With the growing demand for precision in manufacturing, businesses are adopting new methods, such as titanium laser cutting, to ensure efficient and accurate production. Let’s see how it works and how your business can benefit from it.

What Is Laser Cutting?

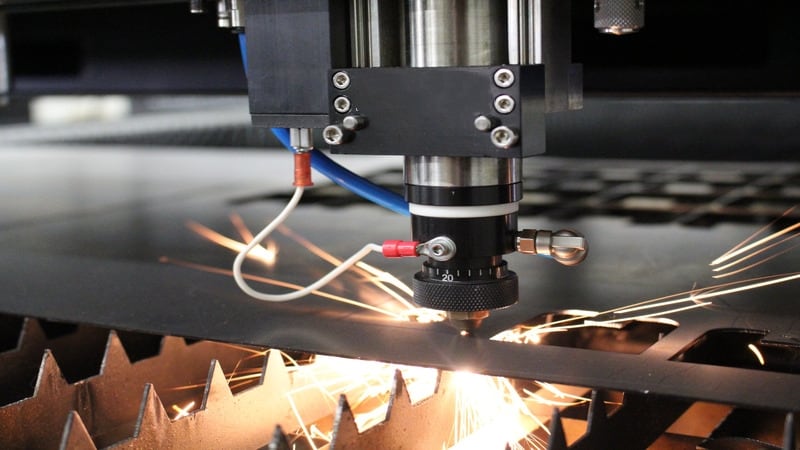

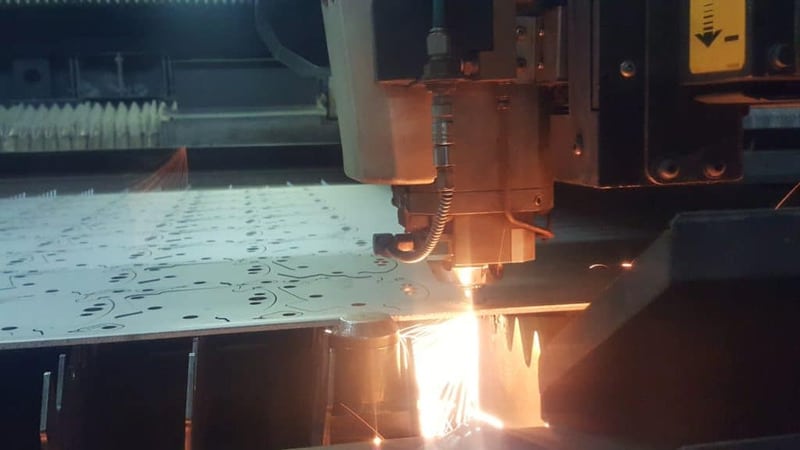

Laser cutting is a versatile manufacturing technique using a concentrated laser beam to cut or engrave various materials accurately. It achieves clean and precise cuts by melting, burning, or vaporizing the material. This non-contact method relies on computer-aided design (CAD) files for guidance, ensuring accuracy and consistency.

Numerous industries benefit from laser cutting, including aerospace, automotive, electronics, and medical.

It is particularly useful for producing intricate metal shapes, fabricating electronic components, and crafting parts for vehicles and aircraft. Laser cutting offers several advantages over other methods like plasma, waterjet, or mechanical cutting.

You can learn more about laser cutting vs. plasma cutting and laser cutting vs. waterjet here.

These include higher precision, reduced material waste, faster production, and minimal damage to materials. As a result, laser cutting is an efficient, cost-effective solution for diverse industrial applications.

What Is Titanium?

Titanium is a lightweight, strong, and corrosion-resistant metal recognized for its remarkable strength-to-weight ratio. The metal’s lustrous silver appearance appeals to various applications.

Titanium Applications

1. Aerospace: Aircraft components, such as engines, airframes, and landing gear, utilize titanium for its lightweight strength.

2. Consumer Electronics: Devices like smartphones, laptops, and watches use titanium casings for protection, durability, and a premium feel.

3. Automotive: High-performance vehicles often feature titanium parts like exhaust systems and engine valves for enhanced fuel efficiency.

4. Sports Equipment: Titanium’s strength, durability, and light weight make it a popular choice for bicycles, golf clubs, and tennis rackets.

5. Medical: The biocompatibility of titanium makes it ideal for implants, prosthetics, and surgical tools.

Titanium Properties

1. Low Thermal Expansion: Titanium’s low coefficient of thermal expansion helps it maintain its shape and size under changing temperatures.

2. Strength: Titanium boasts an outstanding strength-to-weight ratio, providing more strength than many metals while remaining light.

3. High Melting Point: With a melting point of 1,668°C (3,034°F), titanium endures extreme heat, making it ideal for high-temperature applications.

4. Biocompatibility: this allows the use of titanium for medical purposes. It does not react with the human body making it a safe material for us.

5. Corrosion Resistance: This metal resists corrosion from various chemicals and environments, including chlorine and seawater.

The Advantages of Titanium over Other Metals

Unrivaled Strength-to-Weight Ratio

Titanium’s impressive strength, coupled with its low weight, sets it apart from many metals, making it ideal for industries where reducing weight is essential. For instance, the aerospace and automotive sectors employ titanium parts to lower overall weight, resulting in enhanced fuel efficiency and performance.

Outstanding Corrosion Resistance

In contrast to other metals, titanium displays exceptional resistance to corrosion caused by various chemicals and environments, such as acidic solutions, seawater, and chlorine. This quality makes it a favored choice for industries like marine engineering, chemical processing, and desalination plants.

Unique Biocompatibility

As a non-toxic metal that does not trigger adverse reactions in the human body, titanium’s biocompatibility distinguishes it from other metals. This property makes it the go-to metal for medical applications like implants, prosthetics, and surgical tools.

Minimal Thermal Expansion

Titanium’s lower thermal expansion coefficient compared to most metals allows it to maintain its shape and size amidst changing temperatures. This characteristic is highly valuable in industries where components face extreme temperature variations, such as aerospace, automotive, and energy production.

Impressive Melting Point

With a melting point of 1,668°C (3,034°F), titanium can endure extreme heat, rendering it suitable for high-temperature applications. This attribute is vital in industries like aerospace, where components must withstand intense temperatures during flight or re-entry.

Different Types of Lasers Used for Cutting Titanium

Nd: YAG Lasers

Nd: YAG lasers are commonly used by businesses around the world for metal cutting, including titanium. They can generate high peak powers to cut through thick titanium sheets.

However, compared to fiber lasers, Nd: YAG lasers have lower efficiency, increased maintenance requirements, and poorer laser beam quality. Nonetheless, they can be a practical option for specific titanium-cutting applications where their distinct features are beneficial.

Fiber Lasers

Fiber lasers are a popular choice for cutting titanium due to their shorter wavelength, which results in higher precision and smaller kerf widths.

Moreover, fiber lasers boast greater energy efficiency, high-quality laser beam, and lower maintenance needs. However, they can be more costly than CO2 lasers, making them less affordable for some businesses.

CO2 Lasers

CO2 lasers offer high power output that allows them to cut through thick titanium materials. As a result, it is another popular choice of laser used by businesses to cut through titanium.

However, their longer wavelength may lead to larger kerf widths and reduced precision compared to other laser types.

What Should You Consider When Choosing Between Laser Types?

1. Accuracy: Assess the precision needed for your specific application. Fiber lasers usually provide greater accuracy and narrower kerf widths than CO2 and Nd: YAG lasers.

2. Overall Efficiency: Investigate the comprehensive operational efficiency of each laser, including factors like cutting speed, energy usage, and user-friendliness. Balancing these aspects will help you select the most appropriate laser system for your requirements.

3. Expense: Consider each laser type’s initial and ongoing costs. While fiber lasers might have higher upfront costs, they generally require less maintenance and consume less energy.

4. The thickness of Material: Examine the titanium sheet thickness you plan to cut. CO2 and Nd: YAG lasers perform better with thicker materials, while fiber lasers are ideal for the precise cutting of thinner sheets.

5. Maintenance Needs: Evaluate the maintenance demands for each laser system. Fiber lasers typically have fewer maintenance requirements and longer service lives compared to CO2 and Nd: YAG lasers.

The Process of Titanium Laser Cutting

Here Is the Process Explained Step by Step:

1. Design Preparation: Create a digital design of the desired shape or pattern using computer-aided design (CAD) software. This design will guide the laser-cutting process.

2. Material Selection: Choose the appropriate thickness and grade of titanium based on the specific application’s requirements.

3. Laser System Setup: Configure the laser cutting machine according to the chosen titanium thickness and the desired cutting speed, power, and other parameters.

4. Safety Measures: Ensure that the operator wears safety equipment, such as goggles and protective clothing, and that the cutting area is well-ventilated to prevent the buildup of harmful fumes.

5. Laser Cutting: Initiate the cutting process by activating the laser system. The laser will follow the CAD design, precisely cutting the titanium material according to the pre-determined pattern.

6. Cooling: Allow the cut titanium pieces to cool down to avoid potential burns or warping due to high temperatures.

7. Inspection: Check the cut pieces for accuracy, edge quality, and any potential defects. If necessary, make adjustments to the cutting parameters and repeat the process.

Best Practices for Ensuring Quality and Precision on Titanium Laser Cutting

1. Careful Material Handling: Manage the titanium sheets cautiously to avoid surface damage or contamination, which may impact the cutting quality. Make sure the sheets are free of debris and clean before cutting.

2. Laser Settings Adjustment: Determine the appropriate laser parameters, such as focus, power, and speed, based on the grade and thickness of the titanium. Proper settings ensure clean and accurate cuts.

3. Thorough Quality Control: Establish a comprehensive quality control process throughout production. Examine the cut titanium pieces for potential defects, edge quality, and accuracy, making adjustments as necessary to uphold high-quality standards.

4. Routine Maintenance: Follow the manufacturer’s guidelines for regular cleaning, inspection, and calibration of the laser cutting equipment. Consistent maintenance helps prevent issues and maintains cutting performance.

5. Precise CAD Design: Devote time to creating an accurate and detailed CAD design, as it directly influences the final cut quality. Review the design for errors and confirm it meets the application specifications before cutting processes begin.

How to Choose a Titanium Laser Cutting Service Provider?

Business Needs

1. Customization Capabilities: Look for versatility and adaptability to unique project requirements.

2. Pricing: Ensure cost-effective services without compromising on quality.

3. Customer Support: Choose a provider with excellent communication and responsive support.

4. Turnaround Time: Find a provider that meets your deadlines and production schedules.

Manufacturer, Reliability, and Product Quality

1. Equipment and Technology: Ensure the provider uses advanced laser cutting machines and software.

2. Experience and Expertise: Select a provider with a proven track record in titanium fiber laser cutting processes.

3. Reputation and Reviews: Research industry reputation, customer reviews, and testimonials.

4. Quality Assurance: Investigate the provider’s quality control measures and certifications.

Conclusion

In conclusion, titanium laser cutting offers numerous benefits, such as high precision, speed, and versatility, making it an essential technique in various industries.

To make the most of this technology, consider factors such as material properties, laser types, and best practices for ensuring quality and precision. When choosing a service provider, prioritize business needs, manufacturer reliability, and product quality.

Discover Excellence With Baison’s Customized Laser Cutting Solutions

Unlock your business’s full potential with Baison’s bespoke laser cutting services, designed to cater to your specific needs. Our proficient team and cutting-edge technology guarantee accuracy, productivity, and dependability for every engagement.

Partner with Baison for a distinctive laser-cutting experience and elevate your business to the next level. Get a Free Application Evaluation.