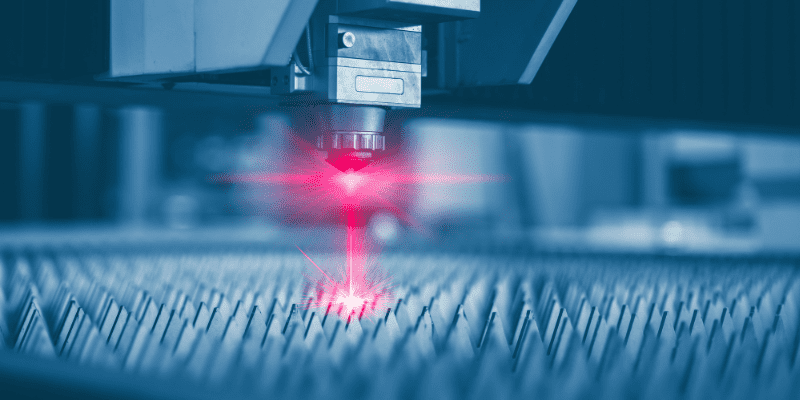

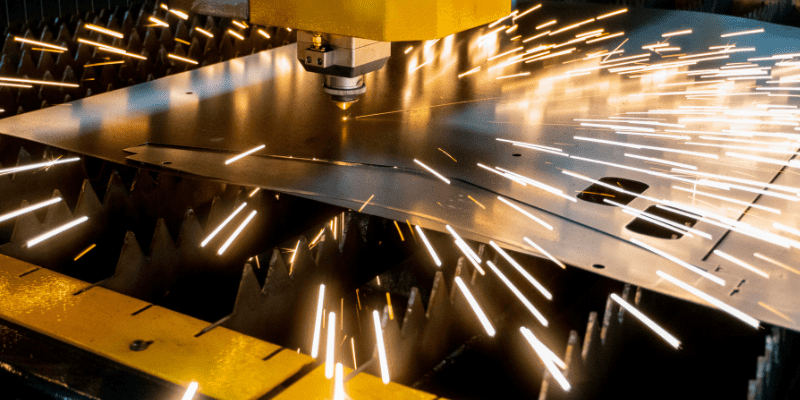

What is Fiber Laser?

Fiber Laser technology is a solid-state laser that liquefies and pierces metals. It is one of the most common methods for cutting metal sheets. In most cases, the laser cuts mild steel, stainless steel, and other non-ferrous metals. Fiber lasers have a high power that allows them to cut through metals over 100mm thick.

Since it offers speed, quality, and efficiency, fiber laser cutters have garnered much attention and favor among significant sectors and industries. The computerized control systems in the fiber laser machine will allow for more precision and accuracy in your work. The price of laser cutters of this type is often higher than that of other types of laser cutters.

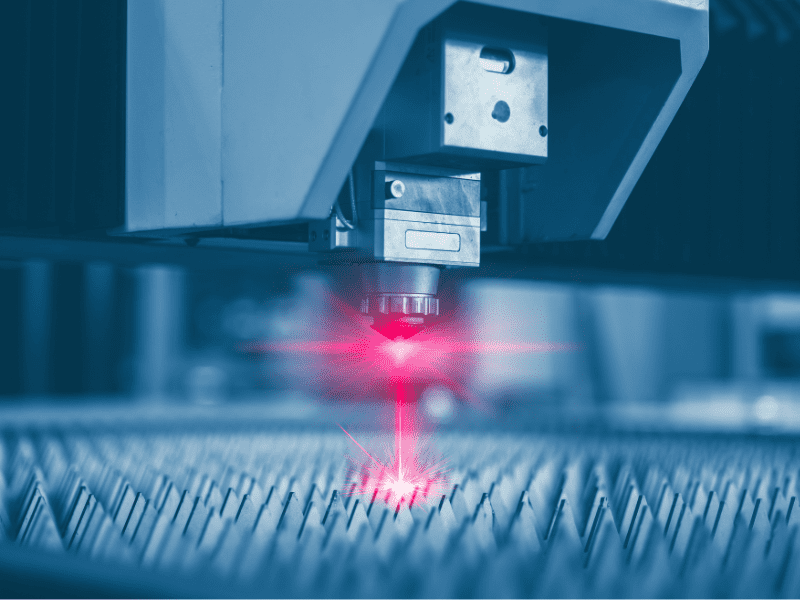

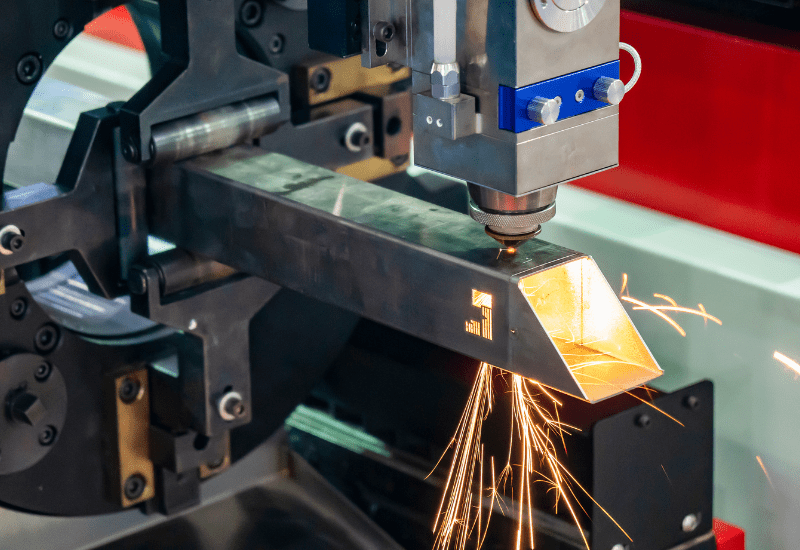

What is a CO2 Laser?

The CO2 laser cutting process is a technique for cutting a sheet of metal that uses an electrically powered gas laser. The laser can cut through metal sheet materials, including aluminum, steel, and stainless steel. The levels of power and control that CO2 lasers possess are remarkable, and these lasers have great accuracy and precision. Their unique, controlling system makes them different from other laser technologies.

The applicability of CO2 lasers to a wide range of substrates is one of its most attractive features. In some circumstances, they can operate with both inorganic and metallic substances. The CO2 laser cutting process primarily sends an infrared laser beam of high intensity via a nozzle. These lasers need a combination of different gases to produce the laser beam.

How Does Fiber Laser Work?

Fiber laser machines function by producing a powerful laser beam via stimulated radiation. A set of diodes is employed in fiber laser devices to form the beam, focused via a fiber optic cable network. After that, the optical components inside the cable are used to create and magnify a particular wavelength. Immediately after the procedure, the laser beam gets manipulated, letting the laser beam do the cutting.

If you still find it complicated and hard to understand, let’s look at a more comprehensive step-by-step process. This step-by-step guide will help you understand the function of fiber lasers better.

- Before beginning the procedure, the electricity will be converted into photons by laser diodes, and the machine will then forward these photons into the fiber optic cable. The process begins when the two semiconductors that diodes utilize (positive and negative charges) come into contact with one another. They give out photons in the form of free electrons. When more power is applied, the pace increases, pushing more light into the fiber cable.

- After being directed into the fiber cable and propelled ahead, the light must continue along a single route for an intense laser beam. This path must remain unchanged. On the other hand, light does not move linearly; hence, to overcome this challenge, fiber optic cables consist of two parts: the “Core” and the “Cladding.”Cladding is the term used to describe the material utilized within the core, the region where the light travels. When the light travels, it meets the cladding and bounces back into the core. It is because the cladding offers an internal reflection, which maintains the light inside the center of the structure and encourages it to continue along its trajectory.

- When the light finally reaches the end of its journey via fiber optics, it will enter a laser cavity. Within this region, the light will only be of a particular wavelength. Because of the rare earth element’s presence, the fiber optics present get doped as the elements surround them. When these particles of the doped fiber come into contact with light, the electrons get a boost in their energy levels. As they eventually return to their initial condition, they release photons, often known as light. The laser cavity acts as a resonator, which is a device that causes light to bounce back and forth between two points. This procedure increases the light, giving out a “Laser.”

- Remember that the resulting wavelength will vary based on the doping element used in the laser cavity. Because there are many distinct doping elements, the wavelength will differ in various ways. These wavelengths of diverse durations get utilized in multiple types of tasks. Therefore, accurately understanding the particular wavelength generated is of the utmost importance.

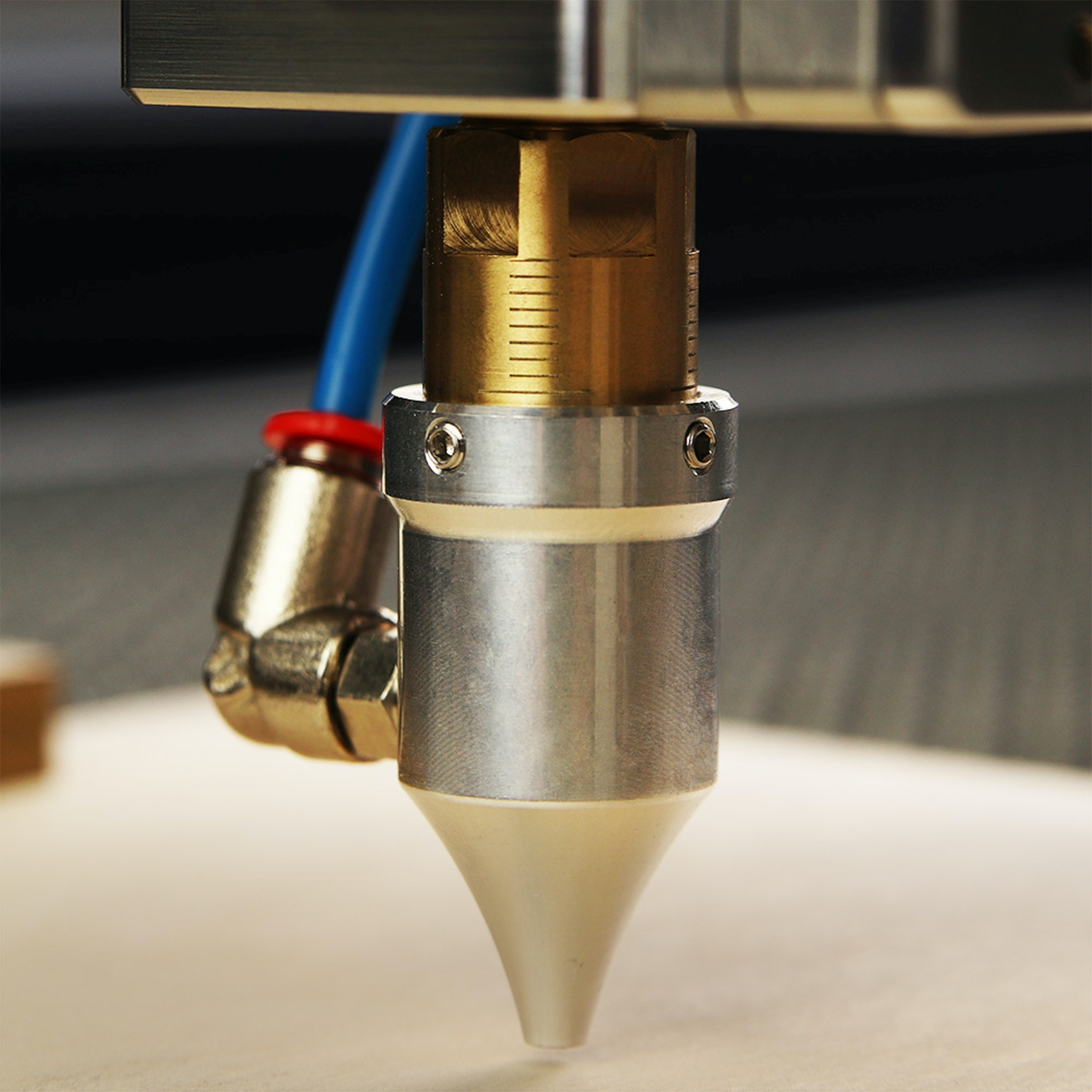

- When everything is complete, the photons that leave the resonant cavity generate the laser beam, which is perfectly straight because of the light guide incorporated into the fiber cables. Later, the shape of the laser gets designed with different types of components based on customer preferences. Most fiber lasers have a lens with a focal length of 254 millimeters. It allows the user to perform laser cutting, possibly due to the short focal length that concentrates more energy in a smaller region. Similarly, combining many distinct pieces of machinery determines the laser’s form.

How Does CO2 Laser Work?

The CO2 laser cutter generates light when electricity is sent through a gas-filled tube and has mirrors at both ends. During the procedure, one of the mirrors will reflect, while the other will allow some light to flow through. These two mirrors direct the laser beam so that it may cut through the material. The process of cutting with a CO2 laser contains two different steps, which are as follows:

- When the electricity passes through the tube, there is a reflecting mirror at one end and a partially reflective mirror at the other. The light is reflected in both directions, going up and down within the tube. The effect of this motion is an amplification in the light’s intensity as it travels down the tube. As a result of the consistent motion, the light intensifies to the point where it can penetrate the partly reflected mirror. The light is reflected from one mirror to the next until it reaches the final mirror in the laser head. This mirror is the one that guides the laser toward the focal length and the material.

- After the laser has reached this point, having control over it is vital because it is now fully developed. Therefore, to make things convenient for you, we will introduce you to a technology known as CNC, which stands for computer numerical control. This innovation enables the CO2 machine’s laser head to be moved in a different direction, giving you more flexibility in your work. While using the laser beam, you can now move around to engrave in different ways by using various technologies and mirror lenses, all without affecting the process’s accuracy and precision. In addition, there are no problems or limitations associated with using the equipment to create precise engravings.

What Is the Major Difference Between Fiber Laser and CO2?

The CO2 laser has been around for many decades. Still, because of its ongoing development, it is now used by various businesses and other organizations.

However, considering new technologies like fiber laser are on the horizon, you could find it challenging to decide which option to choose. Don’t worry about it; we have provided a rundown of all the critical distinctions between the two options so that you can make an informed choice.

Power Consumption

Both of their power consumptions are very different in significant ways. CO2 lasers can reach up to a 20% photoelectric conversion rate. Therefore, if you want to run a laser that is 50W, you will need to have a power supply that is 500W, which will cause the entire cost of your operations to escalate.

In terms of the amount of energy that they use, fiber lasers are far more efficient. The power supply for fiber laser equipment with 50W only has to be between 100 and 200W. As a direct outcome, the expenses in connection with the operation of the laser equipment are reduced by half.

Wavelength

Both of them have a highly unique wavelength, which makes them usable in a variety of contexts. Because of its shorter wavelength of 1.04μm, a fiber laser cutting machine can cut through almost any material.

However, the wavelength of a CO2 laser cutting machine is far greater, at 10.6μm, which confines the types of materials it can cut through. Although a very high-powered CO2 laser device could solve this problem, it would likely result in much higher expenses.

Efficiency

Due to their considerable slowdowns, CO2 lasers are not particularly effective. However, considering the low cost, its effectiveness in the home or a small company environment is not in doubt.

Check out the fiber laser if you want something quick and efficient. These lasers are much more powerful and effective than most other laser devices. It happens because of the beam’s wavelength characteristics and the greater focus region.

Cost and Maintenance Fee

Depending on the power rating and the model, fiber laser and CO2 laser could have a high price tag. The initial investment of a fiber laser could be substantial, ranging from $50,000 to $1,000,000. On the other hand, the price range for CO2 laser equipment is between $2,000 to $10,000. Moreover, the maintenance fee for CO2 cutting is comparatively lower than that of Fiber laser machines.

A CO2 laser cutter is an excellent option if you want to purchase it for a home or small business project. However, suppose you want to purchase a laser cutter for industry or manufacturing. In that case, fiber lasers are the kind of lasers that are most likely to be a profitable investment for you.

| Fiber Laser | CO2 Laser | |

| Wavelength | 1.04μm | 10.6μm |

| Compatible Materials | Carbon FiberAluminumGoldSilverStainless Steel | FabricWoodLeatherBrickFiber Glass |

| Cutting Thickness | 0.5 to 0.8 inches | 0.3 to 0.8 inches |

| Cutting Speed | 45 to 2126 IPM | 50 to 420 IPM |

| Power Consumption | 100 to 200W | 500W |

| Cost | $2000 to $10,000 | $40,000 to $1,000,000 |

What Are the Advantages of Using Fiber Laser and CO2 Laser Cutting Machines?

Now that you have a greater in-depth understanding of how these machines work. You should also know their advantages and how they may assist you. We have compiled a list of some benefits of utilizing CO2 lasers and fiber lasers.

Fiber Laser Benefits

- High Performance: The laser beam produced by this equipment will be of the highest possible power. This beam can be focused, allowing for precise cuts. This approach eventually reduces the total amount of time needed by a substantial margin.

- Low Power Consumption: Surprisingly, this high-powered machine’s energy consumption is relatively low compared to the energy consumption of the other laser machines. The power supply for this device must be between 150 and 200W.

- Flexibility: This equipment does not have to serve strictly in any place. You can use the laser cutting machine wherever and whenever is the most convenient. It can go from one industry to the next without encountering any difficulties or challenges along the way.

- Highly Accurate and Precise: You won’t have trouble achieving very high levels of accuracy and precision in your cuts if you use the machine’s computer numerical control technology. In addition, with the assistance of this machine, you will also be able to attempt an engraving on any surface.

- Versatile: This equipment can work with various metals in various applications. It has no issue cutting through different metals of multiple types. It can penetrate any reflective metal with its laser beams, which have a high absorption rate.

CO2 Laser Cutting

- Versatile: CO2 laser machines also have a great degree of versatility. They can cut through a far wider variety of materials than any other laser. A CO2 laser can cut through almost any non-metal material and some types of metal.

- Deeper Cuts: When it is required to cut through thick materials, CO2 is a viable option. CO2 lasers have a shorter penetrating time for thicker materials than other lasers. They can cut cleanly through the thick material with no difficulty at all.

- Better Surface Finish: Compared to the fiber laser machine, CO2 lasers provide a surface finish that is far more flawless. The surface finish of CO2 is much more pristine and practical. Compared to a fiber laser, they leave a trace of the cut behind once they’ve finished it.

- Low Acquisition Cost: Compared to purchasing a fiber laser machine, the cost of buying a CO2 laser machine is significantly lower. A new CO2 machine can be purchased for between $2,000 and $10,000, depending on the model, which is more than ten times less expensive than a machine that uses fiber laser technology.

- Low Maintenance Cost: The expense of maintaining equipment that uses CO2 lasers is cheaper. It does not call for a very high level of maintenance. As a result, this leads to a cost savings approach. The utilized components are not difficult to get and are not prohibitively expensive. In contrast to the fiber laser, the components might cost several thousand dollars.

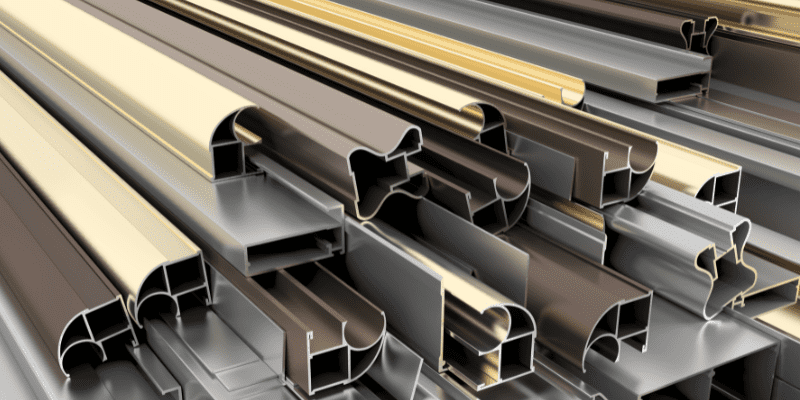

What Materials Can CO2 Lasers and Fiber Lasers Cut?

Since both tools can cut a wide variety of materials, the list is quite diverse. The CO2 laser can cut through various materials, including metals and non-metals. Fiber lasers can operate with all kinds of metals; however, they are not very effective with materials that are not metallic. The following is a list and an explanation of the many materials that laser technology could handle.

CO2 Laser Cutting Materials

In comparison to other types of lasers and cutting tools, CO2 lasers have the advantage of being able to function with a far wider variety of materials. The CO2 laser is the most effective option for cutting various materials. However, since CO2 has a lower absorption rate than other types of lasers, it cannot effectively work with a wide range of reflective metals. The following is a list of the primary substances compatible with the CO2 laser:

- Fabric

- Wood

- Leather

- Brick

- Marble

- Fiberglass

- Plastic

- Rubber

Fiber Laser Cutting Materials

As mentioned earlier, cutting metal sheets is the primary function of the fiber laser machine. Because of their superior engineering, they can cut through any metal, regardless of how reflective it may be. If you want to cut through metals, the fiber laser is the most effective tool. It has widespread use across a variety of industrial sectors and industries. The following is a list of materials readily cut through by fiber laser.

- Carbon Fiber

- Aluminum

- Tungsten

- Chrome

- Nickel

- Gold

- Silver

- Stainless steel

Cutting Speed: Which Technology Cuts Faster?

Fiber laser outperforms every other kind of laser cutting machine on the market regarding how quickly it can cut. When it comes to cutting different materials, fiber lasers are, in general, much quicker than CO2 lasers. The fiber laser contains extremely high-power beams that can quickly cut through any material without wasting time. Even if both devices utilize the same power source, fiber lasers will still be anywhere from two to four times quicker than CO2 lasers.

Using a high-power fiber laser would also reduce the amount of money spent on operational expenses for a specific time. In addition, there is no need for a warm-up period while using a fiber laser, but a CO2 laser requires a buffer time of ten minutes to assist in the machine’s initialization process.

However, the time factor of CO2 makes them superior at cutting thicker metals such as 5mm thick materials. When penetrating through thick metals, a longer wavelength is superior to a standard short wavelength.

Cut Quality: Which Technology Is Better?

Compared to the surface finish produced by fiber laser systems, there is little debate that CO2 laser systems provide a higher quality finish. You will see the finish of the material much more clearly as the material gets thicker. Along the length of the cut, the fiber laser will leave a tiny striation mark. CO2 lasers maintain their accuracy throughout cutting various thick and thin materials. However, due to ongoing research and development, fiber lasers have dramatically enhanced the quality of their cuts in recent years.

When it comes to the quality of their cuts, there are no exceptions. Both of these technologies perform well in their respective roles. Fiber lasers are ideal for use in the information technology business since, in addition to cutting, a wide range of additional capabilities, including engraving, crafting, and many others, are needed. If you are working on a project but do not have the necessary funds, CO2 is the perfect option for you.

Which Machine Has the Highest Acquisition Cost?

It would be best to consider the associated acquisition costs when deciding on the appropriate laser technology. Because of the significant gap in price between the two options, you must be aware of the pricing differential. The upfront investment for a fiber laser is quite substantial. Depending on the model, the price ranges from around $50,000 to $1,000,000.

However, their operating costs are far lower than those of various other technologies combined. CO2 lasers create the exact opposite situation. Purchasing a CO2 laser machine will cost you a small fraction of the price of a fiber laser, ranging from $2,000 to $10,000.

Is Fiber Laser Better Than CO2?

There isn’t a straightforward answer since both options are appropriate in their contexts. They are both used for the same objective, “Cutting,” but their applications are in different places. Therefore, it is quite impossible to evaluate them using the same parameters. However, if you were to examine the technical specifications of both devices, you would find that the fiber laser is far more sophisticated than the CO2 laser.

It uses cutting-edge technology to cut through the materials, and as a result, it is far more effective than CO2 lasers. Purchase a fiber laser cutting machine if you want to use it in an industrial setting; purchase a CO2 laser if you’re going to use it in your house or a small business.

Laser Cutting Machine Market and Trends

In every industrial field, laser cutting is very prominent. The worldwide market for laser cutting machines will be worth $7.1 billion US dollars in 2023, demonstrating a consistent increase over the next few years.

Additionally, the market for these laser-cutting machines will expand at a compound annual growth rate of 9.1% throughout the next seven years. Because of the rapidly increasing demand for these devices, tremendous advancements and investments have been made in a wide variety of software and technological advances to make them much more effective.

These machines are increasingly being used in the manufacturing processes of industries and in various other contexts where cutting is an essential function. These devices can reduce the required labor, hence increasing your profits. The process is completed in a concise amount of time and is highly effective, making them a future poof gadget.

Fiber Laser and CO2 Laser Cutting: Application

These two types of laser technology are used extensively throughout various industry sectors. The CO2 laser cutting machine has been around for many decades and is quite popular because it has a reasonable price and a low maintenance cost. In comparison, the fiber laser is a relatively new technology that is much more efficient. Even though both technologies function for the same purpose, they operate in distinct contexts.

Fiber Laser Cutting Application

The versatility and convenience of using fiber lasers have led to their widespread adoption. Fiber lasers operate at different wavelengths. In addition, there is no interference in the transmission of fiber lasers across vast distances when we use a cable made of fiber optics. The fiber laser is gaining popularity in many different sorts of industry, which includes the following:

- Telecommunication Industry

- Medical Industry

- Manufacturing Industry

- Textile Industry

- Cleaning Industry

CO2 Laser Cutting Application

The usage of CO2 laser cutting machines has increased in recent years due to constant improvements, even though these machines have been available for decades. The medical industry was among the first to use this technology, and it is currently doing so in many other settings. Research conducted over a long time and across various sectors has shown that it is quite beneficial in several of those industries, including the following:

- Medical Industry

- Manufacturing Industry

- Design and Engraving Industry

- Textile Industry

Conclusion

Although each laser machine has strengths and shortcomings, they are among the best laser money can buy. CO2 is an aging technology, and fiber laser is expanding its market share as technology progresses. If you are still unsure about the option to choose, don’t hesitate to get in touch with us for assistance.