What Is Electrochemical Etching

Electrochemical etching or chemical etching is a technique that involves using a process known as electrolysis to transfer certain information onto your product’s surface.

The etching process requires a few things:

- An electrolyte solution

- A mask or stencil

- An electrode marking head

An electrochemical etching machine will create an “oxide” black marking on the surface using forced corrosion. Then, the mark on the surface area will form through a series of actions.

Initially, you must soak your marking stencil or mask in an electrolyte solution. Next, put it on the product or area you wish to mark.

The marking head will then deliver some current to the surface of the metal through the stencil. You must keep repeating this process until you reach the darkness or penetration you are looking for.

The depth or darkness of the mark varies depending on the etching process. This is all affected by the base metal used, the solution and the time.

Forming the stencil, integral in the electrolysis process is the lengthiest part of the etching action. This is because, at first, you have to translate the information on the stencil.

For electrochemical etching machines, you can use different stencil types, such as printed stencils, instant cartridge stencils, photographic stencils, and die impression stencils.

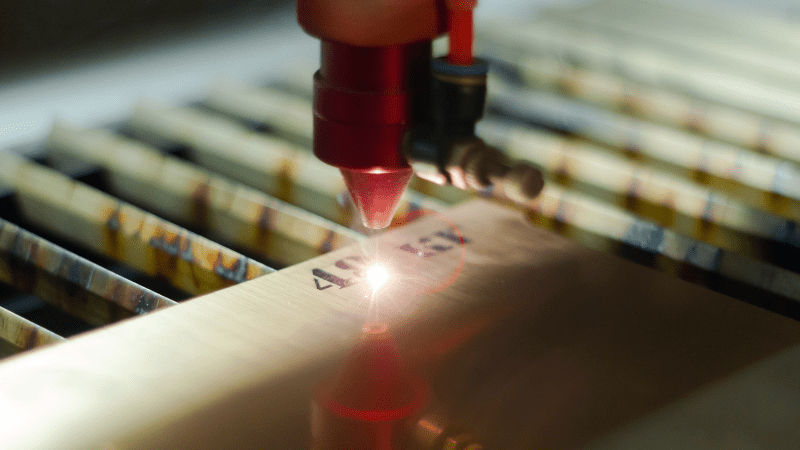

Are Electrochemical Etching and Laser Etching the Same Thing?

Those new to the laser marking and laser etching processes often confuse electrochemical etching with laser etching. Although they both remove some of the material from the surface on which they operate, they are slightly different.

Chemical etching exposes the surface to a corrosive agent. It will lead to a chemical reaction between an electrolyte and the surface, like metal. To be possible, this process requires not only electrically conductive parts but also a stencil of the marking model you want on the material.

Laser etching, on the other hand, does not need any electrically conductive parts. Instead, the laser etching machines will use a laser beam to generate the pattern you are looking for on the surface finish. A controller guides the laser, thus determining its intensity, size, and direction.

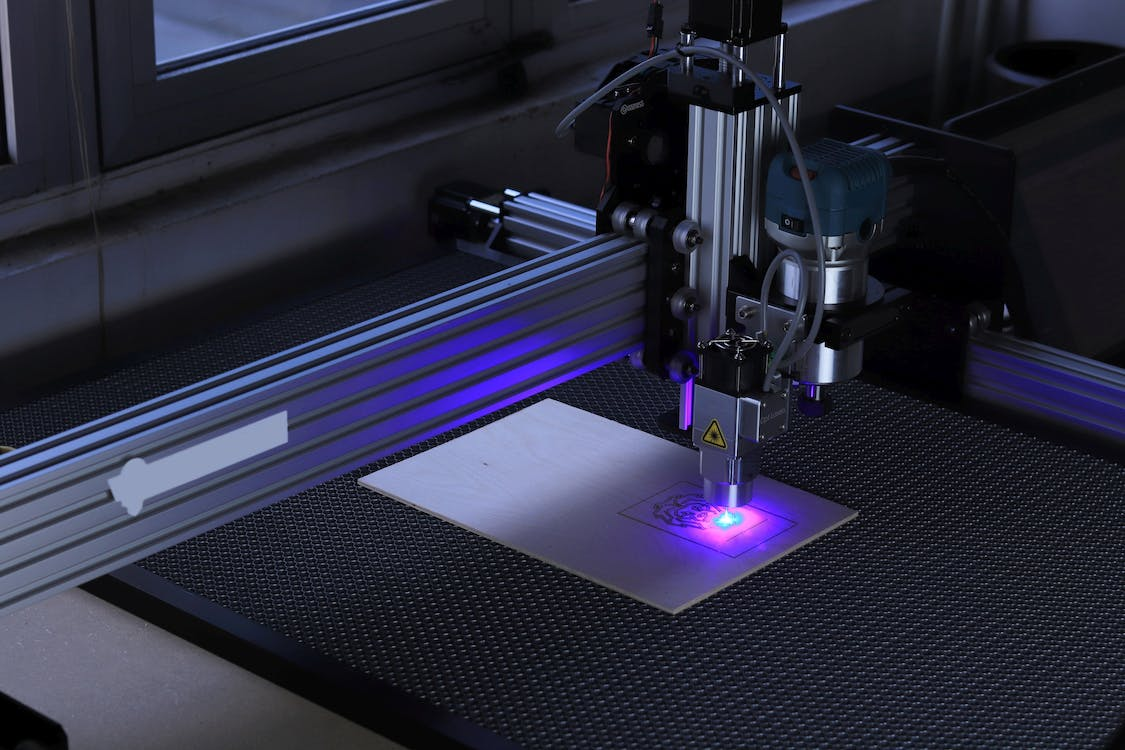

What Is Fiber Laser Marking

Fiber laser marking refers to a new laser engraving type that involves using fiber laser marking machines.

Fiber lasers will vaporize an excellent layer of your product’s material. They send a highly localized laser pulse to the surface, creating the tracking code or any other marking you want to make.

Fiber laser technology uses lenses to give more power to the laser. The laser beam will focus even more on the surface area.

This technique does not alter the metal’s top layer by raising it. Instead, it simply operates on the metal surface by leaving a dark impression on it.

Using these laser marking systems, you can reach up to 0.5mm during the laser etching process. At the same time, it all depends on the material you are working on and the speed of the laser. It takes longer to reach the proper depth when the material is more complex.

What’s great about this laser marking technique is that it’s pretty fast and lets you apply any 2D image. In some cases, fiber lasers let you create minimal dimension markings on the surface, sometimes so small that you cannot achieve them if you use, for instance, dot peen marking.

Although both dot peen marking machines and fiber laser marking machines can create permanent markings, fiber lasers can provide better quality markings. With dot peen-keeping technology, the images on the surface end up being much harder to read.

What Industries Take Advantage of Laser Engraving and Etching?

Fiber laser marking and electrochemical etching are so valuable for the ways they are used in many industries.

Many individuals use laser engraving machines or electrochemical etching machines to mark their company’s logo or different barcodes. Sometimes, they mark data matrix codes, and other times they keep QR codes or serial numbers.

Let’s take a look at some of the industries that take advantage of fiber laser markers or electrochemical etching:

- Manufacturers of Medical Devices

In the medical field, all devices must be identified. What better way to identify them if not by marking them?

With the FDA imposing such regulations, medical device manufacturers now use electrochemical etching or fiber laser marking methods to uniquely keep all medical devices.

- Primary Metals Industry

The traceability capabilities of the metal die casters, smelters, and hot and cold roll plants required some improvements. Part producers required the metal industry to get better at this.

To meet these requirements, smelters and others in the primary metals industry started using laser marking.

- Automotive Industry

The automotive industry also requires marking to identify the different parts they would use in creating cars.

Car manufacturers were among the first to identify the parts that would ultimately be used in the manufacturing process through data matrix codes.

Nowadays, the identification requirements have increased, with manufacturers wanting their parts marked and labeled as soon as possible.

Differences Between Electrochemical Etching and Fiber Laser Marking

Now that we’ve established electrochemical etching and fiber laser marking, you might want to know the differences between the two techniques.

Here are some of the most critical different contrasts between these marking methods so you know what to expect with one or the other:

- Surfaces and Materials Used

Both electrochemical etch and laser marking approaches look to give your working material a long-lasting imprint, but they cannot be used on the same type of materials.

Fiber lasers work by marking a large selection of surface materials or coatings. However, etching is only effective on conductive materials.

For this reason, electrochemical etching may not be suitable for all applications.

- Operation

Perhaps the most apparent difference exists in the operational process of the techniques.

Electrochemical marking works with the help of an electrode marking head, a stencil or mask, and an electrolyte solution. Then, the machine will follow the model on the stencil to create the imprinting.

However, fiber laser marking uses a laser beam that slowly moves across the surface. To create the desired model in the area, the software will send the requirements to the system digitally.

- Marking Accuracy

Both techniques have different levels of accuracy. Typically, laser marking is more accurate, and this is all due to the way etching works.

Factors such as how flat the surface is and the absorption rate of the material will significantly influence the electrochemical etching result. On top of that, etching might need more than one application to make the marking uniform.

- Cost Effectiveness

The electrochemical etching process is more affordable initially. However, other costs will be considered, such as the chemical disposal company or filtration system prices and the cost of the chemicals and stampings.

Therefore, while fiber laser marking is pricier, it’s worth spending money on it due to its benefits in the long term.

- The Impact on the Environment

Environmental impact is worth considering if you don’t want to harm nature.

As such, fiber lasers might be the better option in this case. They do not use any chemicals, not to mention that they are more energy efficient.

Meanwhile, electrochemical etching requires the use of chemicals. These have to be disposed of properly through a reputable third-party company; otherwise, they can pollute the public water system.

- Speed

How quickly you can achieve the metal marking will also be influenced by the procedure you pick.

Marking speed is usually better with fiber laser technology. It only takes a few seconds to complete a more suitable process for large productions.

As for electrochemical marking, it’s generally slower, mainly because you need to repeat it a few times. Besides, you need to make a new stencil for each application.

Sometimes, it takes up to a few hours until the marking process ends.

The Advantages of Electrochemical Etch and Fiber Laser Marking

Laser machines and electrochemical etch processes are great when you use them correctly and in suitable applications. They both come with their benefits and if you’re about to use one of them, you must know what they can bring to the table.

Here are the pros of electrochemical etch and fiber laser marking:

- Electrochemical Etching Advantages

- You do not need a lot of machine maintenance

- Nothing can alter the marking

- For an economical budget, this is a beautiful aesthetic marking alternative.

- Easy marking option

- It doesn’t have any negative impact on the strength of the material

- Fiber Laser Marking Advantages

- It decreases the operating costs

- It doesn’t use any chemicals in the process, making it more environmentally friendly.

- Can create permanent markings

- It’s speedy and more suitable for large productions

- Accurate results

- It decreases the operating costs

Things to Take Into Account When Picking Your Marking Method

If you’ve reached the point where you need to use marking technologies, you must ensure you settle for the right one.

With electrochemical etch and fiber laser marking being so unique, selecting one can be challenging when you don’t know which one would be more suitable.

That being said, here are some things to consider when choosing between the two:

- Production Speed

How fast you need to complete the engraving process comes into play when choosing a marking process.

If you are involved in producing multiple parts and you have a deadline to meet, fiber laser marking would be the better option. It’s faster, allowing you to imprint on more parts in a shorter amount of time.

Electrochemical etch machines would not be as quick in completing the marking process.

- Impact on the Environment

Is your business environmentally friendly? You should also remember this when trying to pick one of the marking methods presented.

Fiber laser marking has less impact on the environment, whereas chemical etching can negatively affect the chemicals required.

- Budget

You should also consider how much money you have at your disposal for the marking or etching.

The electrochemical method is cheaper but requires more cash in the long term. In contrast, fiber laser marking is pricier initially but ensures durability and requires no more costs.

- The Material You Want to Mark

The type of surface you wish to mark is also important.

Fiber laser marking machines can work on different surfaces, including stainless steel or another type of metal. However, electrochemical etching is only suitable for electrically conductive materials.

Finding the Best Process to Meet Your Needs

When trying to find the best marking technology for your business, think about how much each costs and how quickly you want to complete the process.

Also, you should consider how much you can impact the material you use. With fiber lasers, you merely create a dark mark on the surface, while etching will alter the first layer of your fabric. In some industries, modifying the surface like that is not recommended.

You should also consider the design quality you can reach with both techniques. If you cannot afford to sacrifice the model’s accuracy, you should go for a process that can create elaborate patterns and designs.

Conclusion

So, which one is better? Electrochemical etching or fiber laser marking? The answer to this question depends on your specific needs and what you are looking for in a marking process. If you need a high-quality, detailed mark with minor surface damage, fiber laser marking may be your best option. However, electrochemical etching may be the better choice if you are looking for a more cost-effective solution to produce markings on various materials. Contact Baison today to get an instant quote and find out which process is right for your business!