In this comprehensive guide, we’ll explore the top MDF laser cutters on the market, delve into their features, and provide you with the information you need to choose the right one for your needs. Whether you’re a hobbyist looking to create a custom piece or a professional needing a reliable machine for your small business too, this guide will help you navigate the world of MDF laser cutters.

What is an MDF Laser Cutter?

An MDF laser cutter is a game-changer. It’s a machine that harnesses the power of lasers to cut effortlessly and laser engrave Medium-Density Fiberboard (MDF) sheets. With its focused laser beam, this tool vaporizes or burns through the material, leaving you with clean and precise cuts every time.

A powerful laser cutter is a good laser cutter or engraving machine that can be used for making various cutting and engraving materials with laser control software. Don’t miss out on this cutting-edge technology – explore the world of MDF laser cutting now!

Understanding Laser Cutting

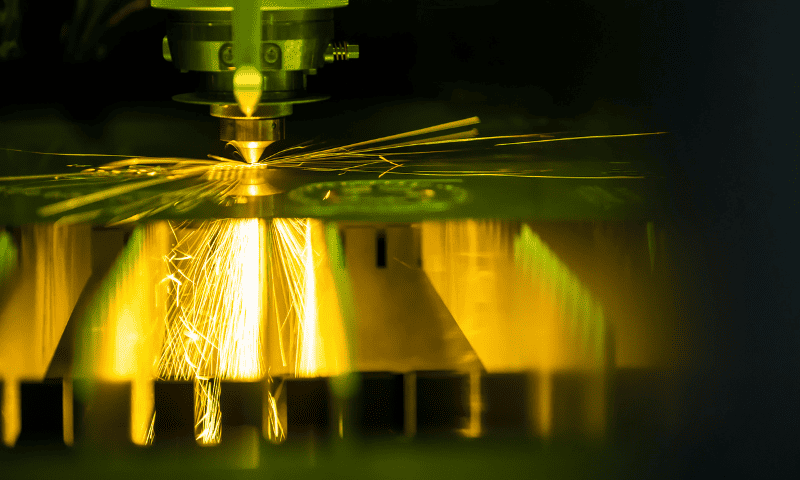

Laser cutting is a technology that uses a high-powered laser beam to cut through materials with precision. It is a non-contact process that involves focusing a laser beam onto the material’s surface, melting, vaporizing, or burning away the material to create a clean and precise cut.

The laser cutting machine, also known as a laser engraver, contains a laser source, which emits a concentrated beam of light. The most commonly used laser types for cutting are carbon dioxide laser (CO2 laser) and fiber laser. CO2 lasers are suitable for cutting non-metallic materials, while fiber lasers are ideal for cutting metals. Although all great laser engraver cutters work in a similar way, there are significant differences in the types of materials they can cut.

The laser beam follows a predetermined path, guided by computer numerical control (CNC) software. Laser cutting is widely used in various industries, including automotive, aerospace, electronics, signage, jewelry, furniture, and architectural design. It is used for cutting flat sheets, tubes, and 3D components, as well as laser engraving, etching, and laser marking surfaces.

Benefits of MDF Laser Cutters

Laser cutters are especially useful when working with thick wood or other dense materials like thick MDF boards. These laser cutters are preferred over other cutting tools and methods. Using laser cutters for MDF (Medium Density Fiberboard) materials has several benefits.

- High precision and accuracy: Laser cutters offer high precision and accuracy, allowing for intricate and detailed cuts on MDF. The focused laser power can create clean and precise edges, resulting in a professional and polished finish.

- Faster production times: Compared to traditional cutting methods, laser cutters are fast and efficient, making them suitable for large-scale production. With a laser cutter, you can complete your MDF projects in a fraction of the time it would take using other techniques.

- Minimal Material Waste: Laser cutting is a non-contact process, meaning there is no physical contact between the cutting tool and the material. This reduces the risk of material wastage and damage, resulting in minimal waste and maximizing material utilization.

- Customization and Personalization: Laser cutters allow for easy customization and personalization of MDF materials. Whether it’s laser engraving logos, text, or intricate designs, laser cutters can accurately etch or engrave them onto the MDF surface.

Top 5 MDF Laser Cutters

It’s important to note that the selection of the best MDF laser cutter depends on specific requirements, such as the desired cutting speed, working area size, and budget. Common laser machines used to laser cut MDF on the market are CO2 laser cutting machines, fiber laser cutting machines, diode laser cutters, such as the xtool d1 pro laser one, glowforge laser cutter and xtool p2 ortur laser master. It’s recommended to thoroughly research and compare different models to find the one laser model that best suits your needs.

CO2 Laser Cutting Machine

CO2 laser cutting machines have a longer wavelength that is better absorbed by non-metal materials, allowing for efficient cutting and engraving. They are commonly used in industries like woodworking and signage for cutting materials like MDF, plywood, acrylic, and more.

These laser machines contain a laser tube filled with various gasses, including CO2, nitrogen, and helium. When the current passes through the laser tube, laser beams are produced. Finally, the laser beams are directed toward the object for cutting or engraving.

Baison’s CO2 laser cutting machine is the best cutter for cutting MDF and comes with a high-power laser module by default. It is able to engrave surfaces with incredible accuracy, engraving and cutting without the use of sharp blades. It offers excellent laser engraving machines and cutting capabilities on MDF, with high-quality results. It is the best laser cutter and is often regarded as the best laser engraver.

A fiber laser machine is a capable laser cutter that can cut materials whether thinner materials or thicker materials. Fibre laser cutters are commonly used for cutting wood and medium-density fiberboard (MDF) due to their precision, speed, and efficiency. MDF is a composite wood product made from wood fibers and resin, and fiber lasers are well-suited for cutting this material. Here are some best laser cutters regarding fiber laser cutting of MDF.

Dual Platforms Sheet Metal & Tube Laser Cutting Machine

Baison Dual Platforms Sheet Metal & Tube Laser Cutting Machine is a high-quality laser cutter known for its precision and speed. It offers a large working area and powerful laser options, making it suitable for cutting MDF with great accuracy.

The laser cutter provides excellent cutting performance on MDF, along with advanced features like programmable Z-axis. You don’t have to manually move the laser head up or down to set the laser focus depending on the workpiece thickness. Whether you need a compact cutter for small-scale projects or a larger one for more extensive designs, this machine has got you covered.

Entry-level Sheet Metal Laser Cutting Machine

The low investment and operating costs of entry-level sheet metal cutting machines make them affordable even for small businesses or startups. Despite the low cost, you can still use it for professional-looking cuts.

The cutting speed of the powerful machine up to 140m/min maximum speed can guarantee your productivity. Because it is an entry-level machine, the operation is straightforward, and even novices can quickly learn to operate the machine.

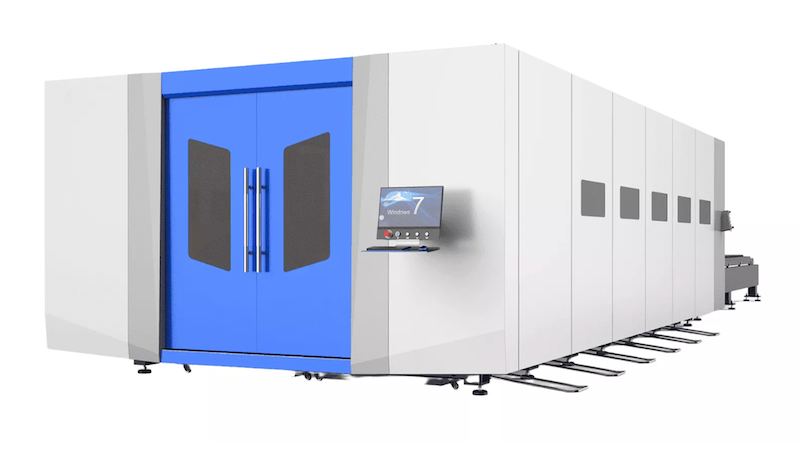

Superior Sheet Metal Laser Cutting Machine

Superior Sheet Metal Laser Cutting Machine is a reliable and user-friendly laser cutter that performs exceptionally well on MDF. It offers precise cutting and engraving capabilities, making it a popular choice for MDF projects.

The laser machine also has a touchscreen controller that enables you to control the laser head and set laser parameters like power and speed. It is higher efficiency of energy utilization spectrum laser, with an intelligent assistant system that reduces operating costs while increasing productivity – giving you the edge over your industry!

High Power Sheet Metal Laser Cutting Machine

Be a leader in your industry with our high-power sheet metal laser cutting machines fused with innovative, premium-grade technologies and fiber optic delivery. Overall, it is a very versatile laser cutter. Our machines are the best in China, allowing you to operate at full production, flexibility, and cost efficiency.

Make your MDF project run more smoothly by diminishing disturbances to operations with a straightforward setup, debugging, and performance levels.

Factors to Consider When Buying an MDF Laser Cutter

When purchasing a laser cutter for your MDF projects, there are several key factors to keep in mind. These considerations will help you find the best laser cutter that meets your specific needs and requirements.

Power and Performance

The laser machine, always equipped with a precise laser head and adjustable laser power, delivers a focused blue laser on spot for optimal cutting results, controlled by advanced laser software.

One of the most important factors to consider is the power of the laser cutter. Ensure that the machine you choose has sufficient power to handle your desired applications effectively. Different materials may require different power levels, so it’s crucial to select a laser cutter with adjustable parameters for optimal results.

Precision and Accuracy

For intricate MDF projects, precision and accuracy are paramount. Look for a laser cutter that offers high precision cutting capabilities, ensuring clean and precise edges on your workpieces. Consider the focal length of the machine, as it plays a vital role in achieving accurate cuts.

Ease of Use

Operating a laser cutter should be straightforward and user-friendly. Opt for a machine with an intuitive interface and easy-to-use controls. This will save you time and effort when setting up projects or making adjustments during operation. Time is money and if you plan to do a lot of laser cutting, you should consider a more powerful laser cutter which will save you a lot of working time.

Price and Value

The price of an MDF laser cutter can vary significantly depending on its features and capabilities. Consider your budget while also assessing the value offered by each option. Look for machines that provide a balance between affordability and quality to ensure you get the most bang for your buck.

By considering these factors—power and performance, precision and accuracy, ease of use, price as well as value—you can make an informed decision when buying an MDF laser cutter that best suits your project requirements. So go ahead, explore your options, and make a confident purchase to bring your laser cut MDF creations to life.

How MDF Laser Cutters Are Used in Crafting and Manufacturing

Laser cutters are an essential tool for cutting and engraving Medium Density Fiberboard (MDF) in crafting and manufacturing. With their precision and versatility, they offer numerous possibilities for creating unique designs and patterns on this popular material.

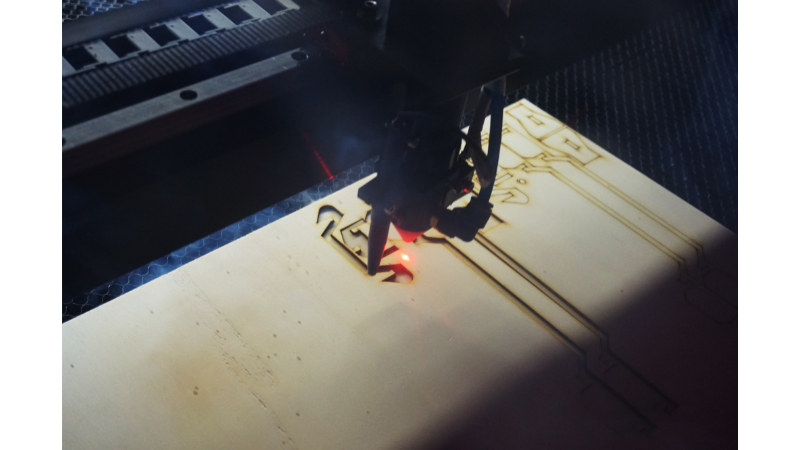

Cutting and Engraving MDF

MDF laser cutters excel in accurately cutting MDF sheets into desired shapes and sizes. Whether it’s intricate designs for crafts or precise components for manufacturing, the focused laser beam effortlessly slices through the MDF material, resulting in clean and precise cuts. The laser engraving process on MDF is also possible, adding depth and detail to the finished piece.

Laser cutting MDF can be more time and cost-effective compared to traditional cutting methods. The automated nature of laser cutting eliminates the need for complex setups, tool changes, or manual adjustments, reducing production time and costs associated with labor.

Creating Unique Designs and Patterns

MDF laser cutters enable crafters and manufacturers to unleash their creativity by producing one-of-a-kind designs. Whether it’s intricate filigree patterns or personalized engravings, laser cutters can bring any vision to life on MDF. This opens up a world of possibilities for personalized crafts, signage, decorative panels, and more. The laser’s precision allows for detailed laser engraving, enhancing the aesthetic appeal of the finished products.

MDF laser master enables the creation of unique designs and patterns that would be challenging or time-consuming to achieve using traditional cutting methods. The flexibility and versatility of laser cutting technology allow for the production of intricate and complex shapes, enabling designers and manufacturers to bring their creative ideas to life.

Safety Tips for Using MDF Laser Cutters

When using a laser cutter for MDF projects, it is crucial to prioritize safety. By following these tips, you can minimize risks and create a safe working environment.

- Wear appropriate protective gear: Put on safety glasses before operating the laser cutter. This will shield your eyes from any debris or sparks that may be produced during the cutting process.

- Properly ventilate the workspace: MDF materials can release fumes and smoke when cut with a laser. To avoid inhaling potentially harmful substances, ensure adequate ventilation in your workspace. Consider using an exhaust system or opening windows and doors to allow fresh air circulation.

- Ensure a stable setup: Place the laser cutter on a sturdy surface that can support its weight and vibrations. Keep it away from flammable materials like papers, fabrics, or chemicals that could ignite if exposed to heat or sparks.

- Maintain cleanliness: Regularly clean the lens of your laser cutter as dust and debris can accumulate over time, affecting its performance. Inspect the machine for any loose or damaged parts that need repair or replacement.

By adhering to these safety guidelines while using an MDF laser cutter, you can protect yourself from potential hazards and create your best projects with confidence. Remember: safety first!

Frequently Asked Questions (FAQs)

Can I use any laser cutter for MDF projects?

While most laser cutters can handle MDF materials, it’s important to check their specifications to ensure they are suitable for cutting through this particular material effectively.

How thick of an MDF sheet can be cut using a laser cutter?

The maximum thickness that a laser cutter can handle varies depending on its power and design. It is advisable to check the specifications of the laser cutter you are considering to determine its cutting capabilities.

Can I engrave designs on MDF using a laser cutter?

Yes, laser cutters can be used for both cutting and engraving on MDF materials. They offer great precision and allow for intricate designs to be etched onto the surface.

Conclusion

We’ve explored the exciting world of MDF laser cutters, highlighting their benefits, key features, and their invaluable role in crafting and manufacturing. Which feature of the MDF laser cutter do you find most appealing for your projects? Share your thoughts in the comments section. If you’re ready to bring your MDF projects to life with precision and efficiency, explore our range of high-quality laser cutters at Baison Laser.

Baison helps you with your MDF project!

Whether you’re in the woodworking industry or crafting intricate designs, an MDF laser cutter is your go-to companion. It offers unparalleled accuracy, making it ideal for creating detailed patterns and shapes on MDF surfaces. So why settle for anything less? Get your hands on the best MDF laser cutter today and experience the wonders it can bring to your projects.

Baison has extensive experience pro laser engraver and expertise in cutting projects. We have various laser machines that involve different laser engravers, you can get the best laser cutters and best laser engravers. If you have more specific questions or need further assistance, feel free to reach out to us or consult with our experts to get an application evaluation. Happy crafting!