Bending machines are integral to the manufacturing industry and are available in various types and sizes. With further classification based on features, characteristics, and applications, selecting the right tool for your business can be daunting.

To aid in your decision-making process, we’ll explore six major types of bending machines and their applications in modern manufacturing. Let’s dive in!

What Is a Bending Machine?

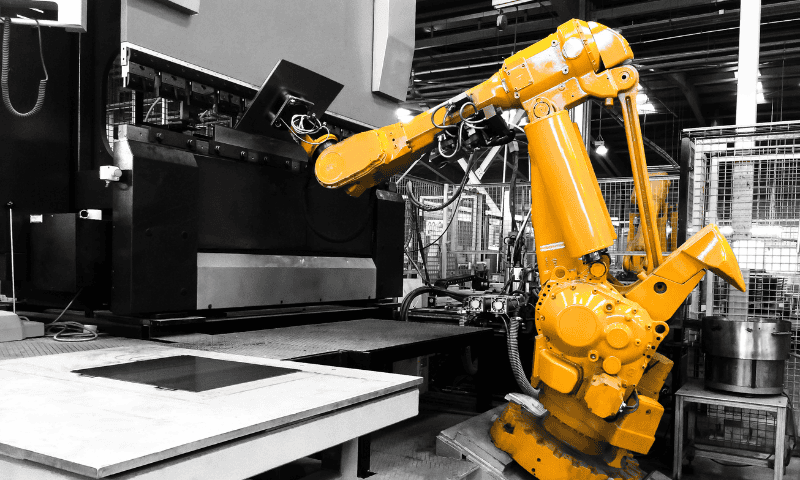

Bending machines are industrial tools used to shape metal parts at different angles. These machines apply pressure evenly, reducing the risk of metal fatigue and breakage during the bending process. They are compatible with numerous materials such as steel, copper, aluminum, and even tough ones like titanium.

The art of bending, an essential technique in manufacturing, has been practiced since the early metal ages. From shaping basic tools to crafting intricate metal works, bending has remained a fundamental skill throughout history. Even now, metal bending machines are in high demand across aerospace, construction, and automotive industries.

According to FMI, sales of metal sheet bending machines are expected to grow to $1,344.60 million by 2034, up from the current valuation of $1,020.1 million in 2024.

Other than major industries, bending machines are used everywhere, from hospital furnishings to boat and swimming pool furnishings, road signs and posters, bathroom furnishings, taps, and faucets, to prams and pushchairs.

Advantages of Bending Machines

Now, let’s delve into the advantages of bending machines:

- Precision: Bending machines offer precise control over angles and dimensions, ensuring accurate and consistent results.

- Efficiency: They enable fast production of bent parts, reducing manufacturing time and costs.

- Versatility: Bending machines can handle a wide range of materials and thicknesses, making them suitable for various industries and applications.

- Automation: Many bending machines feature automated functions, reducing the need for manual labor and improving productivity.

How Many Types Of Bending Machines Are There?

Generally, bending machines are categorized into six main types, as listed below. However, they can also be further classified based on specific characteristics, features, or applications. For instance, there are wire-bending machines specialized for wire manipulation. We will discuss each type in detail in a later section.

- Sheet Metal Bending Machine

- Pipe Bending and Plate Bending Machine

- Press Brake Machine

- Plate Rolling Machines

- Mechanical Bending Machine

- Hydraulic Bending Machine

Ready to Get Your Own Bending Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Types and Applications of Bending Machines

There are different types of bending machines catering to various metal shapes, such as small pipes, large tubes, rebar, thick metal plates, or regular sheet metal, covering a wide variety of applications.

Each bending machine serves particular functions involving various metal fabrication processes. Here is a brief overview of how bending machines function in modern industry.

1. Sheet Metal Bending Machine

Sheet metal bending machines are specifically designed to bend metal sheets of various thicknesses into intricate shapes. Common tasks include bending, curving, and folding metal plates at different angles.

In the manufacturing industry, sheet metal bending machines are commonly paired with metal cutting machines. The newly cut metal sheets are then shaped into 3D designs, resulting in a smoother workflow.

A steel plate bending machine is also used for the “Heming” process, which reinforces metal edges and removes the burs. Primarily applied in the food packaging industry.

Not all sheet metal bending machines are the same. Here is a further classification of machines based on bending techniques. Each has unique features and excels at certain applications.

- Roll Bending Machine Process

- Two Die Shaping Process

- Single Die Beading Process

- Punch and Die Bending Process

Depending on the nature of the business, the fabricator can choose the most relevant one.

Applications

- Electronic Enclosure Manufacturing

- Automotive Body Panels

- Metal Hemming

- HVAC Pipes and Brackets

Operating Parameters

Although sheet metal bending machines vary from maker to maker, generally, they operate on these parameters.

- Sheet Thickness Range – 0.08 to 0.24 inches

- Max Sheet Length – Machine Size Dependent

- Max Sheet Width – Machine Size Dependent

2. Pipe Bending Machine

Pipe bending machines can bend any type of cylindrical or rectangular metal pipe, tube, rod, or channel into the desired shape. They do so in such a way that the pipe’s internal diameter or dimensions remain constant throughout the entire length. However, there is still a risk of collapse and crimping due to excessive compressive force on the inside. High-quality machines are designed to factor in this risk.

Pipe bending machines aren’t one size fits all, so they are further classified into four different types based on their applications and features.

a. Roller Bending Machine

Yields most consistent and solid bends with the help of three rollers arranged in a pyramid shape. Best suited for sharp circular bends and thicker materials.

b. Ram Bending Machine

Use high compressive force of ram to the focal point, bending pipes at much sharper angles.

c. Compression Bending Machine

Utilizes two sideways pressure pistons to hold the pipe together and compress it against a circular bending die. Most suited for bending large-diameter pipes.

d. Rotary Draw Bending Machine

Similar to compression bending, the rotary one clamps the metal pipe, and the lever pulls it along a static die, curving it in the process. Most suited for small to diameter pipes and tubes.

Applications

- Furniture and Architecture

- Handrail Manufacturing

- HVAC Tubing

- Plumbing & Pipe Fittings

- Exhaust Pipes

Operating Parameters

No matter what the type, the pipe bending machines operate on roughly the following parameters.

- Outer Diameter Range – 0.5 inches to 72 inches

- Bending Radius – 1.5D – 20D (D=Diameter)

- Max Bending Angle – 270°

- MAX Wall Thickness – 5 inches

3. Press Brake Machine

Press brake machines bend industrial metal plates and sheets but differ in the process compared to traditional sheet metal benders discussed above. These machines have punch and die components with powerful brakes that stop the punch from going all the way to the die underneath. Such a mechanism helps in creating more complex shapes and designs.

A highly advanced computer numerical control manages the extent of downward force and the braking point, resulting in a diverse range of angles, shapes, and finishes.

The incredible downward force must be countered with an equally powerful braking system. That’s why these machines are further classified based on braking technology.

- Nut-Stop Brakes

- Syncro Brakes

- Hydraulic Brakes

- Electric Brakes

- Hybrid Electric Brakes

Applications

- Heavy Machinery

- Construction

- Automotive

- Ship Building

- Oil and Gas

Operating Parameters

- Sheet Thickness Range – 0.24 to 0.80 inches

- Max Sheet Length – Depends on machine type

- Max Sheet Width – Depends on machine size

Ready to Get Your Own Bending Machines?

Boost your operations with Baison Laser's advanced, customized technology!

4. Plate Rolling Machine

The plate rolling machine is a heavy industrial metal sheet bending machine that can bend thick metal plates. Unlike the press brake and sheet metal bender, its capacity to handle large workpieces is its defining feature.

Plate rollers are either fully automatic or semi-automatic, and any standard machine can handle up to 3-inch (76 mm) thick plates. However, with hot rolling, they can bend even 4-inch (102 mm) thick plates.

It uses three roller systems arranged in the familiar pyramid shape, with the top one providing the main force while the bottom two provide counter-reactions. The difference lies in the powerful motor system that runs the rollers, making such heavy-duty fabrication possible. However, the process is slower and requires multiple passes to achieve the desired angle.

Applications

- Petrochemical and Oil & Gas – Containment Tanks

- Aerospace and Aviation – Rocket Exterior

- Automotive and Transportation

- Mining Equipment

- Underwater Piping

Operating Parameters

- Workpiece length – 12ft. 144 inches.

- Workpiece Width – As Per Roller Length

- Workpiece Thickness – 3 inches (Cold Rolling) or 4 inches (Hot Rolling)

- Maximum Rolling Diameter – 12 ft.

5. Mechanical Bending Machine

The mechanical bending machine is a traditional industrial tool that relies on motors, wheels, pulleys, levers, and gears to bend metal workpieces, as opposed to pneumatic, hydraulic, or electrical systems. Both automatic and manual operating machines are available in the market and dominate small to medium-scale businesses.

Though mechanical, it still provides accurate and precise bends of metal sheets, pipes, and tubes. Nowadays, they are primarily used for work that is more complex or requires more attention to detail.

Applications

- Construction

- Automotive

- Plumbing

- HVAC Ducting

- Electronic Enclosures

6. CNC Hydraulic Bending Machine

A CNC hydraulic machine is a versatile industrial bending tool that has many advantages over other bending machines we discussed above. Thanks to the power of hydraulics, this CNC bending machine can transmit exponentially higher force onto the workpiece.

The higher power of hydraulic actuation is guided by CNC systems, making the operations safe and accurate. Manual hydraulic bending machines are also available in the market; however, they are more labor-intensive.

Applications

- Automotive and Railways

- Aerospace Industry

- Mining and Heavy Equipment

- Shipbuilding and Marine Industry

- Construction and Architecture

Table 1) Brief overview of different bending machine types.

| Bending Machine Type | Description | Applications |

|---|

Ready to Get Your Own Bending Machines?

Boost your operations with Baison Laser's advanced, customized technology!

9 Factors to Consider When Selecting a Bending Machine

Now that we’ve covered the basic types of bending machines let’s explore some essential factors to consider when choosing the best product for your business.

1. Bend Accuracy

Evaluate the machine’s ability to achieve precise bend angles and lengths for accurate part production. You can order sample products from the manufacturer.

2. Material Ductility

Select a machine suitable for the material’s ductility to ease the bending process.

3. Number of Tool Stacks

Always select a machine with multiple tool stacks for increased flexibility and efficiency.

4. Production Volume

Consider the machine’s throughput and efficiency to meet production demands effectively.

5. Automation and Control

Assess the level of automation and control features for optimized operation and reduced setup time. However, higher automation levels also increase the upfront cost of the machine.

6. Maintenance and Support

Look into the machine’s maintenance requirements and the availability of support services to ensure smooth operation over time.

7. Warranty Specifics

Check the manufacturer’s warranty for coverage of essential components and common issues, ensuring peace of mind and investment protection. Inquire about the accidental damage policy during shipping.

8. Shipping Costs

Consider shipping expenses, especially for overseas purchases. Compare options and factor in additional fees to determine the total cost.

9. After-Sales Services

Evaluate the manufacturer’s reputation for helping with technical issues, having spare parts, and doing maintenance. Good support reduces downtime and makes the machine last longer.

Ready to Get Your Own Bending Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Conclusion

We’ve covered all the major types of bending machines, their operating parameters, and general applications. Additionally, we’ve discussed important factors for business owners to consider when purchasing a suitable machine. Be sure to thoroughly discuss these points with manufacturers for greater success in the future.

Bend with Precision: Discover Baison Laser’s Superior CNC Metal Bending Machines

Baison stands tall as a pioneer in crafting cutting-edge fiber laser systems. From the finesse of laser cutting to the precision of marking and the durability of welding, our product lineup boasts diversity and excellence. Fueled by cutting-edge CNC systems, our tools redefine precision. Presenting our latest innovation—Metal Bending Machines, meticulously engineered to meet our international standards of quality and performance.

Our next-level customer support services include a FREE Application Evaluation and a FREE Customer Training Program. So, you always get the best value.

Get a Customized Quote Today! Contact us Now!