Maintaining cleanliness and efficiency in various industries is crucial to ensuring smooth operations and high-quality products. Laser cleaning systems have become increasingly popular among businesses seeking to streamline their operations and boost efficiency.

This article aims to explore the advantages of implementing laser cleaning machines in various industries, such as aerospace, automotive, and manufacturing, for optimal results. We’ll discuss how Bison’s state-of-the-art solutions can help your business thrive in an increasingly competitive landscape.

Laser Cleaning Technology

Laser-based cleansing techniques provide a non-invasive, eco-conscious, and highly effective approach to eliminating pollutants, coverings, or unwanted elements from diverse surfaces. By harnessing the strength of laser rays, this cutting-edge method delivers an accurate and regulated cleaning procedure appropriate for numerous sectors and uses.

How Does the Laser Cleaning Process Work?

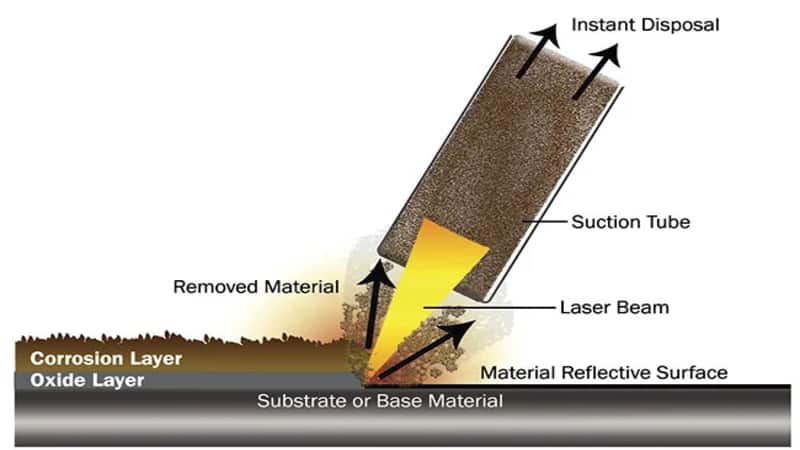

The laser cleaning process emits a focused, high-energy laser beam onto the target surface. As the laser light interacts with the surface, it vaporizes or removes the contaminants, leaving the underlying material clean and undamaged. You can customize this process to remove specific layers or particles without affecting the base material.

The process typically involves using short laser pulses that generate minimal heat, preventing damage to the surrounding areas. A specialized vacuum then collects and disposes of the removed contaminants. This ensures a clean and environmentally friendly operation.

Laser Power for Different Cleaning Tasks

The power of the laser used in the cleaning process depends on the specific task and the materials involved. Lower laser powers are utilized for delicate or sensitive surfaces to prevent potential damage. On the other hand, more robust materials or heavy-duty cleaning tasks may require higher laser powers to remove contaminants effectively.

Laser Cleaning Machines

These machines have specific designs and features to cater to the needs of every other business. They offer a range of features and capabilities to ensure efficient and effective cleaning results, regardless of the task.

Some common types include:

1. Handheld Laser Cleaning Machines: These portable devices offer the flexibility to clean surfaces in hard-to-reach areas or situations where mobility is crucial. They are ideal for spot cleaning, maintenance tasks, and small-scale projects.

2. Automated Laser Cleaning Machines: An automated laser cleaning machine will be useful if you have a large-scale production and laser setup. You can integrate them into existing production lines, offering automated, non-contact cleaning solutions that enhance efficiency and reduce downtime.

3. Custom Laser Cleaning Machines: For unique or specialized cleaning requirements, custom laser cleaning machines can be designed and built to address specific needs, ensuring the highest precision and effectiveness.

Laser Cleaning Systems in Fiber Laser Technology

Fiber laser cleaning machines offer several advantages over traditional cleaning methods and other laser technologies thanks to the laser cleaning system:

1. High Power Density: Fiber lasers deliver a high power density, enabling them to remove contaminants quickly and effectively, even from robust or heavily soiled surfaces.

2. Energy Efficiency: Fiber lasers are known for their energy efficiency, consuming less power than other laser types and traditional cleaning methods, ultimately reducing operating costs.

3. Precision and Control: With fiber laser cleaning machines, users have precise control over the cleaning process, ensuring that the target surface is cleaned effectively without causing damage to the base material.

4. Minimal Maintenance: Fiber laser cleaning machines require minimal maintenance, contributing to lower long-term costs and higher overall productivity.

How Do Laser Cleaning Machines Stand up Against Traditional Cleaning Methods

Some key benefits of laser cleaning machines include the following:

1. Chemical-Free

Traditional cleaning methods often involve using chemicals, solvents, or abrasive materials to remove contaminants. These substances can pose risks to the environment, operator health, and the integrity of the cleaned surface. Hence, the chemical-free nature of these machines makes them highly safe and suitable for a lot of applications.

2. Precision and Accuracy in Cleaning

The focused laser beam can target specific areas or layers of contamination without affecting the base material. This level of control is not achievable with traditional cleaning methods, making laser cleaning machines an ideal choice for intricate or sensitive surfaces.

3. Time-Saving

Faster cleaning times translate to reduced downtime, increased productivity, and cost savings. By adopting laser cleaning technology, businesses can maximize efficiency and stay ahead in an increasingly competitive landscape.

What to Consider When Choosing a Laser Cleaning Machine

Selecting a suitable laser cleaning machine for your business requires careful consideration of various factors to ensure optimal performance and results. Some key aspects to consider include the following:

1. Underlying Material and Coating Layer

The nature of the material being cleaned and the type of coating or contamination to be removed play a crucial role in determining the most suitable laser-cleaning machine. Different materials and coatings may require specific laser types, wavelengths, or power levels to achieve the best results without causing damage. Always consult experts or manufacturers to identify the most appropriate machine for your needs.

2. Cleaning Method and Safety Concerns

Different cleaning tasks may necessitate the use of different cleaning methods, such as non-contact cleaning or more aggressive processes. Consider the level of safety required for your application and choose a machine that provides the necessary features, such as built-in safety measures, protective enclosures, or exhaust systems, to ensure a secure working environment.

3. Continuous Wave and Pulsed Lasers

Laser cleaning machines are available with either continuous wave (CW) or pulsed lasers. CW lasers emit a constant beam, making them suitable for tasks requiring consistent power. On the other hand, Pulsed lasers emit short bursts of energy, allowing for more precise control and reduced heat generation. These two options depend on the specific cleaning task and the processed material.

Applications of Laser Cleaning

Laser cleaning technology has various applications across various industries, offering precise and efficient solutions for diverse cleaning tasks. Some common applications include:

1. Laser Surface Texturing

Laser cleaning can be used to modify the surface properties of materials, such as creating micro-textures or roughening surfaces. This technique is useful in industries like automotive, aerospace, and manufacturing, where surface texturing can enhance the adhesion of coatings, improve friction, or optimize the performance of functional surfaces.

2. Laser Oxide Removal

Laser cleaning technology can effectively remove oxide layers from metal surfaces, which is critical in the metalworking, welding, and manufacturing industries. Laser cleaning ensures that subsequent processes, such as painting or bonding, can achieve optimal results by eliminating oxide layers.

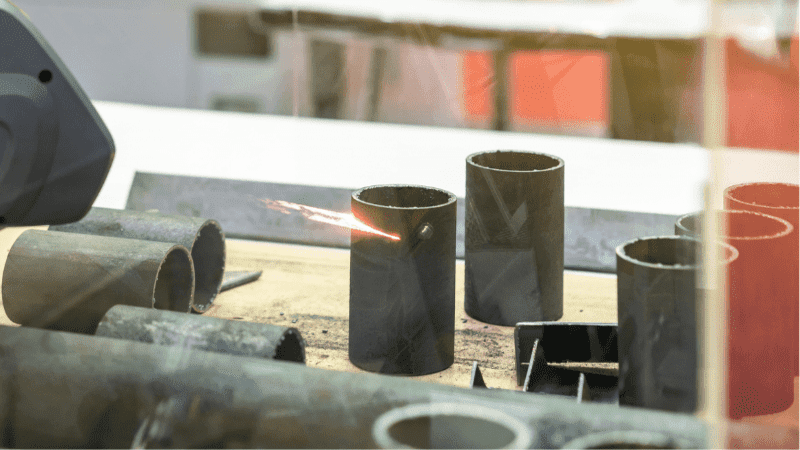

3. Laser Rust Removal

Rust can cause damage and degradation to metal surfaces. Hence, removing it before further processing or extending the affected component’s life is essential. Laser rust cleaning machines provide a non-contact, efficient, and precise method for removing rust without the need for chemicals or abrasive materials. This makes it an ideal solution for the automotive, shipbuilding, and heavy machinery maintenance industries.

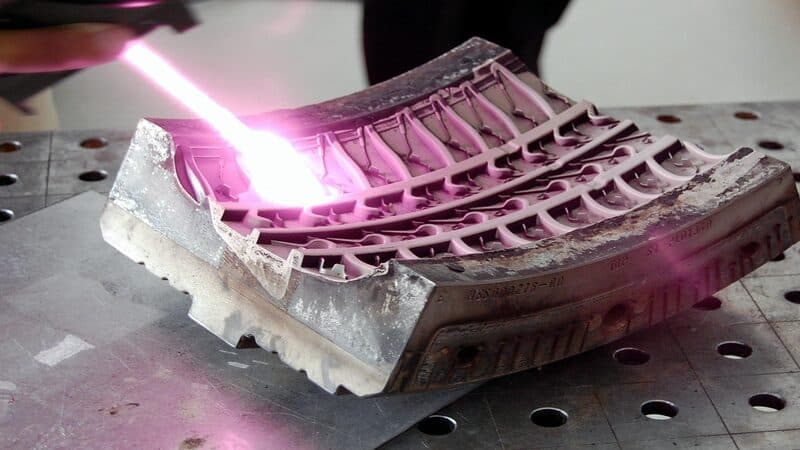

4. Laser Paint Removal

Laser cleaning is an effective method for removing paint or coatings from surfaces without damaging the underlying material. This application is precious in industries such as automotive, aerospace, and restoration, where it is essential to remove old paint or coatings before applying new ones or preserving historical artifacts.

Conclusion

Laser cleaning machines have revolutionized the way businesses approach cleaning tasks, offering a range of benefits over traditional cleaning methods. With applications spanning numerous industries, these machines deliver precision, efficiency, and environmentally friendly solutions for various challenges.

Boost Your Business Efficiency with Baison Laser Cleaning Machines

Use the opportunity to enhance your operations and productivity with Baison‘s cutting-edge laser cleaning technology. Experience unparalleled precision, performance, and reliability backed by our commitment to excellence and customer satisfaction. Contact us today to discover the perfect laser cleaning solution for your business.