Understanding Laser Tube Cutting

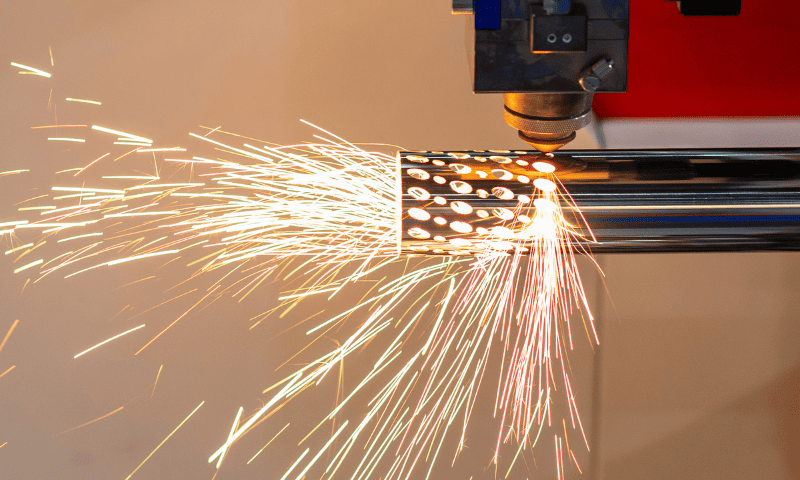

Have you ever wondered how metal tubes are precisely controlled and cut into complex shapes? The answer lies in laser tube cutting, a revolutionary method that combines high precision with maximum power and efficiency. By harnessing the high power of a high-intensity laser beam, this cutting process effortlessly slices through tube materials with remarkable accuracy.

The Basics of Laser Tube Cutting

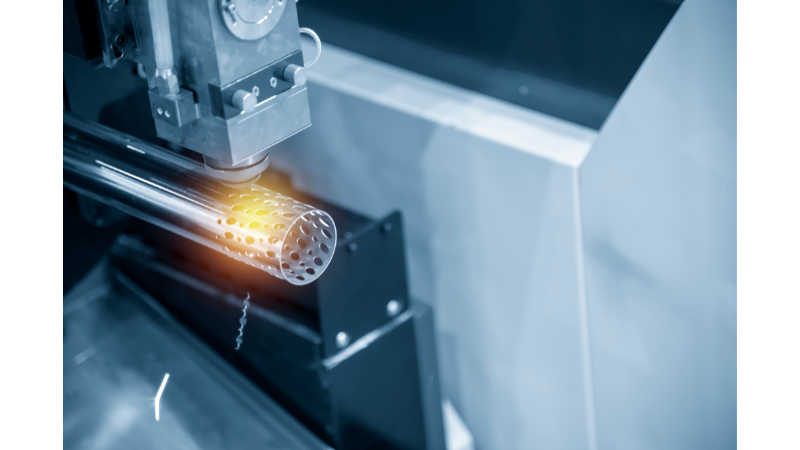

The working principle of laser tube cutting is simple yet effective: a laser cutting head that directs the focused laser beam onto the workpiece, melting or vaporizing the heat-affected zone along the desired path. Using a laser cutter machine, this allows for intricate designs and hole cutting with ease. Whether creating slits or crafting custom shapes, laser tube cutting unlocks endless possibilities in machining.

This advanced machining technology, including tube and fiber laser cutting machines, finds applications across various industries, including automotive, aerospace, and manufacturing. Its ability to produce clean cuts without distortion makes fiber laser and pipe-cutting machines indispensable for fabricating components used in critical systems.

With high power laser tube cutting at your disposal, achieving precise results has never been easier. Discover the potential of this game-changing technique and explore new horizons in metal fabrication.

Applications of Laser Tube Cutting

Laser tube cutting, using a CNC machine and a specialized laser cutter itself, is a versatile and efficient method for machining and shaping tubes of different materials, such as stainless steel tubes. Click here for details of the process. Here are some common applications of laser tube cutting.

Automotive Industry: Laser tube cutting is widely used in the automotive industry for fabricating exhaust systems, roll cages, chassis components, and structural parts. The high precision and speed of laser cutting ensure accurate and consistent cuts, resulting in high-quality components.

Furniture Manufacturing: Laser tube cutting is employed in the furniture industry for creating intricate and precise designs on metal tubes used in chair frames, table legs, and other decorative elements. It allows for customization and adds aesthetic value to the furniture pieces.

Construction and Architecture: Laser tube cutting is utilized in construction and architecture for fabricating structural components like beams, columns, and trusses. The ability to accurately cut complex shapes and angles makes laser cutting ideal for creating customized and lightweight structures.

Industrial Machinery: Laser tube cutting is integral in manufacturing machinery and equipment. It is used to fabricate tubes for conveyor systems, hydraulic and pneumatic systems, frames, and other structural components. The precise cuts and high-quality edges ensure the proper fit and functionality of the components.

Medical Equipment: Laser tube cutting is employed in the medical industry for manufacturing tubes used in surgical instruments, implants crystal lasers, and medical equipment. The cutting accuracy and cleanliness of laser cutting are crucial in ensuring the safety and effectiveness of these medical devices.

Aerospace and Aviation: Laser tube cutting is extensively used in the aerospace and aviation industries for fabricating tubes used in aircraft frames, landing gear, exhaust systems, and fluid distribution systems. The ability of fiber lasers to cut lightweight materials with high precision is essential in maintaining the structural integrity and performance of aircraft components.

Overall, laser tube cutting machines find applications in various industries where precision, speed, and versatility are required for processing and shaping tubes. Its ability to handle a wide range of materials and produce high-quality results makes it a preferred choice for many manufacturing processes. Laser tube cutting equipment is highly efficient and reliable in delivering accurate cuts and shapes.

Types of Laser Tube Cutting Machines

Laser tube cutting machines are essential tools in various industries for precise and efficient cutting of metal tubes. There are several types of fiber laser cutters and tube cutting machines available, each with its own unique features and capabilities. There are three primary types of laser cutters utilized in the manufacturing industry: CO2 Laser Cutters, Fiber Laser Cutting Machines, and Crystal Laser Cutters.

CO2 Laser Cutters

CO2 laser cutting machines use a carbon dioxide laser beam to cut through various materials, including tubes and pipes. These co2 laser using machines are high efficiency with low operating costs, commonly used for cutting non-metallic materials like acrylic, wood, and some metals. They are suitable for thin-walled tubes and materials with low reflectivity.

Compared to other thermal cutting methods, CO2 laser cutting machines are known for their versatility and ability to provide high-quality cuts with good edge quality. The CNC laser cutting part is easy to maintain and requires almost no consumables. They are essential equipment in gas processing facilities.

Fiber Laser Cutters

Fiber laser cutters employ a fiber optic cable to transmit a high-powered fiber laser beam to cut through tubes made of metal and other materials. The fiber laser machine can be adapted to different material thicknesses, cutting materials like thin materials, thick materials and even thicker materials like sheet metal. At the same time, the oxide film of oxygen on the surface of the pipe contributes to the absorption of the light beam by the reflective material. These machines are known for their high cutting speeds, excellent precision, and ability to cut a wide range of tube diameters and material thicknesses.

Fiber laser cutters are perfect machines for cutting reflective metals like stainless steel, aluminum, and copper. They are capable of handling thick-walled tubes and various material thicknesses. These machines are commonly used in industries such as automotive, aerospace industry, and manufacturing for processing equipment.

Crystal Laser Cutters

Crystal laser cutters, also known as Nd: YAG laser cutters, use a crystal laser medium to generate a concentrated beam for cutting tubes. These machines are primarily used for cutting thick-walled tubes made of metals like steel and stainless steel. Here is the demonstration of the laser cutting system for tube specimen. Crystal laser cutters are known for their ability to cut through thick materials, high peak power and their high beam quality. They are particularly effective for intricate designs on round tubes with varying diameters.

These different types of laser tube cutting machines provide professionals with versatile options to meet their specific needs. Whether you require precise cuts on non-metallic materials or want to achieve superior results on reflective metals, there is a suitable laser cutter available.

By utilizing advanced laser technology instead of traditional cutting methods, these machines offer numerous advantages compared to other machines. They ensure clean cuts without burrs or deformation while reducing material waste. Their CNC capabilities allow for automated machining processes that enhance productivity.

Factors to Consider when Choosing a Laser Tube Cutting Machine

When selecting a laser tube cutting machine, there are several important factors to consider.

Material Type

Different laser tube cutting machines are designed to cut specific types of materials, including pipe and processing. Consider the materials you will be working with, such as metal, plastic, or wood, and ensure that the first cutting machine that you choose is compatible with those materials.

Tube Dimensions

Consider the diameter, length, and wall thickness of the tubes you will be cutting with a laser pipe cutter. Ensure that the machine you choose for processing can accommodate the size cutting thickness, and dimensions of your tubes. Some machines may have limitations on the maximum and minimum tube sizes they can handle due to the laser generator and laser power.

Cutting Speed and Precision

Evaluate the required cutting speed and precision for your applications using tube laser cutters. Different machines, such as laser tube cutters, have varying cutting speeds and levels of precision. Consider the desired production rate and the level of accuracy needed for your specific projects with a professional laser tube. Look for features like high-speed cutting, accurate beam and control system, and advanced processing technology in a laser generator.

Cost and Maintenance

Consider your budget and the long-term costs associated with tube laser cutting machines. Evaluate the initial purchase cost of the fiber laser cutting machine and system, as well as ongoing maintenance costs and operational costs. The fiber laser cutting machine has lower operating costs and delivers higher cutting speeds than the CO2 laser cutting equipment. Additionally, consider the availability and cost of spare parts in the cutting process, as well as the machine’s reliability and durability in achieving cutting efficiency.

When choosing a laser tube cutting machine, it is crucial to consider factors such as material type compatibility, tube dimensions, laser cutting speeds, maximum thickness and output power. By carefully evaluating these aspects, you can ensure that your chosen equipment meets your specific processing needs.

Whether it’s working with different types of materials like metal or achieving precise cuts on pipes at high speeds, finding the right machine will enhance your production line’s efficiency. Keep in mind that each workpiece, such as a metal pipe, may have unique processing requirements based on its thickness and composition. Therefore, select a machine capable of adjusting light focus and lens settings accordingly. Ultimately, investing in a suitable machine will enable you to achieve optimal processing quality while meeting your production goals efficiently.

Benefits of Laser Tube Cutting

Laser tube cutting using a machine is a popular choice for various industries due to its several benefits. The processing technique involves using a laser to cut through metal pipes efficiently. Here are some key advantages of laser tube cutting.

Precision and Quality

Laser tube cutting provides exceptional precision and quality in cutting metal pipes. With advanced laser technology, these machines can accurately process and cut through various materials, ensuring clean and precise cuts every time. The laser beam is highly focused, allowing for precise and accurate cuts, even on intricate designs or complex tube shapes. This level of precision ensures consistent and high-quality results, reducing the need for additional finishing processes and speeding up the manufacturing process.

Speed and Efficiency

Laser tube cutting machines excel in delivering quick and efficient results. The use of fiber laser technology enables these machines to cut through tubes at impressive speeds, significantly increasing efficiency in your production process and reducing production time. This increased efficiency allows for higher productivity levels, enabling businesses to meet tight deadlines and fulfill customer demands promptly.

Versatility

One of the key advantages of laser tube cutting is its versatility. These machines can handle a wide range of materials, including metals like steel, aluminum, copper, and more. Whether you need to cut round tubes, square tubes, or even irregularly shaped pipes, a laser tube cutter can accommodate various dimensions and shapes with ease. This versatility makes it an ideal choice for industries such as automotive manufacturing, construction, furniture production, and many others. Additionally, laser tube cutting machines can handle different tube shapes and sizes, providing flexibility in design options.

Overall, laser tube cutting with a machine offers numerous advantages in terms of precision, speed, versatility, and efficiency in processing metal. These benefits make it an attractive choice for industries seeking high-quality and efficient cutting solutions using a pipe.

Why Choose Baison Laser

So why should you choose Baison Laser for your laser tube cutting needs? Let’s recap the key points. Baison Laser is one of the most excellent laser cutting machine manufacturers with outstanding laser cutting technology, that offers top-of-the-line laser cutting machines, for precise and efficient laser tube cutting.

With our advanced technology, we can process a wide range of metal tubes with ease. Trust Baison Laser can help you make an informed decision about the right laser cutting machine for all your pipe cutting requirements.

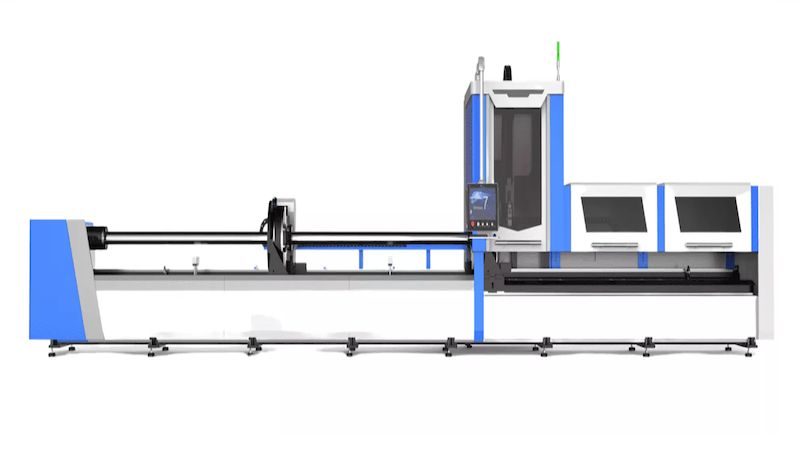

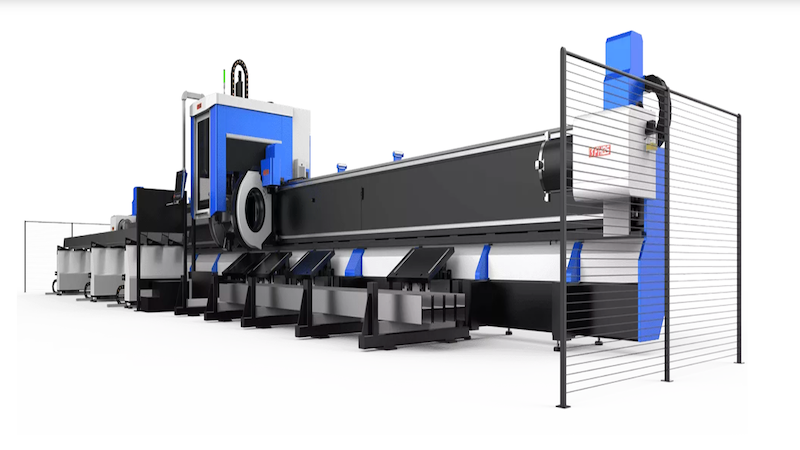

Our Cutting-edge Machines

Baison Laser offers various types of laser tube cutting machines, involves fiber laser cutting machines and CO2 laser cutting machines, ensuring that you can find the perfect fit for your specific requirements. Baison Laser offers cutting-edge laser tube cutting machines that are built with advanced technology and high-quality components. Our machines are designed to deliver precise and efficient cutting results, ensuring superior quality and productivity.

We continuously invest in research and development to stay at the forefront of laser cutting technology. Whether you need a compact laser machine used for small-scale projects or a high-powered one for heavy-duty industrial applications, Baison Laser has got you covered.

Exceptional After-sales Service

At Baison Laser, we prioritize customer satisfaction and provide excellent customer service for your cutting process needs. Our team of experienced technicians and engineers is dedicated to assisting you with any technical support or maintenance needs related to your machine. We offer prompt response times, timely repairs, and spare parts availability to maximize laser cutting machine efficiency and minimize downtime, keeping your operations running smoothly.

Custom Solutions for Your Needs

We understand that every customer has unique requirements and challenges. Baison Laser offers custom solutions tailored to your specific needs. Our team works closely with you to understand your application, material, and production requirements and provides personalized recommendations to ensure optimal performance and efficiency. With Baison Laser’s machines, you can experience these benefits firsthand.

In conclusion, by choosing Baison Laser as your provider of laser tube cutting machines, you can expect exceptional quality, reliability, and efficiency in your operations. For most manufacturers, buying an industrial laser cutting machine is not just the initial price you pay, but the fact that the purchase will have a great impact on the entire manufacturing process. Don’t settle for subpar or wrong equipment.

You may even consider buying a new laser cutting machine accompany material handling automatic. The purchase of such a machine can be an overwhelming task. However, you can take advantage of Baison Laser’s expertise and state-of-the-art technology to elevate your production volume and stay ahead in the industry. We are dedicated to helping you achieve your laser tube cutting goals efficiently and effectively.

FAQs

Q: Can I use a laser tube cutting machine for different materials?

Yes! Baison Laser’s machines are versatile and can handle various materials such as stainless steel, carbon steel, aluminum alloy, copper tubes, and more. Our machines are designed for efficient pipe cutting and processing, ensuring high cutting efficiency and speed.

Q: Are the laser tube cutting machines easy to operate?

Absolutely! Baison Laser designs our pipe cutting machines with user-friendly interfaces and intuitive controls, ensuring efficient processing and cutting speed. This makes them accessible even for operators with minimal experience in pipe cutting.

Q: Can I expect fast production speeds with Baison Laser’s machines?

Yes, Baison Laser’s high quality machines are designed for efficiency edge quality and speed. They can deliver swift cutting processes without compromising on precision or quality.

Conclusion

We’ve walked through the intriguing landscape of laser tube cutting, breaking down the process, machines, selection criteria, and the unmatched benefits it offers. What aspects of a laser tube cutting machine interest you most for your project? Share your thoughts in the comments below. If you’re ready to take your manufacturing to the next level with our laser tube cutting machines, browse through Baison Laser’s range of state-of-the-art machinery and services. Contact us to bring back the perfect laser equipment now!