In this post, we’ll delve into the intricacies of laser marking processes, discuss different types of laser markers available, explore applications beyond soft products, and highlight the advantages of incorporating laser technology into your business operations.

Understanding Soft Products

At its core, the term “soft products” alludes to items that differ from their harder, more rigid counterparts in their composition, flexibility, and often sensitivity. Soft products find applications in various fields such as energy and power due to their unique properties.

These products are designed to operate at specific wavelengths for optimal performance. The distinction between soft materials is essential, especially when introducing methods or processes that involve heat, pressure, and laser power. It is crucial to consider the characteristics of the product and ensure proper contact with the materials.

Definition and Examples of Soft Products

Soft products are primarily characterized by their flexibility, pliability, and the ease with which they can be deformed. They are often materials that require gentle handling due to their delicate nature. A few common examples include:

- Textiles and Fabrics: Whether it’s a soft cotton T-shirt, a luxurious silk scarf, or a delicate lace curtain, these materials are quintessential examples of soft products that can be marked using laser engraving machines.

- Soft Plastics: Silicone wristbands, rubber seals, or soft PVC toys all fall under this category, displaying flexibility and elasticity.

- Leather and Its Counterparts: Natural leather, faux leather, or suede. These materials are not only soft but often prized for their texture and finish.

- Elastomers: Think of rubber bands, silicone molds, and certain flexible plastics. Tires, seals, and gaskets are a few examples of products made from elastomers.

- Foam Materials: Memory foam pillows, mattress toppers, and sponge materials fall under this category.

Why It’s Challenging to Laser Mark Them

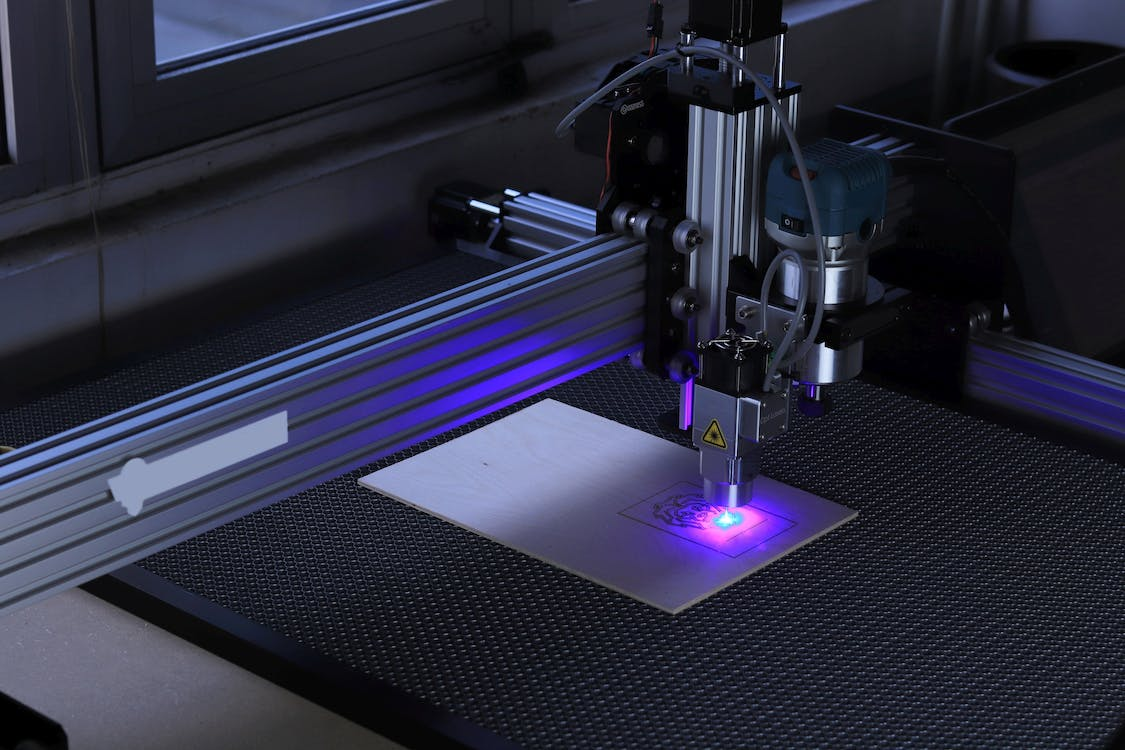

Laser marking involves using a laser to produce marks on an object’s surface. In marking, the laser beam removes some material from the surface. The process often generates heat, especially where the laser interacts with the material. For harder products, this isn’t usually a problem. However, with soft products:

- Heat Sensitivity: Soft materials can easily melt, deform, or get damaged due to the heat generated by the laser.

- Inconsistent Surfaces: The pliable nature of some soft products can lead to an uneven surface, making laser engraving consistent marking challenging.

- Absorption Issues: Soft materials might absorb the engraving laser’s energy differently, leading to varying engraving mark qualities or even damage.

- Texture Changes: The heat from the engraving laser can alter the texture of soft materials, turning a smooth surface rough or vice versa.

By understanding the unique nature of soft products and employing appropriate laser engraving techniques, manufacturers can achieve precise markings while maintaining product integrity. Investing in advanced laser engraving technologies tailored for soft materials can lead to improved efficiency, reduced waste, and enhanced customer satisfaction within various industries.

Benefits of Laser Marking Soft Products

Laser marking soft products offer several advantages and benefits, making them an ideal choice for high quality marking. Here are some key points to consider:

Permanent Markings

Laser marking technology provides a permanent solution for marking soft products without compromising their integrity. Unlike other methods, laser marking does not damage the material, ensuring that the mark remains intact over time.

Intricate Designs with High Resolution

One of the major benefits of a laser marking system is its ability to create intricate designs with exceptional precision. The high-resolution capabilities allow for fine details, enabling manufacturers to incorporate logos, serial numbers, or other personalized markings seamlessly.

Excellent Resistance

Laser-marked soft products exhibit remarkable resistance against fading, washing, and abrasion. This ensures that the marks remain visible and legible even after repeated use or exposure to harsh conditions.

Eco-friendly Marking

Laser marking on soft products is a nod to sustainability. The process eschews inks, solvents, or harmful chemicals, minimizing environmental impact. For brands and manufacturers keen on green processes, laser marking emerges as the method of choice, ensuring that products bear no trace of harmful residues.

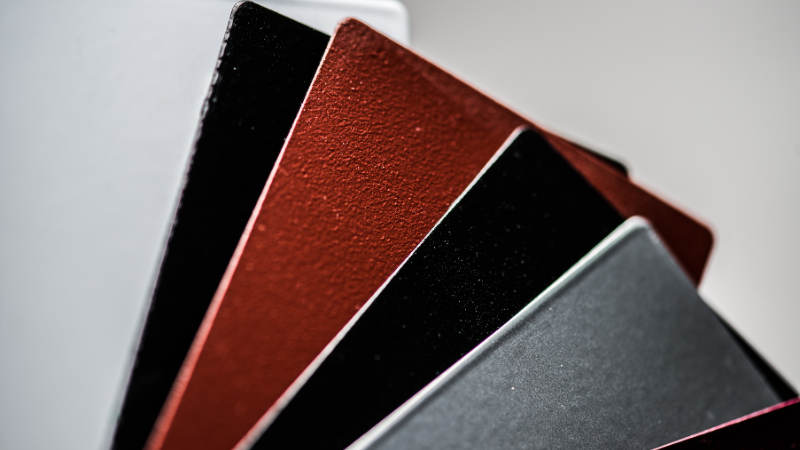

Choosing the Right Laser for Soft Products

Successfully laser marking soft products hinges significantly on selecting the appropriate laser type. Just as different materials have varied responses to heat and light, different lasers have unique properties that make them more or less suitable for marking particular materials. Let’s delve into the main types of lasers and understand their compatibility with soft products.

Different Types of Lasers

CO2 Lasers

Originating from a gas mixture, primarily carbon dioxide, CO2 laser is widely used in the marking industry, especially for non-metal materials.

Best suited for: Wood, acrylic, glass, and some plastics.

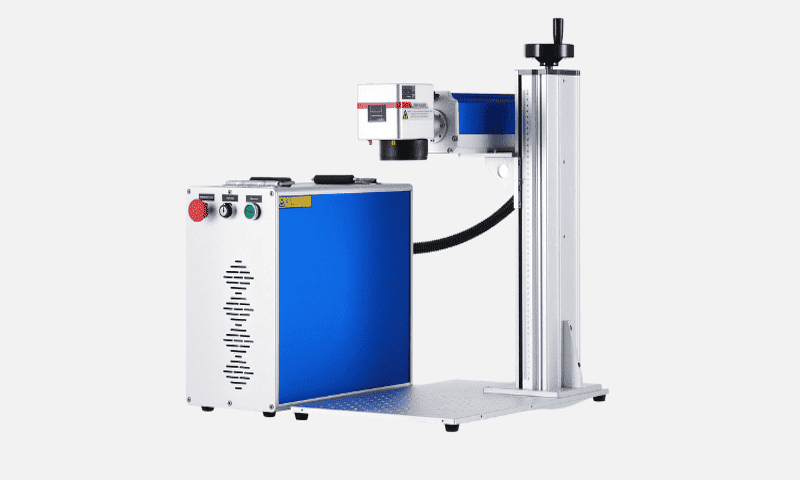

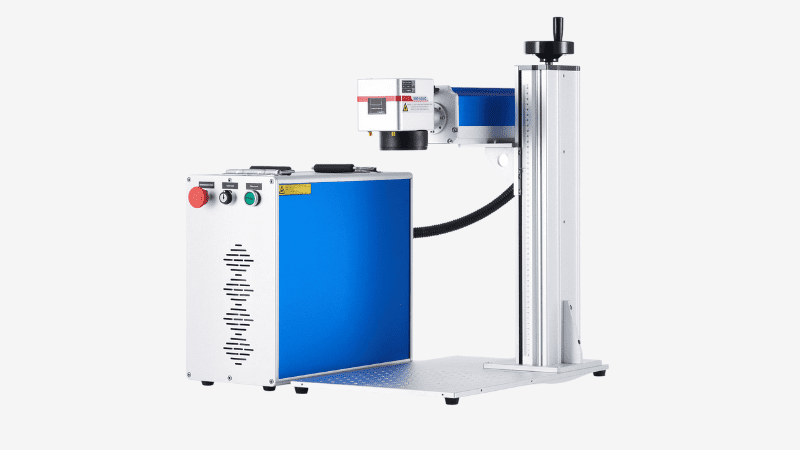

Fiber Lasers

Utilizing a solid gain medium, the fiber laser marking machine is renowned for its capability to mark metals but also work on certain plastics.

Best suited for: Metals, hard plastics, and some darker-colored soft materials.

Green Lasers

Emitting a green light, green laser marking is particularly effective for materials that might be sensitive to other wavelengths.

Best suited for: Silicon, certain plastics, and some reflective metals.

UV Lasers

UV Laser Marking Machines create permanent marks on the material surface. Ultraviolet lasers operate at a wavelength that allows for extremely fine and precise marking without generating much heat.

Best suited for: White or clear plastics, silicon, and other sensitive materials.

You may want to know about the difference between fiber laser and UV laser marking.

Pros and Cons of Each Laser Type for Soft Materials

CO2 Lasers

Pros: Versatile for many non-metals; provides a clear contrast on materials like wood and acrylic.

Cons: May generate more heat; not ideal for heat-sensitive soft materials.

Fiber Lasers

Pros: Durable markings; fast processing speeds.

Cons: Might be too intense for certain soft materials, risking damage.

Green Lasers

Pros: Good for heat-sensitive and reflective materials; offers precision.

Cons: Generally more expensive; might not be as effective for thicker materials.

UV Lasers

Pros: Minimal heat generated, making it great for very sensitive materials; allows for high-detail marking.

Cons: Higher initial cost; might not provide as strong a contrast on some materials.

Selecting the right laser for soft products is pivotal to the success of the marking process. By understanding the strengths and limitations of each laser type, one can make informed decisions, ensuring both the integrity of the soft material and the quality of the mark.

Techniques for Successful Laser Marking on Soft Products

When it comes to marking soft products, finesse and precision are paramount. It’s not just about operating the machine, but mastering the art of its application. Here are some tips.

Importance of Focus

To achieve accurate laser marking on soft products, it is crucial to ensure the correct focal length. The laser etching process heavily relies on precise focus to create clear and legible marks. By adjusting the focal length, you can optimize the laser beam’s concentration and achieve optimal marking results.

Controlling Heat

When laser marking soft products, preventing burns or unwanted marks caused by excessive heat is essential. Proper heat control helps maintain the integrity of the material while achieving desired markings. Employing techniques such as annealing marking or carbonizing can minimize heat-related issues and produce high-quality marks.

Multiple Passes

In certain cases, multiple passes may be necessary during the laser marking process for soft products. This technique allows for deeper penetration into the material or enhances contrast in the mark. By carefully considering when and why multiple passes are required, you can ensure satisfactory outcomes.

Use of Additives or Coatings

Depending on the specific soft product being marked, incorporating additives or coatings can enhance the laser marking process. These additional substances can improve the contrast, durability, and overall visibility of the mark. When applicable, consider utilizing suitable additives or coatings to optimize your laser marking results.

By focusing on precise focal length adjustments, controlling heat effectively, employing multiple passes when needed, and exploring additive options where applicable, you can achieve successful laser marking on soft products. Implementing these techniques ensures clear and durable markings without compromising the integrity of delicate materials.

Common Mistakes and How to Avoid Them

Congratulations! You’ve now gained a solid understanding of laser marking soft products. By learning about the materials suitable for laser marking, the benefits it offers, and the techniques for successful marking, you’re well-equipped to embark on your laser marking journey. However, it’s important to be aware of common mistakes that can hinder your progress. Here are a few pitfalls to avoid:

- Insufficient testing: Before diving into large-scale production, make sure to conduct thorough testing on various soft materials. This will help you determine the optimal settings and ensure consistent results.

- Inadequate preparation: Proper surface preparation is crucial for successful laser marking. Ensure that the material is clean, free from contaminants, and properly positioned in the laser marking machines.

- Lack of maintenance: Regularly maintain your laser systems by cleaning lenses and mirrors and replacing worn-out parts. Neglecting maintenance can lead to subpar results or even damage your equipment.

Now that you’re armed with this knowledge, it’s time to put it into practice! Start experimenting with different soft materials using your chosen laser system and see what works best for your specific needs.

FAQs

Can I use any type of soft material for laser marking?

Yes, laser marking can be performed on a wide range of soft materials such as fabrics, leather, rubber, silicone, foam, and more.

Can I achieve different colors when laser marking soft products?

Laser marking typically produces a permanent, contrasting mark without changing the color of the material. However, certain materials may react to laser energy and produce different colors.

How long does laser marking on soft products last?

The durability of laser marks on soft products depends on various factors such as material type, application, and environmental conditions. Generally, laser marks are highly resistant to fading, abrasion, and other forms of wear.

Explore these FAQs to address any lingering doubts you may have about laser marking soft products. Remember, experimentation is key!

Conclusion

Navigating the nuances of laser marking soft products can be intricate, but the rewards are undeniable. With the right knowledge, tools, and preparation, you can achieve precise, durable, and eco-friendly markings that elevate the value of your products. As we delve deeper into the era of advanced manufacturing, mastering such techniques is not just beneficial—it’s essential for staying ahead.

Unleash Precision with Baison Laser!

In the realm of laser marking, Baison Laser stands unparalleled. Our advanced solutions, laser machines designed meticulously, ensure markings of the highest precision and durability. Esteemed by industry experts and trusted by businesses globally, Baison Laser is more than just technology—it’s a testament to excellence. Dive into a world where quality meets innovation. Reach out to us today and experience the Baison Laser difference for yourself!