What Is Dry Ice Blasting?

Dry ice blasting is the process of using pressurized dry ice to clean surfaces. The dry ice is accelerated out of the gun and hits the surface, cleaned at high speeds, dislodging dirt, grime, and other debris.

It’s a popular cleaning method because it’s relatively safe and environmentally friendly – unlike traditional ways like sandblasting, which can use harmful chemicals and damage surfaces.

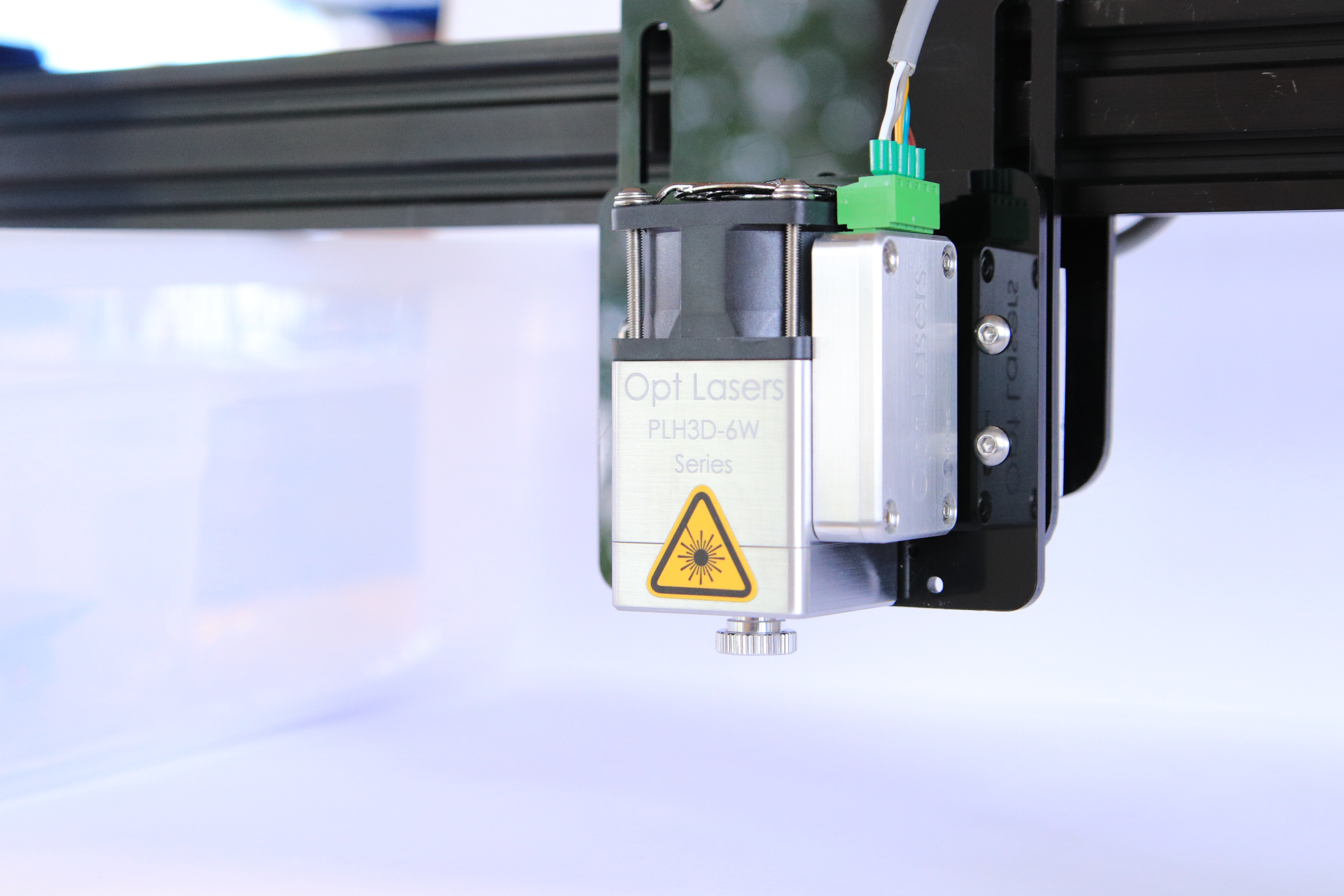

What Is Laser Cleaning?

Laser cleaning refers to the technique of removing impurities from a surface with the use of laser beams. Pulses of laser beams with nanoseconds duration fired in the direction of the contaminants. When the laser interacts with the impurities, the contaminants absorb the laser light, causing the pollutants to turn to gas or disintegrate due to high pressure.

How Do They Work?

The ice blasting mechanism and the laser cleaning mechanism each have their intriguing functioning to investigate. The procedure is not too complicated, but it is interesting to get acquainted with. Let’s learn more about the procedures used in these two cleaning methods.

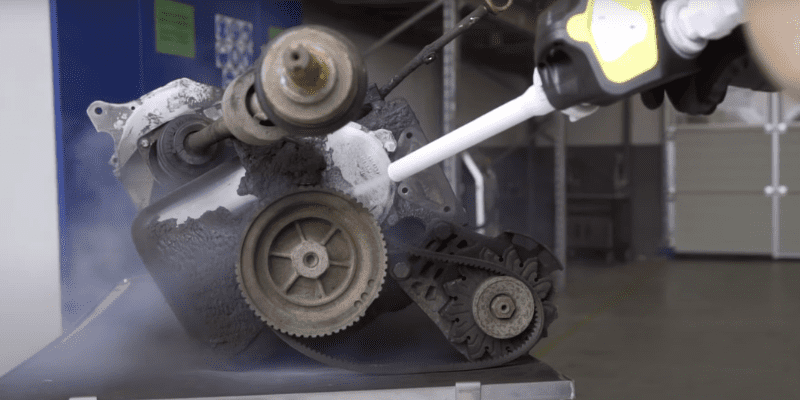

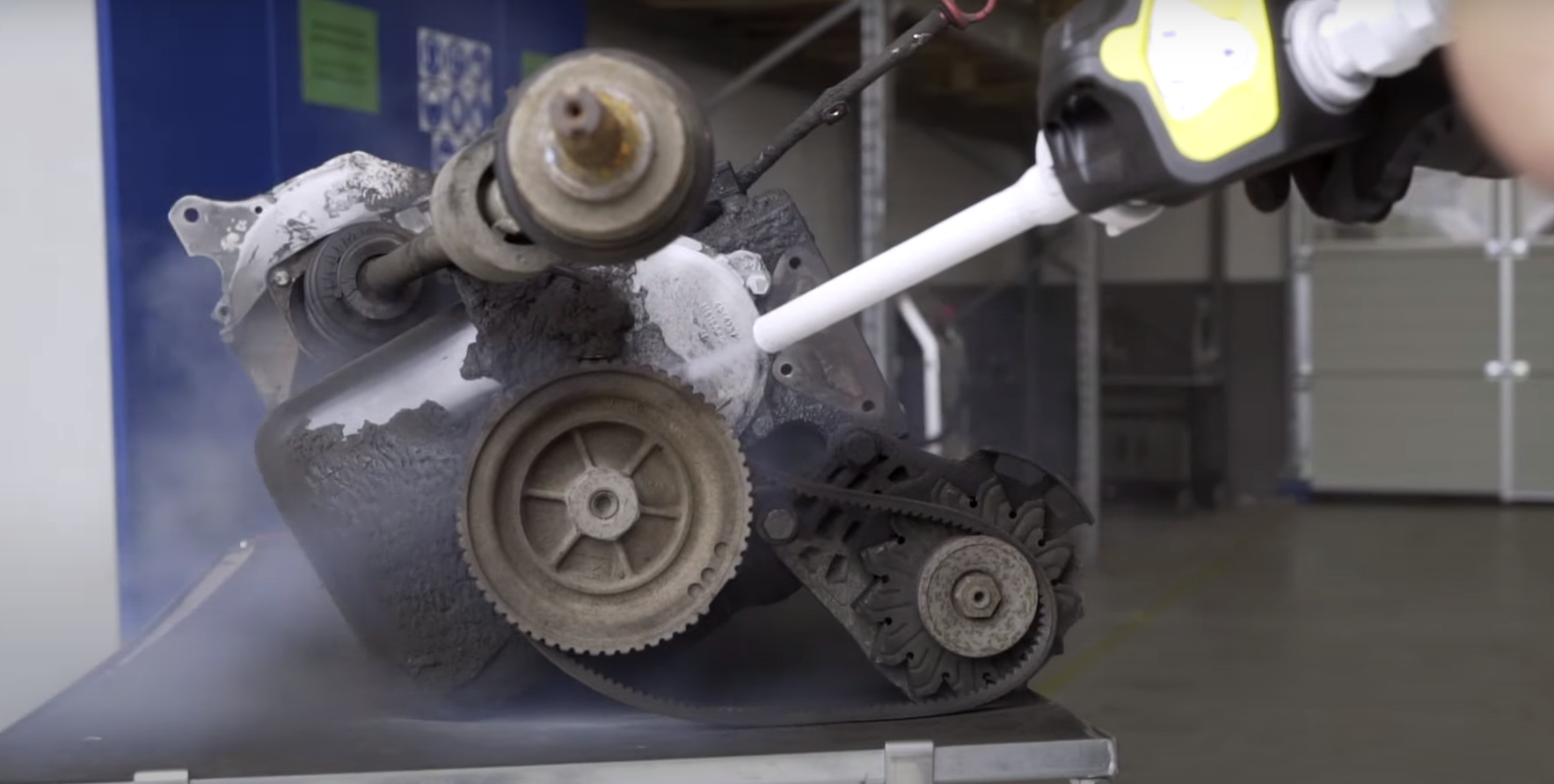

Dry Ice Blasting

The functioning of the dry ice blasting mechanism can be broken down into three separate sections that are easier to keep in mind. They use the abbreviation ICE, meaning Impact, Cold, and Expansion.

Step 1 (Impact): During this process phase, a kinetic energy effect is produced due to the collision caused by the dry ice pellets discharged from the dry ice blasting machines. The dry ice is propelled rapidly by the pressurized air that passes through the nozzle they have been specifically designed.

Step 2 (Cold): After the impact has resulted in the formation of kinetic energy, the process proceeds to the following step. “Thermal Effect” is brought about by the very low temperature of the dry ice pellets. Due to the extremely low temperature, which is -109°F, the pollutants become fragile. Over time, the contaminants will have less effect on the surface.

Step 3 (Expansion): Expansion is the last and concluding stage of the method. The expansion of dry ice pellets occurs at this step of the process. The pollutant is eliminated due to the dry ice pellets’ ability to sublimate upon contact, resulting in a volumetric expansion in size. After finishing up with all of the steps in the procedure, you should now have clean equipment.

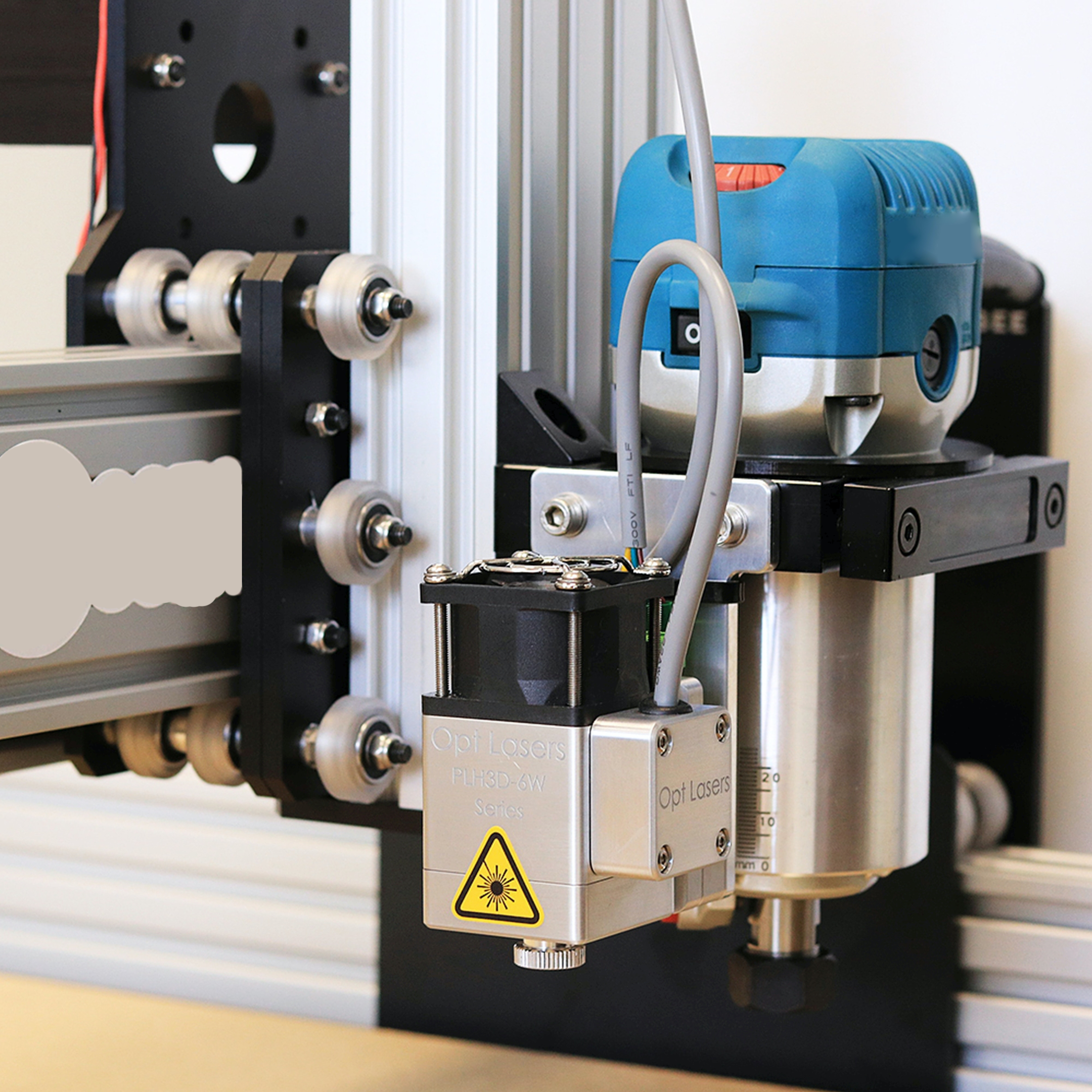

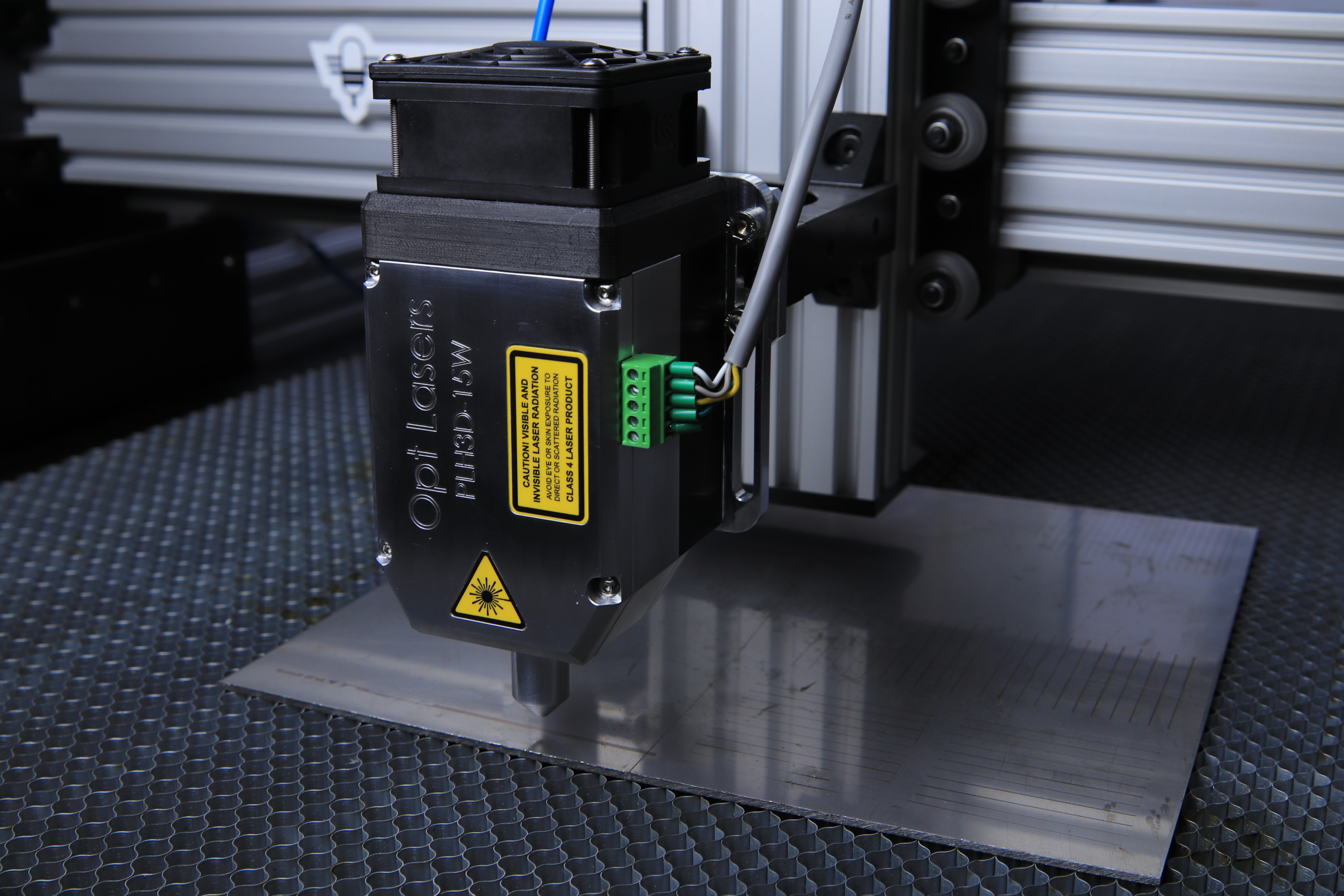

Laser Cleaning

The cleaning process that uses laser technology is significantly distinct from the dry ice blasting medium. For the laser cleaning method to be effective, a pulse of laser light with a length of nanoseconds is directed toward the surface of the contamination.

After the laser interacts with the pollution, the dirt particle will either convert into gas or move away from the surface where they interact. Laser cleaning is the most effective method available regarding its efficacy and operation.

There are also several more types of laser cleaning, such as dry laser cleaning, wet laser cleaning, laser shock cleaning, and more.

Dry Ice Blasting & Laser Cleaning Benefits

Both dry ice blasting and laser cleaning offer a variety of advantages to their users. Various manufacturing facilities and commercial enterprises worldwide utilize their advanced cleaning solution. The process has never been more straightforward now that cutting-edge technology machines are being used. Here are some of the advantages of utilizing these great cleaning tools.

Dry Ice Blasting

- Highly Time Efficient: Dry ice blasting uses high-speed technology to accomplish your work in minutes rather than in the hours it would take using traditional methods. Thus, it can assist you in saving a lot of time and effort.

- Non-Abrasive: The method is 100% reliable and risk-free. During the cleaning process, it does not compromise the integrity of the surface or the substrate.

- Healthy and Productive Machine: Regular maintenance keeps the equipment in good working order and maximizes output.

- No Secondary Waste: After the service, no residue or waste is left behind from the procedure. Dry ice immediately evaporates upon contact; therefore, it does not leave any additional waste.

- Usable in Vast Environment: It doesn’t matter if you’re in the bakery or automobile business; you can get this service everywhere.

Laser Cleaning

- Quality Removal: Laser cleaning service is clear and precise, leaving no trace.

- Time-saving: The cleaning procedure with its supersonic laser beams is 18 times quicker than any standard cleaning method.

- Reduces Base Material Abrasion: This tool will serve you best if you want to prevent abrasion of any type. The laser used in the instrument offers precision cleaning that does not leave any residue.

- Highly Eco-Friendly: Laser cleaning generates no pollution except a filter that occasionally has to be replaced. Therefore, laser cleaning is the most environmentally friendly method available.

- No Maintenance Fee: Laser cleaning equipment, in contrast to other types of machinery, is not subject to the exact stringent maintenance requirements. You only need to clean the filter, which does not incur further costs.

- Low Power Consumption: compared to the cleaning done with dry ice or other methods. The laser cleaning equipment has a low power consumption while delivering effective results.

- High-Speed Laser Cleaning: In practically every market aspect, lasers can offer high-speed cleaning and surface preparation services. The devices produce a laser beam traveling at high supersonic speed, which completes the task in a matter of seconds.

Dry Ice Blasting & Laser Cleaning: Average Cost

Since the price varies depending on location, overall, this service has no predetermined cost. However, we could conclude the cleaning services’ average cost by consulting various sources.

Dry ice blasting, as the name suggests, involves dry ice. Dry ice pellets are notoriously tricky to work with and also incredibly expensive. It is impossible to keep the ice in a typical warehouse; the ice must be kept in a location with temperatures ranging from -80℃ to -100℃.

To provide excellent service, the machine consumes a significant amount of ice, necessitating a substantial quantity of dry ice. As a result, dry ice blasting costs range from $300 to $300 per hour and include a full complement of highly experienced team members.

Laser cleaning is a significantly more cost-effective surface cleaning method than dry ice blasting. Maintaining and operating a laser cleaning instrument is far less expensive than traditional cleaning methods.

Since the devices do not need dry ice or other external input, you can expect your service fee to be around $50 to $150 per hour, depending on the laser cleaning model.

Which Is Better for Your Needs?

Dry ice blasting and Laser cleaning are used for practically identical functions, yet not everyone has the same need. Even though both pieces of equipment are used for cleaning, they have distinct differences.

Using dry ice blasting as a cleaning solution for cleanrooms is beneficial because it generates dependable results without leaving residue behind. However, you will need ample space with proper ventilation to use the dry ice-blasting instrument.

The use of laser cleaning equipment, on the other hand, does not need the installation of any specialized spaces or ventilation systems for them to function effectively. In addition, it is eight times quicker than ice blasting and does not cause significant health risks.

We have included a concise chart outlining all the features of the two different cleaning equipment. You will have no trouble determining which cleaning is best for your needs.

| Dry Ice Blasting | Laser Cleaning | |

| Features | Uses Dry Ice to Blast Contaminants | Uses Laser Beams to Remove Contaminants |

| Requirements | Dry IceProper VentilationSafety Equipment | No Specific RequirementSafety Equipment |

| Application | All types of small-scale business | Mainly used in large-scale industries |

| Drawback | ExpensiveLarge space required maintenance Cost | Heavy Equipment |

| Cost | $300 to $400 | $50 to $150 |

Conclusion

These two cleaning methods are remarkable and compelling. As observed, both pieces of cleaning equipment have numerous qualities that give them characteristics for different usage. If you are still unsure which one to choose, you can contact Baison via our website to arrange a one-on-one consultation for better guidance.