To give you an idea of just how popular it’s becoming, it was valued at $66.1 million in 2018 and is predicted to grow by 8.5% by 2019-2029. This figure alone, alongside many others, shows that coil-fed lasers are becoming a global leader in manufacturing processes, and there are many benefits to support this.

In this post, we’ll explain more about coil-fed laser cutting, its benefits, and tips on what to look for before buying a coil-fed laser cutter for your company.

What is coil-fed laser blanking?

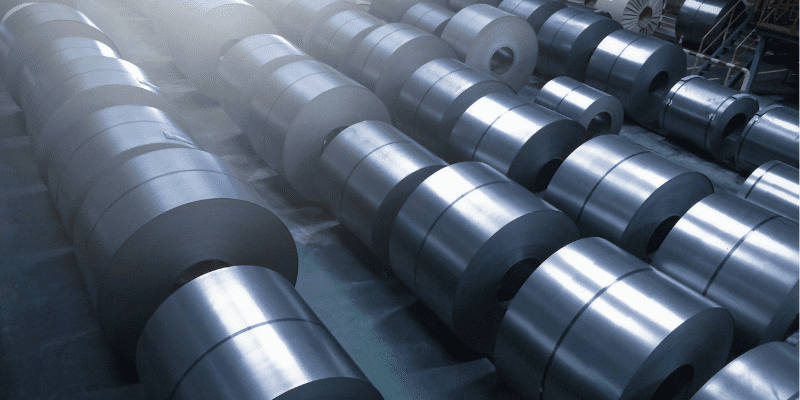

Coil-fed laser cutting allows you to produce metal parts straight from coils, reducing the unnecessary time involved in storing, transporting, and producing coils. In particular, it ditches the traditional method of uncoiling coils, leveling them, and using a fiber laser cutting machine to cut the sheet metal.

The coil-fed production side is tailor-made to match your specific material requirements and automate the process. This coil processing equipment combined can reduce your labor costs and time and increase accuracy and efficiency, as opposed to laser cutting sheet metal. It’s a lot less tedious than other methods.

Advantages of coil-fed laser blanking

If you use this method of laser cutting for your business, you’ll reap a lot of benefits, such as the following:

Flexible production

As you can tailor laser blanking lines to your materials, the machine can quickly adapt to any change in the production process. Therefore saving you time having to use a different machine or training your staff to deal with the changes.

Another way the production process is flexible is because the machine can use various materials and thicknesses. It can also produce multiple parts and configurations with zero sheet changeovers, allowing you to produce higher yields.

Also, when changes are involved, like various material widths, you can easily oversee them using a click of a button to amend the 2D graphics on the program software. This saves you the headache and time of changing any hardware structure for your equipment.

Increased speed

With coil-fed laser blanking, you can increase the speed of your production cycle. This is because coil-fed laser systems eliminate material loading and unloading as they acquire the maximum possible output. As a result, cycle times reduce, and so does the total processing cost.

Automated production

This laser-cutting machine can allow you to speed up your operations. As they have different levels of automation, you can choose to automate them involving unloading and sorting metal parts entirely. This allows your production cycle to work on its own, freeing up operators and allowing them to supervise other production processes and increasing your performance.

Low costs involved

As the process is automated and the laser head speeds are fast, it saves your finances having to spend on hiring additional labor. Similarly, as it has fewer consumables and utilizes materials efficiently, it reduces the costs dramatically associated with production.

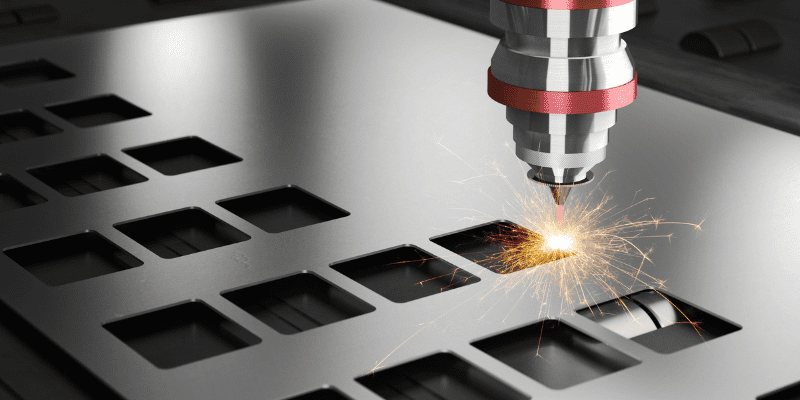

Precise and high-quality cuts

This laser-cutting system is smooth as it uses an open-air laser and innovative mechanical slats that move with the head. As a result, there’s no flashback, and clean and high-quality edges are made on either side. If you have demanding applications, this machine is one of the best to use as it has a high tolerance for various sheet metals.

Material is utilized

This machine has a limited scrap level due to its automatic typesetting function. This function can quickly be selected using your computer at any time based on the spare parts required. Multiple parts are simulated and arranged on the software to reduce scrap, efficiency, and production. Also, various material types are positioned by the coils in the best way on the sheet metal, so the material is used to the fullest and produces the maximum output.

Add etchings and markings.

You can even personalize your manufacturing process as this machine has options to etch text and markings onto your metal. This can save you money in the long run without worrying about hiring a third party for engravings.

No outsourcing

When using a coil-fed laser, you don’t have to look for an outsourcing complete machine shop as everything is done in-house. Because of this, you have greater control over your quality, timeline, procedures, and processes.

Lifetime support

Many manufacturers of these machines act as an industry’s lifetime support partner for the equipment. Once purchased, they take care of the service, support, replacement parts, and more.

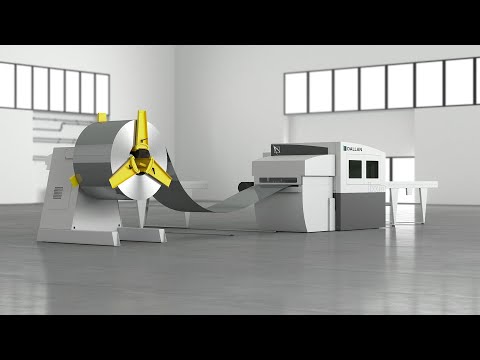

How does this machine work?

Coil-fed laser cutting is far more efficient than table lasers or mechanical blanking. Its multiple laser heads automatically unwind coils, correct defects, cut the required blanks, and produce parts straight from the coils.

The laser speeds can be changed from a simulator and the product material, reducing the production processing time. Similarly, the automation control system and auxiliary equipment help with this machine’s loading, feeding, and power. The following pieces of equipment make up a coil-fed laser:

- Decoiler

- Blanking machine

- Laser cutting machine

- Automatic stacking device

How to choose the right blanking machine?

To ensure you don’t just choose an average fiber laser cutting machine, you’ll want to look at the companies providing coil processing equipment and the equipment specifications. To help with your selection, here are some things you should consider:

Program Ease

With more tech advancements in laser cutting, you must find a machine with software that is easy to use. While this innovative software can save your business money by creating different patterns, maximizing raw materials, and reducing scrap, it’s important you can use it and train someone to use it easily.

You’ll also want to ensure that the machine’s software and tools align with your goals. For instance, some machines come with high-tech CAM tools such as common line cutting and nesting and help configure the right laser parameters. No matter what software you choose, you should always ensure it can include grain constraint, multiple laser heads, and peripheral automation.

The simpler the programming is and in line with your goals, the less likely you’ll need to employ a skilled technician or cut down on your costs to oversee the machines.

Zero Scrap/Scrap handling

Many laser-cutting machines help maximize the number of raw materials used to save you from paying excess scrap costs. Some systems have specific conveyor lanes which you can reposition to keep a clear path and automatically shed while cutting. However, if you make money from your scrap parts, you might want to look for a machine or a feature within its simulator that does not automatically shed scrap while cutting.

Power and Speed

You’ll want to know its power to ensure you fully utilize a laser machine. You may not notice that companies calculate the power differently when looking at different laser configurations. The power voltage could be the same, yet the machine could be slightly different, for instance:

Machine 1: 3 x 4kw Laser heads = Total Power 12kW

Machine 2: 2 x 6kW Laser heads= Total Power 12kW

If the power is the same, you’ll want to know its speed. You’ll want to see if the time it takes for the laser to cut your sheet metal is sufficient for your operations. If you require a faster production process, you might look for laser blankers with multiple heads to evenly balance the workload.

Stacking Capability

You’ll also want to see how the system removes scrap at the end of the production line. If it does not, you’ll likely have to use a robot to pick your finished parts from the coil strip and collect the scrap from the conveyor belt. Doing this can take a lot of time and slow down your operations. To avoid this, you might want to check for ones with simulators that have greater control over their feed and stacking process.

Space Considerations

While these machines are no doubt big, you may be able to reduce the size required if you’re flexible with your stacking and press feeding. Similarly, you might want to consider other factors such as the number of laser heads, size of parts, method of stacking, and more. After all, many laser systems are not made the same, so you must ensure that the size is appropriate and the system delivers all the requirements you’re after.

Conclusion

Overall, coil-fed laser cutting can enhance the productivity and efficiency of your operations. The high-tech CAD simulation and continuous automation can help reduce labor costs and free your attention to focus on other areas of your business.

What’s great about these machines is that they are highly adaptable to your production process. Therefore you don’t need to be worried about changes to the size of your laser head; if you have a thick material or anything else, they’re flexible. You can also quickly input changes to the machine through its responsive built-in CAD software.

The machine and its program can save you the time of seeking new solutions and training your staff to follow them. They’re also known for eliminating flashbacks and providing quality clean cuts on metal.

However, when looking for the right coil-fed laser, you must find one that meets the goals of your production process. Before buying, you’ll want to consider its size, stacking capability, power, speed, and program ease.

At Biason Laser, we have a variety of coil-fed laser machines to choose from. Contact us today to learn more about them and how they can enhance your production process.