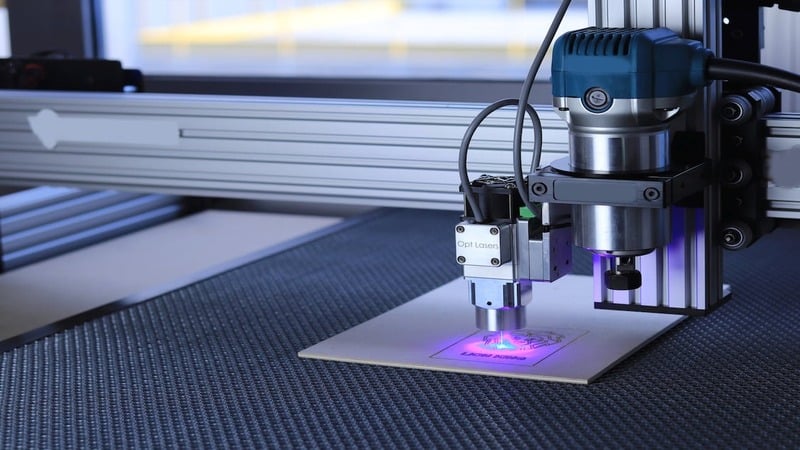

A laser cutter is a machine that is used to cut or etch materials using high-powered laser beams. The focused laser beam is an intense light source that moves very quickly.

The machine uses this light to laser cut or engraves material with high precision. You can cut materials with a fiber laser cutter, including paper, cardboard, fabrics, plastic, leather, rubber, and glass.

They are often used in industrial settings and are also available for purchase by individuals. This article will provide everything you need to know about fiber laser cutters, how they work, and how to use them.

What Is the Machine Tool of a Laser Cutter?

Every machine has a machine tool. The machine tool of fiber lasers is known as the laser cutting head, or laser tube, which is the component that directs the energy beam to cut through thicker materials.

The power source connected to this component is called an amplifier. The light amplification powers and amplifies the signal from the power output of the computer so that it can be directed to the fiber laser tube.

The laser tube works by directing a beam of light onto a piece of material, causing it to melt and burn away until there’s nothing left but dust (this laser-cutting process is known as ablation).

It does this by emitting infrared light at high frequencies, then focusing a concentrated beam from the laser head into a narrow beam that travels along with the material being cut.

Fiber lasers are so effective at cutting through thicker materials, like wood or metal, because they’re able to focus all their energy into one very small area at very high temperatures.

This means they’re able to burn the electrically stimulated gas mixtures through materials quickly without having to spend much time heating up or cooling down afterward.

What Is the Function of the Machine Tool?

The function of a machine tool is to process the workpiece by machining.

The machine tool has a high degree of automation and can manufacture precision or large parts.

The laser cutter is an advanced type of laser engraving machine that uses CO2 lasers to cut materials such as wood, plastic, and paper.

It also allows you to make designs on surfaces like glass or metal sheets using acrylic paints. It’s best if you use acrylic paints because they’re more resistant than other laser technologies.

What Is the Manufacturing Technology of the Laser Cutter’s Machine Tool?

The manufacturing technology of the fiber lasers cutter’s machine tool includes casting, machining, heat treatment, surface treatment, and assembly.

1. Casting

Casting is a process that creates a metal part by using a mold to remove liquid metal from its surface. This method is used when you want to create parts with complex shapes or when you need very small amounts of metal.

2. Machining

Machining is a process that uses tools to cut metal into desired shapes. Machining can be done through turning (a cutting operation involving rotating a cutting tool) or milling (which involves moving a cutting tool in two directions).

It can also be done through drilling (which involves using material thickness cutting holes), and grinding (which involves removing material). Machining technology can be done manually or with computer-guided machines.

3. Heat Treatment

Heat treatment is an industrial laser-cutting process that alters the properties of materials at high temperatures for specific purposes, such as increased hardness or strength.

Heat treatment can be done with an oven or furnace that heats up all sides of the object evenly so no distortion occurs during the cooling down phase.

4. Surface Treatment

Surface treatment involves applying protective coatings or decorative finishes to various surfaces. Such as glass, plastic, etc., to improve their appearance and functionality.

It can be done by adding chrome or nickel plating over brass or stainless-steel components to resist corrosion. Or by adding anodizing to aluminum parts to provide abrasion resistance against wear and tear.

5. Assembly

This stage involves putting together all the parts from different manufacturers into one final product.

This ensures the product works properly together without any issues present within each individual component (like cracks forming from being too brittle).

The Manufacturing Process of a Machine Tool

The manufacturing process for a machine tool is complex, but the overall process is fairly simple.

This is a brief overview of what you’ll need to know about the manufacturing process for a machine tool.

1. Design

The first step in manufacturing a machine tool is designing it. The designer creates a computer model of the tool, which can then be used to manufacture the components needed for assembly.

They also create a set of drawings that will be used by the manufacturer to create all of the parts for assembly.

2. Component Manufacturing

Once the design has been finalized and approved by management, it’s time to start making components for assembly.

This process usually involves creating 3D models of each component using a Computer Numerical Control (CNC) machine or other types of milling machine.

These components must be made with high precision to fit perfectly when assembled into their final CNC machine form.

3. Assembly

After all of the components have been made and tested individually by quality control teams, they are ready to be assembled into one complete machine tool unit. This can be done manually or with automated machinery like CNC machines or robots.

This depends on how complex your product needs to be at this stage in order for it to function properly after being installed in your facility.

4. Testing and Adjustment

After the laser cutter is assembled, you need to pay attention to some of its settings. The adjustment of the machine tool is the most important part of the manufacturing process.

It mainly uses three ways: adjusting the position and orientation of cutting tools or adjusting laser power based on material properties. It can also be setting up parameters such as speed or feed rate diode laser according to different materials.

5. Maintenance and Upkeep

The maintenance and upkeep of the machine tool is very important. You should keep it in good working condition by performing regular maintenance such as cleaning and lubricating the machine tool regularly.

This will ensure that your machine tool has a long service life and can be used for many years to come.

What Is the Most Common Problem in Machine Tool Manufacturing?

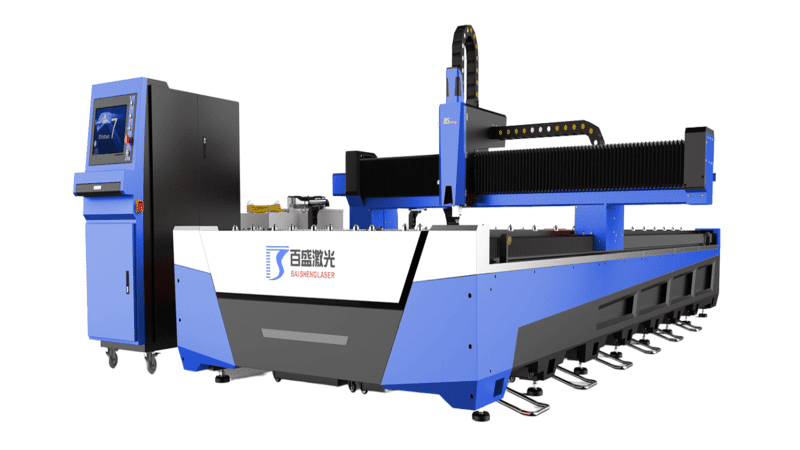

A laser cutter machine is a computer-controlled machine tool that uses an extremely concentrated beam to cut materials. These machines are used for laser cutting service using, engraving, and marking metallic, non-metallic, and other solid materials. There are many companies that produce these laser machines, and they use different laser technologies to make them.

The most common problem in machine tool manufacturing is stress which is the effect of a force applied to a material at a point where it is not supported by another material. The negative impact on machine tools’ stability, accuracy, and service life due to stress are discussed below.

1. Stability: It affects the stability of the machine tool when stress occurs in its structure. The stability of a machine tool refers to its ability to maintain accuracy without any change over time or after long-term usage. The more stable the machine tool is, the less likely it will break down easily during operation.

2. Accuracy: It refers to how well a product matches its intended use or purpose. When there is high stress on the structure of a laser cutter machine, its accuracy will decrease significantly because there is no longer enough support for the laser cutting process for the machine to be accurate.

3. The service life of machine tools: It also affects your service life because if there are any problems with your machine tool, you will need a replacement part or repair work done, which will require money from you.

How to Relieve Stress in Laser Cutter’s Machine Tool Manufacturing?

Stress can be a major problem in the manufacturing of laser-cutting machine tools. It can cause the machine to break down or not perform as efficiently as it should.

Here’s how to relieve stress in the fiber laser cutter machine during the manufacturing process.

1. Heat Treatment

This process involves heating up the metal until it reaches its melting point, then allowing it to cool gradually to keep its structure intact.

This is done to increase strength and hardness in the metal used for a particular part of your Baisons’ laser cutter machine tool’s manufacturing process.

2. Mechanical Processing

Mechanical processing can also cause stress on materials when they’re subjected to high forces for long periods of time.

To relieve this stress, it’s important to limit both the force and duration of any mechanical processing processes.

Consider using vibration-dampening equipment and supports during these processes so as not to adversely impact nearby personnel or property (including other equipment).

3. Cooling

After heating and mechanical processing, some materials need to be cooled down quickly. This is done for them to retain their current property and improve their properties further.

Cooling is usually done by quenching or air cooling, but sometimes other ways of cooling may also work well for different types of materials.

4. Rest

Rest is one of the best ways to reduce stress in any situation, and it’s just as important for laser-cutting machines as it is for humans.

After being processed by heat treatment and mechanical processing, many materials need time to rest before they can reach their peak performance level.

This resting period varies depending on the material type and its degree of processing. Take a break every hour or so, even if it’s just for a few minutes at a time.

5. Vibration Treatment

In order to relieve stress in laser cutting machine tool manufacturing, it is advised to use vibration treatment.

This is because vibrations are known to cause stress on the machine tool, and hence, vibration treatment must be done before the machine is used for the intended purpose.

Vibration treatment can be done using a vibrating table or a vibrating cone. The vibrations are applied up to 500 cycles per minute, and this should be done for about 3 hours at a time.

6. Chemical Treatment

Chemical treatment is another way of relieving stress from various types of laser cutters and machine tools manufacturing parts.

Chemical treatment involves applying chemicals on the surface of the metal parts of the machine tool that are prone to stress and corrosion.

In this treatment, the part is immersed in a chemical bath that removes residual stresses from the material, resulting in reduced residual stresses after completing the machining process.

These chemicals include phosphoric acid and nitric acid, which help reduce oxidation and corrosion respectively.

Conclusion

A laser Cutter is a kind of machine with a high-power laser beam to cut and engrave materials. It is capable of producing rapid results with speed and accuracy.

Recently, laser cutters have become popular because they can be used on a wide range of materials, including metals, wood, plastics, etc.

If you’re looking forward to acquiring a Baison laser cutter, request an instant quote and plan yourself on the best machine for your business.