Laser cutting is an efficient way to cut sheets and metal fabrication. It has revolutionized the metal fabrication industry with its accurate and precise cutting. The traditional banking system in laser cutting was time-consuming. A coil-fed blanking system is more efficient and eliminates the need for a time-consuming tooling setup.

This article will discuss how the coil-fed laser blanking system works and how it differs from the traditional feeding system. Before we get into the details of coil-fed lasers, let’s look at laser cutting.

What Is Laser Cutting

Laser cutting uses laser machines to cut material. It can be metal, ceramic, plastic, or alloy. Laser cutting involves using laser machines. The laser cell of the machine consists of the laser source, beam delivery system, and laser heads. Laser cutting heads send a high-powered beam that passes through a lens or material.

The laser beam vaporizes the material and cuts it into the required shape. After cutting, the material may need to undergo additional forming processes such as bending, folding, or rolling to create a final product.

Advantages of Laser Cutting

Laser cutting is by far the most efficient way of cutting any material. Here are a few advantages:

Precision: Laser machines are the most precise cutting machines. They use a narrow laser beam to cut material directed by computer software. It cuts the material with high precision. Even complex shapes and designs are cut with precision.

Accuracy: Accuracy is essential in metal fabrication and cutting operations. Only laser-cutting machines provide the accuracy required for complex shapes and materials. It can even cut the most thin and thick materials with equal precision and accurate design.

High-Speed: Traditional ways to cut materials are time-consuming. Laser Machines are almost ten times faster than other cutting tools. They reduce the fixed and variable costs per part.

Versatility: Laser machines are versatile. They can process steel, aluminum, alloys, and other materials, including ceramic, paper, plastic, fabric, metal, and alloys. They can handle the toughest materials like tough or mild steel. Ad cut them with equal precision as glass.

Reduced waste: As the laser beam effect is the only spot it is directed at, it does not damage the surrounding material. Laser machines reduce manufacturing costs as well.

Better finish: With the accuracy and precision of cutting, the end product has a better finish. It is used in demanding high-tech industries and produces excellent quality products and parts.

Reduce Cost: Laser machines can be fully automated. The production speed is fast and does not require a lot of manual intervention. The production cost is reduced due to material efficiency, speed, and lack of manpower required for these machines.

What Is Coil-Fed Laser Blanking Line?

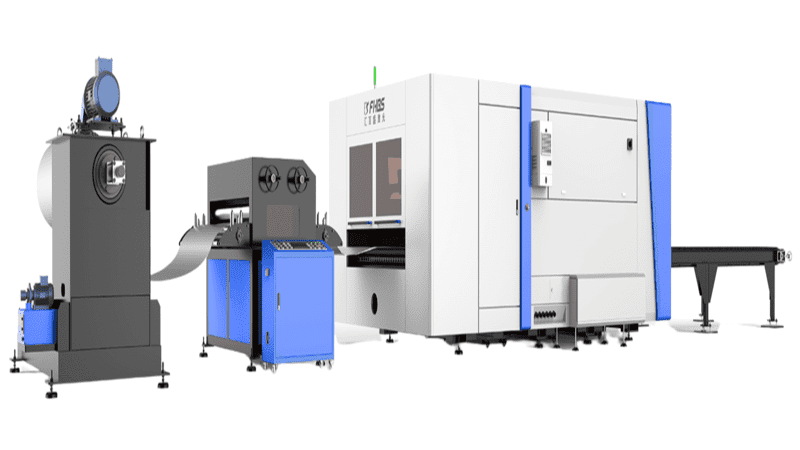

Coil-fed laser blanking technology is a modern sheet processing technology that uses laser power to cut sheets into desired shapes. It is different from the traditional blanking lines.

Traditional blanking lines require dies and a manual blanking system, which is time-consuming and inefficient. Coil-fed laser blanking eliminates the need for manual feeding, thus speeding up production.

n traditional blanking lines, a large press machine is used to stamp out metal parts from a sheet of metal previously cut to the correct size. The press machine uses a die and punches set to shape the metal into the desired part.

However, creating the necessary tooling requires significant setup time and cost. Additionally, traditional blanking lines must improve their ability to produce complex shapes.

In contrast, coil-fed laser blanking uses a laser to cut metal directly from a continuous coil, eliminating the need for tooling setups. The laser is guided by computer-aided design (CAD) software, allowing for greater design flexibility and the ability to produce complex shapes with precision and speed.

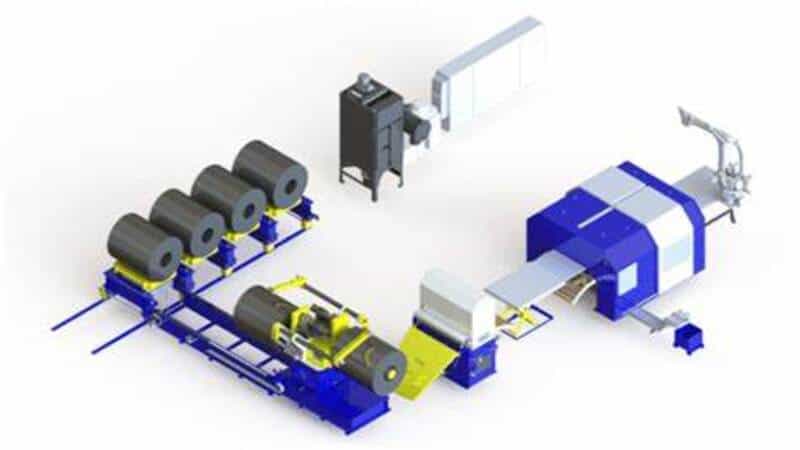

Coil-fed laser blanking is also more efficient than traditional blanking lines because it can process multiple coils simultaneously, reducing the downtime required for tooling changes.

Overall, coil-fed laser blanking is a highly efficient and flexible sheet metal processing technology that allows for faster production, greater design flexibility, and the ability to produce complex shapes precisely.

How Does coil Fed Laser Blankers Work?

The process starts with feeding the metal coil into the machine. The coil is typically made of flat sheet metal rolled up into a cylindrical shape and loaded onto a decompiler, which gradually unwinds the coil and feeds it into the laser machine. The metal coil is straightened to ensure a uniform shape to cut different sizes.

The laser beam is directed onto the surface of the sheet. It is controlled by a Computer program that cuts the sheet with the required design and shape. Once the parts are cut, they are stacked for further processing.

Differences between Coil-fed and Traditional Blanking Lines

Coil-fed blanking lines are different than the traditional ways of cutting metal sheets. Here is how it is different:

Material Handling

Traditional blanking lines work with large or small sheets manually fed through the system. Coil-fed lines take the raw material from the continuous coil; thus, no manual intervention is required.

Speed

As there is no need for manual feeding, coil-fed lines are generally faster than traditional blanking lines. They can process the material continuously, and there is no waste of time or resources.

Material Waste

Coil-fed machines do not require the sheets to be cut in parts. They take continuously and cut only through the laser beam as much as is required. Traditional blanking lines waste more material because they require a larger margin between the material being cut and the edge of the sheet.

Precision

Coil-fed lines are high-tech machines designed to cut the sheets with precision. They use advanced technologies such as laser cutting, which can accurately cut complex shapes.

Cost

They may have a higher upfront price than traditional blanking lines, but they are fast and process material accurately. Manufacturers save more money on manual feeding, fast processing, and high finish of end product.

How Coil Fed Laser Blankers Improve Production Rates and Profit Margins

Here is how coil-fed blanking improves profit margins:

Continuous Production

Coil-fed laser blankers take the sheet from the coil without manual help. They can continue to process the sheets without wasting any time. With traditional lines, operators must stop the machine from manually cutting and feeding the sheet.

Material Utilization

Coil-fed lasers provide maximum material utilization. Pre-cut sheets can waste the material from the edges. Coil-fed blankers fully use the material, and there is no material waste. Coil-fed machines provide minimum scrap.

The coil-fed system can be easily modified or expanded to meet changing production requirements. This allows manufacturers to optimize their production processes, improve efficiency, and reduce costs over time.

Improve Production Process

Production quality increases with an Automatic feeding system and accurate cutting of laser machines. Laser machines cut with extreme precision and can process the most complex designs. There is no deviation from the design. All of these enhance the production quality. The quality of the product is better than shearing or any other traditional means of cutting.

High Volume Production

The coil-fed system can process a large quality of sheets at a time. It can give high-level production with precision and accuracy.

Modular Design

A coil-fed system can be easily modified or expanded to meet changing production needs. It allows manufacturers to optimize their production processes. The system consists of separate, distinct modules that work even when one or two are lost. It reduces maintenance costs and allows manufacturers to continue production even if a few parts need maintenance.

Implementing Coil Fed Laser Blankers

The system uses a coil of material, typically metal, to feed a machine for the cutting process to perform a specific task. Here is how you can implement the coil-fed system:

- Determine the type of material and its specifications, such as thickness, width, and weight.

- Select a coil feeder that is appropriate for the type of material you will be using. It should be able to handle the type of coil you are using.

- Install the coil feeder and adjust it to the appropriate settings, like the speed and tension of the coil.

- Set up the material handlings equipment, such as a straightener or a decompiler.

- Connect the coil feeder to the laser cutting machine.

- Monitor the system to ensure that the material is being fed at the correct speed and tension.

What Are Some Applications of Coil Fed Laser Blankers?

Coil-fed laser cutting systems are used in a variety of applications, such as:

- Automotive Industry

- Electronics

- Furniture

- Medical

- Aerospace

- Architecture

Overall, coil-fed blankers are used in industries that require precise and accurate sheet processing.

Conclusion

Coil-fed blankers have revolutionized the sheet-cutting industry by improving product quality; they increase efficiency and reduce scrap and waste.

The industry can process sheet metal coils using a coil-fed blanker into precise, consistent blanks. They save the time of manual feeding and are an essential tool for many industries, from automotive to aerospace, where precision and efficiency are vital.

Increase your Sheet Processing Efficiency with Baison’s Laser Cutting Machines

Baison offers the best laser cutting technology for sheet cutting and metal fabrication. Our laser cutting machines are one of a kind in the industry, offering fast and accurate sheet processing.

Contact us to learn more about our laser-cutting system. We offer a free sample evaluation and also free sample proofing.