Tube manufacturing is an essential part of many industrial sectors, and with the advancement of technology and industries, traditional methods such as gas welding cutting, saw cutting, and roller extrusion are no longer efficient or practical for mass production.

Laser cutting offers many benefits for manufacturers who want faster tube production processes, higher cutting efficiency, reduced production costs, and lower labor intensity. Hence the laser tube-cutting process has a crucial role in the industrial business model, particularly in pipeline construction.

In this blog post, we’ll take a deeper look into how laser-cutting technology offers numerous benefits to the pipeline construction industry by improving efficiency, reducing costs, and enhancing productivity.

What Is Laser Cutting?

Laser cutting is a process that uses an intensely focused laser beam to melt and vaporize various materials, cutting or etching them into the desired shapes and sizes. A continuous cut is made by the laser cutter under the control of a Computer Numerical Control (CNC) system, allowing for a precise, intricate, and efficient manufacturing process.

Although this cutting process is mainly used in the manufacturing industry, it is beginning to have applications in others, including automotive, aerospace, medical, oil and gas, shipbuilding, etc.

How Does a Laser Cutter Work?

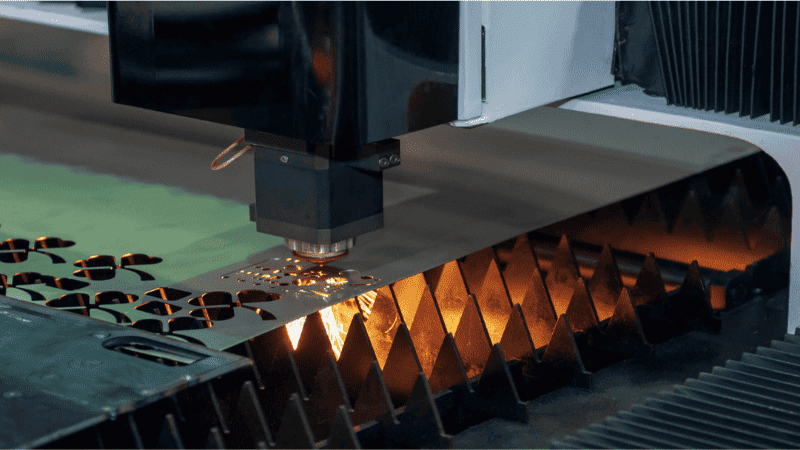

The laser cutter uses a thermal process to concentrate a powerful laser beam on the work material to begin the cutting process. The laser beam is controlled using a CNC system that automatically translates the desired design or cut path and guides the laser movement through that path.

The laser beam originates from a CO2, Neodymium, or fiber resonator, which sends the beam through a series of lenses and mirrors to be reflected within the cutting head into a thin, intense point of energy.

The CNC moves the laser beam according to the programmed design, while the assist gas, such as nitrogen or oxygen, blows away molten material from the work area from cleaner cuts.

What Are the Three Products of Laser Tube Cutting Machines?

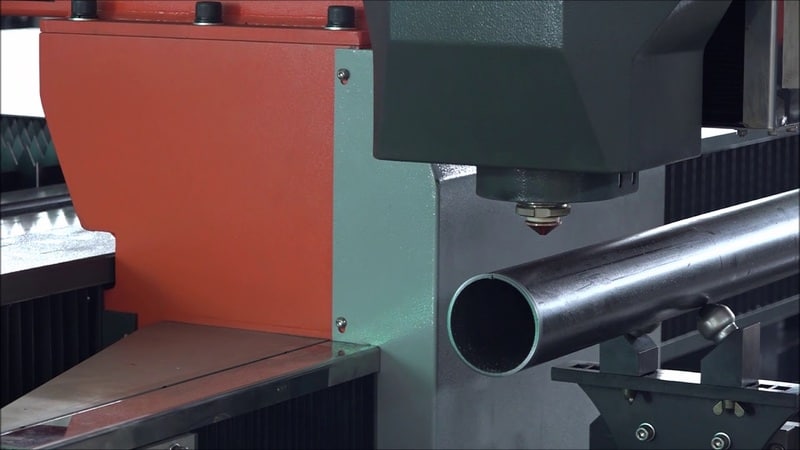

Small Tube Laser Cutting Machine

These laser cutters are specialized laser machines designed solely for cutting tubes with small diameters with high precision. These machines are common in industries where small-diameter tubes are essential components, such as automotive, medical, and electronic.

They use laser technology to cut through various materials, including metal, plastic, or glass, offering high accuracy, efficiency, and shorter processing time for cutting and processing small-diameter tubes in a compact package.

All-round Tube Laser Cutting Machine

The all-around tube laser cutter has a wider range of tube applications as it can be used to process metal materials of various sizes and thicknesses from 10 to 220mm diameters.

This laser machine is easy to use as it doesn’t require any special setup or operation, providing optimal tube laser cutting services that allow for accuracy, speed, flexibility, and zero material wastage in your manufacturing processes.

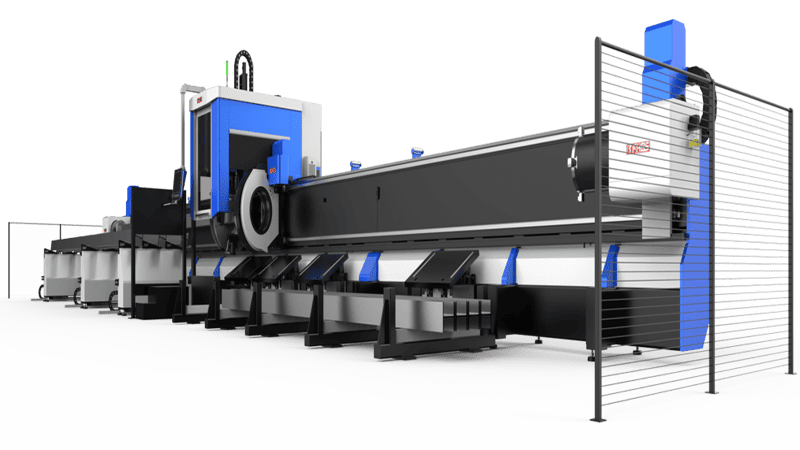

Heavy Duty Tube Laser Cutting Machine

The heavy-duty laser cutter is a large, powerful, industrial-grade machine designed for cutting and processing large and heavy tubes with diameters of up to 500 mm and lengths of 1200mm using a fully automated process. This machine can handle the most strenuous tasks, allowing for higher accuracy and reduced labor.

Which Tube Laser Cutting Machine Is Suitable for Pipeline Construction?

Heavy-duty tube laser cutting machines are best suited for pipeline construction mainly because they handle large-diameter and thick-waled tubes primarily used in construction.

Heavy Duty Tube Laser Cutting Machine

- Capacity: Our heavy-duty tube laser cutter has a large cutting capacity as it can process all sizes of tubing up to diameters of 500mm and lengths of 1200mm. With up to four heavy-duty chunks and a robust structure, the machine can handle prolonged cutting operations of thick and heavy tubes, ensuring stability throughout the process.

- Benefits: One of the significant benefits of using a heavy-duty tube laser cutter is the ability to handle tubes with significant thicknesses and diameters. It also incorporates advanced loading and unloading technologies for efficient material handling, reduced labor, and optimized production time. These tube laser cutters also offer high precision, flexibility for complex cuts, and position accuracy.

- Common Applications: Heavy-duty tube laser cutters have a wide range of applications across many industries. However, they are commonly used in pipeline construction, shipbuilding, oil and gas, automotive, aerospace, industrial equipment manufacturing, and decorative industries.

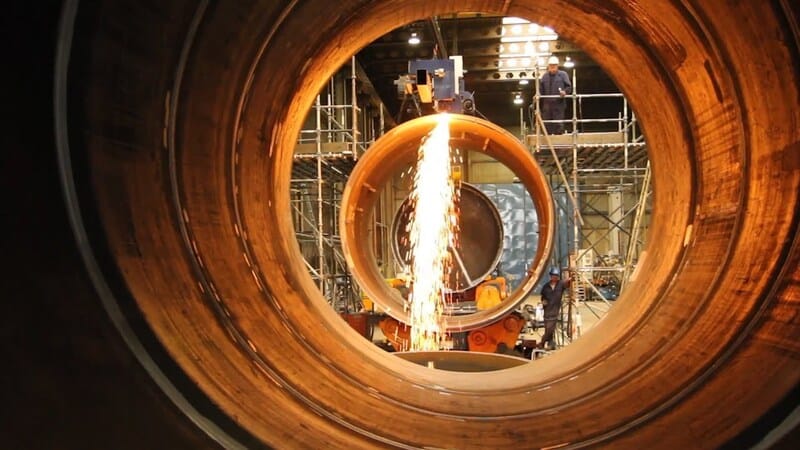

What Is Pipeline Construction?

Pipeline construction is the process of building, installing, maintaining, replacing, repairing, or modifying pipes to serve various purposes, but mainly to transport liquids such as oil, fuel, water, or gas.

These pipelines are usually constructed across roads, highways, wetlands, etc., through a series of methods aimed at creating a reliable physical pipeline infrastructure that can efficiently move these materials over a long distance.

Pipeline construction involves various stages, from planning and design to surveying, clearing, and grading of the construction site, trenching, pipe stringing, welding of pipe sections, coating and wrapping, lowering the pipeline, and testing and inspection to the final restoration of the site.

It requires knowledge, skilled labor, expertise, equipment, and compliance with environmental and regulatory requirements. Careful planning and collaboration are essential to meet the stakeholders’ specific needs.

Benefits of Using Laser Cutting in the Pipeline Construction

Precision

Precision is one of the many advantages of the laser-cutting process in constructing your pipelines. The focused, highly powerful laser beam uses an automated system to concentrate the laser on the cut path based on the design and instruction given to its CNC, allowing you to achieve accurate cuts. This precision allows proper alignment of parts during the welding and joining stage.

Speed

A laser cutter operates at high speeds, enabling you to meet production deadlines and quicker completion of projects, increase productivity, and maximize output. Its speed, combined with high accuracy and precision, allows you to save time by optimizing the workflow efficiency in your pipeline construction, especially if your company gets a lot of requests for customized tubes.

Versatility

Laser cutters can handle a wide range of pipe sizes and thicknesses used in the construction of pipelines since pipeline construction usually requires using long, super-long, and thick materials for durability.

From stainless steel and aluminum to alloys and carbon steel, using a laser machine provides the flexibility to meet various project opportunities and take on other business opportunities.

Quality

Its ability to achieve precision and accuracy ensures you have a reliable, leak-free pipe after joining and welding. Due to a high-powered laser beam, the laser cutter also produces a narrow heat-affected region, minimizing the deformation and distortion of areas around the material.

This is especially beneficial when working with sensitive raw materials to maintain the structural integrity of the pipes.

Safety

Laser cutters are mainly automated and prevent the need for human labor, allowing reduced physical contact between man and machine. These machines are also equipped with safety features such as cooling systems, protective enclosures, etc., to ensure operator safety and a safe working environment during manufacturing processes.

How to Use Laser Cutting Machines in Pipeline Construction?

A laser cutter is used in several ways in pipeline construction. Some of them include:

Pipe Fabrication

Laser cutters are used to fabricate pipe sections accurately and cut various pipe materials such as metal parts, steel, and alloys into different shapes and sizes based on the construction requirements.

Branch Connections

Laser technology can be used to cut holes and notches on the pipe, allowing the installation and connection of branch pipes and fittings used to divert or connect the main pipeline.

Mitre Cuts

Mitre cuts are essential for pipe connections that need to be inclined or angled. In pipeline construction, this can be achieved using laser-cutting to ensure accurate alignments and fits during welding.

Marking and Engraving

Some manufacturers like to engrave their logos or identification number after constructing their pipes to help them track specific pipes during maintenance or inspection. Laser-cutting technology allows you to mark or engrave your pipes for easy identification.

Bevelling and Chamfering

Bevels and chamfers are essential in pipeline construction for proper welding and stuffing. A laser cutter can be used to make precise angles and shapes to create bevels and chamfers on the pipe’s edges.

Why are Laser-cutting Machines Ideal in Pipeline Construction?

Laser-cutting technology is ideal in pipeline construction because it delivers precise and accurate cuts of different shapes and sizes on various materials with various thicknesses. Precision and accuracy allow for high-quality cuts and welds, which ensures that sections fit perfectly, minimizing gaps and resulting in a reliable, leak-free pipeline.

Tips for Businesses Choosing Precision Manufacturers

Experience and Expertise

Knowledgeable precision manufacturers understand the intricacies of the manufacturing process, and their expertise allows them to deliver high-quality products that exceed client expectations consistently. Their experience has equipped them with technical know-how and adequate problem-solving skills should any challenging surface.

Quality Control

Quality products ensure customer satisfaction, and when you choose a precision manufacturer that prioritizes quality control with robust systems in place to ensure, you can have confidence in the reliability and performance of your products, which can help strengthen your business’s reputation in the market.

Technology and Equipment

Precision manufacturers with the latest technology and equipment are committed to providing cutting-edge solutions and staying ahead in their industry. This provides you access to advanced technology to help you meet your business requirements.

Moreover, these manufacturers’ technology and equipment affect their efficiency and manufacturing capability.

Capacity and Scalability

You must choose a precision manufacturer with the equipment, workforce, and resources to meet your production demands within your desired timeframe. The manufacturer must have scalable operations to grow and adapt as your business grows and evolves.

Communication and Customer Service

Every business must have an effective customer service channel dn good communication to help build trust and transparency with their customers. This is also true for precision manufacturers. Unexpected challenges might arise, requiring prompt responses from your chosen manufacturers.

Without effective communication and a reliable customer support system, problem-solving and identification would be hampered, affecting your business.

Cost and Pricing

It is necessary to ensure that the cost of the precision manufacturing services aligns with your budget. This helps to prevent any financial constraints that can hinder the progress of your project. You should also consider how your chosen manufacturer can help reduce costs, increase efficiency, and provide overall cost-effectiveness in the long run.

Benefits of Choosing Basion as Your Partner

High-Quality Products and Services

At Baison Laser, we understand the importance of precision in your business. This is why we’ve always had quality as our watchword, reflected in our laser products and components to meet or surpass customer expectations.

Competitive Pricing

We understand the importance of getting value for your money, so we offer some of the most competitive prices in the market without compromising on quality and value. You get clear and upfront pricing information when you request a quote.

Exceptional Customer Service

Our customer service agents work round the clock to ensure you get satisfactory answers to every question regarding our products and services, wherever and whenever.

Strong Reputation

As one of the leading companies in the laser industry, our reputation for delivering high-quality products and services, consistently meeting customer expectations, complying with industry standards and regulations, and having a fountain of expertise and experiences, precedes us.

Innovative Solutions

We are a company dedicated to continuous improvement and staying ahead of industry trends, ensuring that you are never outdated or left behind by advancements in your industry.

Conclusion

It’s safe to say that laser cutting technology has a significant role in pipeline construction if you want to attain high precision and accuracy, efficiency, and optimization of your manufacturing process. However, it would do your business a lot of good in the long run to consider some of the tips we’ve listed before choosing a precision manufacturer.

For more information and resources on tube laser cutting technology and its applications, visit our website.

Discover the Perfect Solution for Your Business with Baison

Now that you know the numerous benefits and applications of tube laser cutting machines, take the bold step and contact us for your pipeline construction needs.

We offer free application evaluations to help you choose a machine that suits your manufacturing needs. Take advantage of our competitive prices today and help your business stay relevant in your industry.