How to Choose the Best Laser Tube Cutting Machine for Your Industry

A good selection of a laser tube cutting machine can make or break your manufacturing business. The possibilities are endless, with various types of lasers and solutions to automation, which can be overwhelming. The secret lies in understanding your industry’s requirements and aligning them with the respective machine features.

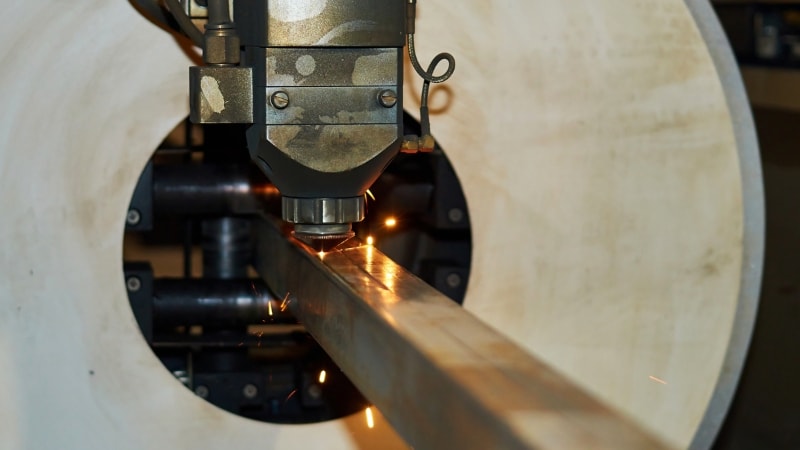

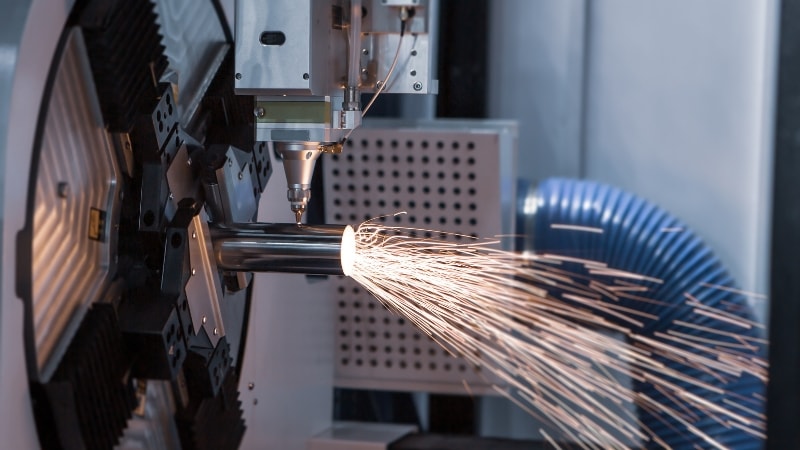

What Is a Laser Tube Cutting Machine?

A laser tube cutter machine is a type of machine that cuts through tubes with the laser beam focuseddirectly on the tube using extreme precision. It is like a super-advanced saw that can cut and create intricate shapes, holes, and cuts in tubes without physically touching the material.

The machine has three essential elements, which are the laser source (it produces the cutting beam), the system that feeds the tube into the right position and movement, and a control panel that controls the whole process of laser cutting.

These parts combine in a way that they produce clean and accurate high-speed cuts. These machines can handle a wide variety of materials. It includes carbon steel, stainless steel, aluminum, copper, brass, and even some plastics.

The key advantage is that they can cut different wall thicknesses and tube shapes. They can cut simple round tubes to complex square, rectangular, or custom profiles.

Benefits of Using a Laser Tube Cutting Machine

The laser tubes cutting machines of modern-day present some attractive benefits over the conventional mode of cutting:

- Low-end precision and sharp edges: Laser cutting has tolerances that are as good as +/- 0.1mm with smooth and burr-free finishes, avoiding much of the finishing procedures that are usually required.

- Increased cutting speed: Laser cutting may be up to 5-10 times faster than less advanced techniques such as sawing or plasma cutting, depending on material and thickness.

- Minimal material waste: The thin cut lines are created using the narrow Laser beam (0.1-0.3mm), which maximizes the use of the material and saves on those scrap costs.

- High automation and control: Modern machines are capable of operating unattended for hours, and loading of tubes, cutting of parts, and assorting the final products is automated.

- Versatility in shapes and materials: Multiple tube profiles can be loaded individually into one machine and easily change materials without tooling adjustments.

Key Factors to Consider When Choosing a Machine

When purchasing the laser tube cutting machine, it is important to weigh the tips on various significant factors in order to select the most appropriate one. All of them influence the levels of performance, efficiency and return on investment of your machine.

1. Material Type and Thickness

Depending on the different materials, different types of lasers are used. Fiber lasers and moderate power levelsfind easy cutting of carbon steel and high power settings of stainless steel at the same cutting speeds.

Aluminium is a bit sticky due to its great reflectivity; thus, it needs a particular wavelength and power to cut. The thickness of the material also matters. A 1kW laser may cut 3mm carbon steel flawlessly but would have problems with 10mm. Generally speaking, thick material requires additional laser power.

To take one example, the minimum laser power requirements to cut 6mm stainless steel efficiently are usually in the range of 2-3kW, but 1mm can be cut with 500W-1kW systems.

2. Tube Shape and Size

Each machine cannot work with all the tube types. Simple machines could simply accept round tubes. More sophisticated systems could handle square and rectangular shapes. They could also handle oval, hexagonal, and even custom-extruded profile tubes.

The capacity of the size is also important. Large construction companies usually deal with pipes of a high diameter (100mm+). This is why they need a more powerful machine with a wide chuck opening.

Meanwhile, some manufacturers of medical equipment may require machines. These machines must be able to work with very small tubes of 1mm in diameter.

Think about the sizes of your existing tubes as well as projects in the future. The machine with a 20mm/200mm ability will offer you a large degree of freedom compared to the type limited to 50mm/100mm.

3. Cutting Speed and Accuracy

Speed is usually at the expense of accuracy. They are paramount variables to you, depending on what you are using. Producing at volumes demands speed. Extreme precision, such as aerospace or medical devices, needs additional accuracy.

Modern machinery is capable of cutting thin-walled tubes at higher speeds. They can cut up to 20-50 meters per minute. To achieve the accuracy of “+0.05mm” and “-0.05mm”, low speeds may be called upon.

Low speeds are 5-15 meters per minute. What is important is to identify machines. These machines can accommodate the two needs of your specific applications.

4. Automation Level

Automation has the power to make incredible increases in productivity and cut labor expenses. Simple machines need constant loading and unloading of each tube. Fully automated machines can run unattended for hours.

Other features are key parts of automation. They are automatic loading tubes in bundles. They also include robotic removal of parts. Another feature is the automated sorting of the completed parts. The last one is the connection to handling equipment.

Automation is necessary where quantities produced are large or where the plant operates lights-out (unattended during part of the night). The extra investment will be paid within 12 -18 months only with the lab or savings.

5. Software Compatibility

The productivity and ease of use are directly related to the software capabilities of your machine. Seek and find the system that is compatible with your current CAD/CAM software. It should also be able to import common standard files. These include DXF, DWG, and STEP files.

The high-level nesting software can use automated or semi-automated arrangement of parts. This is to maximize materials use. Production management software can be used to monitor the status of the jobs. It can also monitor the use of the machines.

Other systems also include the possibility of remote monitoring. You can check the state of the machines through your phone.

6. Industry Application Fit

Various industries are distinct. They have different sets of requirements. This should resonate in the notch that you use in choosing your machines. Knowing what your industry needs specifically can streamline the choices. It will make sure you will invest in what is important with respect to your industry.

Consider industries such as:

- Automotive: High volume, near-zero tolerance, assembly line-enabling.

- Furniture: versatility of design, design appearance, and the capacity to support different profiles of tubes.

- Medical: Ultra-high accuracy, burr-free cuts, meeting the medical device regulations.

- Construction: Fast high-speed laser welding and cutting, a lot of tube capacity, and heavy-use assembly.

7. Budget and ROI

Depending upon the specification of the laser-tube cutting machine, the cost varies between 50,000 dollars to more than 500,000 dollars. The cost varies with the power of the lasers, the level of automation, the brand image, and the features to be supplied. But concentrate on the total cost of ownership, not the purchase price.

Consider factors like:

- Cost of operation (electricity, maintenance, consumables).

- Automatic saving of labor.

- Waste reduction savings.

- More sales through the speed of output and quality.

Through efficiency, low labor costs, and the potential to complete higher-valued projects, many companies achieve payback of 1-3 years. These projects need a high-accuracy cutting process.

Types of Laser Tube Cutting Machines

Knowledge of the various types of laser technologies can aid you in the selection of an appropriate system for your materials and applications.

Fiber Laser Machines

This is the most popular one to use to cut metal. They have fiber optic technology to produce the laser beam. Therefore, they have high efficiency and reliability. Fiber lasers are superior in carbon steel, stainless steel, and aluminum cuts. Their high speeds produce good edge quality.

They are also a more economical form of energy in terms of cost of operation when compared to others. Fiber laser is most popular in the case of new installations in metal tube cutting.

Fiber laser cutters work up to five times faster than traditional CO2 lasers while utilizing half the operating costs.

CO 2 Laser Machines

These machines make use of a mixture of gases to create the laser beam. Although not as effective on metals as fiber lasers, they fare better when cutting non-metallic substances.

These include plastics, wood, and composites. CO2 lasers are lower in initial costs and higher in operation costs since they use gas and require more repairs.

Hybrid Machines

These are the systems where several laser or cutting technologies are combined. They are most suitable for shops that need to cut both metallic and non-metallic materials. This comes with increased complexity and price. They are sensible when maximum flexibility is required.

In the majority of metal tube cutting requirements, fiber lasers provide the maximum extent of performance, efficiency, and reliability.

Choosing the Right Machine by Industry

Select the proper machine according to your industry. Here is the explanation:

Automotive Industry

The automotive industry requires materials that are strong, have high tolerances and large volumes. Exhaust pipes, roll guards, chassis, and fuel lines need to be cut to meet strict safety standards.

Automated feed mechanisms and compatibility with robotic arms are key requirements. These facilitate the smooth flow of production.

The capability to cut high-strength steel commonly used in new vehicles is another requirement. The industry standards in the automotive environment also require quality tracking and documentation.

Furniture Industry

Design flexibility and aesthetic quality are the highlights of furniture manufacturers. They usually process decorative tubes and strange profiles. They require the ability to create intricate structures and perform complex incisions.

An optimum machine will provide high-quality cuts. These cuts have minimum heat-affected areas. The software should support complex image designs. It should also have the versatility to cut different tube shapes and diameters. Speed is not as important as precision and a good quality surface finish.

Medical Industry

The production of medical devices is the most precision-oriented type of manufacturing. This involves micro-tubes and even exotic materials like titanium. The use of burr-free cuts is high because there are numerous parts that have to be used within the human body.

Superior capabilities are ultra-high precision (to within 0.02mm or better). This also includes clean room compatibility, full documentation, and traceability. The capacity to work with small-diameter tubes with thin walls is also crucial. There is also regulatory compliance and validation assistance.

HVAC & Construction

These are industries that concentrate on high-speed production of huge-diameter pipes and tubes. Flow is of great importance, and sometimes 99.999 precision is not as important as acceptable levels of volume transfer.

Notable characteristics are large sizes of tube storage (up to 300mm+ in diameter) and fast cutting speeds. They are strongly built as they run all the time.

Automation is strong in cutting back on labor requirements. Overall efficiency can also be enhanced through integration with tube bending and welding equipment.

Best Brands and Models to Consider

Knowledge of the various types of laser technologies aids you in selecting the appropriate system with regard to the materials and application.

Trumpf (Germany)

It is universally considered a luxury brand. It provides maximum accuracy and trustworthiness. Their machines are perfect when it comes to high-end applications. This is where precision and uptime matter. You should expect premium prices. The return on the investment tends to be in high performance and dependability in the long term.

BLM Group (Italy)

It specializes in the processing equipment for tubes. It provides superior machines for complicated tube designs. They are especially remarkable in furniture and automotive applications. The software they use specializes in complex 3D cutting.

Mazak (Japan)

It integrates both laser cutting and automation know-how. It has highly integrated solutions in high-volume manufacturing. They have popular machines in the automobile and industrial sectors.

Han’s Laser (China)

It offers low-cost alternatives that are reasonably good. This applies to general-purpose applications. They are not as accurate as the European brands. They are highly cost-effective solutions to businesses with a low-cost focus.

Prima Power (Italy)

It specializes in end-to-end automation. It combines laser cutting and material handling with part sorting systems. They are perfect for light-off manufacturing.

Conclusion

Choosing a laser tube cutting machine can be one of the most crucial decisions you are going to make. The trick is to align machine capabilities to your needs in the particular industry. It includes quality requirements and production quantities as well.

Do not forget that we should not always focus on the machine with the lowest price. Look at the total cost of ownership. Future growth and changing needs often make a machine more worthwhile as it better accommodates value in the long run. This is preferable over a machine that only accommodates current demands.

FAQs

Which laser technology is widely used in industrial cutting?

CO2 laser cutting has dominated the industry for several decades and remains prominent.

In which industry is laser cutting most commonly used?

Laser machines are very handy in electronics, where the small electronic parts are cut with precision. Circuit boards, enclosures, connectors, and heat sinks are components of machines when being cut by means of tube laser cutting.

What is the market size of laser-cutting machines?

In 2024, the laser cutting machines market size in the global market was 6.31 billion USD. According to the projected market size, the market is expected to expand from USD 6.85 billion in 2025 to USD 14.14 billion in 2032, with an average annual growth rate of 10.9% during the forecast period.

Ready to boost your production with the perfect laser tube-cutting machine?

Baison laser cutting experts are available. We will assist you in reviewing your unique needs. We provide you with the perfect machine that fits your industry and budget.

Ask for a free quote and sample cutting. To understand how laser tube cutting can change your manufacturing process.