We will discuss their efficiency, adaptability, and the distinct advantages they offer. We aim to enlighten businesses on how this technology can optimize operations, ensure superior quality, and ultimately increase overall productivity. Let’s get right into it!

What Is a Laser Pipe Cutter?

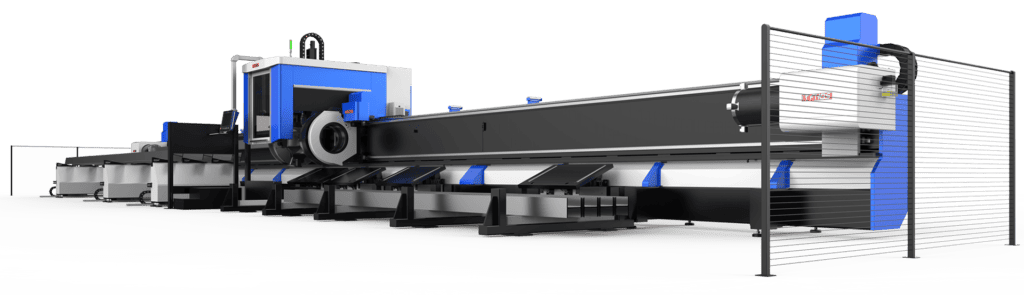

A laser pipe cutter is an advanced manufacturing tool that utilizes concentrated laser technology to cut pipes and tubes. It offers incredible precision and speed. Moreover, these cutting machines can seamlessly handle various materials, including metal round pipes like aluminum alloy pipes, stainless steel pipes, carbon steel pipes, and other metal composite pipes.

Furthermore, we cannot emphasize enough the importance of laser pipe cutters in the guardrail processing industry. It streamlines the cutting process and allows metal pipe manufacturers to create intricate, custom shapes like round, rectangular, and special-shaped pipes. On top of it, with capabilities to reduce material waste and enhance production efficiency, the use of laser pipe cutters is revolutionizing the guardrail industry.

Guardrail Processing Industry: Overview and Challenges

The guardrail processing industry plays a vital role in the safety and structure of numerous public and private spaces. It manufactures robust and reliable guardrails from various materials such as stainless steel, carbon steel, aluminum alloy, and galvanized steel. The end products range from simple protective fences to complex, custom-made guardrails for specific applications in the protective fence manufacturing industry. Let’s have a look at the challenges, solutions, and the benefits.

The Challenge: Traditional Cutting Processes

Traditional cutting processes pose significant challenges for the guardrail industry. They are time-consuming, often result in material waste, and may not always provide the precision required for complex designs. Traditional methods can limit productivity and material utilization for manufacturers working with various shapes, such as round, square, and rectangular pipes.

The Solution: Laser Pipe Cutting Machines

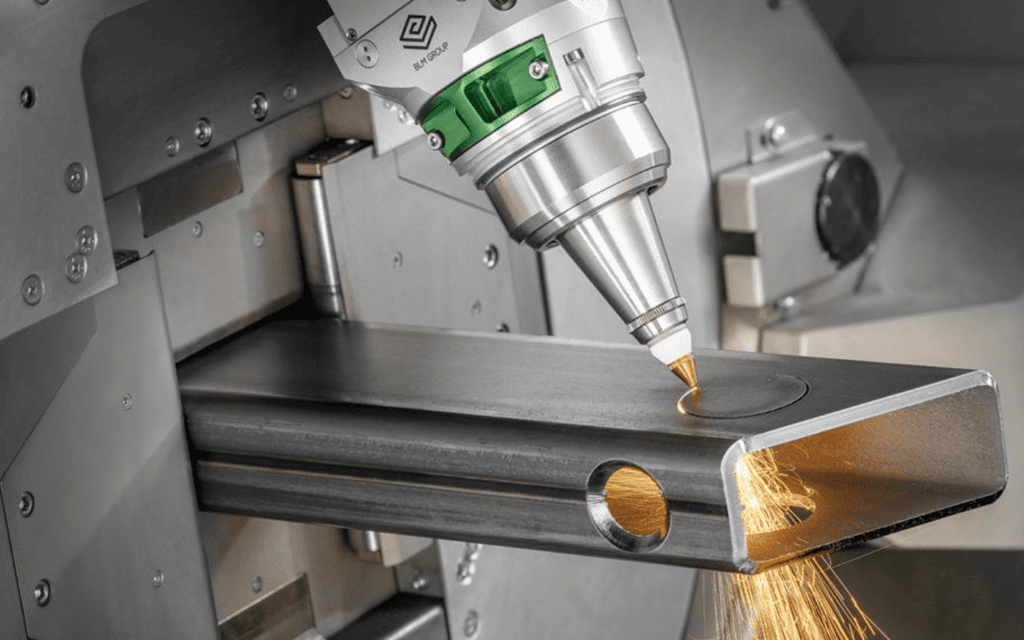

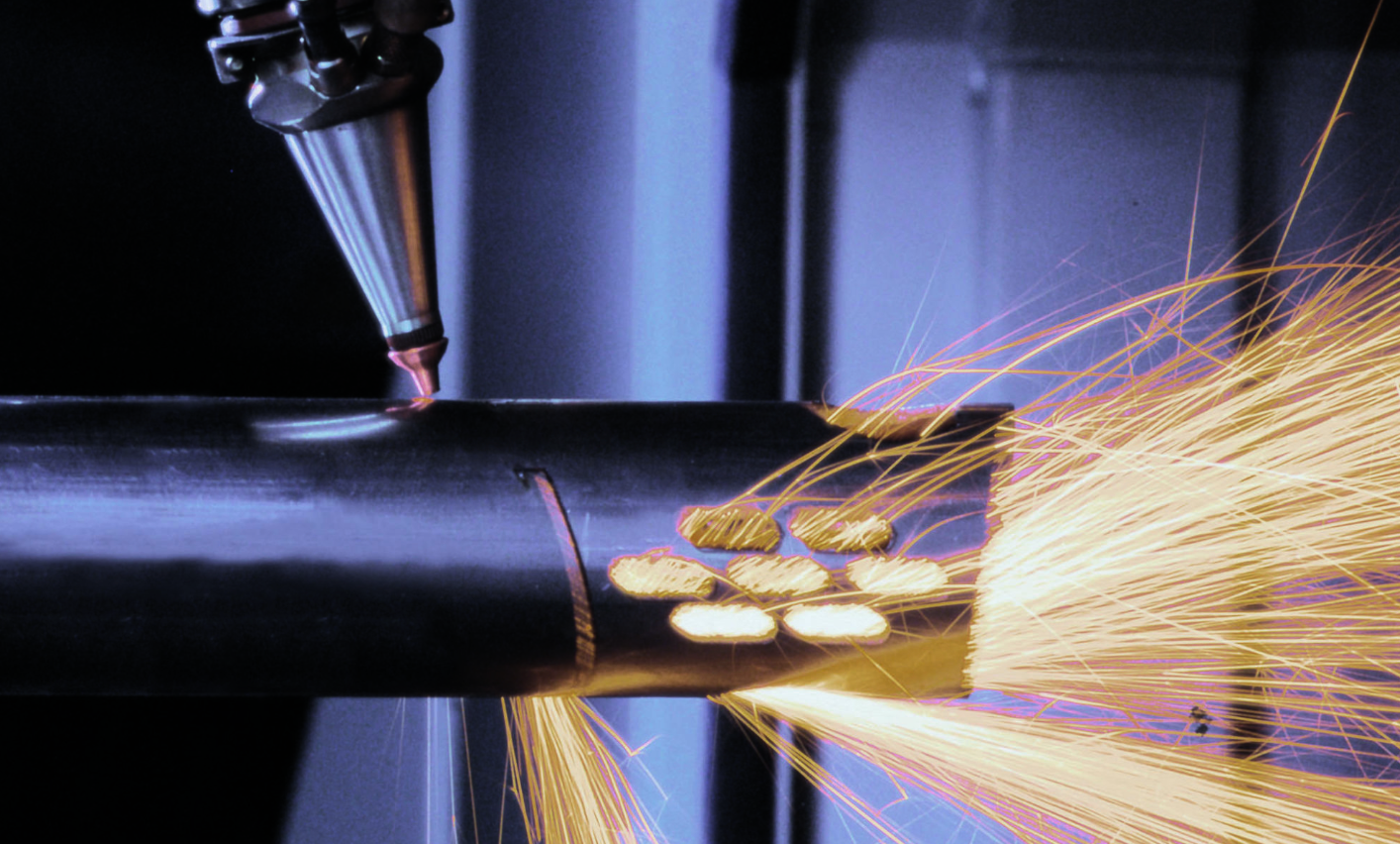

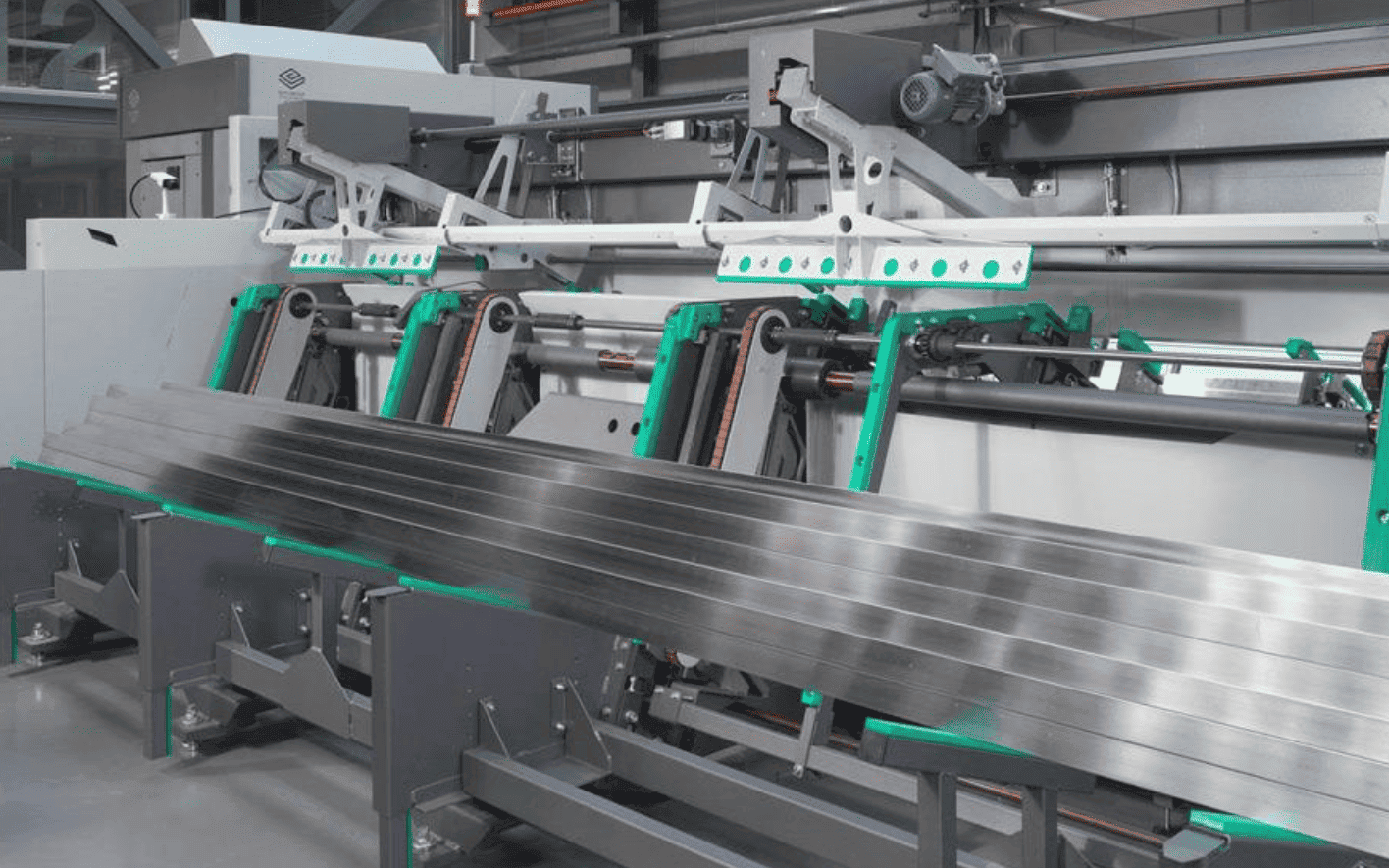

Enter laser pipe-cutting machines. With their high cutting efficiency, the ability to handle a variety of shapes, and minimal material waste, these machines are transforming guardrail manufacturing. For example, a tube laser cutting machine can seamlessly cut through a range of metal pipes, enabling manufacturers to produce guardrails of varying shapes and sizes with unprecedented accuracy and speed.

The Advantage: Corner Fast Cutting System

Another advantage is the corner fast-cutting system offered by some laser pipe-cutting machines. This system allows for rapid cutting at the corners of square or rectangular pipes. As a result, it significantly increases production efficiency. Moreover, given the many benefits, laser pipe cutters are becoming essential in guardrail processing.

Types of Cutting Machines in the Guardrail Industry

Selecting the appropriate cutting machine can make a world of difference in the guardrail processing industry. It influences product quality, production efficiency, and, ultimately, profitability. This section explores the strengths and weaknesses of various cutting machines – plasma, laser, oxy-fuel, and cold punching – and why understanding these is crucial for your business’s success.

Plasma Cutting Machines

Plasma-cutting machines use a high-velocity jet of ionized gas, or plasma, to cut through metal pipes. This technology enables manufacturers to cut intricate shapes and patterns in their guardrail products. However, the process involves high temperatures, which can potentially alter the metal’s properties.

Laser Cutting Machines

There’s no doubt laser cutting machines have revolutionized the guardrail industry. They provide precise, clean cuts in a variety of metal pipes, including round, square, and special-shaped pipes. Furthermore, laser-cutting machines offer higher productivity, less waste, and increased cutting efficiency, making them an ideal choice for many manufacturers in the industry.

Oxy-Fuel Cutting Machines

Oxy-fuel cutting machines, or torch-cutting machines, use a flame produced by a fuel gas mixed with pure oxygen to cut metals. This method is known for its ability to cut thicker materials; however, it lacks the precision offered by other cutting technologies.

Cold Punching Machines

Cold punching machines, also known as punching presses, use sheer force to create holes or shapes in metal pipes. Although this process is quick and suitable for mass production, it is less flexible regarding the complexity of shapes it can produce compared to laser or plasma cutting machines.

Advantages of Laser Pipe Cutting Machine in the Guardrail Industry

Understanding the significance of an efficient, accurate, and versatile cutting machine is essential in the guardrail industry. A laser pipe-cutting machine serves as a high-performing solution, addressing the industry’s unique challenges. Let’s delve into the compelling advantages of using a laser pipe-cutting machine:

- Perfect Accuracy: Laser pipe cutting machines are like skilled artists, carving out complex patterns on guardrails with the utmost precision, ensuring each piece looks just as good as the last.

- Quick Work: When it comes to making guardrails, these machines are like sprinters, getting the job done much faster than traditional methods. This speed is a game-changer for manufacturers dealing with big orders.

- Jack of all Materials: Whether it’s round pipes made from aluminum alloy or uniquely shaped stainless steel ones, laser pipe cutters handle it all. This flexibility lets guardrail makers meet a wide range of customer needs.

- No Mess, More Savings: Laser cutting is incredibly accurate, meaning less material gets wasted. This makes it a cost-friendly and green option for businesses looking to save money and protect the environment.

- Top-notch Quality: The laser does all the work without ever touching the material, resulting in a smooth, burr-free finish. This means guardrails not only look great but are structurally sound too.

Laser Pipe Cutters in Action

Seeing the practical application of laser pipe cutters can really highlight their worth. Here are a few industry-specific examples that show these machines in action:

- Boosting Production: Imagine a large company, churning out guardrails by the thousands. They were doing fine but wanted to up their game. Enter the laser pipe-cutting machine. With these machines, they saw their production speed rocket by 70%, and every guardrail that came out was a carbon copy of the last.

- Creating Masterpieces: Now picture a boutique firm, known for its unique, designer guardrails. Their clients had come to expect the extraordinary, but their traditional cutting tools were limiting their creativity. When they brought in laser pipe cutters, they were suddenly able to craft complex, intricate designs with ease, leaving their clients even more impressed.

- Saving the Environment: Finally, visualize a company that’s all about eco-friendly practices. They were troubled by the material waste from their cutting processes. Once they switched to laser pipe cutters, the waste problem significantly diminished, bringing them one step closer to their green goals.

Conclusion

In conclusion, integrating laser pipe cutters in the guardrail industry revolutionizes productivity and precision. Baison Laser provides these cutting-edge solutions, helping businesses meet industry demands. Explore our website or connect with our team for more insights on enhancing your manufacturing process.

Transform your production line today with Baison Laser!

We excel at providing laser-cutting solutions designed to enhance efficiency, precision, and profitability. We’re committed to pushing your business forward, from free sample proofing to application evaluations. Contact us today or request an instant quote for our laser pipe-cutting machines.