Laser cleaning technology has been replacing traditional cleaning methods for quite a while now. Since they’re contactless and highly precise, businesses as well as individuals are getting into this technology. However, they’re often quite expensive and may not be a very feasible investment if your business is small and doesn’t need frequent cleaning.

This also presents you with a new opportunity. Why not make a business out of it and provide laser cleaning to clients as a service? In this article, we will explore the profitability of the laser cleaning business and its potential.

What Is Laser Cleaning and Why Are Businesses Paying for It

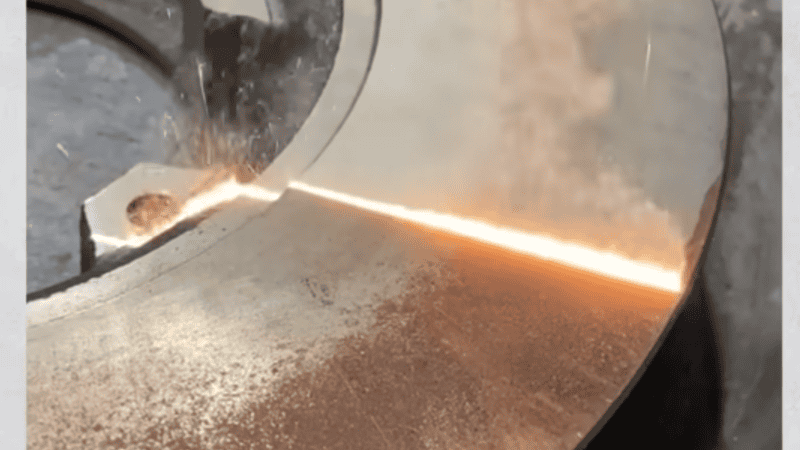

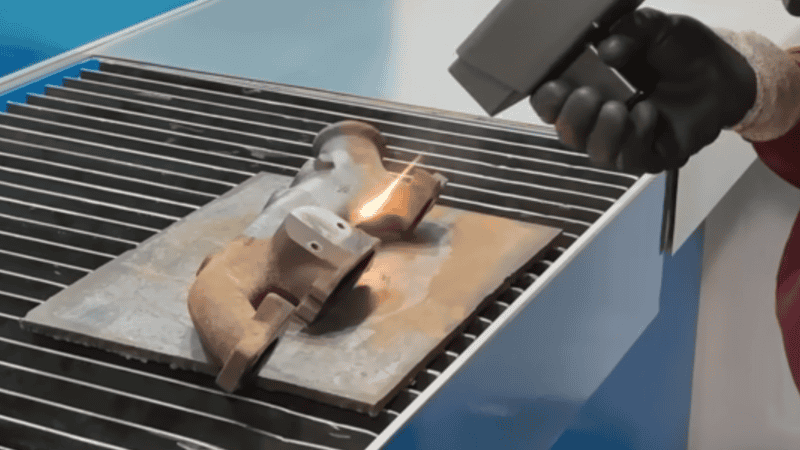

Laser cleaning is a non-contact, eco-friendly surface cleaning method that uses high-energy laser beams to remove contaminants, coatings, or unwanted materials from surfaces. The laser energy ablates or vaporizes unwanted substances without damaging the underlying material. Contrary to traditional mechanical cleaning, it is precise and produces minimal waste.

Laser cleaning avoids chemicals, abrasives, and physical contact. So it’s safe for workers and also environmentally friendly. Some common applications laser cleaning is used for are:

- Rust removal

- Paint stripping

- Degreasing

- Oxide treatment

- Surface preparation (e.g., welding or bonding)

- Restoration of historical artifacts and monuments

Industries Using Laser Cleaning Several industries actively adopt and outsource laser cleaning services:

- Automotive: For rust removal, paint stripping, and battery component preparation.

- Aerospace: Maintenance of aircraft components without abrasion.

- Marine: Removal of rust and marine growth from ship hulls.

- Construction: Preparing steel structures for welding or painting.

- Energy: Cleaning turbines, pipelines, and power generation equipment.

- Public Infrastructure: Maintenance of bridges, heritage buildings, and urban structures

Laser technology is in high demand due to several factors. We’ve highlighted three of them below:

- Compliance with Eco-Regulations: Stricter environmental protection laws are driving industries to adopt greener technologies. Laser cleaning does not use hazardous chemicals and generates minimal waste. It’s an eco-friendly alternative to traditional methods like abrasive blasting or chemical solvents.

- Labor Shortages and Automation: Laser cleaning integrated with robotics and automation helps address labor shortages by reducing dependence on manual processes. Automated systems ensure consistent quality, improve efficiency, and lower operational costs.

- Reduced Downtime: Laser cleaning is faster and more precise than traditional methods. It minimizes the time required for maintenance or surface preparation. Fewer operational interruptions and minimal downtime make it particularly valuable for the aerospace, automotive, and energy industries.

The Business Potential of Laser Cleaning Machines

So what are the opportunities in laser cleaning technology? What kind of business can you craft out? Here are some ideas:

Service-Based Businesses: If you’re an entrepreneur, you can establish mobile laser cleaning services for tasks like rust removal, paint stripping, and degreasing. These services are highly versatile and can cater to diverse industries. Many small or medium industries require on-site cleaning solutions for equipment, vehicles, or infrastructure.

In-House Cleaning for Manufacturers: Manufacturers can invest in laser cleaning machines to streamline their own surface preparation or maintenance processes. This reduces dependency on external service providers while ensuring precision and efficiency in cleaning operations.

Subcontracting/Outsourcing Contracts: By building a dedicated laser cleaning company, you can secure subcontracting agreements with industrial clients for large-scale projects. These may include factory maintenance, nuclear plant cleaning, and specialized tasks like aerospace component cleaning.

High-Value Projects Laser cleaning machines are ideal for high-value applications such as:

- Bridge Cleaning: Removing rust and contaminants from steel structures.

- Factory Maintenance: Cleaning machinery and production lines without dismantling equipment.

- Heritage Restoration: Safely removing dirt and corrosion from historical artifacts and monuments.

Who Needs Laser Cleaning Services? (High-Demand Industries)

Let’s understand your clients first. Who could be hiring your laser cleaning services? Some of the potential customers include:

- Automotive shops (chassis rust removal, engine part cleaning)

- Aerospace & Defense (paint removal, oxidation)

- Shipyards (marine buildup removal)

- Construction companies (steel, concrete cleaning)

- Municipalities (graffiti removal, infrastructure cleaning)

- Restoration firms (historic metal, statues, artwork)

Many of these industries prefer outsourcing laser cleaning services rather than purchasing machines due to the high upfront costs of equipment and the need for specialized expertise. This creates significant opportunities for service-based businesses offering mobile or contract-based laser cleaning solutions.

How Much Can You Earn? (Profitability & ROI Breakdown)

Example of Average Service Rates

Laser cleaning businesses typically charge $100–$300/hour for standard tasks like rust or paint removal. Rates may vary by location, project complexity, and equipment requirements.

Heritage restoration and delicate artifact cleaning command even higher fees—sometimes $400+/hour—due to the specialized expertise and precision needed.

Mobile services often add a premium (15–25%) for on-site convenience, especially for clients in industries like construction or shipyards that can’t pause operations. A single high-value project, such as bridge cleaning or factory maintenance, can generate $5,000–$20,000+ in revenue (depending on the scale).

With low ongoing costs (minimal consumables, no chemicals) and efficient workflows, profit margins often exceed 40–60%, especially after covering the initial machine investment ($20k–$100k). Targeting industries with strict eco-regulations or labor shortages amplifies ROI, as clients prioritize speed and compliance over cost-cutting.

Profit Margins

Profit Margins

Laser cleaning offers high-profit margins due to minimal consumables—no sand, chemicals, or abrasives—and low operational costs. Electricity is your primary expense, often under $5/hour for most machines.

Unlike sandblasting, laser systems face less wear-and-tear, reducing maintenance costs and downtime. With efficient pricing and consistent job volume, ROI is achievable in 6–18 months with mid-range machines ($30k–$60k).

High-volume contracts (e.g., bridge cleaning, factory maintenance) may generate high yields, while premium restoration projects boost margins further.

Key takeaway: Optimize machine usage and target industries with urgent regulatory or labor challenges to maximize profitability.

Sample ROI Table

| Item | Pulsed Laser (200W–500W) | Continuous Laser (1000W–3000W) |

| Machine Cost | $15,000 – $35,000 | $45,000 – $100,000 |

| Hourly Rate Charged | $100 – $200/hour | $150 – $300/hour |

| Monthly Job Hours | 60–80 hours | 80–120 hours |

| Monthly Revenue | $6,000 – $16,000 | $12,000 – $36,000 |

| Monthly Durability Loss | ~0.5% (low wear) | ~0.3% (robust build) |

| Service Life | 5–7 years (with maintenance) | 7–10+ years (industrial-grade) |

| Maintenance Cost/Year | $500 – $1,500 | $1,500 – $3,500 |

| Break-Even Time | 6–12 months | 10–18 months |

What Kind of Laser Cleaning Machine Should You Buy for Profit?

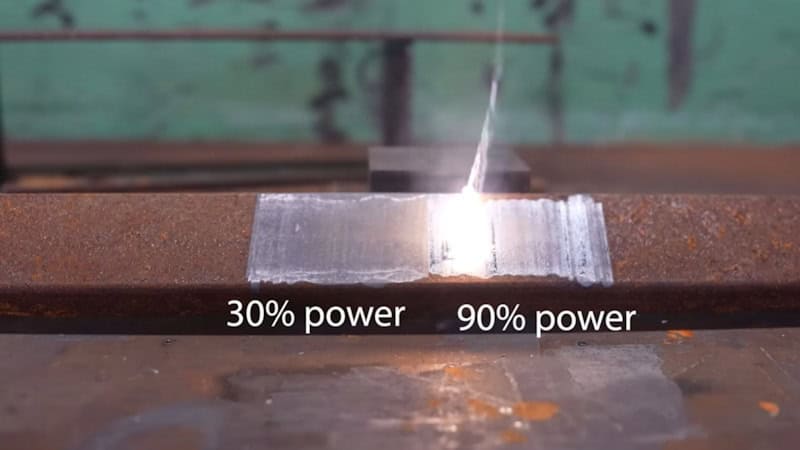

Choose the Right Power Level

100W–200W (Entry-Level): Ideal for light, mobile jobs, such as removing surface contaminants, cleaning delicate parts, or restoring artifacts. Perfect for startups focusing on precision tasks like electronics cleaning or small-scale restoration. They are portable, affordable ($15,000–$35,000), and great for sensitive materials where minimal heat impact is required.

500W+ (Mid-Power): Suited for industrial tasks like corrosion removal, paint stripping, and surface preparation for welding. These machines balance power and portability, making them versatile for industries like automotive and aerospace. Mid-power systems ($35,000–$60,000) can handle larger projects while maintaining precision.

1000W–3000W (High-Power): Designed for heavy-duty industrial contracts such as ship hull rust removal, large steel structures, and factory maintenance. These machines ($45,000–$100,000) are best for high-speed cleaning of thick contaminants over large areas.

Fiber Laser Is Preferred

Fiber lasers are the top choice for laser cleaning due to their efficiency, durability, and low maintenance requirements. They’ll help you with a long lifespan of up to 100,000 hours, significantly outlasting CO₂ lasers. They’re much more versatile and generally considered a better investment.

Unlike CO₂ lasers, fiber lasers have lower maintenance needs because of their solid-state design, which means it doesn’t need mirrors or delicate components. Thanks to this, they’re more robust and cost-effective for industrial use. Additionally, fiber lasers are highly energy-efficient, delivering precise cleaning with minimal power consumption.

Get a more detailed insight into CO2 laser vs Fiber laser.

Look for Easy Operation & Support

- Plug-and-play systems simplify setup and reduce training time. They allow faster deployment for cleaning jobs.

- Dedicated after-sales service ensures quick access to spare parts, technical support, and warranties, minimizing downtime.

- Adjustable software settings allow customization for different materials and contaminants.

- Cooling mechanisms prevent overheating during extended use, especially in high-power machines.

- Safety features, such as enclosed lasers or protective cabinets, enhance operator security and compliance with workplace regulations.

- Mobility options, like handheld or wheeled designs, provide flexibility for on-site cleaning tasks.

- Trusted manufacturers offer durable machines with reliable optics.

- Integration compatibility with conveyor systems or robotic arms improves efficiency for industrial applications.

- Energy efficiency lowers operating costs, making the machine more profitable over time.

How to Start a Laser Cleaning Business (Step-by-Step Guide)

1. Market Research & Business Plan

Analyze your local industrial needs to identify potential clients and industries that can benefit from laser cleaning, such as automotive shops, manufacturers, or restoration firms. Research competitors to understand their pricing, services, and market presence. Develop a detailed business plan and outline your target market, pricing strategy, marketing approach, and financial projections.

2. Choose Your Business Model

Decide whether to offer mobile on-site cleaning services or a workshop-based service. Alternatively, focus on B2B subcontracting by partnering with manufacturers or contractors for recurring industrial cleaning jobs. Each model has unique benefits; choose based on your resources and target market.

3. Invest in the Right Machine

Start with a mid-range power output like a 1000W portable fiber laser. It’ll help you learn the curves and also let you take contracts. Once you’re an expert, you can budget for a more advanced model and additional essentials like training programs and a transport van if offering mobile services. Ensure the machine is versatile enough to cater to multiple industries while balancing cost and performance.

4. Get Trained & Certified

Learn safe operation techniques and material compatibility to ensure effective cleaning without damaging surfaces. Obtain certifications that demonstrate your expertise and commitment to safety standards. Offering quality assurance builds trust with clients and sets you apart from competitors.

5. Build Your Network & Market Services

Target B2B clients through platforms like LinkedIn, Google Ads, and local SEO strategies. Partner with auto shops, contractors, factories, and restoration firms to secure contracts. Social media marketing is a very effective way to spread your business. Showcase your work, get reviews, and create demo videos showing your laser cleaning capabilities to attract attention and build credibility in your niche market.

Real-Life Case Studies / Success Stories

Rolls-Royce uses laser cleaning for preparing titanium alloy surfaces before electron beam welding. It helped them achieve nearly 100% first-time success rates for aero-engine components. BAE Systems has adopted it for airframe manufacturing, replacing chemical cleaning methods. They now save millions annually.

Laser rust removal technology has also been applied to bridges in Quebec and the Canadian Parliament building while preserving structural integrity. These projects highlight their efficiency for large-scale urban infrastructure maintenance.

Challenges and Considerations

- Upfront investment can be high, especially for higher-power systems.

- Maintenance costs are lower compared to traditional methods, but still require budgeting for occasional repairs.

- Training and certifications for safe operation add to initial expenses.

- Competition from established players may limit pricing flexibility in some regions.

- Market demand depends on local industries; niche applications may require specialized marketing.

- ROI varies based on job volume and machine utilization, with scaling challenges for smaller businesses.

- Regulatory compliance and safety standards must be met, increasing operational complexity.

- Mobile services need additional investments in transport vehicles and logistics planning.

- Client acquisition requires effective networking and marketing strategies to secure contracts.

- High energy consumption for industrial-grade machines impacts operating costs over time.

- Upfront investment can be high, especially for higher power systems.

- Not all materials are suitable for laser cleaning.

- Requires some technical knowledge and training.

- You may need business licenses or safety permits, depending on your region.

Conclusion: Yes, You Can Make Money — If You Do It Right

Although it requires a sizable investment, it can also earn you back multiple folds of your investment if you play your cards right. Start by assessing local demand, the type of contracts you may get, and the number of competitors in the region. Invest in a versatile machine that can handle both short and long-term projects. Train a team and reach out to businesses. With wit and dedication, you can make handsome profits with laser cleaning technology.

Ready to Launch Your Laser Cleaning Business? [Call to Action]

Want to learn more about which machine fits your goals, or how to get started profitably? Baison laser is your one-stop solution! We’ll help you choose the best solution to grow your industrial service business with confidence.

Contact us today to schedule a free consultation, request a demo, or get a customized quote tailored to your industry.