It is essential to use cabinet filters for laser machines. Not only do they ensure the safety of your staff ad environment. But there are state regulations all over the world for the safety of the environment. Proper filtration and fume exhaustion systems are essential for the safety of employees and the workplace.

This article discusses cabinet filters: what are they? Why are they important? and how to choose them? Let’s see what cabinet filters are first.

What are Cabinet Filter Elements

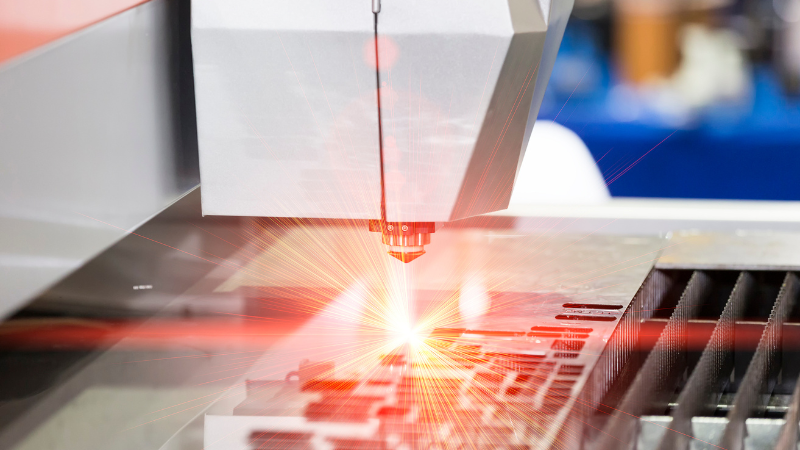

Cabinet filters are also called fume extractors or dust collectors. They are essential to laser cutting machines to remove hazardous fumes and particles generated during cutting. The cutting process can produce a lot of gases, fumes, and debris that are unsafe to ventilate to the outside world. This is why laser machines come with a fume extraction system.

The purpose of this system is to use different filters to absorb fumes and dust while the cutting process. The filters are important to protect the health of the operator and the environment.

Cabinet filters comprise several filtration media with layers to absorb dust, particles, and other types of contaminations. Different filters can be used depending on the material the laser cutter is working on. The configuration of the filter depends on specific applications and textiles. These filters need to be replaced when they are saturated.

What are the Advantages of Cabinet Filter Elements?

Improve Air Quality

Laser engraving, welding, or cutting deals with all materials, including hard alloys and metals. Cutting, engraving, and drilling may cause a lot of dust particles or fumes to fly all around during the cutting process. Cabinet filters can effectively remove fumes, smoke, and dust generated during the laser-cutting process, improving air quality in the workspace and preventing operators from inhaling harmful substances.

Compliance with Regulations

Industries have to follow the rules and guidelines of the state in any country. Cabinet filters can help companies comply with environmental and workplace air quality and emissions regulations.

Extended Machine Life

Not only can these cabinet filters save staff and the environment, but they also extend the machine’s life. The same dust and small particles can damage the machine if left to fly all around. Removing fumes and dust from the laser-cutting process can help extend the life of the laser equipment and reduce maintenance costs.

Reduced Fire Hazard

They keep the workplace safe. Removing fumes and dust from the laser-cutting process can also reduce the fire risk in the workspace.

Enhanced Operator Safety

Although some laser machines are fully automated, staff must still operate the control panel, adjust the laser power and head, or monitor the laser cut. Fumes, gases, and dust can pose many health issues. So laser safety considerations include removing fumes and dust.

Cabinet filters can help create a safer work environment for operators and reduce the risk of respiratory problems or other health issues associated with exposure to harmful substances.

Longevity of Machines

Laser machines have expensive lenses and components like a lens, laser head, optics, mirrors, etc. All of these require extra care. If you allow dust and debris to settle on these parts, they can be damaged. The use of a fume exhaustion system is essential for the lifespan of our machine as well.

Types of Cabinet Filter Elements

Let’s look at some cabinet filters of the fume extraction system:

Pre Filter

This is the first line of defense in the filtration system, which captures larger particles before they reach the main filter element. Pre-filters can be made of various materials, including foam, polyester, or fiberglass.

HEPA Filter

High-Efficiency Particulate Air (HEPA) filters are commonly used in laser machines to capture small particles and contaminants. These filters are made of a dense mesh of fibers and can remove 99.97% of particles that are 0.3 microns or larger.

Activated Carbon Filter

Activated carbon filters remove odors and fumes produced by laser machines. These filters use activated carbon to adsorb gases and vapors, which are then trapped in the filter media.

Electrostatic precipitators

These filters use an electrical charge to capture and remove particles from the exhaust stream. The particles are attracted to charged plates or wires and are removed from the air.

Factors to Consider When Choosing Cabinet Filter Elements

Here are a few things to consider when choosing the cabinet filter:

Laser-Cutting Machine Specifications

The first and foremost consideration is to check your laser cutting machine’s specifications. Whether it operates with high or low power and the manufacturer’s recommendations. It can vary depending on the machine’s specifications.

Types of Material

What type of materials are you processing? It can be metal, plastic, or composites. Each material may have a specific need for a filter. In some cases, some pure metals may not produce any smell at all. Odorless gases do not mean you don’t need filters. They can still be toxic, and their fumes can harm health and the environment.

Some materials may produce only a few dust particles or gases during cutting or welding. Even if the materials do not produce too many fumes and odors, it does not mean that.

Airflow Requirements

Considering airflow is very important. The filter may not perform if the airflow is not enough. It may not trap all the contamination if the airflow is too high or may not function properly if it is very low.

Laser annealing or foaming has minimal waste or by-products, so it may not need high airflow. However, engraving or laser cutting produces high fume and dust particles and requires high airflow.

Cost

Laser machines are costly, and if you need a good filtration system, it can also reduce your machine’s lifespan. These filters need to be replaced from time to time as well.

Applications of Cabinet Filter Elements for Laser Machine

Applications, where cabinet filters are used are:

Metal fabrication

Metal fabrication generates a lot of gases and fumes, so cabinet filter elements are essential in this industry.

Woodwork

Cutting wood and engraving also causes a lot of debris and dust.

Textile Industry

In the textile industry, cabinet filter elements are used for engraving and cutting fabrics.

Electronic Industry

The electronic industry uses cutting and drilling a lot of o materials. So cabinet filter elements are essential to be used with these machines.

Why are Cabinet Filters Important?

Cabinet filters are important in laser cutters because they help to remove harmful fumes and particles from the air within the laser cutting cabinet.

Laser machines engrave metals or are used for cutting, marking, and oxidizing the cleaning of metals. These processes cause a lot of gases, fumes, debris, dust, and pollutants that can contaminate the environment. These toxic chemicals can cause serious health hazards like asthma or cancer.

In addition to protecting the operator’s health, cabinet filters can also help prolong the laser cutter’s life by preventing the buildup of debris and other contaminants within the machine. This can reduce maintenance costs and downtime, ensuring that the laser cutter remains in good working order for longer.

How Often Should Cabinet Filter Elements be Changed?

It depends on the type of material you are working on with the laser machines. How often the filter needs to be changed depends on the

- Type of material to be cut

- Type of machine

- Type of filter

- Frequency and duration of use.

Some materials produce more debris and dust particles, while others may not produce as much fumes and dust. So It is important to inspect the filters. If they seem saturated, they need to be changed. Also, you can refer to the manufacturer’s specifications of the machine and filter.

Final Words

Laser machines cut, mark, weld, and engrave materials. These machines use a high-powered beam to cut or vaporize the material. Cutting or engraving metals mean many gases, dust, small particles, and fumes fly around.

During laser processing, materials react in ways so fumes, bubbles, smoke, and melts as by-products. Filtering these fumes and particles is essential for the safety of operating staff, machines, and the overall environment.

Industries must comply with certain regulations for the safety of employees and the environment. Cabinet filters in laser cutting machines ensure that all fumes and particles are trapped in filters, even of the size of microns.

Make Your Workplace Safe and Secure with Baison Laser Machines

Baison offers laser products for cutting, welding, cleaning, and marking. We offer state-of-the-art technology, and our laser systems are equipped with the best filter systems for the safety of your workplace and employees.

Contact us to learn more about our laser machines. We also offer a free sample evaluation application if you still need to determine which of our laser systems best suits your industrial needs.