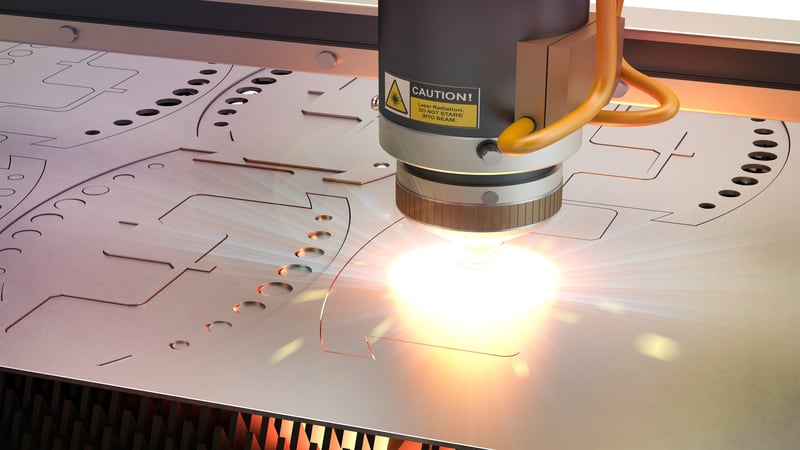

Laser cutters have revolutionized how we cut, engrave, and shape materials. They use a highly focused light beam to precisely cut through various materials such as metals, plastic, wood, and even stones. Thus, they find applications in multiple processes in various industries, from manufacturing and automotive to art and fashion.

One of the most critical factors in the laser and cutting process is the laser cutter’s power. The laser cutter power, measured in watts, determines the machine’s ability to cut through materials of different thicknesses.

The power consumption varies based on the application and nature of the material being cut. It can be as low as 10W for cutting paper and can go beyond 6000W for cutting hard metals.

Further, in this comprehensive guide, we will walk you through the ins and outs of laser cutters. We will discuss how laser cutter power is measured, what factors affect laser cutter power, and why choosing the right laser cutter power is essential for your applications.

How Does a Laser Cutter Work?

The working principle of a laser cutter is entirely different from conventional cutters that utilize sharp blades. Its principle of operation is hidden in its name, LASER, which is an acronym for Light Amplification by Simulated Emission of Radiation.

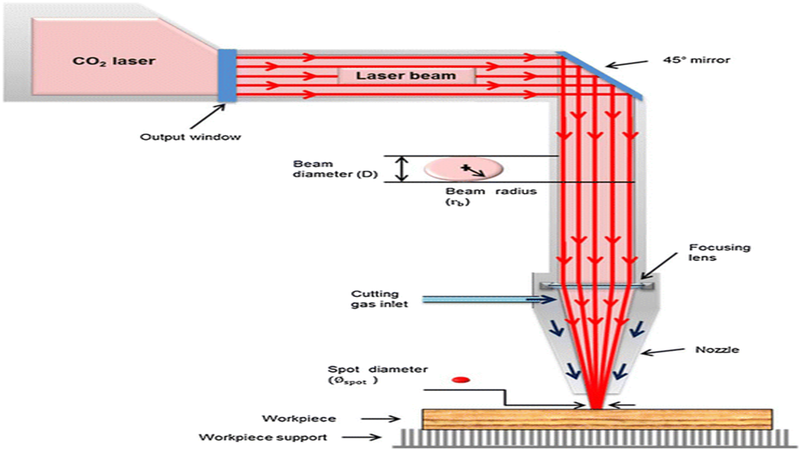

The laser beam is generated inside a specialized tube containing special gases (can be carbon dioxide) and then passed through a series of specialized mirrors placed such that they all converge the beam to a single point, called the laser head.

The head brings out a concentrated beam of electromagnetic waves. This focused laser beam is capable enough to melt and cut even the hardest metals.

The laser head is controlled via a computer numerical control part. Hence, these laser cutting machines get the name Computer Numeric Control (CNC) laser cutters.

Before the laser cutting process, the CNC is programmed and fed with all the details of the workpiece, such as length, width, thickness, and the desired laser engraving pattern. Then, after the machine is turned on, the laser head precisely runs over the workpiece and cuts it to the desired shape and dimensions.

What Are the Factors That Affect the Power of Laser Cutters?

It is a common fact that not all materials can be cut through the same laser cutter since each material has a different strength and thickness. So, some factors, along with the power, determine the effectiveness of a laser cutter.

Wattage:

The power delivered by a laser cutter is determined by its wattage, mentioned in watts. The higher the wattage, the more power the laser cutter can generate, which allows it to cut thicker materials at faster cutting speeds. However, higher-wattage laser cutters also require more cooling and may be more expensive.

Beam Quality:

The beam quality of a laser cutter refers to how well the laser beam can be focused and controlled. Higher beam quality produces a more precise, focused beam, allowing for more precise cutting and engraving.

The beam quality is typically measured in terms of M2, with lower values indicating better beam quality.

Wavelength:

The power of the laser is also a function of wavelength; technically, they both have an inverse relationship. Moreover, reflectivity, which ultimately decides the cutter’s accuracy, is also a function of wavelength.

For instance, let’s take the case of CO2 lasers. CO2 laser bears a large wavelength which is not readily absorbed by metals. In that case, a higher power is needed. So, we can say the optimal power needed to cut through metal depends on the laser wavelength and the ability of the material to absorb that wavelength.

What Are the Types of Laser Cutter Power?

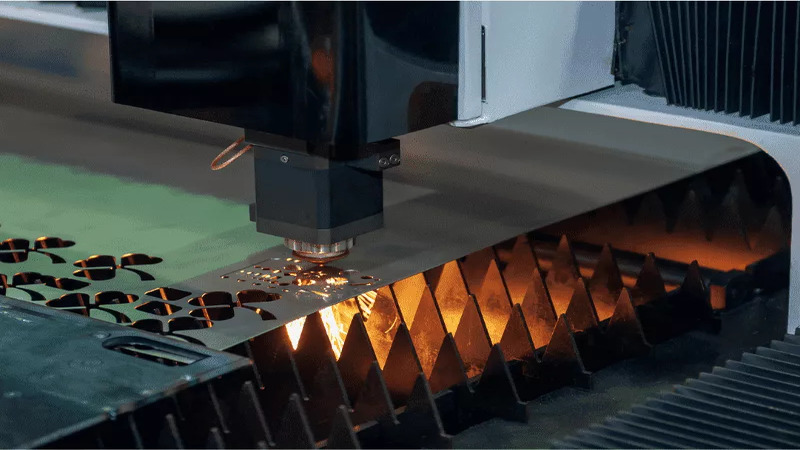

Based on how the laser beam is generated, laser cuter are classified into two types, CO2 laser cutters, and fiber laser cutters. Since a different material is being utilized, the power and functionality of each of these laser cutters also vary.

CO2 Laser Cutter Power

CO2 laser cutting machines, as their name suggests, use CO2 along with other gases, helium and nitrogen. Usually, these gases are injected with electrical discharge, which produces lasers.

These co2 laser cutters usually have a laser beam wavelength of 10.6 nm and are usually used for nonmetallic cutting applications. However, some high-powered co2 laser cutters can also cut through metals.

We have further classified the CO2 lasers into three main groups based on power consumption. Based on the use case, choose the appropriate CO2 laser-cutting machine.

- Low-Powered CO2 Lasers consume less than 100 W (can be as low as 10W) and are used for small-scale household applications like cutting paper, wood, etc.

- Medium-Powered CO2 Lasers usually use power in the range of 1000 -1500 W and are used for engraving metallic and non-metallic parts. We have also developed our medium-range CO2 laser cutter, which consumes 1500 w and is best suited for precise engraving and cutting.

- High-Powered CO2 Lasers are used when deep and high-precision cuts are required. They usually consume more than 1500W. Baion laser’s high-powered CO2 laser cutter consumes about 2500W.

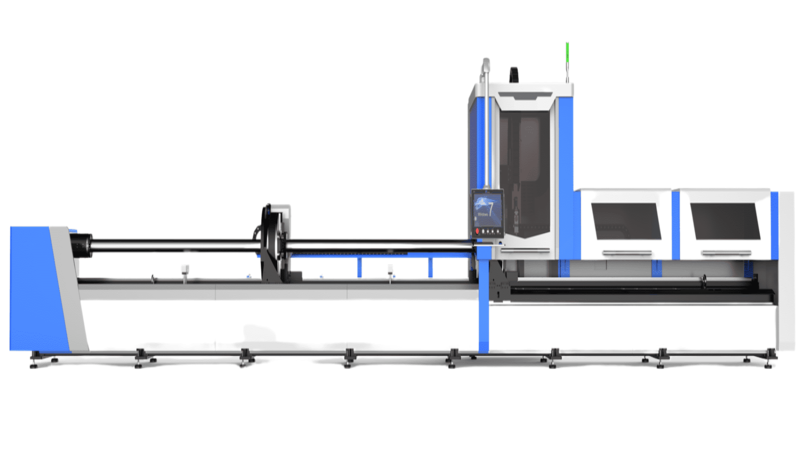

Fiber Laser Cutter Power

Fiber laser cutters are commonly called solid-state lasers. As their names, they use a doped fiber optic cable as an active medium for the application of the laser beam. Earlier, they were used as seed lasers that were amplified and magnified with specialized optical fibers.

A fiber laser is a highly effective and economical tool to cut reflective and conductor-grade metals. They cut at twice the speed compared to CO2-based laser cutters and can be used on various organic or metal materials. Although fiber lasers are very similar to crystal lasers, their operation is more efficient.

Based on the continuity of the laser beam, there are around three types of fiber lasers.

- Continuous Wave (CW) Fiber Lasers: These lasers operate continuously, producing a steady laser light output. They are commonly used for high-speed cutting, welding, and drilling.

- Pulsed Fiber Lasers: Pulsed fiber lasers emit short pulses of laser light, typically with a duration of a few nanoseconds to a few microseconds. They are commonly used for marking, laser engraving, and micromachining applications.

- MOPA (Master Oscillator Power Amplifier) fiber lasers are a type of pulsed fiber laser that use a master oscillator to generate the laser pulses, which are then amplified with a power amplifier. MOPA fiber lasers can produce very high peak powers (in the kilowatt range) and short pulse durations (in the nanosecond range).

How to Choose the Right Laser Cutter Power for Your Applications?

Each application requires a certain laser power. Choosing the right optimal laser power and cutter power for your applications is crucial to achieving efficient and high-quality results.

In this response, we will discuss the different power ranges available in laser cutters, how to determine the appropriate power for specific materials and thicknesses, examples of different applications, and the ideal laser cutter power to use for each.

Laser Cutter Power Ranges and Ideal Uses:

Laser cutters come in different power ranges, typically ranging from 10W to 6,000W or more. Here are some general guidelines for the ideal uses of different laser cutter power ranges:

10W – 100W: These laser cutters are suitable for engraving and cutting thin materials such as paper, cardboard, and thin plastics.

100W – 500W: These laser cutters are suitable for cutting thicker materials such as wood, acrylic, and metal up to 1/4 inch thickness.

500W – 2000W: These laser cutters are suitable for cutting thick materials such as metal up to 1-inch thickness.

2000W – 6,000W or more: These high-powered laser beam cutters are suitable for cutting thick materials such as metal over 1-inch thickness or for industrial-scale cutting applications.

Determining the Appropriate Power for Specific Materials and Thicknesses:

Multiple factors should be considered to choose the right laser cutter power for specific use cases, including the material type, thickness, desired finish, and available laser cutter power.

Here are a few things that might help you choose the right cutter for your needs:

Thin Materials:

For thin materials such as paper, cardboard, and thin plastics, a laser cutter power between 20W to 100W may be appropriate. In these applications, a higher power may result in the burning and melting of the material.

And in this case, the CO2 laser cutter is the best-suited option.

Thick Materials:

For thicker materials, such materials as metals, the appropriate laser cutter power depends on the thickness of the material.

Generally, a laser cutter power between 100W to 500W is suitable for materials up to 1/4 inch thickness, while a power between 500W to 2000W is suitable for materials up to 1-inch thickness. However, that’s just an estimate. You can consult our experts to guide you through the exact power you will need

Ideally, the best solution for thick and deep metal cuts is a fiber laser cutter.

Examples of Different Applications and Ideal Laser Cutter Power:

Next, we have tried to provide you with the range of laser cutting machines used in different industries:

Small Business Laser Cutters: Small businesses usually use laser cutters, which typically require a power range between 20W to 500W, which is very compact. However, the exact power depends on the size and thickness of the cut materials.

Industrial Laser Cutters: Most large-scale manufacturing units, where speed, accuracy, and precision are needed, require a higher power range between 500W to 10,000W. Again, the reasonable power and laser machine type depending on the job’s complexity. Mostly fiber laser cutters are used in industrial units.

Custom Laser Cutter Solutions: A 20 W to 500 W power range is usually suitable when designing your DIY projects. But to be precise, the choice of laser for custom solutions will ultimately depend on the customer’s specific needs and what materials you need to cut.

The Relationship Between the Power and Speed of Laser Cutter

Regarding laser cutting, two parameters are often used extensively, power and cutting speed. The power of a laser cutter is the amount of energy the laser beam delivers per unit of time. While cutting speed is the rate at which the laser beam moves across the cut material.

The Tradeoff Between Laser Cutter Power and Speed

Technically, speed and power are both independent of each other. We cannot state that speed depends on power or power depends on cutting speed. However, they go hand in hand; when we change one parameter, we have to alter the other parameter accordingly.

For instance, a high-powered laser produces more energy per second. If we set this type of laser cutter machine at low cutting speed, there are chances that the laser would burn out the workpiece unless we need a deep cut. So, a higher-power cutter needs a high cutting speed. So, in layman’s terms, we usually say that power and speed are directly related.

Optimizing the Power and Speed Settings for Different Applications

As mentioned earlier, both power and speed go hand in hand. Power and speed setting needs to be optimized based on the application and type of cut we need. Here are a few situations and how you can optimize the laser cutters power:

Here are some general guidelines for optimizing the power and speed settings for different applications:

- For thin and soft materials such as paper, cardboard, and thin plastic sheets, a low laser cutter power, and high speed may be appropriate to prevent burning and melting.

- For thick materials such as metals, a high laser cutter power, and low speed may be necessary to achieve a clean and precise cut.

- Low laser cutter power and high speed are appropriate for engraving applications to achieve shallow and smooth engraving.

- For applications that require high-quality cutting, a medium laser cutter power and moderate speed may aid in achieving a balance between precision and speed.

What Is Laser Cutter Power Density?

One of the parameters that define the strength and capability of a laser cutting machine is laser cutter power density. It directly tells us about the speed and quality of the laser cutter.

Simply put, laser cutter power density refers to the amount of laser power delivered to a specific area of material being cut.

Mathematically, the power density is the ratio of laser power to the cross-sectional area/spot size of the laser beam. So, its units are Watt per millimeter square. (W/mm2)

Laser Cutter Power Density = Power / (π x (Spot Size/2)^2)

For instance, if a laser cutter has a power output of 500 watts and a spot size of 0.2 mm, the power density would be:

Power Density = 500 / (π x (0.2/2)^2)

Power Density = 198,943 W/mm2

Applications That Require High Laser Cutter Power Density

The high power density of the laser is required when high-strength materials are involved or when we want to make deep and precise cuts. Here are a few examples where high power is utilized:

Metal Cutting:

Since metals have higher strength, so high laser cutter power, and high energy density is often required for cutting them. More power density allows the laser to melt and vaporize the metal quickly, resulting in a clean and precise cut. Aerospace, automotive, and manufacturing do greatly rely on laser cutting.

DEEP Cutting:

For cutting thick materials, the laser needs to penetrate the material deeply and quickly to produce a clean cut. Hence, that’s another use case for high-powered lasers.

Medical Device Manufacturing:

High laser cutter power density is also used for manufacturing medical devices such as stents and surgical instruments. The high power allows for the precise cutting and shaping of delicate materials.

What Should You Consider When Choosing a Cutting Machine of Different Power?

When choosing a cutting machine of different power, several factors need to be considered, including the material type and thickness, cutting speed, and precision requirements.

Material Type and Thickness:

Different materials have different cutting properties and require different types of laser cutters and cutter powers. For example, thicker materials require higher-power laser cutters, while thinner ones require lower ones.

Furthermore, it is also essential to ensure that the chosen laser-cutting machine is designed to cut the specific material type. For instance, if you need to cut metal materials, choose a laser cutter especially made for metal cutting, such as those offered by our company.

Cutting Speed:

The cutting speed refers to the speed at which the laser cutter moves across the cut material. Higher laser cutter power may require increased cutting speed, but balancing this with the desired cutting quality is essential.

Precision Requirements:

The precision requirements for the laser cutting machine depend on the desired cutting quality and the material being cut. Higher precision may require lower cutting speeds and higher laser cutter power, while lower precision may allow for higher cutting speeds and lower laser cutter power.

Cost:

Cost is another factor when establishing a laser-cutting setup. High-powered lasers do cost higher the low-cost ones. Similarly, fiber laser cutting machines are priced higher than their CO2 counterparts.

Common Misconceptions about Laser Cutter Power

There are a lot of misconceptions regarding laser cutter power, and we believe that they need to be addressed in this article.

More Power Is Always Better

That is not always the case. The choice of power cutter must be based on the material surface that needs to be cut. For instance, we don’t have to use high-powered fiber lasers for small-scale applications like cutting paper or wood. That is like cutting an apple with a saw instead of a knife.

Higher Power Means Faster Cutting Speeds

Technically, there isn’t any relationship between power and faster cutting speeds. However, we have to adjust based on our desired needs. At times, yes, the increased power necessarily requires high cutting speed. But that isn’t always the case.

High-Power Lasers Can Cut Any Material thickness

Though we need high-powered laser beams to cut through thicker metals, it doesn’t necessarily mean these lasers can cut materials of any thickness. There’s a specified thickness range for every material and every laser-cutting machine. You can check the specific machine’s manual to figure that out.

What Should You Consider When Using Laser Cutters?

Since lasers are highly powered, multiple potential hazards are associated with their use. Some of these include:

Eye Damage: The laser beam is powerful enough to damage the eyesight of the operator or anyone else in the area if not used carefully.

Fire Risk: Since laser cutters generate a lot of heat, fire risk is always involved. The situation can escalate when the surrounding area or the cut material is flammable.

Skin and Respiratory Issues: The smoke and toxic gases generated during laser cutting can cause skin and respiratory issues, particularly if the operator is exposed to them for an extended period.

To mitigate these risks, the following safety measures must be taken:

Set SOPs: The organization needs to set a standard operating procedure for using each laser machinery. Furthermore, field operators need to be fully aware of the machine, including correctly using safety equipment and handling emergencies.

Equipment Maintenance: The various laser cutting equipment and machines need to be maintained regularly. This includes cleaning, calibrating, and repairing any broken or worn parts.

Choose materials wisely: The selection of materials being cut is also important. Operators should avoid the use of laser machines for cutting materials that are flammable or emit harmful fumes.

Wear Protective Gear: All field operators must have all the protective gear needed for safely performing the laser cutting procedure.

We at Biason laser give safety the most priority. That is why all our equipment is fully closed with a cover design that prevents any human-to-laser contact. Thus, it is safe and secure to use at your workplace.

How to Maintain Laser Cutters?

As described in the last section, maintenance is of prime importance when using laser cutters. This maintenance includes proper cleaning, inspection, and replacement of worn parts regularly.

Further, we have a list of things you can do to maintain laser cutters and prolong their lifespan.

Clean lenses regularly: Laser cutters have a series of mirrors that are prone to catch dirt. Regularly clean the machine’s lens, mirrors, and other components. This can be done using a soft cloth and a gentle cleaning solution.

Check the optical mirrors for damage: Check the machine’s optics regularly for damage or signs of wear. If any issues are found, replace the damaged components immediately.

Inspect and align the track: Inspect the machine’s alignment regularly to ensure the laser beam is correctly focused on the material being cut.

Perform regular maintenance checks: Create SOP and schedule regular maintenance checks with a professional technician to inspect the machine’s components. To replace worn parts and perform any necessary repairs.

Emerging Trends in Laser Cutter Power

Laser technology is not new in the manufacturing industry. It has been in the market for the past few decades now. However, the due to technological advancements, laser-cutting machinery is getting better and better over time.

Here’s a list of emerging technologies in the laser cutter segment:

- Integration with Automation Systems: Automation and robotics are becoming increasingly prevalent in the laser cutting industry, allowing for more precise and efficient cutting. The laser cutters can now be integrated with automation systems and programmed to cut specific shapes and designs, reducing the need for manual intervention. Baison laser also worked a lot on this segment and developed automated laser-cutting solutions.

- Advanced Control and Monitoring Features: Work is being done adding advanced control and monitoring features, including real-time monitoring, cloud connectivity, and intelligent material detection to the laser cutters. These features allow operators to monitor all the critical data in real-time and control laser machinery remotely.

- Integration with CAD Software: Laser cutters are increasingly being integrated with CAD software. With this integration, designers can create intricate designs and send them directly to the laser cutter, saving time and increasing accuracy.

Conclusion

Selecting the appropriate laser cutter power for your application is crucial for achieving optimal results. When choosing a laser cutter, it is important to consider factors such as material type and thickness, cutting speed, and precision requirements.

Low-power laser cutters are ideal for thin materials, while thick materials require high-power laser cutters.

We at Baison Laser manufacture all kinds of all laser cutting machines, from CO2 laser cutters to sheet metal and multi-function laser machines. So, contact us now if you’re looking for a laser-cutting setup.