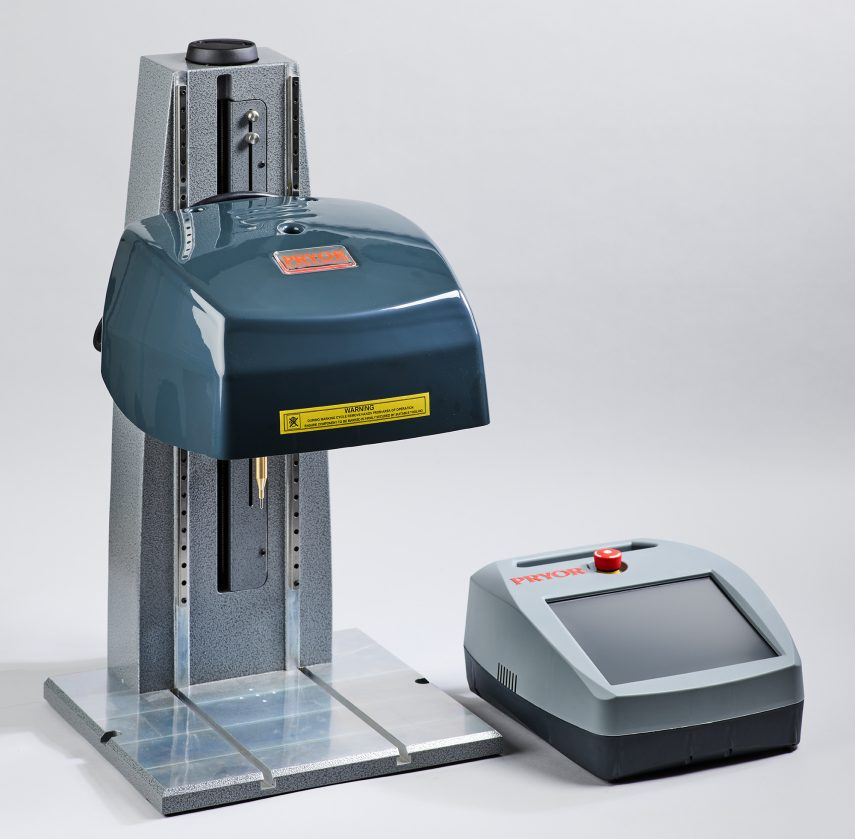

What is Dot Peen Marking Process?

Dot peen marking is the latest technology to puncture or automate the direct part mark on a metal surface by utilizing high force. This marking technology ensures quality marking marks by hitting the surface of the metal with small pins of rigid material. This material may be diamond or carbide, and the succession of these dots may result in:

- Logos/ Serial code

- Date/ Time Stamping

- Operator identifications

- 2D data matrix code

- Digits and text.

Dot peen has limited marking capabilities; it is also named pin marking, pin stamping, or dot peening. In this process, the dot peen machines leave small holes to change parts’ visual aspects. Dot peen units provide non-visible contrast, which makes marks more challenging to find. The dot peen marking machine creates permanent, deep impressions for traceability and identification. The marking depth in the dot peen system can adjust using the Z-axis of the stylus.

What are the Advantages of Dot Peen Marking?

Dot peen marking machines have intuitive software to input information. Some main advantages of this system are:

- It is one of the permanent, reliable, and good marking solutions for identification and coding.

- Dot peen systems are one of the cheaper and best industrial mark options.

- Dot peen technology is more flexible due to portable dot peen marking machines.

- Dot peen systems are especially recommended for marking 2D barcodes, data matrix codes, and alphanumeric serial numbers.

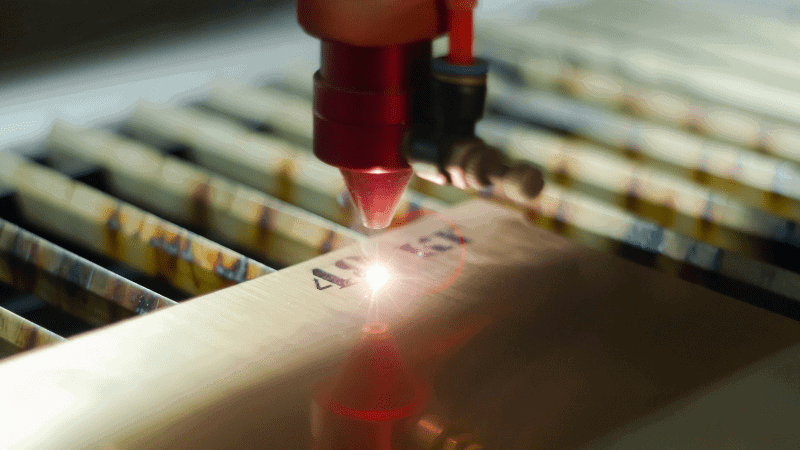

What is Fiber Laser Marking?

Laser marking systems provide quality markings vs. dot peen and are widely utilized for better quality markings. Initially, the product’s mark may require logos, barcodes, texts, and numbers. In contrast to these marking systems, modern marking technology, such as fiber laser marking, uses fiber lasers to mark a short, clear, and permanent mark.

No specialized laser marking equipment is required. Instead, the mark is made through a fiber marker machine. The marking machine uses a special laser beam to perform tracking codes and markings ranging from 2D barcodes to serial numbers. Being a computer-controlled technique, there remains no chance of mark errors. Not involving inks and tools during the process effectively lowers the risks of spreading ink and mark problems. The computer-controlled laser beans produce the markings with higher accuracy.

Fiber laser marking machines are classified according to their usage. These machines offer a long lifespan and can precisely mark up to 100,000 hours. The laser marking technique is commonly done for the following purposes.

- The fiber laser beams adequately mark in the form of data codes, serial numbers, logo and branding insertion, barcode labels, image placement, and QR codes.

- The laser marking process successfully generates smart identification cards.

- In addition, the cutting and engraving of the components can be achieved through fiber laser marking.

- It is used on many materials to mark and identify components and marks.

A few materials used for fiber laser marking are described below.

- Glass & Leather

- Wood & Plastic

- Metals & Plexi

- Rubber &Silicon

The correct functioning of the fiber laser machine entirely depends on its appropriate installation and setting. You must set the device according to marking requirements to get accurate results. The main setting requirements are:

Power in Fiber Laser System

The power of the laser marking systems directly affects the marked speed. The laser with high power shows incredible speed.

Speed in Fiber Laser Marking

Laser marking speed has a more significant impact on the product’s mark. The speed adjustment can be made using galvanometer mirrors present on the machine according to requirement.

Range of frequency in Fiber Laser Marking

It is compulsory to set the frequency range of a fiber laser machine correctly. It dramatically affects the mark, cut, and engrave.

What are the Benefits of Fiber Laser Marking?

Fiber laser marking offers an efficient marking process, and some main advantages of this system are:

Provide Great Flexibility & Versatility

The fiber laser mark system provides greater versatility than the dot peen mark system. It can apply to many materials, including gemstones, polymers, metals, ceramics, wood, plastic, etc. The fiber mark system has a computer-controlled interface to provide constant output and a low marking spot.

It is a non-contact marking process that requires no surface treatment and provides a much better writing contrast and a higher price tag than dot peens. Fiber Lasers offer a minor mark of fewer than 15 microns to mark Hi-resolution images.

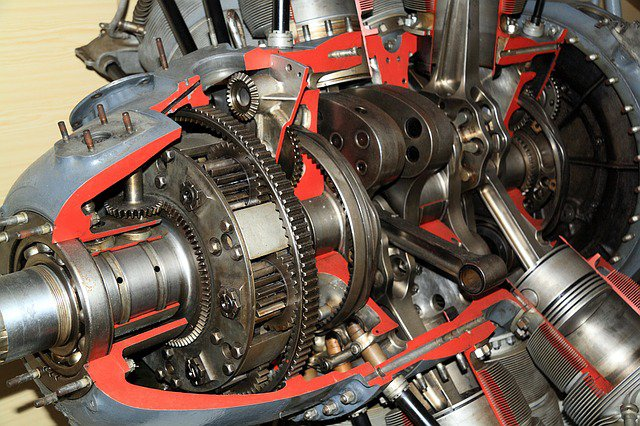

It will ensure constant output and good marking quality. Because of these features, laser technology is applied in the automotive and aeronautics industries.

Fiber laser machines do not demand consumables and preparation time during manufacturing, making them better than dot peens and other methods.

It uses fiber laser beams to mark, engrave and cut various materials.

Minimize Risk of Damage

The heat output of the fiber laser marking is less, and it minimizes the risk of any damage during marking that may result from extra heat production. Moreover, the high-quality fiber laser machine needs less maintenance, thus automatically increasing the durability of the marking process.

Automated laser machines are primarily used in assembly lines, casting, and smelting plants for automated mass production.

High Speed

The speed of the fiber laser is higher, resulting in fast marking and engraving, and it eliminates most of the manual tasks essential for other methods.

Compact and Practical Design

The main benefit of fiber laser marking is the compact design of fiber laser machines. They are portable because of their lightweight and small size.

Drawbacks of Fiber Laser Markings

The main drawbacks of fiber laser marking systems are as follows:

- Fiber laser markers are unsuitable for engraving on non-metallic metals such as wood and plastics.

- The major drawback of this marking process is the high initial investment cost of the fiber laser marking machines.

- It is ideal for engraving, painting, coating, or cutting. The laser marking is achieved on a 2-dimensional axis.

Factors to Consider When Choosing a Marking Method

The selection of any process is not easy. You must ponder over different aspects during the selection. The following considerations may prove helpful when choosing a suitable methodology.

Consider the Materials You Need to Mark

Your working material directly affects the marking system. Thus, you must choose a material according to a specific method. You do not select fiber laser systems using organic materials such as plastics, wood, and organic materials. It is because they can cause fire or melt or may get distorted due to their malleable structure when marked through other marking techniques such as roll stamping, etc. Dot peens are suitable for rigid materials.

Consider the Environment in Which the Markings will be Used.

Considering the environment to mark is an essential factor. You must look for a suitable location or environment for your specific method. Determining whether your marking machine will work in an open environment or a closed area is also recommended. It would be best to have skilled workers that could work perfectly in a given environment. Overall, the environment should be free of dirt and grease.

There should be a proper dirt removal system to prevent the accumulation of marking waste. It provides a clean and safer environment for the marking process and prevents the effects of dirt on the markings. As a result, permanent markings are produced with no chance of their fadeless.

Consider Your Budget

Considering the maintenance, laser type, and initial cost of the marking method before choosing a marking machine is compulsory. You must ensure the machine’s running and maintenance at lower prices. If the maintenance cost is the same as the purchasing cost, it can be expensive. You must spend much of your money on the marking machine and process. Always choose a marking process that proves to be cost-friendly from a long perspective. Laser marking is recommended to get benefits at less price vs. dot peen system.

Significant Differences Between Dot Peen Marking and Laser Marking Systems

Some main differences in dot peen marking and laser marking are as below:

1. Limitation

When we compare both methods, the dot peen system is more limited and provide non-visible contrast making mark very difficult for coding. It is used only for a single style font type. It can apply to rigid materials like hard plastics and metal. At the same time, the laser marking system has a wide area for applications and provides the darkest contrast to plastics, ceramics, and metals.

Laser energy can create contrast and allow for grade-A data matrices. Laser marking provides unlimited prospects for optical configuration and makes it more effective for various materials such as wood, ceramics, and plastics.

2. Overall performance

Dot peen must be clamped or fixed due to the hammer effect, and parts with more than 60 Rockwell hardness can be marked adequately. It is not suitable for thinner and soft products. Printing marks may be unreadable and unclear for soft material due to the return of material memory.

On the other side, fiber laser provides a reasonable standoff distance and a high-resolution mark on the surface of different materials. You can utilize non-intrusive fiber laser marking for the parts which require critical and tight tolerance. Critical parts are primarily used in aircraft engines and high-stress systems.

Conclusion

Choosing the right and appropriate marking system makes a big difference for your business need and applications. You must select the best option according to your product and materials. both systems- dot peen mark system and fiber laser marking have specific features and downsides. Both may be suitable for deep engraving and metallic surfaces. Still, laser marking can mark clear, visible QR codes, serial numbers, and barcodes, while pot peen is cheaper, ideal for industrial usage, and efficient due to portable machines.

What Can Baison Help You?

If you are still unsure which marking technology suits your needs, don’t worry. We can help. Contact us now for an instant quote, and we will be happy to discuss your options. With our years of experience in the industry, we can help you find the best marking technology for your business—and get you up and running as quickly as possible.