Understanding Laser Cutting Machine

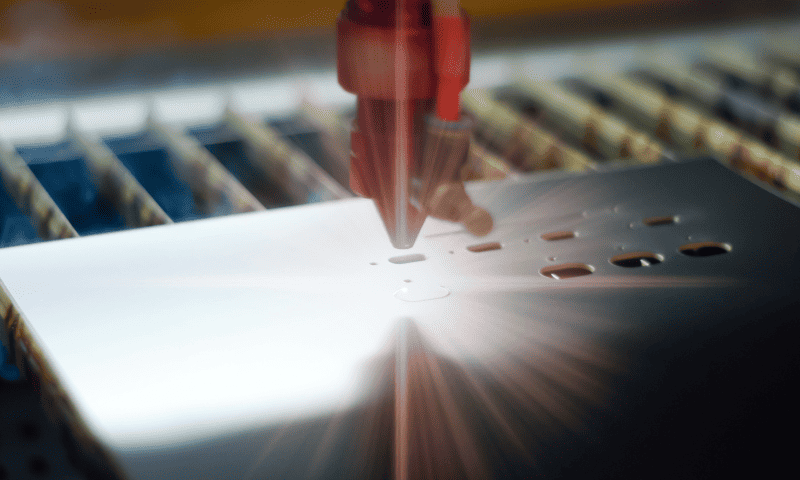

A laser cutting machine is a type of technology that uses a laser beam to cut through various materials with precision. It works by directing the laser beam onto the material, which then melts, burns, or vaporizes the material, resulting in clean and accurate cuts.

Advantages of Laser Cutting Machine

- Precision: Laser cutting machines offer exceptional accuracy, allowing for intricate and detailed cuts.

- Versatility: These CNC machines can cut through a wide range of materials, including metal, wood, acrylic, and more.

- Efficiency: The laser cutting process is fast and efficient, enabling quicker turnaround times for projects.

- Clean Cuts: The laser beam produces clean and smooth cuts without the need for additional finishing processes.

- Minimal Waste: With precise cutting capabilities, laser cutters minimize material waste, saving costs in the long run.

Application of Laser Cutting Machine

- Manufacturing Industry: Laser cutters are widely used in manufacturing processes such as sheet metal fabrication and automotive production.

- Signage and Advertising: These machines are employed to create custom signs, lettering, and logos with precision and high speeds.

- Architecture and Design: Architects utilize the laser cutting service to bring their intricate designs to life.

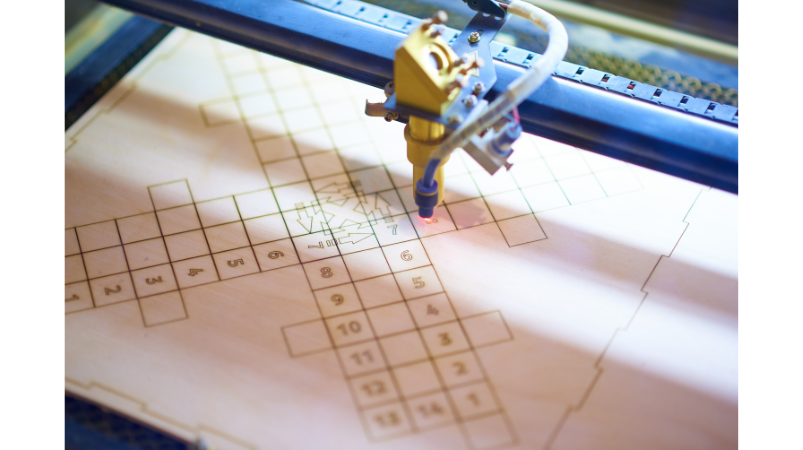

- Arts and Crafts: Artists benefit from laser cutting services to create unique shapes and patterns on various materials.

In summary, a laser cutter is a versatile technology that offers precise and efficient cutting capabilities, making it suitable for a wide range of applications across various industries.

Understanding Laser Cutting Machine Costs and Usage Charges

The cost of laser cutting equipment can vary depending on various factors such as the power of the laser, the size of the machine, the brand, and additional features. Generally, laser cutters can range from a few thousand dollars for smaller, entry-level machines to several hundred thousand dollars for larger, high-powered industrial machines.

Factors that impact the overall costs of operating a laser cutting machine should also be considered. These include:

- Material waste: Minimizing material waste through efficient nesting techniques can help reduce material costs.

- Maintenance and repairs: Regular maintenance ensures optimal performance and longevity of the machine, preventing costly breakdowns.

- Energy consumption: Laser cutting machines require electricity to operate, so being mindful of energy usage can lead to significant savings.

When considering the costs and usage charges of a laser cutter, it’s important to evaluate the potential return on investment. Laser cutting machines can significantly increase productivity, reduce material wastage, and improve the quality of cuts, which can result in total cost savings and increased profitability in the long run.

It’s recommended to thoroughly research and compare different laser cutting machine options, considering factors such as the machine’s capabilities, reliability, and service and support offered by the manufacturer. Additionally, it’s advisable to consult with industry professionals who have experience with laser cutters to better understand the laser cutting costs and usage charges specific to your needs and requirements.

How Does a Laser Cutting Machine Save Costs?

The costs saved by using a laser cutting machine can be significant, and many manufacturers have found that the initial investment in a laser cutting machine can be quickly recouped through the laser cutting cost savings achieved.

Optimizing Efficiency and Cost Savings through Grouping Projects

By grouping similar projects together, you can maximize efficiency and reduce laser cutting costs. Batch processing is a key strategy that can lead to significant time and laser cutting cost savings. Here are some strategies to optimize project grouping for improved efficiency and cost-effectiveness.

- Identify Similar Projects: Start by categorizing your projects based on their design files or specifications. Look for commonalities such as material type, thickness laser cutting, or complexity.

- Batch Processing: Once you have identified similar projects, batch them together for processing. This allows the laser cutting machine to work continuously without the need for frequent setup changes, resulting in time and money savings.

- Reduced Operational Costs: Grouping projects reduces the operational cost of laser cutting by minimizing machine downtime and maximizing productivity. With batch processing, you can complete multiple projects in one continuous run, reducing the number of times the machine needs to be started or stopped.

- Lower Service Costs: By optimizing project grouping, you can also minimize service costs associated with maintenance and repairs. The laser cutting machine operates more efficiently when running continuously, reducing wear and tear on components.

Lower Lead Times: Time and Cost Savings with Laser Cutting

Shorter lead times in laser cutting result in faster project completion and reduced laser cutting costs. With laser cutting technology, the cutting time is significantly reduced compared to traditional methods, allowing for quicker turnaround times and increased efficiency in project timelines.

High precision is a significant factor. Laser cutting machines offer exceptional accuracy, ensuring that every cut is made with utmost precision. This eliminates the need for additional finishing or rework, saving both time and money.

Sheet metal and stainless steel are commonly used materials in various industries. Laser cutting provides a cost-effective solution for working with these materials by minimizing waste and maximizing material utilization. By optimizing the use of raw materials, laser cutting helps reduce overall production costs.

Efficient planning and production processes play a crucial role in minimizing lead times further. By streamlining workflows and implementing effective scheduling strategies, projects can be completed more quickly without compromising quality. This not only can save time but also reduces operational expenses.

By harnessing the advantages of laser cutting technology, many businesses can achieve significant laser cutting cost savings throughout their projects while delivering high-quality results.

Features of Different Laser Cutting Machines

For a modern manufacturer who wants to attain a competitive edge in the market, our laser pipe-cutting machines are the best option to speed up their own fabrication processes. Let’s explore the features of different types of laser cutting machines available in Baison.

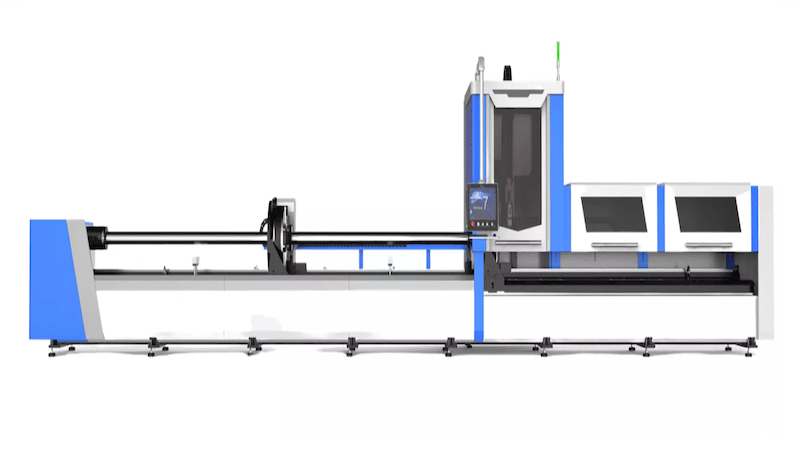

All-Round-Tube Laser Cutting Machine

The all-around tube laser cutting machine uses a solid-state laser to decrease the processing time and increase the production volume.

- It provides more flexible cutting through a dynamic combination of chuck and laser head.

- It ensures accuracy in cutting through a pneumatic chuck.

- The three-chuck design produces minimum waste of material.

Superior Sheet Metal Laser Cutting Machine

- Equipped with an advanced cutting head for more precise cutting.

- Cut through various thin, thick, or complex metal materials easily.

- Cut through thick sheets easily without worrying about energy expenditure.

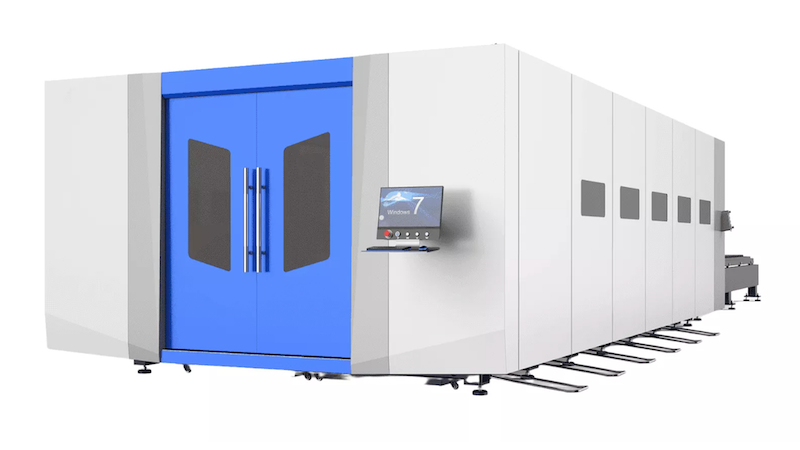

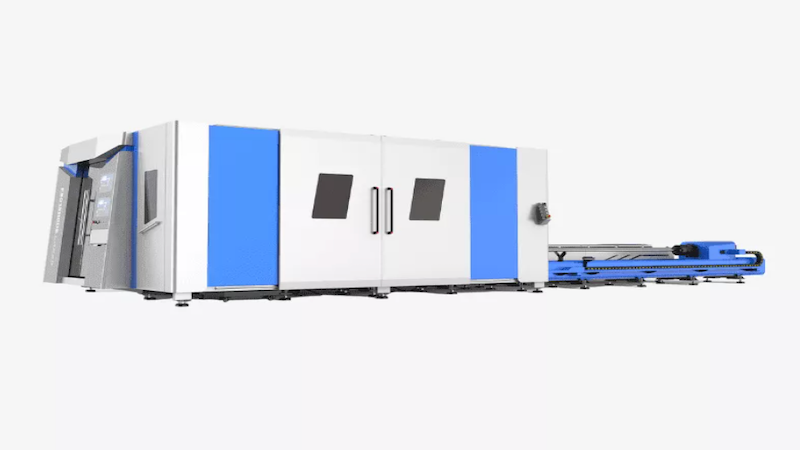

Dual Platforms Sheet Metal & Tube Laser Cutting Machine

- More accurate as it allows the laser cutting head to cut without changing the z-axis.

- A fully enclosed design with an advanced ventilation system makes it cleaner.

- Energy consumption can be reduced by 15-20% compared to similar laser cut products.

CO2 Laser Cutting Machines

- Handle complex jobs with ease.

- Operates in near silence. No air pollution

- Increase productivity. Process orders quicker.

By comparing these various types of laser cutting machines, you can choose the one that best suits your project requirements. Whether you need to cut non-metal materials or work with high-speed metal cutting, there is high quality equipment tailored to your needs.

Utilizing CNC technology, these laser cutting machines offer area engraving capabilities. This means you can easily mark or engrave specific areas on your materials without affecting the rest. This feature allows for greater customization and accuracy in your projects.

FAQs

Can I use a laser cutting machine for both small and large-scale projects?

Yes, laser cutting machines can be used for projects of varying scales. They offer flexibility in accommodating different project sizes, making them suitable for both small prototypes and large-scale production runs.

How do I ensure the quality of laser-cut parts?

Ensuring the quality of laser-cut parts involves regular maintenance of the machine, proper calibration, and adherence to recommended settings. Working with experienced operators and following best practices will help maintain high-quality output.

What if I don’t have enough money to buy a laser cutter?

You can outsource laser cutting projects eliminating the need to spend months or even years mastering laser cutting and CNC machines, as well as the associated difficulties and expenditures.

What types of materials can be cut using a laser cutter?

Laser cutting machines can cut a wide range of materials, including metals (such as steel and aluminum), wood, acrylics, textiles, plastics, and more. However, it is important to check the compatibility of specific materials with your chosen machine.

Conclusion

In the intricate dance of project management and execution, every penny counts. Laser cutting machines, as we’ve seen, are more than just state-of-the-art technology; they’re an investment in efficiency and precision. By reducing waste, increasing accuracy, and accelerating production times, these machines not only elevate the quality of your work but also offer tangible financial benefits. In the realm of cost-effective solutions, laser cutting stands out as a game-changer.

Elevate Precision: Choose Baison Laser!

In conclusion, laser cutting machines offer significant cost-saving benefits for your projects. To fully capitalize on the cost-saving potential of laser cutting machines, it is essential to take action to get a Baison application evaluation now. With up-to-date technology and energy-efficient qualities, our machines and components can be used across various manufacturing processes and industries. Baison is proud to offer laser cutting services and execute custom work and also offers laser welding, laser cleaning, and laser marking machines.