Can laser remove rust from metal surfaces? How energy efficient is laser cleaning equipment? Or how much does a laser cleaning machine cost?

Prices can be daunting, but you’ll be surprised at the results and returns on investment! Find out all there is to know about laser cleaning!

The Laser Cleaning Process: How Does It Work?

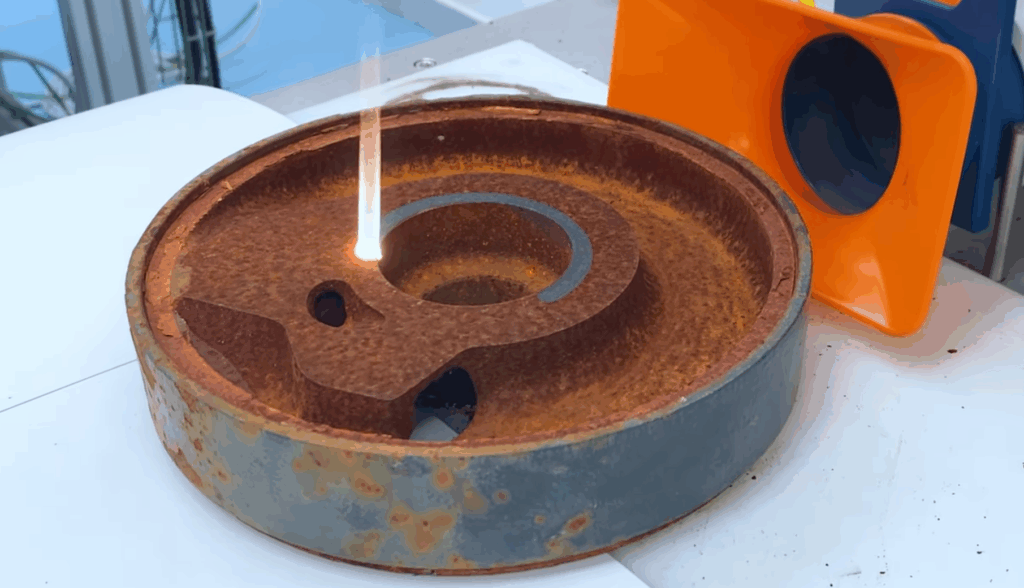

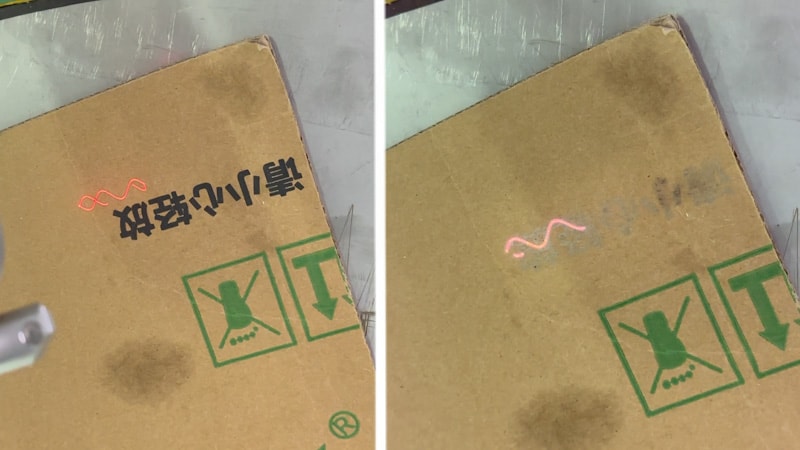

Laser cleaning is a non-contact surface preparation method that uses focused laser beams to remove contaminants, coatings, or unwanted materials from a substrate. The process works by directing high-energy laser pulses onto a surface. These pulses are absorbed by the unwanted layer, causing it to vaporize or break apart, while the underlying material remains unharmed.

Laser technology relies on precise control of laser parameters such as pulse duration, energy, and wavelength to selectively target contaminants without damaging the base material. Contrary to traditional methods, laser cleaning is highly controlled and repeatable for industrial applications.

Thanks to its versatile nature, laser cleaning is widely adopted in aerospace, automotive, and electronics industries. In aerospace, it is used for removing coatings, mold cleaning, and preparing surfaces for bonding or welding, all without altering sensitive substrates.

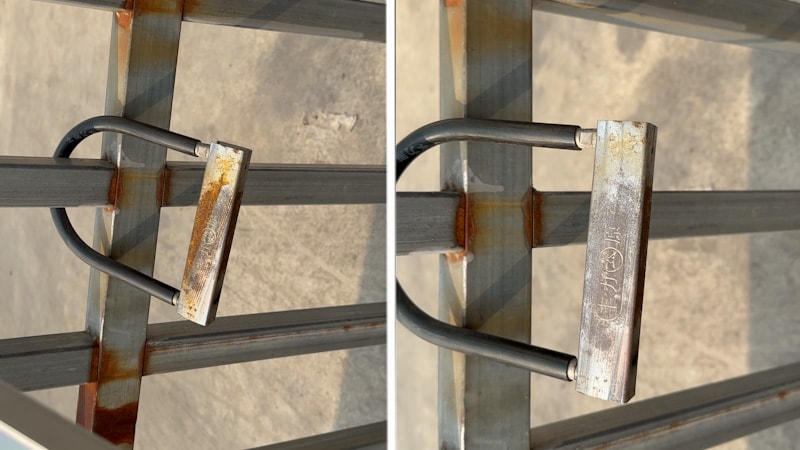

The automotive sector uses laser cleaning for rust removal, weld preparation, and cleaning injection molds. In electronics manufacturing, the method is applied to remove oxides, films, and residues from delicate components in automated or robotic setups.

Sectors like shipbuilding, construction, and precision engineering also benefit from this environmentally friendly surface treatment method.

The main benefits of laser cleaning include exceptional precision, as the laser can be focused on specific areas without affecting adjacent surfaces. The process is eco-friendly because it does not require chemicals or abrasive media.

Key Benefits of Laser Cleaning

High Precision and Control

Laser cleaning provides you with unmatched precision and control. The laser beam can be finely tuned to remove only surface contaminants, leaving the underlying material untouched. This capability is crucial when you work with delicate components or parts with complex geometries.

You can clean intricate surfaces and sensitive substrates without causing micro-cracks, distortion, or loss of detail. Automation and real-time monitoring further enhance the accuracy and repeatability of the process, making it suitable for industries that demand high-quality surface preparation.

Eco-Friendly and Sustainable

Laser cleaning stands out as an eco-friendly solution for your industrial cleaning needs. The process does not require chemicals, abrasive materials, or water, so you avoid generating hazardous waste or chemical runoff. Laser vaporises the contaminants and produces only minor particulates that you can easily filter.

Laser cleaning reduces your environmental footprint and helps you comply with strict environmental standards. In addition, the absence of consumables and waste management requirements streamlines your workflow and supports your sustainability goals.

Minimal Wear and Tear on Equipment

The non-contact nature of laser cleaning means you do not subject your equipment or workpieces to mechanical stress or abrasion. This approach prevents surface erosion, material loss, and deformation, which are common in abrasive cleaning methods.

Your laser cleaning system experiences minimal wear, fewer breakdowns, and longer service intervals. This reliability translates to consistent cleaning quality and reduced downtime, critical for maintaining productivity in demanding industrial environments.

Cost-Effectiveness Over Time

Although the initial investment in a laser cleaning system can be significant, you benefit from lower operational costs over time. You do not need to purchase consumables such as chemicals or abrasives, and maintenance requirements are minimal due to the lack of moving parts.

Automation reduces labor costs and increases throughput. You also save on waste disposal and regulatory compliance expenses. These factors make laser cleaning a cost-effective and scalable solution for your long-term industrial cleaning needs.

Applications of Laser Cleaning in Various Industries

1. Automotive Industry

Laser cleaning removes rust, paint, and debris from car parts and engine components without damaging the underlying metal or plastic. You can restore vintage car bodies by stripping oxidized paint layers or clean engine blocks by vaporizing oil and grease.

Laser surface cleaning also eliminates abrasive media, making it ideal for delicate surfaces like aluminum panels or intricate engine parts. Automated systems integrate with production lines for fast, consistent cleaning of chassis, wheels, or transmission components.

2. Aerospace Industry

In aerospace, laser cleaning maintains turbine blades, landing gear, and bonding surfaces by removing oxides, coatings, and other contaminants. You achieve precision cleaning for welding or adhesive bonding, ensuring optimal performance and safety. ,

The non-contact method avoids microdamage to heat-sensitive alloys, critical for components like fan blades or fuel nozzles. Laser systems also clean molds used in composite manufacturing, streamlining high-stakes production processes.

3. Electronics Manufacturing

Laser cleaning eliminates micron-level pollutants like dust, grease, and oxides from sensitive electronic components such as circuit boards or silicon wafers. You avoid chemical residues or physical stress caused by traditional methods, preserving the integrity of microcircuits and connectors. Since it doesn’t use chemical solvents, it sharply reduces environmental pollution.

4. Heavy Machinery and Equipment

For heavy machinery, laser cleaning removes corrosion, scale, and grime from steel structures, gears, or hydraulic systems.

You restore surfaces without abrasive media that could wear down critical components. The method handles large, uneven surfaces efficiently, even in hard-to-reach areas, and prepares parts for recoating or inspection while maintaining structural integrity.

5. Cultural Heritage and Restoration

Laser cleaning preserves historic artifacts, sculptures, and buildings by gently removing dirt, soot, or biological growths. You target protective coatings layer-by-layer without harming the underlying substrate like stone, wood, or gilded surfaces. The process reveals original details lost under centuries of decay, offering a non-invasive solution for restoring cultural heritage with unmatched precision.

Types of Laser Cleaning Systems: Which One Is Right for Your Needs?

Fiber Laser Cleaning Systems

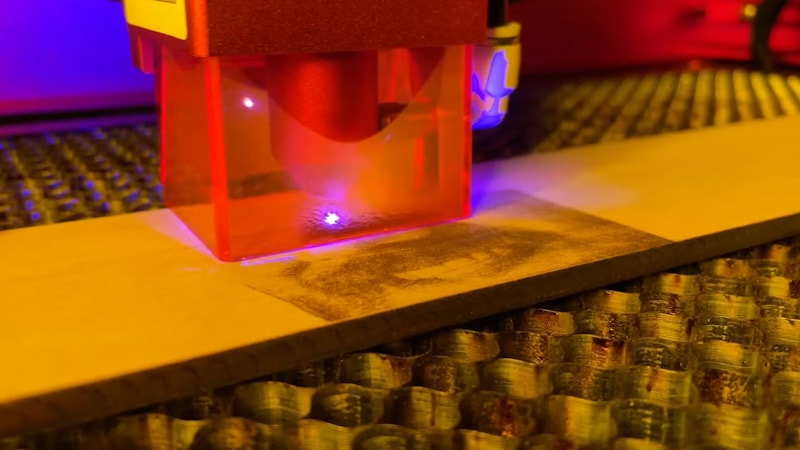

Fiber laser cleaning systems offer you high flexibility and efficiency for precision cleaning tasks. These machines use focused laser beams to remove rust, paint, and other contaminants from metals and other surfaces without damaging the base material.

Fiber lasers are well-suited for industries like automotive, aerospace, and electronics because they deliver consistent results and can be easily automated. You can use them for intricate parts or hard-to-reach areas, so they are ideal when you need both precision and speed.

Diode Laser Cleaning Systems

Diode laser cleaning systems provide a cost-effective solution for large-scale cleaning applications. These systems use semiconductor-based lasers, which are generally less expensive to manufacture and maintain.

Deploy diode lasers for cleaning tasks that require less precision but higher throughput, such as removing surface coatings or preparing large metal structures. Their lower energy consumption and simpler design make them attractive if you want to minimize operational costs while efficiently covering broad surfaces.

Hybrid Laser Cleaning Systems

Hybrid laser cleaning systems combine the strengths of both fiber and diode lasers, giving you versatility for a wide range of applications. Depending on your cleaning requirements, these systems allow you to switch between different laser sources or use them together.

You benefit from the precision of fiber lasers for detailed work and the efficiency of diode lasers for bulk cleaning. Hybrid systems are ideal if your operations demand flexibility, as they can adapt to various materials and contamination types without needing multiple machines.

Laser Cleaning vs Traditional Cleaning Methods: Why Choose Laser Cleaning?

| Criteria | Laser Cleaning | Sandblasting | Chemical Cleaning |

|---|---|---|---|

| Precision | High; targets contaminants without substrate damage | Moderate; can cause surface roughness or wear | Variable; may leave residues or react with substrate |

| Surface Impact | Non-contact, preserves fine details | Abrasive, may damage delicate or soft materials | Can etch or discolor sensitive surfaces |

| Environmental Impact | Eco-friendly; no chemicals or abrasive waste | Produces dust and spent abrasive waste | Generates hazardous waste and chemical runoff |

| Safety | Safe; minimal PPE required. | High PPE needed; dust inhalation risks | Toxic fumes and skin contact risks; strict protocols needed |

| Cleaning Effectiveness | Excellent for rust, paint, and organic residues | Highly effective for thick coatings and heavy contaminants | Effective for dissolving specific contaminants |

| Cost | High initial investment, low operating costs | Lower initial cost, ongoing abrasive and maintenance costs | Moderate; recurring chemical and disposal costs |

| Maintenance | Minimal; few moving parts | Frequent nozzle and media replacement | Regular chemical handling and waste management |

| Best Use Cases | Sensitive, high-value, or precision components | Large-scale, robust surfaces | Removing specific contaminants from compatible materials |

Cost Considerations: Is Laser Cleaning Worth the Investment?

The laser cleaning machine price may be concerning, but considering the long-term value, it’s well worth it.

| Aspect | Laser Cleaning Systems |

|---|---|

| Initial Investment | $10,000 – $500,000+, depending on power (100W–3,000W), brand, and features like automation or safety enclosures. Higher-powered systems suit large-scale industrial applications. |

| Maintenance Savings | Minimal wear due to non-contact operation; no abrasive media or chemicals are required. Compared to sandblasting or chemical methods, reduced downtime and part replacements. |

| Operational Efficiency | Faster cleaning cycles and automation reduce labor costs. High precision minimizes rework. |

| Environmental Compliance | No hazardous waste (chemicals/abrasives) or runoff. Complies with strict regulations, avoiding disposal costs and fines. |

| ROI | Achievable in 6–18 months for mid-range systems. High-profit margins from reduced labor, waste, and rework costs. Premium restoration projects yield higher returns. |

| Total Cost of Ownership | Lower long-term costs due to energy efficiency, minimal consumables, and extended equipment lifespan (5–10+ years). |

Choosing the Right Laser Cleaning Partner: What to Look For

Here’s how to quickly assess a long-term partner in 10 steps:

- Look for providers with proven industry experience, like Baison Laser, and relevant case studies in your sector.

- Assess the quality and reliability of their equipment and laser technology.

- Check for customization options to match your specific cleaning requirements.

- Confirm the provider offers comprehensive customer support and technical assistance.

- Ensure operator training and onboarding are part of the service package.

- Evaluate their after-sales service, including maintenance and spare parts availability.

- Review certifications like CE or FDA for compliance and safety standards.

- Ask about demo availability or trial periods for hands-on evaluation. Sample proofing is an excellent assessment method.

- Consider their global service network and response times for support.

- Read customer reviews and request references to verify satisfaction and performance.

Types of Laser Cleaning Machines

1. Handheld Laser Cleaning Machines

Handheld laser cleaning machines are portable, compact, and user-friendly devices ideal for on-site maintenance, rust removal from irregular surfaces, and hard-to-reach areas. They offer high flexibility, minimal setup, and lower initial investment, but are less suitable for large-scale or high-speed production tasks.

2. Automated Laser Cleaning Systems

Automated laser cleaning systems integrate lasers with robotic arms or conveyor setups, making them ideal for high-volume production lines in automotive, aerospace, and heavy machinery industries. They deliver high throughput, consistent cleaning quality, and reduce manual labor.

They further boast precise, scalable, and safe operation within enclosed work cells. However, to optimize performance, these systems require a higher initial investment, specialized integration, and training.

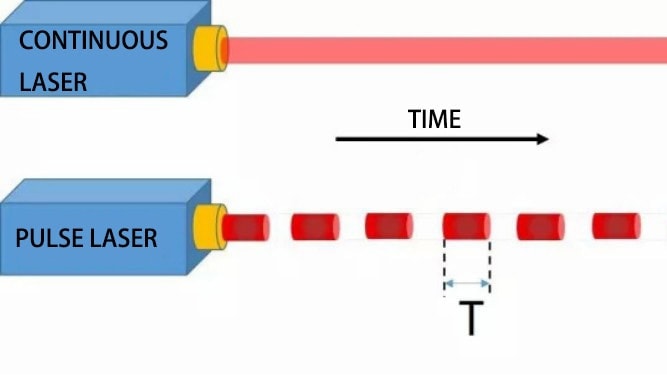

3. Pulsed vs. Continuous Wave (CW) Laser Systems

| Feature | Pulsed Laser Systems | Continuous Laser Systems |

|---|---|---|

| Operation Mode | Emits pulses (1–200 ns duration) at 10–1000 Hz repetition rates | Emits a steady beam, continuous output |

| Peak Power | 10–100 kW per pulse (average power: 100–500 W) | 1–3 kW continuous output |

| Precision | Spot size: 20–100 µm; depth control: ±5 µm | Spot size: 100–500 µm; depth control: ±20 µm |

| Thermal Impact | Heat-affected zone: <10 µm; substrate temp rise: <50°C | Heat-affected zone: 50–200 µm; substrate temp rise: 100–300°C |

| Cleaning Speed | 0.5–2 m²/hr (depending on contamination and material) | 5–15 m²/hr (depending on contamination and material) |

| Surface Suitability | Suitable for 0.1–5 mm thick, heat-sensitive, | Suitable for 2–50 mm thick, robust, or large flat surfaces |

| Applications | Electronics (PCB, sensors), aerospace (turbine blades), precision molds, pre-weld prep | Ship hulls, pipelines, steel beams, automotive frames, heavy machinery |

| Energy Efficiency | 0.1–0.3 kWh/m² cleaned | 0.5–1.5 kWh/m² cleaned |

| Cooling Needs | Air or water cooling, 0.5–1.5 kW cooling capacity | Water cooling, 2–5 kW cooling capacity |

| Estimated Cost | $30,000 – $500,000+ (100–500 W, industrial grade) | $10,000 – $250,000+ (1–3 kW, industrial grade) |

| ROI | 12–24 months (typical for high-value, precision applicati | 6–12 months (typical for large-scale, high-throughput operations) |

| Typical Power Range | 100–500 W (industrial cleaning) | 1,000–3,000 W (industrial cleaning) |

4. Fiber Laser Cleaning Machines

- Most commonly used in industrial settings.

- Applications: Rust, paint, oxide, oil, and surface prep for welding.

- Advantages: Long service life, energy efficiency, minimal maintenance.

- Why B2B Clients Prefer It: Reliable performance for a wide range of metal cleaning needs.

5. Other Laser Types (Brief Overview)

CO₂ Laser Cleaners

CO₂ laser cleaners use infrared light to clean surfaces. You can use them effectively on non-metallic materials such as glass and plastics. These systems are less popular for heavy-duty industrial cleaning because they perform poorly on metals or thick coatings. Find out more about CO2 and Fiber laser differences.

UV Laser Cleaners

UV laser cleaners emit ultraviolet light that achieves ultra-precise ablation. You can rely on them for applications in microelectronics, semiconductors, and precision tools. The process generates minimal heat, so it protects sensitive components from thermal damage.

Green Laser (532nm)

Green laser cleaners operate at a 532nm wavelength, which is well-suited for sensitive materials. They can also be used to clean surfaces that require a gentle approach. The green laser effectively removes contaminants while limiting thermal effects.

6. Air-Cooled vs. Water-Cooled Systems

| Aspect | Air-Cooled | Water-Cooled |

|---|---|---|

| Power Range | Suitable for lasers up to 1–2 kW (low to mid-power) | Handles lasers from 2 kW up to 20 kW+ (high-power, continuous use) |

| Portability & Size | Lightweight and compact (10–30 kg); easy to move and install | Bulky and heavy (50–200 kg+ with chiller); best for stationary or industrial setup |

| Cooling Efficiency | Cooling is limited by ambient air; less stable at high duty cycles; temperature rise can reach 10–20°C | Superior cooling; maintains stable temps within ±1°C; supports continuous operation and high precision |

| Maintenance | Requires frequent dust cleaning on fans, higher noise, and easy basic upkeep | Needs water replacement, leak checks, and periodic cleaning; quieter operation; more complex upkeep |

| Cost | Lower initial cost ($500–$3,000); minimal infrastructure | Higher initial cost ($2,000–$10,000+); requires chiller and plumbing |

7. Stationary Laser Cleaning Workstations

Stationary laser cleaning workstations, available as bench-top or enclosed systems, are perfect for lab environments, clean rooms, or precision component cleaning. You can expect high stability, enhanced safety, and excellent repeatability from these units. They’re also ideal for controlled and meticulous cleaning tasks.

Conclusion: Is Laser Cleaning Right for Your Business?

Laser cleaning is highly versatile. It handles most cleaning processes, from intricate to heavy-duty. Since the machines are pretty expensive, always assess your needs first. Why do you need it? How much cleaning does your business do? Are you buying for personal use or as a service?

A pre-purchase assessment will definitely help you in the long run. Consult with experts, get a clear idea about safety classifications, and prioritize your ROI for maximum benefits.

Call to Action:

Interested in getting your own unit? Request a quote today!

Baison Laser has the most industry-leading fiber laser machines, programmed to satisfy your specific needs. Clean smart with the best laser cleaning technology!