In this post, we will explain how the fiber laser cleaning machine can help your business and help you to choose the right fiber laser cleaners for your needs. We will also ensure that you know about the cost considerations and the training needed to utilize this tool for your purposes.

Getting a fiber laser cleaning machine can change and improve every aspect of your business, and you should consider this an essential upgrade for businesses in many different industries.

What Are Fiber Laser Cleaning Machines?

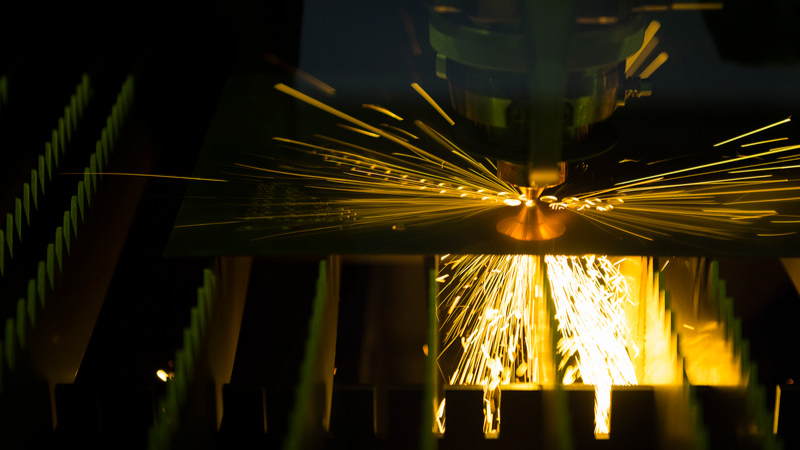

Fiber laser cutting machines use a laser beam with high energy density to remove rust and oxide from layers of metal and ceramic surfaces. These laser cleaning machines are common in the high-end manufacturing industry and the aerospace industry for removing contaminants from metal surfaces without causing damage to the surface below the oxide and rust.

A chemical cleaning machine is used in the manufacturing industry to clean and sanitize various pieces of equipment and machinery. These machines are commonly used in food and beverage production, pharmaceutical manufacturing, and other industries where strict hygiene and sanitation standards are necessary.

Fiber laser cleaning and chemical cleaning have their own benefits. You can see the instruction in the article “Chemical Cleaning vs. Fiber Laser Cleaning: Which is Better?“.

No force, chemical reaction, or thermal effect is necessary to clean metals with this kind of laser cleaning machine. This technology has been around since the 1960s, but in the past 20 years, interest in this technology has increased exponentially. Today, this is one of the most reliable ways to clean steel, aluminum, titanium, glass, and composite materials.

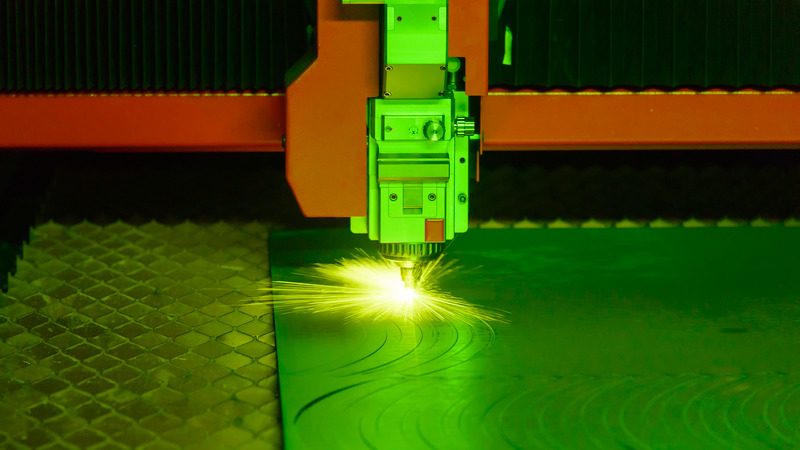

Fiber laser cleaning machines offer benefits like fine-tuned work, high laser safety, and easy fume removal during work processes. The mechanical components of this kind of laser beam are easy to include in assembly line environments or can be accessed through the use of handheld tools as well. It is easy to operate these machines remotely, making them ultra-safe and highly effective compared to other cleaning machines.

Being freed from the need for a blast medium helps to make the work area clean and safe, and it also saves a lot of money as compared to traditional cleaning methods. There are many reasons that fiber laser cleaning is the future, and an increasing number of companies are switching to the use of this fantastic tool to avoid all the common pitfalls of more traditional methods of carrying out these tasks.

How Do Fiber Laser Cleaning Machines Work?

There are different types of laser cleaning machines on the market today. Fiber laser cleaning machines are among some of the newer technology to have been pushed out to consumers in various industrial markets. These devices use a fiber laser beam to remove contaminants from surfaces. This kind of laser utilizes a high-powered beam of light that quickly cleans surfaces without causing damage to them.

The key to the power and speed of the fiber laser cleaning process is that a lens is used to increase the heat of the cleaning process. This vaporizes the materials that must be removed from various surfaces. Fiber laser technology offers access to one of the best laser cleaning technology options today. There are some key perks to choosing this kind of laser cleaning machine for your business:

- Faster cleaning

- More efficient cleaning process

- Easy to reach difficult and small areas that would not be accessible with other cleaning tools

- Highly effective at cleaning many different kinds of surfaces

- Uses high-energy pulses that vaporize contaminants readily

- Very safe to use

- Lower cost than other solutions in this space

- Does not require consumables

- Very effective at safely cleaning delicate surfaces

- Does not create pollution

The safety and cleanliness of laser cleaning machines are two of their key benefits, but they are also more cost-effective and easier to operate than other systems. Being able to improve the turnaround time of various cleaning jobs while also improving safety is a huge benefit for many industries. Best of all, you can use these lasers for various tasks and work on many different kinds of materials.

Factors to Consider When Choosing a Fiber Laser Cleaning Machine

There are some things that you will need to consider when you are choosing a fiber laser cleaning machine. These considerations can impact the choice of laser cleaning technology you make in important ways, and you should be certain that you are thinking about all of them when shopping through your options.

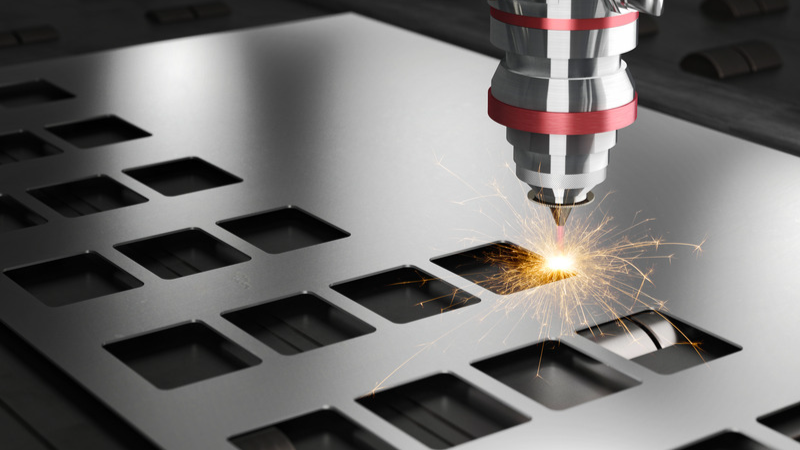

1. Pick the Right Power Category

The laser power category of your laser cutting machine can greatly impact its use. Most machines come in 3 power categories. The specifications of the power levels for each kind of machine can vary somewhat per manufacturer, but you will need to know if you actually need the top level of laser beam power for your daily tasks. The more power, the faster the cleaning process, but some jobs require a lower-power laser. 20W to 100W is a better power for light rust removal and for saving costs when using the machine.

2. Mobility/Configuration

There are three major options that you can pick from for the mobility and setup of the fiber laser cleaning machine that you invest in. Handheld units are really common and they only weigh a few kilos. These machines are ideal for nooks and crannies and for cleaning smaller items that don’t need to be carried through a conveyer belt-style cleaning process.

A machine-fixed laser cleaning system is made to be used with conveyor belts for maintenance and repair-style jobs. The fixed machine cleans for a portion of the time that the item is on the belt before it heads off to be treated with other processes. This is a very efficient option for larger jobs. There is also a cabinet-style system that offers an enclosure where the item can be placed, and someone can use the laser remotely to clean the surfaces of imperfections and materials that need to be removed.

3. Price

The price of the chosen laser cleaning system can be a big factor in your choice between different units. The size, power, and technology used in the laser cleaner can change the price significantly. The basic range that you should expect to pay would be anywhere from $10,000-$20,000. Exact specifications for your unique needs can also alter the price, so getting a complete quote is key.

Advantages of Fiber Laser Cleaning Machines

Adding a fiber laser cleaning machine to your business assets has many advantages. You will need to consider the following benefits of fiber lasers in your business environment:

- Fiber lasers work largely through an automated cleaning process that is easily done remotely.

- Easy to integrate with existing applications and processes.

- Fiber lasers offer a chemical-free cleaning method that is safe for use even in the food and medicine niche.

- The cleaning process does not change the chemical composition of the item being cleaned.

- There is no need to rub out further, remove, or clean surfaces once fiber lasers have completed their work.

- The cleaning process is of the highest quality.

- Reduces manpower needed to clean surfaces and repair items.

- Spot cleaning is easy and highly effective with fiber lasers.

- Corners and nooks of items are easy to access with laser cleaning technology.

- It is simple to train people to make use of fiber lasers.

Applications of Fiber Laser Cleaning Machines

The fiber laser cleaning machine can be used for a variety of different kinds of jobs and tasks. Many people are unaware of what laser cleaning solutions can do for them. Knowing about the wide array of options for the use of this kind of machine can make it that much more obvious that you need one in your business.

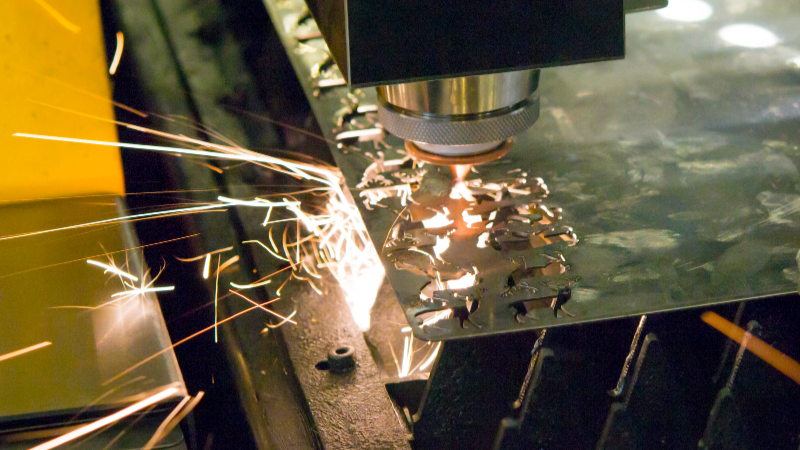

Surface Cleaning

Surface cleaning is one of the most common uses of this kind of cleaning machine. Cleaning activities might include paint removal, metal restoration, rust and oxide removal, imperfections on the surface of items, degreasing, and more. Cleaning of rust from a metal surface is the most common use for this kind of machine since rust and oxide are very difficult to remove using other processes.

Laser spot repair of a metal surface is another application that falls into the surface cleaning category, and this is one of the biggest time sinks for those who repair metal items that are used in various industries.

When repairing or performing maintenance on metal items of various kinds, removal of rust can be quite time-intensive. The laser cleaning machine will take care of these tasks easily and without requiring much hands-on labor.

Degreasing is also quite time-intensive when completed using old-school methods. Being able to readily remove grease and other contaminants without needing a team of people to work on these jobs can benefit any business engaged in this kind of work. Plus, the possible cleaning with a laser cleaning machine is far superior to what can be accomplished using other traditional methods.

Cleaning Molds

Cleaning molds of impurities can be a very time-consuming task that wastes manpower and adds cost to any job in this space. These are usually also jobs that require a lot of hand labor to get into small nooks and crannies that are not accessible with other cleaning methods. This is one of the best reasons to invest in a fiber laser cleaning machine if you have a business in the food or medical industries.

Rubber molds are the most challenging items in this category to clean due to the nature of the material itself and the relative fragility of rubber when exposed to other forms of the cleaning process. Rubber has absorption properties and cannot be treated like other materials when it needs cleaning and sanitizing.

A laser cleaning machine can clean out even the small spaces in rubber molds and traditional mold types, making it easy for your business to keep on top of this previously time-consuming task.

Being sure that things like rubber molds will not be damaged is key when working in the food and medical industries. Access to a laser cleaning machine can make all the difference when performing maintenance on these items.

Cleaning Welds

Welding often leaves surface deposits that need to be removed before a product can be sold or used again. Laser cleaning is ideal for this kind of process because these items would normally have been cleaned and perfected by hand. Since laser cleaning machines can safely be used on all kinds of metal alloys, removing imperfections related to a welding job is a snap.

Best of all, the weld strength will not be compromised through the cleaning process. Ensuring that you have not damaged a welded connection or repair just by cleaning it after the repair is complete can offer peace of mind and improved product quality.

Cost Considerations

There are various reasons that the initial investment in your fiber laser cutting machine will offer you great ROI over the long term. These machines can be used for more than 10 years with minimal maintenance. This can save you hours of time and keep the assembly line up and running without breaks, as is common with other kinds of cleaning machines.

Laser cleaning is also a green technology that does not require additives or chemicals to clean surfaces. This is a big cost saving for most businesses compared to blasting machines or other cleaning processes requiring some form of cleaning medium.

Some laser cleaning machines can also qualify for government subsidies to help offset costs. There are various clean manufacturing tax credits that you might qualify for just for using a laser cleaning machine in place of older-style cleaning methods.

Perhaps best of all, you do not have to allow costs to dispose of toxic wastes leftover from the cleaning process with a laser solution. This can be one of the most onerous and frustrating parts of providing cleaning services in your business since these wastes can never be used for anything else.

Training and Certification

Many companies that sell laser cleaning machines offer training in the use of these machines to employees and owners. This training often involves some classroom learning hours and then hands-on demonstrations of the machines that the class is teaching about. At the end of the class, there is often a certificate that is awarded to those who have completed the training.

The regulatory organization that certifies trained users of this technology is the Board of Laser Safety. Employees who operate the machines should have a certified laser safety officer certificate to operate the machines during daily work tasks. OSHA governs some of the rules and regulations about this kind of operator job, and you should verify what is required for your area of operations when training and certifying employees for the use of this tool.

Maintenance and Upkeep of Fiber Laser Cleaning Machines

Routine maintenance is all that is required for this kind of cleaning machine. Annual inspections are recommended, but often nothing is needed for these machines until they have operated for about 10 years.

Obviously, performance changes might indicate that something will need to be repaired. Still, since there is no medium being used and the heat produced during cleaning is very minimal, slowdowns and repairs for the laser cleaner are quite rare.

Maintenance of other cleaning machine types can be required a few times a year and can end up being quite costly. This is one of the primary benefits of the selection of this cleaning machine as compared to other options on the market today. Being able to keep your assembly line up and running without delays and being sure that your laser cleaning machine will work every time it is needed can offer a lot of peace of mind to business owners.

Conclusion

Fiber laser cleaning machines from Baison Laser are becoming an increasingly important part of business operations for many companies. Saving money and time and saving the environment can be great arguments for adding this machine to your assembly line or even for small and delicate jobs you have completed by hand.

This machine will pay you back for the purchase price by saving you time, speeding up the processing of various jobs, and remaining operational for years without anything but routine maintenance.

If you are tired of spending money on expensive blast mediums, sick of paying for toxic waste removal, and tired of paying for handwork to be done despite these other expenses, then an upgrade to a laser cleaning machine is the right answer. Being able to produce high-quality work safely and with amazing time savings is well worth the switch to this kind of cleaning machine.

If you are ready to upgrade your business and improve many of your work processes, you need to ask for a quote today!