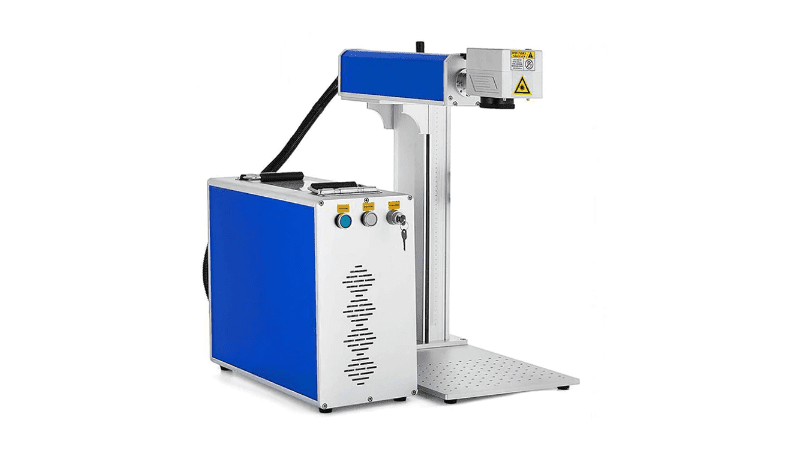

Choosing high-quality laser cleaning machines with proper power delivery is a nightmare for novices. These tools are widely used in the medical, aerospace, and automotive industries for their efficient energy and high precision.

Learning the role of power, wavelength, and output in laser cleaning will help you make the best selection.

This article will explain laser cleaning and how it works, including the power requirements for specific tasks. You’ll also learn how to evaluate energy requirements for different applications and reasons to choose the best equipment. Let’s get started.

Laser Cleaning Process and Principles

Light amplification by stimulated emission of radiation (laser) cleaning systems is handy for manufacturers in the automotive and aerospace industries.

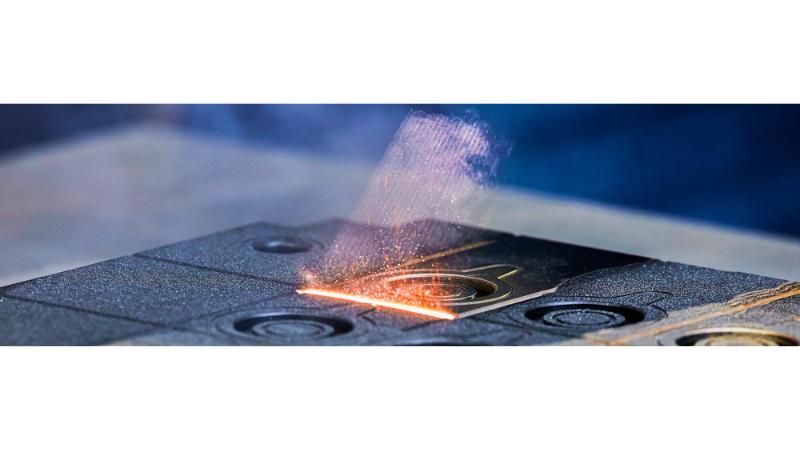

The principles are excellent for different applications as it involves heat generation, leading to material ablation. Usually, the item absorbs the laser cleaner heat to remove unwanted impurities, leaving the surface smooth and clean.

What is Laser Cleaning, and How Does it Work?

Laser cleaning is an established method for removing hydrocarbon contaminants from metal surfaces. It’s the best way to vaporize impurities from a solid item using high-powered beams.

The process is a non-abrasive, non-contact, cost-effective, and efficient cleaning technique. It’s repeatable, eco-friendly, and ensures high precision without damaging the material surface.

Laser cleaning works by transferring the laser light nanosecond-length pulses toward a surface. When the contaminants interact with the light rays, they vaporize in a controlled manner and turn into fumes and dust.

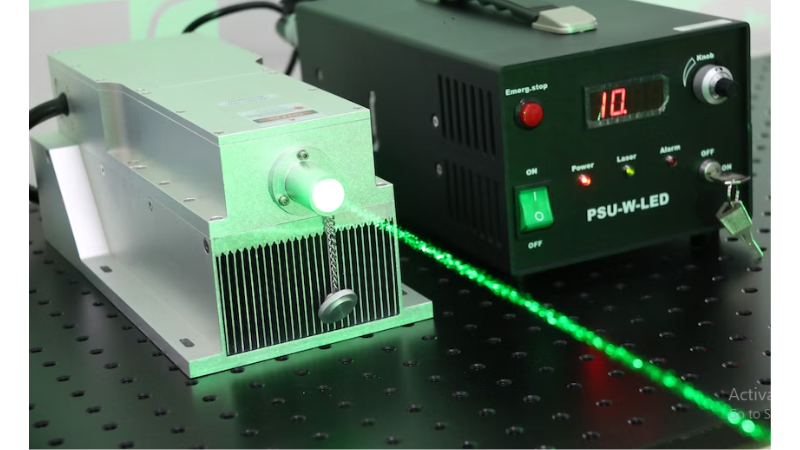

The Role of Power, Wavelength, and Output in Laser Cleaning

When cleaning material surfaces, wavelength, power, and output play significant roles for laser users.

The laser power determines the amount of energy delivered and how effectively it removes impurities from the item’s surface. The equipment wavelength dictates what contaminants to remove, as various materials require separate requirements for effective cleaning.

The laser output power determines the energy delivered per unit of time, often impacting the cleaning process’s efficiency and speed.

These factors dictate the laser cleaning process’s effectiveness by working together. Consider calibrating them carefully to achieve optimal results.

Power Requirements for Specific Cleaning Tasks

Laser rust, paint, and corrosion removal are specific cleaning tasks for laser machines that require different power requirements. Some of them include the following:

- Laser Rust Removal:The power required to remove rust from a material using a laser cleaning machine is 1000 to 2000 Wattage. This energy range is very effective whether integrated, handheld, or high-power laser systems. It’s an accurate laser cleaning system for vaporizing rust and oxidation.

- Paint RemovalThe power requirements to remove paint coating on a material surface with a laser cleaning system is between 100 and 2000 Wattage.Most machines within this range provide similar cleaning results but differ in speed and substrate finish quality. Consider the material type and size before selecting equipment for this application.

- Mold CleaningThe power requirement for mold cleaning with a laser cleaning technology is between 50 to 1500 Wattage. Both high and low-energy machines can remove mold on various materials without damaging the surface.

Relationship Between Power and Cleaning Efficiency

There is a complex relationship between laser technology power and cleaning efficiency. Higher laser powers deliver fast, efficient, and effective cleaning results by providing more energy to the material surface.

But there are some limitations. For example, when a laser power becomes too high, it often leads to surface damage. It might remove contaminants but also cause warping or discoloration.

Different materials might require varying laser powers for efficient cleaning. An item that absorbs laser energy poorly might need high energy to achieve a similar cleaning effect.

It might also require less energy for materials that you can vaporize quickly.

Optimal power depends on various factors, such as the laser type, material, and the specifics of the laser process.

Factors like scanning speed, pulse duration, and beam diameter also impact cleaning efficiency, including the laser power. Consider calibrating these parameters carefully when using laser cleaning techniques to achieve the best possible results.

Evaluating Power Requirements for Specific Applications

Laser cleaning machines have different applications that require various energy levels, and below are ways to evaluate them:

- Laser WeldingConsider the material you’re working with to evaluate power requirements for laser welding, as alloys and metals require different power levels.Although equipment with 100 wattages is ideal for the project, consider the item size and thickness. The focal spot size, pulse duration, wavelength, and laser type also impact the power requirements.

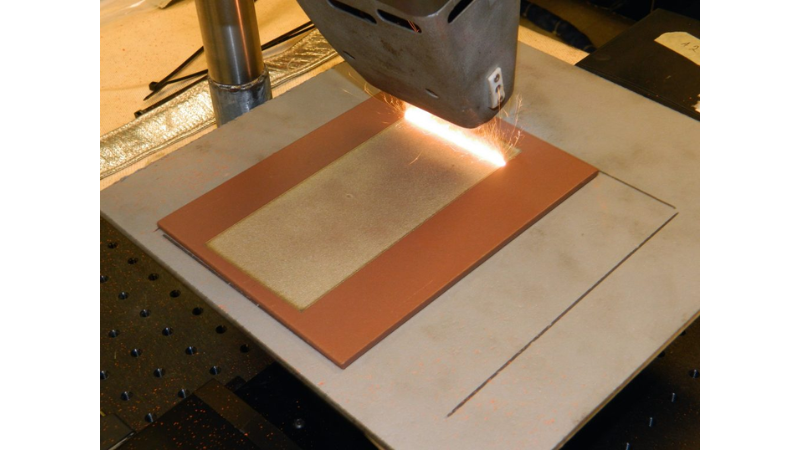

- Metal Surface CleaningExamine substrate thickness and contaminant type to evaluate laser power requirements to clean metal surfaces.Higher laser power with 1000 to 2000 wattage is ideal for thick contaminants or materials. Low-power equipment with 50 to 200 watts might be sufficient for light impurities or thin materials.

- Surface ProfilingExamine your material, surface area size, and resolution when evaluating laser power requirements for surface profiling.

- Beam quality and pulse durationYou’ll need medium power equipment with 200 to 1000 wattage for laser marking and to achieve desired results.

How to identify appropriate laser cleaning methods

Firstly, identify the material type, which often requires different laser wavelengths. Select a machine with a suitable wavelength for the item you’re cleaning.

Secondly, the surface contamination level is crucial to your laser cleaning method. A high-power machine can remove thick layers of debris, while low-power equipment is more effective in vaporizing thin coatings without surface damage.

Another factor that influences your laser cleaning method choice is the desired surface finish. Laser ablation often creates a rough surface finish, unlike laser engraving, which produces a precise and smooth finish.

How to Select Cost-Effective Laser Cleaning Solutions for Your Production Line

Careful consideration of power, wavelength, and output are ways to choose cost-effective laser cleaners. Below are their details:

Power

Consider power before selecting the right fiber laser cleaning machine because it determines the effectiveness of removing impurities. A device with high energy can vaporize stubborn paint and rust to increase productivity.

A high-power laser requires less maintenance and a longer lifespan, ensuring long-term cost savings. The machine power also impacts the cleaning speed, which reduces production downtime.

Wavelength

A laser wavelength is crucial in determining its effectiveness in eradicating impurities from surfaces. The materials absorb different wavelengths, which affects the cleaning process efficiency.

Plastics and metals require shorter wavelengths to vaporize surface debris effectively, while glass and ceramics need longer wavelengths.

Choosing a laser optimized for a particular material can help you achieve cost-effective cleaning results. It enables you to avoid potential surface damage when cleaning, which could lead to additional costs.

Output

Consider a laser solution output because it determines the machine’s efficiency and cleaning speed.

A laser technology with high output can keep your production line smooth and effective. An inexpensive machine with lower output is also ideal for those who don’t want high-speed cleaning.

You can select the best tool to deliver optimal performance and value by understanding the needs of your production line.

Other Cleaning Approaches

There are various types of cleaning approaches compared to laser technology. Some of them include the following:

- Chemical Cleaning: This method involves using acids, solvents, and detergents, which give metal items a shiny finish. They dissolve to remove grime and dirt but are toxic and harmful to the environment.

- Mechanical Cleaning: This technique uses mechanical force such as pads, sponges, and brushes to eradicate impurities from material surfaces. Carpet cleaners and pressure washers are other examples. But this method might not be a versatile option as it comes with labor.

- Abrasion Blasting: This cost-effective solution removes contaminants using glass beads, walnut shells, and sand. But it could damage the surface of your material.

Why It Is Important to Choose the Suitable Power for Laser Cleaning Machines

Selecting the appropriate power for laser cleaning machines is crucial to avoiding surface damage and achieving optimal results. The process might become slow and inefficient if the cleaning equipment’s power output is too low. When it’s too high, it might melt or burn the material you’re cleaning.

The suitable power output depends on the surface contaminant level, material type, and thickness. Choosing the proper energy delivery for cleaning machines can reduce downtime and minimize damage risks.

Conclusion

After learning about these cleaning machines in-depth, it’s time to choose the right laser machine with proper power delivery. The best equipment should have the requirements to weld, mark, engrave, and clean materials without surface damage.

Knowing its capabilities and limitations, you’ll select a laser cleaning machine with suitable power for surface treatment.

Buy Premium Laser Cleaning Machine from Baison Laser

Buy a high-quality laser cleaning machine with proper power delivery from the best producers. Baison Laser fits the description as a reliable and reputable manufacturer.

Contact us today for a consultation, and we’ll provide premium laser cleaners with suitable power for surface treatment.