laser machines are devised to cut aluminum, brass, and copper! As such, their laser beam is not reflected and is more readily absorbed.

Thermal Conductivity

A laser beam cuts through a material by vaporizing it. However, this can be problematic if the material has high thermal conductivity.

Aluminum is one of those materials that is good at absorbing heat and thus can dissipate heat. So, when the laser beam touches the aluminum surface, it cools off quickly. As a result, the laser cutter fails to reach the high temperature necessary for melting and vaporizing.

A simple solution to this problem is a high-speed laser cutting machine such as a fiber laser cutter. Roughly speaking, a fiber laser machine is five times faster than a typical CO2 laser cutter.

In fiber laser cutting, the laser touches the aluminum surface quickly so that it can melt quickly rather than dissipate into the surroundings.

Upfront Costs

Cutting aluminum with a seamless, high-quality finish and precision requires a high-powered fiber laser cutter or a CO2 one. This means that you will need to incur high upfront costs. However, over the long run, This can help you save money. That’s because these machines offer fast cutting with high precision.

Laser cutting would require post-treatment aluminum parts to obtain a smooth and seamless cutting edge.

How to Get the Best Results When Laser Cutting Aluminum Parts

Now that we covered the problems related to cutting aluminum parts – let’s have a look at some of the best practices to employ when dealing with aluminum laser cutting:

Laser Power

One of the most important factors for cutting aluminum is the laser power of your laser cutter. A machine with low laser power can only cut through a thin aluminum sheet, while a machine with a high-power laser can easily cut through thick aluminum sheets.

Furthermore, note that aluminum is a reflective material! Accordingly, low laser power may also become quite an issue!

So, you’ll need to ensure that you’re using a high-power laser cutter! For example, 500W power rating or higher fiber lasers can easily cut through thick aluminum sheets (around 3mm). Similarly, a pulsed laser cutter with a 500W power supply can also cut aluminum, but its speed is slow compared to fiber lasers.

Cutting Speed

The cutting speed is another parameter that can help you achieve a smooth finish and a refined edge. A machine with a fast cutting speed is always preferred when working with aluminum.

However, the cutting speed alone will not be enough to cut the aluminum properly. Combining high laser power with fast cutting speed would be best to achieve optimal results.

You will also need to adjust the laser cutter’s cutting speed according to the aluminum’s thickness. Also, remember that the operation’s speed can differ depending on whether you use a CO2 laser or a fiber laser!

A laser cutter that cuts at a low speed can cause cracks in the aluminum sheet. Similarly, a very high cutting speed can lead to rough edges. Therefore, choosing the right cutting speed is essential to this process!

Auxiliary Gas

Using auxiliary gas in laser cutters removes the waste material formed during the cutting process. Furthermore, it prevents the overheating of the cutting head & can help achieve a high-quality cut.

Different auxiliary gases are used, such as oxygen, air, argon, Nitrogen, etc. However, no auxiliary gas can be used when working with aluminum. For example, using oxygen gas can cause the oxidation of aluminum sheets.

When air is used in laser cutters, it causes only a little oxidation and improves the cutting speed.

But for best results with no oxidation and smooth edges, the auxiliary gas of choice is Nitrogen.

Accordingly, using nitrogen auxiliary gas can help you achieve better results when cutting aluminum with a laser.

Reflection Detector

The reflection caused by aluminum and other reflective materials can damage the machine’s laser module. As mentioned earlier, a fiber laser cutter can solve this reflection problem. However, many still use a high-powered CO2 or ND: YAG laser cutter for reflective materials.

So, to prevent the reflection from damaging the laser module and hindering the cutting process, we recommend using a machine with a reflection detector.

All modern laser cutters manufactured by trusted brands usually come with a reflection detector. This feature can detect if a lot of laser beam returns to the laser head via reflection. So, once the amount of reflected laser beam reaches a certain level, the machine automatically shuts off to prevent damage.

So if you plan to use a CO2 or ND: YAG machine, you must buy a machine with a built-in reflection detector. This will prevent your machine from breaking or catching fire from the reflected laser!

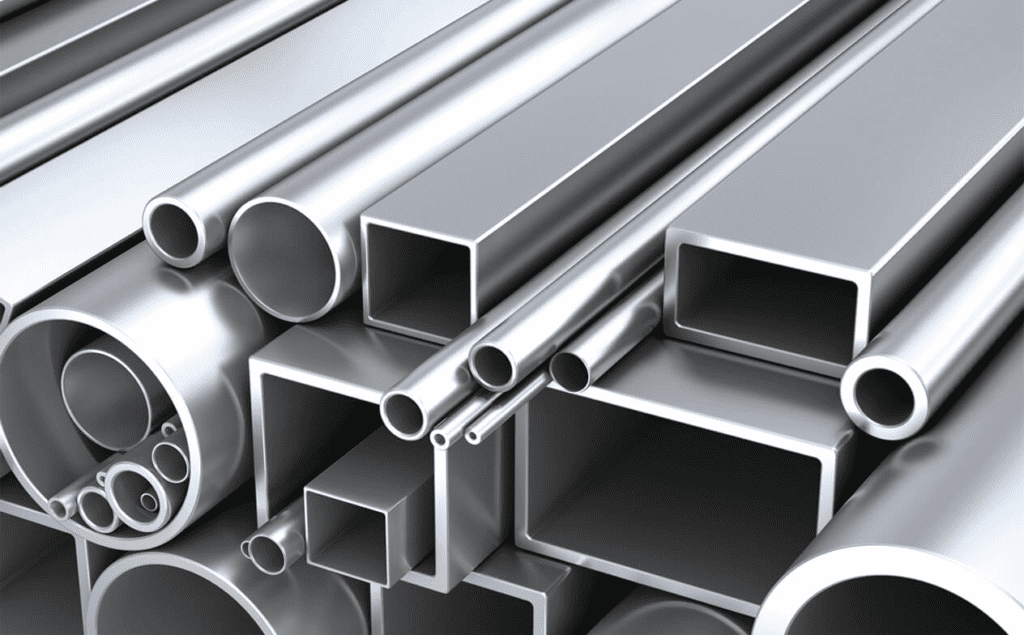

Laser Technology

You can spot different laser cutters operating under different technologies in the market. Some popular laser technologies for cutting include CO2 lasers, fiber lasers, ND: Yag lasers, and so on.

Out of all these different technologies, the one which is the most suited for cutting or engraving aluminum is the fiber laser. It allows one to work with ferrous and non-ferrous materials and offers high speeds.

How to Choose a Suitable Laser Cutting Machine?

Material type, cost, and speed… are all factors that affect choosing a suitable laser-cutting machine. Let’s take a look at each factor to help you choose the right type of laser-cutting machine:

Type of Material

Regular CO2 laser cutters are the most straightforward option for cutting many types of material. An adequately powered laser cutter would seamlessly cut wood, paper, plastic, metals, leather, and even rubber!

But if you want to cut reflective materials such as aluminum, stainless steel, carbon steel, brass, copper, and titanium, the best choice is to go with a Fiber laser cutter.

However, this doesn’t mean you won’t be able to cut reflective materials, including aluminum, with a CO2 laser cutter. There are more than a workaround to resort to when working on aluminum with a CO2 laser cutter. For example, applying a coat of paint on the surface of reflective material makes cutting even with a CO2 laser cutter possible.

Price

The next item to consider is the price of laser cutters. A more advanced and high-power laser cutter will cost you more than older models with less power.

On the other hand, low—or medium-powered laser cutters are more accessible. However, they take more time to cut and are limited in their ability to cut through thick materials.

Lastly, the type of laser cutter you choose will also determine the price. Typically, CO2 lasers cost less than the more pocket-friendly fiber laser ones… However, the latter type enables you to enjoy faster cutting speeds and effortlessly cut through reflective materials—that’s usually tricky with a CO2 laser cutter!

Material Thickness

A high-power laser cutter makes it easier to work with thick materials and provides a much higher speed. So if you want to work with thick materials, then the best choice is a high-power laser cutter – since it would be the best choice.

On the other hand, it would be better to choose low-powered CO2 laser cutters if you only want to work with thin materials.

Available Space

Do you need a laser cutter for your industrial needs, or is it to complete orders for your small business setup? The available space is also a factor that must be considered when buying the right laser cutter.

A more high-powered laser cutter for industrial usage will take up more space. However, it will also allow you to work with the material. For example, it is common to use bigger machines in the ceramics industry, which requires handling a lot of material simultaneously.

So, another factor to consider is your business requirements and the space you have!

Conclusion

Laser cutters are quite versatile if you do work with various materials. However, you cannot use every laser machine with any material you like. Different laser cutters are optimized to work with different materials.

A fiber laser cutter or a highly-powered CO2 laser is the most prominent choice when cutting aluminum. We have shared extensive resources to help you understand which laser cutter suits you and how to cut aluminum effortlessly!

Looking for a precision fiber laser cutting machine?

Baison Laser understands that different manufacturing processes have different needs. We aim to deliver the best laser-cutting technology available to our clients. This ensures that our clients continue to focus on high quality and fast cutting rather than feeling frustrated with poor results.

Feel free to contact us today to get customized advice. Our team of experts can help you choose the right type of laser-cutting machine depending on your needs.

If you know what type of machine you want and are looking for affordable prices, feel free to ask for a quote.

However, if you want to check the quality of our laser-cutting machines or ensure that you are choosing the right product, you can also contact us to schedule a free sample proofing. This option will allow you to check the results without investing in laser technology.