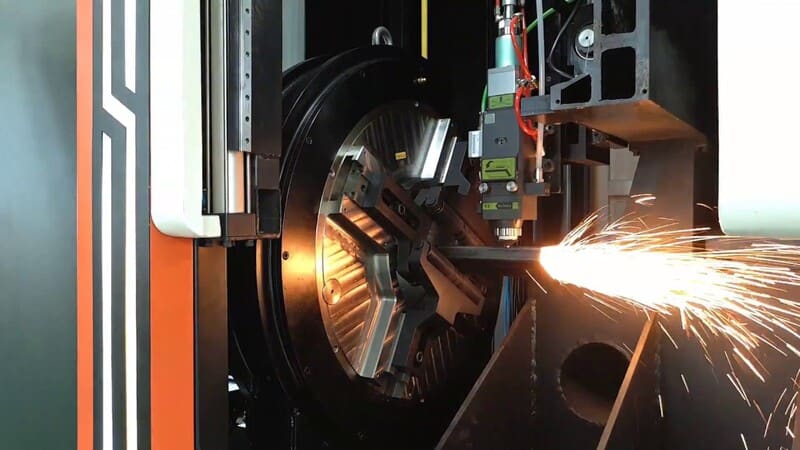

The latest technology has allowed laser cutting machines to cut not only thin materials but also thick metal plates and tubes. The cutting process is completed with high efficiency and accuracy. Therefore, the laser cutting process is considered more efficient than many other cutting processes.

The heavy-duty tube laser cutting machine has had an immense impact on manufacturing. Its cutting efficiency, cutting speed, and cutting quality are unmatched by many other cutting technology forms.

Go over this blog post to gain a deeper knowledge of tube laser-cutting machines.

Understand a Heavy Duty Tube Laser Cutting Machine

As its name suggests, the heavy-duty tube laser cutting machine is used for strenuous work. The machine incorporates fiber lasers in its work.

Hence, this fiber laser cutting machine cuts different hollow metal material surfaces and round metal workpiece surfaces like pipes. Some of these materials include stainless steel, carbon steel, galvanized cutting surface, and so on.

This type of laser tube-cutting machine is used in material handling, building, and manufacturing. It is also used in industrial pipelines, the processing of furniture, and gym equipment.

On the other hand, the small tube laser cutting machine is used for comparatively minor projects. It is an ideal choice for first-time users.

The machine has great cutting efficiency, despite being cost-effective. It also has a shorter processing time, increasing its accuracy and lowering the processing cost.

Hence, the small tube machines are perfect for new start-ups and small equipment manufacturers.

Benefits of Heavy-Duty Tube Laser Cutting Machines

A heavy-duty tube laser cutting machine has tons of advantages. It is far superior to the traditional processing methods used.

Some of the advantages are mentioned below.

High Precision in the Cutting Process

The work of a heavy-duty tube laser cutting machine is very precise. The cutting surface and final product come out flat, straight, and smooth. There is no burr formation involved throughout the process.

The workpiece surface also encounters minimum material loss due to its high precision, high cutting accuracy, and processing accuracy.

Saves Time

Due to the high precision and cutting accuracy, you can save a lot of time in manufacturing. No extra time, energy, or effort is required to finish the final product.

The end results are smooth and finished with perfection. Hence, extra time is unnecessary to smooth the cut ends, grinding, deburring, etc.

Small Heat-Affected Zone

The work done by this fiber laser cutting machine results in a small heat-affected zone. Therefore, there are no temperature deformations involved.

The small heat-affected zone is a great advantage in automatic welding procedures.

Large Batch Production

The cutting process is very fast. The cutting speed is also maintained at a high pace. Hence, there is great cutting efficiency involved as well.

The time required to clamp and position the workpiece surface and cutting surface is greatly reduced. Hence, batch production is made quite smooth and easy to manage.

The high cutting efficiency and overall high-quality cutting ensure each piece of the batch is perfect. This ensures minimal errors even in batch production.

Automated System of Fiber Laser Cutting Machine

The tube laser cutting machine is controlled using an automated control system. Strong software is used, which makes the entire processing method operate digitally.

Additional time is also saved due to automated loading, unloading, and alignment. You do not have to change tools in between different processes as well. The control system makes the cutting speed and overall tube-cutting process even more efficient.

Highly Versatile

The tube laser cutting machines are very versatile in use. They can offer a wide range of cuts to the manufacturers.

The machine is not just capable of making straight lines and cuts. You can use it for cutting at different angles, slotting, notching, beveling, and even marking holes on surfaces.

Cost Effective

This kind of laser pipe-cutting machine saves money. The equipment maintenance cost for most types of machines is reduced significantly due to high technology being involved. The processing cost is also reduced due to the high output power of the machines.

Different Applications of Heavy-Duty Tube Laser Cutting Machines

The heavy-duty laser tube-cutting machine is used in numerous manufacturing processes.

Some of them are explained below.

Household Appliances

The advancements in science and technology have developed many smart home devices and household appliances. Manufacturing such appliances has been possible thanks to tube laser cutting machines.

The flexibility and dimensional accuracy of the pipe laser cutting machine enables you to make unique designs. Household appliances can now become extremely personalized. They are far more detailed and user-friendly than ever before.

Furniture Industry

The furniture industry is also shifting from its traditional processing method. The high efficiency of the laser machine has paved the way in furniture manufacturing.

The strong cutting power of laser drilling makes furniture manufacturing a lot more effective. Higher laser power and the latest laser technology can easily cut thick plates and thin materials.

The strong beam focus position can cut through a pipe wall like butter—stainless steel pipes of whichever wall thickness can also be cut smoothly.

Compared to traditional processing methods, the laser pipe-cutting machine is 30% more efficient in furniture manufacturing.

Transportation Pipelines

The focused laser beam of the laser tube cutting machine is used in manufacturing transportation pipelines.

The high precision offered by laser cutting equipment is extremely important. The cutting thickness achieved by the laser machine is better than mechanical drilling.

The laser technology possessed by this laser cutter allows proper refining of metal tubes. This ensures a smooth and well-accurate processing quality that is essential for making transportation pipelines.

Oil Refining Materials

The manufacturing of oil refining equipment has been revolutionized by the CNC system of the tube cutting machine.

The different metal material parts involved can be cut accurately. This laser-cutting process ensures that no raw material gets wasted. The laser beam ejected from the laser head ensures adequate dimensional accuracy of the oil refining equipment.

The laser output power is well-maintained as well. This makes the whole process quite cost-effective than any other traditional processing method.

Bridge Construction

Accuracy is pivotal when it comes to building bridges. You cannot afford to have even a single angle to be out of place. This can cause the entire bridge to collapse and cause enormous damage to both life and resources.

The high laser power cutting machine ensures high efficiency in bridge construction. The processing tubes and metal tubes involved are cut accurately.

The laser beam can cut through any metal wall thickness with great precision. Hence, the machine’s high laser power can easily replace mechanical drilling for tube cutting.

Gym Equipment

The use of metal pipes in gym equipment is very common. The quality of cutting thickness and dimensional accuracy in this field by the laser cutting machine is unmatched.

The laser head ensures beauty in the final processing. Labor and time cost are greatly reduced if gym equipment is manufactured by the laser tube cutting machine.

Things to Consider Before Buying a Laser Tube Cutting Machine

You must consider a few things before purchasing a pipe laser-cutting machine.

Type of Materials

The laser tube cutting machine can cut a variety of metals. These include stainless steel, brass, copper, aluminum, and even galvanized metals.

Go over your material-cutting needs prior to purchasing a fiber laser-cutting machine. This will help you determine what kind of machine suits you and your business best.

Specs

Do your research well. Make sure to know the details of the specifications the laser tube cutting machine offers.

Evaluate the machine’s cutting speed, the strength of the laser head and laser beam, the cutting quality, etc.. See how strong the laser output power of the machine is.

Only invest your money in that machine if all the suitable features are present.

Budget

Budget is a very important thing to consider before making a purchase. Go over different laser-cutting machine options. Choose the one that you find is good and suits your budget.

Final Thoughts

Laser tube-cutting machine has revolutionized the processing of metal tubes. The high precision, strong quality control, and immaculate end products make this technology the best.

This technology makes the entire process a high-efficiency one. It reduces manufacturing time which ultimately saves a lot of costs.

Therefore, you can maximize output using a heavy-duty tube laser cutting machine for manufacturing.

Discover the Perfect Solution for Your Business with Baison

At Baison, our customers always come first.

We provide our clients with the best laser cutting machines and handheld welding machines. You can find a laser machine that best suits your needs.

For any assistance regarding our products, feel free to contact us today.