Are you done wasting hours scrubbing rust, peeling paint, and fighting stubborn grime that just won’t go away?

We’ve all been there. The chemical smell, the messy brushes, the ruined gloves, the dust everywhere — and the worst part? The results don’t even last.

But guess what?

There’s finally a smart way to clean surfaces without headaches, harsh chemicals, or endless elbow grease. The benefits of laser cleaning machines include superior performance, enhanced safety, environmental friendliness, and cost-efficiency compared to traditional cleaning methods.

Meet the laser cleaning machine — the modern tool that removes rust, paint, grease, and surface contaminants with pure light. Yes, actual laser beams. And surprisingly gentle on the material underneath.

In this guide, we’re breaking down how laser cleaning works, why industries love it, where it’s used, its pros and cons, and how you can choose the right machine.

Let’s get started!

What Is a Laser Cleaning Machine?

A laser cleaning machine is a device that uses a focused laser beam to remove rust, paint, oil, dirt, and other layers from a surface without touching or damaging the material underneath.

It works by sending quick bursts of laser light onto the unwanted layer, which absorbs the energy and instantly disappears.

This machine is popular because it is clean, fast, and safe. It does not use chemicals, water, or sand, so no mess is left behind.

The laser only targets the dirt or coating and does not harm the underlying metal or object. People use laser cleaning machines in car workshops, factories, shipyards, and even museums.

They help restore old metal to its original appearance and prepare surfaces for painting or welding. It is a modern and eco-friendly method for cleaning various materials. There are different types of laser machines available, each designed for specific cleaning tasks and materials.

Why Lasers Are the Smart Choice for Removing Rust & Paint?

If you’ve ever tried scraping rust or stripping old paint, you already know how tiring, messy, and unpredictable it can be. Compared to other methods, such as sanding, grinding, or chemical treatments, laser cleaning is faster, safer, and more efficient.

That’s exactly why so many industries are now turning to laser cleaning. It’s cleaner, smarter, and delivers the kind of precision that traditional methods can’t match.

Here’s why lasers have become the preferred solution.

Laser cleaning is a completely non-contact process, meaning that nothing physically touches the surface. This protects the material from scratches or unnecessary wear.

The beam is highly selective, removing only rust, corrosion, or paint while preserving the original metal intact. Another major advantage is that no chemicals are involved—so you avoid toxic fumes, harsh solvents, and the headache of waste disposal.

Lasers also offer remarkable precision, easily reaching tight corners, small parts, and complex shapes. Because there’s no abrasive blasting or water involved, it becomes a far more environmentally friendly option; however, proper fume extraction remains important for safety.

Plus, the entire process is repeatable and easy to automate, making it ideal for factories and robotic cleaning lines.

Now, let’s dive deeper into how a laser actually makes rust and paint separate from the surface.

The Physics: How a Laser Removes Rust and Paint?

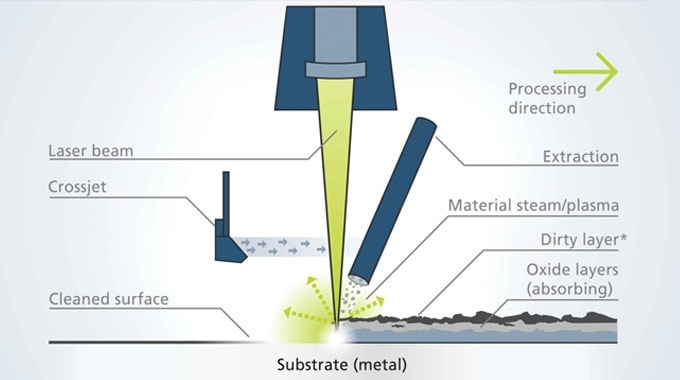

Laser cleaning uses a concentrated beam of light—typically pulsed or continuous wave from a fiber, diode, or solid-state laser—directed at the contaminant.

Continuous wave lasers deliver a steady, uninterrupted beam, which affects material removal speed and increases thermal impact compared to pulsed lasers.

The laser energy interacts with surface material in a few key physical ways, depending on wavelength, pulse duration, peak power, and the optical/thermal properties of the contaminant and substrate.

1. Ablation (vaporization)

When the laser energy is absorbed by the paint or rust layer faster than the heat can dissipate into the substrate, the local temperature rises rapidly.

The ablation threshold is the minimum energy required for the material to be vaporized or removed by laser ablation. Understanding the ablation threshold is crucial for achieving the selective removal of coatings or contaminants without damaging the underlying base material.

The contaminant material reaches vaporization temperature and is removed as vapor and small particulates. This is called laser ablation. It’s very effective for thin paint or light corrosion layers.

2. Thermal Decomposition / Pyrolysis

Some coatings break down chemically when heated rather than fully vaporizing. The laser heats the coating to the point where it decomposes into volatile compounds and char. Those decomposition products are then swept away by the extraction system or gently lifted off.

3. Photomechanical Ejection (shock)

Short, high-peak pulses (in the nanosecond or picosecond regimes) can deposit energy so quickly that rapid expansion creates a micro-shock or micro-explosion in the contaminant layer.

That generates mechanical forces that crack and eject the rust or paint — very useful for brittle coatings or heavily flaked rust.

4. Photochemical Effects

At very short pulse durations and certain wavelengths, photons can break chemical bonds directly (photochemical ablation), which helps remove certain polymers or organics without significant heating of the substrate.

5. Differential Absorption / Selectivity

A crucial reason lasers can remove rust/paint without harming the base metal is differential absorption: rust or paint often absorbs the chosen laser wavelength much more strongly than the underlying metal.

That means the contaminant heats up and is removed, while the substrate reflects or transmits enough light to stay relatively cool. This selectivity enables the laser to remove one layer or contaminant without affecting the underlying material, making it highly effective for removing contaminants from complex surfaces.

Laser Parameters that Matter

Effective cleaning requires tuning several parameters:

Wavelength: Many industrial laser cleaners use near-infrared (e.g., 1064 nm fiber/solid state) because metals and oxides absorb enough energy, while fiber technology is robust. UV or green wavelengths may be more suitable for certain paints or plastics.

Pulse duration: Nanosecond, picosecond, or continuous. Nanosecond pulses are common and economical; ultrafast pulses (picosecond/femtosecond) give extreme precision and a minimal heat-affected zone.

Peak power / average power: Determines how quickly material is removed. Higher power cleans faster but risks substrate heating.

Repetition rate & scanning speed: Control how much energy hits a spot over time.

Spot size & focal length: A smaller focused spot increases intensity, while a larger spot provides gentler cleaning.

Operators adjust these to get efficient removal without discoloration, melting, or substrate damage.

The Laser Cleaning Process — A Step-by-Step Guide

Laser cleaning may seem like magic, but it’s actually a highly precise and controlled process. By following each step carefully, operators can remove rust, paint, and contaminants while keeping the base material perfectly safe.

To achieve optimal results, it is important to adapt laser settings and equipment to the specific surface type and contamination being addressed. Here’s how it works from start to finish:

Step #01: Assessment

Begin by examining the surface to identify the type of material, the thickness of rust or paint, and any delicate or sensitive features.

This assessment is especially important for applications like laser rust removal, where the type and extent of rust determine the most effective cleaning approach.

Taking photographs and performing material tests helps set the right laser parameters and ensures accurate cleaning without surprises.

Step #02: Set the Machine

Choose the appropriate wavelength, pulse mode, power level, frequency, scanning speed, and focus. For rust removal tasks, a laser rust remover may be chosen and configured with the appropriate settings for efficient operation. For unfamiliar surfaces, it’s best to start with low power and run small test patches.

Step #03: Fixturing & Masking (If Needed)

Secure the part in place and mask areas that should remain untouched. Fixtures help maintain the correct distance and angle for precision work.

Step #04: Extraction & Filtration

Connect fume extraction systems to capture vapors, dust, and particles produced during cleaning, keeping the workspace safe and clean.

Many setups use air-cooled laser machines and air filtration systems to further enhance safety and efficiency during the cleaning process.

Step #05: Cleaning Pass

Move the laser head or part in a controlled pattern, whether using a handheld device, CNC, or a robotic system. Watch the surface carefully to ensure the contaminants are removed uniformly.

Step #06: Inspection

After cleaning, visually inspect the surface and use non-destructive tests, such as thickness gauges or surface profilometers, to confirm base metal integrity and the required level of cleanliness.

Step #07: Post-Clean Treatment

If necessary, immediately apply corrosion inhibitors, primers, or fresh paint to prevent flash rust and protect the newly cleaned surface.

Applications — Where Laser Cleaning Truly Shines

Laser cleaning machines are transforming the way industries remove rust, paint, and surface contaminants. They offer efficient paint removal and can remove paint from a variety of surfaces, including wood.

Laser cleaning is also highly effective in removing dirt from delicate or historical materials, making it suitable for sensitive restoration projects.

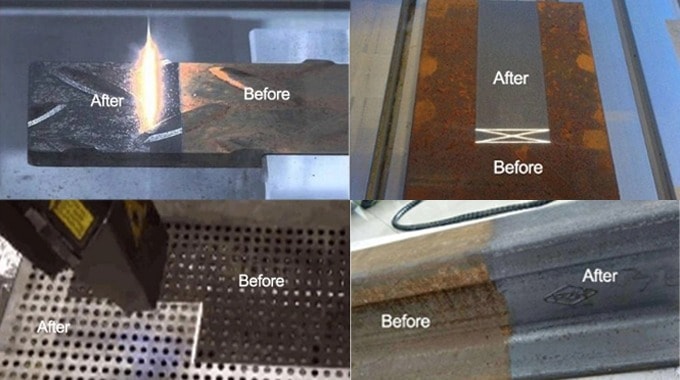

1. Automotive Restoration and Maintenance: Laser cleaning removes rust, old paint, and corrosion from body parts, engine components, and chassis. Unlike sanding or grinding, it cleans without scratching the metal, leaving parts ready for further work.

2. Shipbuilding and Marine Maintenance: Laser cleaning targets rust and corrosion on ship hulls, tanks, and decks. It works in hard-to-reach areas where sandblasting or chemical methods would be risky or costly.

3. Aerospace: Aircraft components, including turbine blades and structural parts, are cleaned without abrasion. Laser cleaning preserves critical dimensions and surface integrity.

4. Heritage Conservation: Statues, monuments, and artifacts can be cleaned without damaging delicate surfaces. Laser cleaning avoids the harmful effects of chemical stripping and is effective for removing dirt and paint from wood in historical restorations.

5. Manufacturing and Maintenance: Industrial applications include pre-weld preparation, coating removal before plating or bonding, and mold/tool maintenance. Laser cleaning reduces downtime and ensures high-quality results.

6. Electronics and Precision Parts: Laser cleaning carefully removes oxidation, flux, or coatings from circuit boards, connectors, and other sensitive components without causing damage.

Advantages of Laser Cleaning Machines

- Non-contact cleaning prevents scratches, dents, or material loss.

- No chemicals, water, or sand required; minimal waste generated.

- Works with precision on small, delicate, or complex parts.

- Small or intricate components can be cleaned quickly compared to manual methods.

- Laser rust removal provides a fast, efficient, and safe method for eliminating rust from metal surfaces, surpassing traditional rust removal techniques.

- Fewer consumables and less equipment wear.

- Every pass produces uniform cleaning quality.

Limitations of Laser Cleaning Machines

- Equipment is expensive compared to traditional tools.

- Manual laser cleaning can take longer than sandblasting.

- Vapors and particles must be safely removed.

- Correct laser settings and handling are essential.

- Multi-layer paint or deep corrosion may need pre-treatment.

Typical Results and Surface Condition After Cleaning

After laser cleaning, surfaces appear bright, smooth, and free of rust, paint, or oxidation. The microscopic texture may be slightly rough, which improves the adhesion of paint or primer.

Minimal heat is applied to the substrate, resulting in a clean, ready-to-use surface with no chemical residue or abrasive debris.

Safety and Environmental Considerations

Operators must wear laser-rated protective glasses and follow interlock and shielding protocols. Fume extraction with proper filtration is crucial for removing hazardous particles.

Fire safety must be considered because hot particles or vaporized material can ignite.

Compliance with occupational and environmental regulations is essential, particularly for hazardous coatings such as lead-based paint. Proper training ensures both safety and optimal cleaning results.

Equipment Components and Setup Basics

A typical laser cleaning system includes a laser source (fiber, diode, or YAG), beam delivery (handheld scanner, articulated arm, or fiber cable), and scanner optics to control focus and sweep patterns. Controllers and software allow adjustment of pulse, power, and pattern.

Fume extraction units, safety enclosures, and protective accessories are essential. In production settings, lasers are often integrated with robotics and vision systems to ensure the consistent cleaning of complex parts.

Laser Cleaner Maintenance

Taking care of laser cleaning machines is very important. Good care helps machines work well every day. Clean machines last much longer than dirty ones. The best results come from machines that get regular care.

The laser beam path needs to be cleaned frequently. Dust on the lens impairs the laser’s performance. Dirty parts can break the sensitive pieces inside machines. The laser machine also needs regular checking and adjustment. The beam must point in the right direction. The energy output must remain constant for effective cleaning.

Key parts wear out and require close monitoring. Fiber parts and laser pieces get old with time. Bad parts cause machines to stop working suddenly. New parts keep machines running smoothly and keep them clean. The maker provides guidelines for care and maintenance. A regular schedule helps identify problems before they become significant.

Good care saves businesses money and time. Machines break down less when they get proper care. Repairs cost less when machines stay in good shape.

Clean machines work much longer than ones without care. Companies that clean rust from metal parts need reliable machines. Top care means every surface gets cleaned the right way. Effective machines help companies generate more revenue every day.

Cost-Effectiveness of Laser Cleaning Machines

Laser cleaning saves money when removing rust and paint from metal. Old methods, such as sandblasting, are more expensive and time-consuming. Laser cleaning cuts work costs and makes less waste.

Sandblasting requires materials that are expensive to dispose of. Chemical cleaning requires hazardous liquids that are also expensive. Laser cleaning utilises only the power necessary for cleaning. This helps save money on electric bills every month.

Laser cleaning machines last for many years with good care. Many machines work well for ten years or more. The first cost pays back over time with savings.

Companies that clean surfaces regularly tend to save the most money. Laser cleaning removes rust and dirt very effectively. Clean surfaces last longer and break less often. Machines stay strong when rust does not eat them. This saves money on new parts and fixes.

Steel-making companies use laser cleaning on their big machines. These companies save money and lose less time on work. Small shops like the clean way laser cleaning works.

Wrap Up…

Laser cleaning machines remove rust and paint by harnessing controlled bursts of light energy to vaporize, decompose, or mechanically eject contaminant layers while leaving the underlying material intact.

Their precision, non-contact nature, and avoidance of toxic chemicals make them ideal for restoration, precision maintenance, and industrial production where part value, environmental concerns, or delicate geometry rule out blasting or chemical stripping.

Although initial investment and fume management are considerations, the long-term advantages for repeatable, automated, and selective cleaning frequently outweigh the downsides—especially when equipment is matched to the job after careful testing.

For more information about available models and prices, please visit our website.

FAQs

Q1: Will laser cleaning damage the metal underneath?

Properly set parameters ensure the laser removes contaminants while keeping the substrate intact.

Q2: Is laser cleaning faster than sandblasting?

For small or intricate areas, yes. For large uniform surfaces, sandblasting may be faster per square meter.

Q3: Are lasers eco-friendly?

Yes, they eliminate chemicals and blasting media waste, though proper fume extraction is still necessary.

Q4: Can lasers remove all paint types?

Most organic paints and coatings can be removed, but very thick or specialized coatings may need multiple passes.

Q5: Do parts need preparation after laser cleaning?

Often, surfaces are ready for primer or paint, though testing and corrosion inhibitors are recommended.

Take Your Cleaning to the Next Level

Baison offers a complete range of high-quality laser cleaning machines designed for precision, reliability, and long-lasting performance. Whether you want to remove rust, paint, or surface contaminants efficiently and safely, our machines deliver exceptional results with minimal waste.

Our expert team is ready to guide you at every step, helping you select the ideal laser cleaning solution tailored to your specific needs. From handheld systems to fully automated setups, we ensure you get a machine that matches your application, budget, and production goals.

Don’t wait—upgrade your cleaning process today with Baison’s advanced laser technology and experience faster, safer, and eco-friendly surface cleaning like never before. Contact us now to find the ideal solution for your project.