This is important because a new phase in the elevator manufacturing and parts industry is coming. The reason for this is that the demand for elevator manufacturing is rising in the middle of the manufacturing transition between old ways and new technology. As laser-cutting machines get some favorable nods from several manufacturers and clients, the process is becoming much more efficient.

From the 1990s, when processing plates for elevator manufacturing included multi-station punching, the 21st century ushered in the use of laser cutting machines. The manufacturing process for elevators now included speed and efficiency. To help you understand this better, we look at what a fiber laser cutting machine is and how it helped transform the elevator manufacturing process.

What Is a Fiber Laser Cutting Machine?

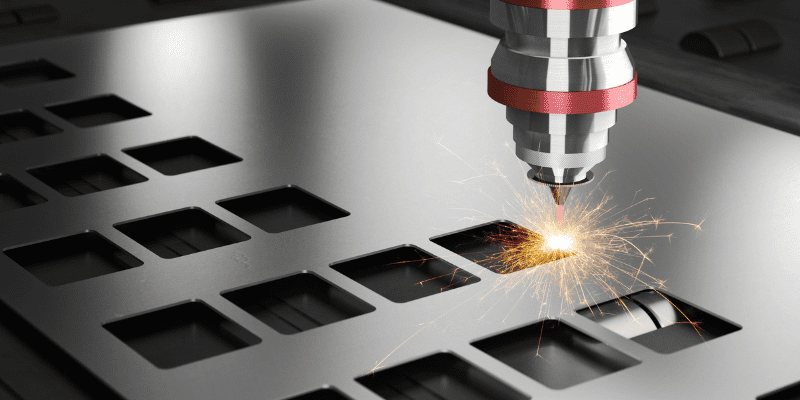

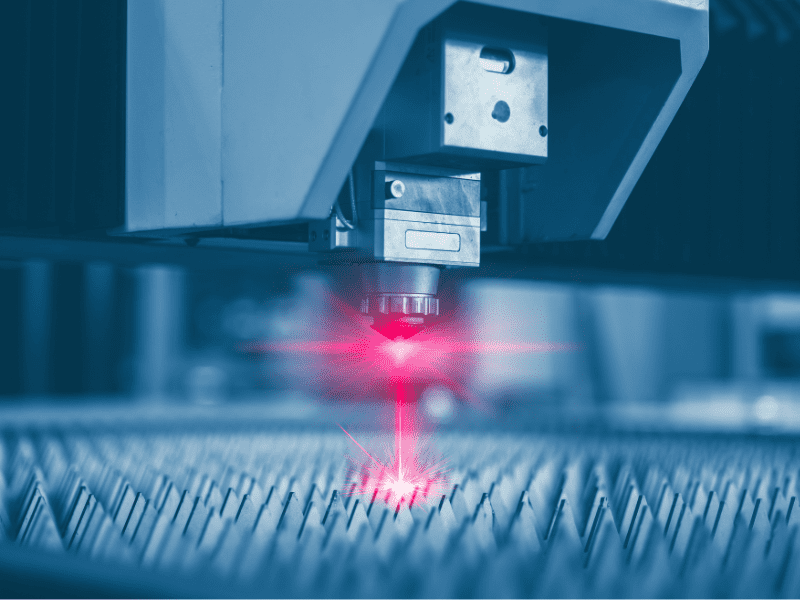

A fiber laser cutting machine is used to cut metals, especially with various widths and thicknesses. It uses optical fibers as it creates and transports laser beams to the machine’s cutting head. The hot laser that is created by the machine is directed to a narrow beam where it starts to go through different types of metal to be cut.

When you integrate a fiber laser system into a cutting framework, it now becomes the tool for the cutting machine. But why are laser machines starting to be the preference in the elevator manufacturing industry and other industries?

Here are three of the top reasons why people prefer to work with laser machines:

- Safety for workers and overall operation

- Automation for the entire process

- Lasers can be utilized for precise operations

Now that you know what a fiber laser cutting machine is, let’s take a closer look at what fiber laser cutting is.

What Is Fiber Laser Cutting?

As the name suggests, this is a fiber laser-cutting process. The laser goes through a fiber cable that is mostly composed of silica glass which enables it to guide the laser. This results in a more precise cutting procedure with the laser beam simply because it can cut with smaller precision.

One reason this is possible is that optical fiber intensifies the power of the laser. Since the laser is concentrated light, the optical feature of the fiber elevates the power state of the laser, making it more powerful and efficient.

Benefits of Using Fiber Laser Cutting Machine

A fiber laser cutting machine is simple to operate with automation, and maintenance is much easier. Not to mention that the cuts are much more precise and not too messy. Here are some more benefits of using a fiber laser cutting machine, especially in the elevator manufacturing and parts industry.

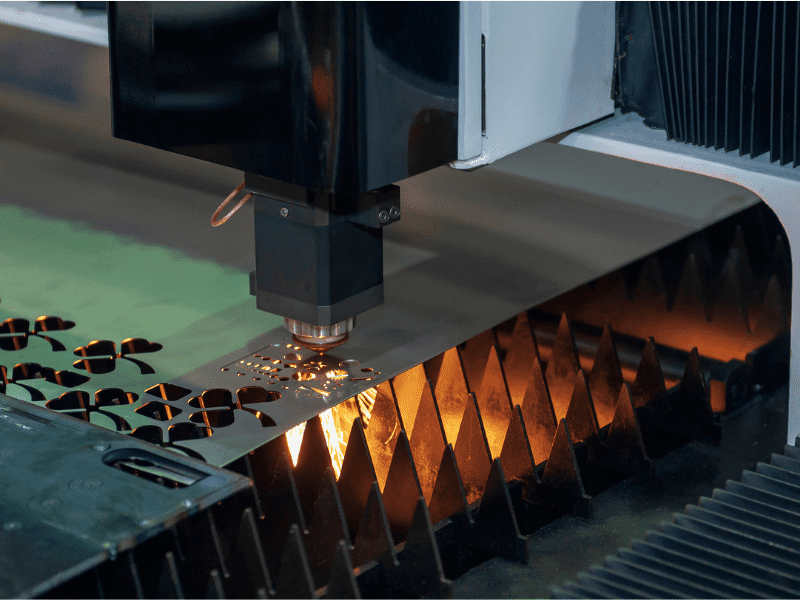

- More manageable cycle for the production process – the sheer mold and even size for some metal sheet parts in elevator manufacturing make it difficult to cut them down to custom size. Some elevator requirements require small metal sheet parts only. It would take a mold to do this in the past, but this took a long time. A fiber laser cutting machine can cut these metal sheets to size without waiting for a custom mold. This makes the production cycle much shorter and faster.

- Superb cutting outcome – in the old days, when the material would have to go through several stations to get cut, it would usually leave marks on it. Fiber laser cutting machines eliminate possible deformation from the old cutting process. No mechanical stress is laid on the material, just the laser beam touching it.

- Product cutting flexibility – there are instances where there is a need to make small and irregular cuts on metal sheets. Fiber laser cutting machines can easily make those cuts, unlike when you needed to create molds before you could cut.

- Clean process – while the laser beam cuts the material, a parallel airflow stream goes with it. This helps the cut more efficiently as it blows away possible materials in the way of the laser.

- Materials you can cut – one of the biggest advantages of fiber laser cutting is its ability to cut through reflective materials. Of course, it can also make clean cuts on sheet metals like carbon steel, brass, stainless steel, copper, aluminum, and even titanium.

- More power leads to deeper cuts – the more powerful the machine, the deeper it can cut. But a 13mm metal sheet is easy for most fiber laser cutting machines. For machines with 10 KW of power – 30mm of aluminum and even 2mm of steel are manageable.

- Longer working operations – fiber laser cutting machines are much more efficient because they have low downtimes and very minimal set-up. This allows you to spend most of the time cutting metals.

How to Choose the Suitable Fiber Laser Cutter for Elevator Manufacturing

Cutting speed, cutting depth, and even flexibility of the machine are some factors to consider when looking for the most suitable fiber laser cutter for elevator manufacturing. These areas directly affect the efficiency and final product output in every cutting job. Let’s dive into the details and look at other factors you need to consider.

Power – The power output capability of the fiber laser cutting machine dictates the speed and depth of cut it can make. This is crucial in the elevator manufacturing and parts industry. Since the materials used in making elevators need to be tough and sturdy, the thickness of the materials is a given. Metal sheet and tube cutting require high-powered fiber lasers to cut through them at acceptable speeds. For speed, a 1200W laser can help you cut through a carbon steel plate with 2mm thickness at an average of about 600cm every minute. So factor in the power of the machine about the materials you are using.

Time – More than cutting speed, the efficiency of the fiber laser cutting machine should include less downtime. Working with laser-cutting machines eliminates the need for materials clamped down throughout the process. This is something very prevalent in the past with multi-station punch presses. As a result, it saves you tremendous time in loading and even unloading materials you are cutting.

Adaptability – Gone are the days of old-fashioned elevators that all look alike. At present, design and aesthetics also play a big part next to the safety and functionality of the elevator. This is a big factor for a lot of elevator manufacturers. This is why most elevator makers are using fiber laser cutting machines. More than dealing with thick materials for the elevators, it can also handle small and irregular cuts for elevator design. This would have been a long and tedious process with punch presses, especially when you are limited with mold and even tonnage or size.

Durability – When you use your scissors to cut paper, your scissors or cutting tool directly interacts with the material you are cutting. Over time, this contributes to the wear and tear of your scissors. This is one of the reasons why a fiber laser cutting machine is durable – the cutting torch does not come into direct contact with the material. It drastically reduces wear on the tool. Not only that, but it also contributes to low noise levels in the production place and minimal vibration.

Cleanliness – One of the things you need to look out for when choosing a fiber laser cutting machine for elevator manufacturing is the post-cleaning requirement. Yes, fiber laser cutting machines usually have an airflow stream that runs parallel to the laser. But this blows away potential contaminants. It would be best if you had a machine that covers your cutting area and even an exhaust system for a cleaner job.

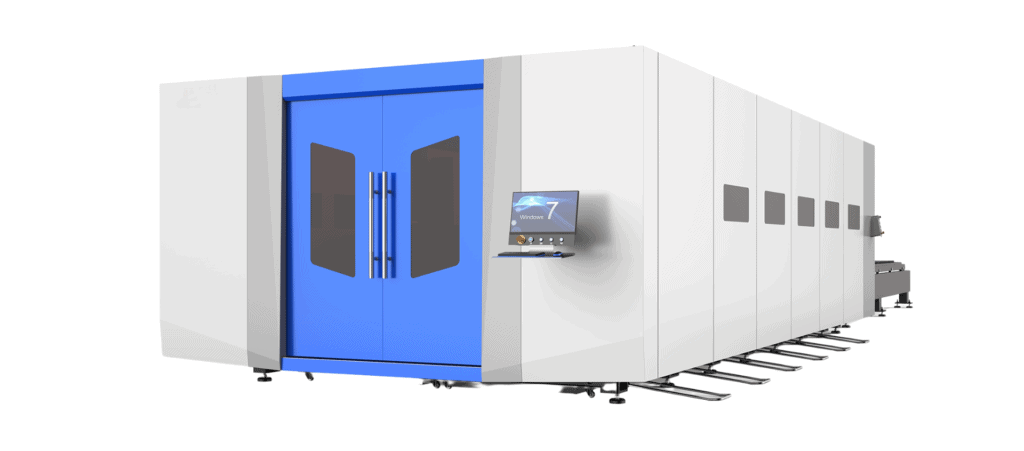

The easy-to-use control system sets the HBE Series apart from the rest in the industry. Since the fiber laser cutting machine is fully automatic, the intelligent functions developed by industry experts make the process smooth and easy. Some features include smart collision prevention and even automatic edge-seeking technology.

Conclusion

In wrapping up, selecting the right fiber laser cutting machine for elevator manufacturing is pivotal to ensure precision and efficiency. By considering factors like power, speed, and material compatibility, manufacturers can achieve optimal results. As the elevator industry continues to evolve, having the right equipment in place is key. Make informed decisions and elevate your production to new heights.

Ready to Elevate Your Production? Discover Our Fiber Laser Solutions Now!

If you are looking for the most reliable fiber laser cutting machine for elevator manufacturing, then our HBE Series checks everything you need for an efficient cutting machine. It provides quick and effective cutting operations from start to finish and ensures quality metal cuts over a long period. Click here for a quote now!