Factors to Consider for Choosing the Right Laser Welding Machine Manufacturer

Buying a laser welding machine, and picking the right company that makes it, is a big deal. This is especially true for businesses that make things, fix cars, work with electronics, or build airplanes.

A laser welder is much more than a tool that joins metal. It sets the speed, accuracy, and quality of everything you make.

A poor choice can cause expensive delays, bad welds, and wasted money. A good company will make sure the machine works smoothly, gives steady results, and offers reliable help later.

This guide will show you what to think about before you choose a manufacturer and who is the best one. We’ll explain how each choice affects your business.

Yes, buying a laser welder costs a lot at first. But in the long run, it can save you money because it works faster and doesn’t need many extra supplies.

Without further ado, let’s dive into the topic:

What is a Laser Welding Machine?

A laser welding machine is a modern tool. It uses a strong, focused laser beam to join two or more materials, usually metals. It uses a focused heat source to melt and bond the materials. This approach ensures both precision and efficiency in welding.

It creates a focused heat spot, unlike traditional arc welding. This melts and fuses materials with little distortion, affecting just a small area. This allows for quick, precise, and clean welds on thin or delicate materials. It greatly cuts down on material deformation during welding.

These machines can work with many materials. They include stainless steel, aluminum, copper, titanium, and alloys. Laser welders come in a few main types:

- Handheld models let you move the tool around easily.

- Bench-top units sit on a desk and are very accurate.

- Robot systems do the work automatically for large factories.

This kind of welding works very well for tough materials like aluminum and copper.

Industries like cars, planes, electronics, jewelry, and medical devices use them often. They make strong, clean joints that you often can’t see.

Picking the right manufacturer is key. They need to make sure the machine does what you need, always works correctly, and offers help for years to come.

Key Factors to Consider

Here are 20 factors to consider when choosing a laser welding machine manufacturer.

1. Welding Requirements: Materials, Thickness, and Geometry

First, you need to know what materials and thicknesses you’ll be welding. Different metals — stainless steel, aluminum, copper, or alloys — react differently to laser beams.

Aluminum needs more power and better beam control since it is reflective. Stainless steel is easier to weld. But, it needs exact speed settings for a smooth finish.

Geometry also matters: flat sheets are easier to weld than 3D shapes or narrow seams. Choose a manufacturer that shows the power range and welding head needed for your parts.

Make a mistake, and you might overpay for too much power or deal with weak penetration.

2. Laser Source & Power Options

The laser source is the heart of the machine. Most modern systems use fiber lasers. They are known for high efficiency, a long lifespan of over 100,000 hours, and great beam quality.

When comparing manufacturers, check their fiber sources. Look for names like Raycus, IPG, or Maxphotonics. This choice impacts performance and maintenance costs.

Ask about the power range. Handheld welders usually range from 1,000W to 2,000W. Automated systems, however, can go up to 6 kW or more for welding thick plates.

Adjustable power is crucial for welding both thin and thick materials.

A good laser welding manufacturer helps you find the right power level. This ensures consistent weld penetration, giving you enough depth while wasting little energy.

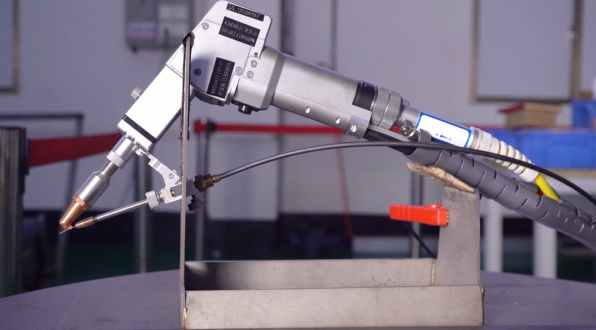

3. Beam Quality, Optics, and Welding Head Design

Beam quality (measured in M²) is how focused and stable the laser is. High beam quality goes deeper and creates narrower, cleaner seams. It also keeps heat-affected zones to a minimum.

The design of the welding head is important. It should include protective lenses, anti-reflective coatings, and air purging. These features help prevent damage from dust or spatter.

Ask if the manufacturer has quick-change optics or protective glass to cut downtime.

Bad head design means more maintenance. Good design leads to smoother welding and lower costs for consumables.

A good manufacturer should share details about the optics’ lifespan. They should also mention the cost of replacement parts and how easy it is to maintain.

4. Cooling System and Duty Cycle

Laser machines produce a lot of heat. So, cooling is key to keeping them stable and extending their lifespan.

Manufacturers usually provide air-cooled systems for low-power handheld machines. For higher-powered industrial welders, they offer water-cooled chillers.

If you run 24/7, the duty cycle matters: a 100% duty cycle means the machine can run non-stop without overheating.

Before you buy, ask the manufacturer these questions:

- How is their cooling system sized?

- Do they use branded chillers?

- What ambient conditions can the machine handle?

Bad cooling causes power issues, welding problems, and higher downtime costs. So, choose manufacturers that offer strong cooling solutions.

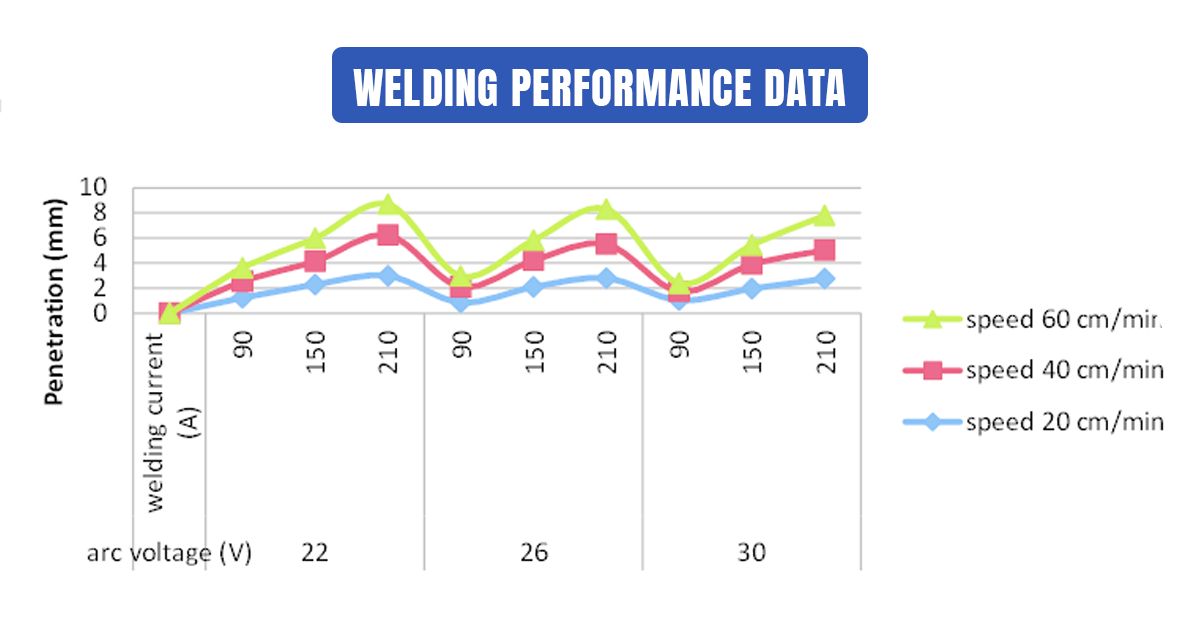

5. Welding Performance Data

Everyone claims great results, but you need proof. Could they provide weld samples of materials?

Request to include details on:

- Penetration depth

- Travel speed

- Surface finish

- Metallurgical integrity

Request technical test reports or a demo. Then, review the demo results or product evaluations. This will help you understand the machine’s capabilities better. Reputable manufacturers like Baison offer free test welding before you make a purchase.

Look at the heat-affected zone (HAZ): smaller is better, less distortion

Also check for porosity, cracks, or undercuts. A reputable manufacturer will provide performance charts and consistently deliver repeatable weld quality.

This alone saves you from buying a machine that looks good on paper but fails in production.

6. Control System and Software Integration

Laser welding machines rely on control systems. Choose manufacturers with user-friendly interfaces. This helps operators easily adjust pulse width, frequency, and laser power in real-time. Handheld laser welding machines are easy to use. Users don’t need as much technical skill compared to regular welding methods.

The user interface must be easy to navigate. This way, even beginners can access it. Operators can learn the system quickly. The controls are straightforward, so minimal training is needed.

Advanced software should allow you to save and recall weld recipes. It should also work with robots, CNC systems, and factory automation lines.

Some manufacturers provide real-time monitoring and data logging. This is key for quality audits.

Ask if their software is proprietary or open—open systems are easier to update.

The right manufacturer offers operator training. This helps your team use the system well. So, it cuts down on the need for constant technical support.

7. Safety Standards and Compliance

Laser systems are powerful and must follow safety regulations. Trusted manufacturers make machines that follow Class 1 or Class 4 laser safety standards. This depends on the type of enclosure used.

Machines should have interlocks, emergency stops, safety goggles, warning lights, and protective housings.

Manufacturers need to supply all documents needed for CE, FDA, or ISO certifications in their regions. Beyond compliance, ask if they offer operator training programs for laser safety.

Not considering this factor can lead to employee injuries, fines, or machine shutdowns. A good manufacturer prioritizes both operator safety and machine performance.

8. After-Sales Service and Spare Parts Availability

Even the best machine will need spare parts. Before you buy, see if the manufacturer has a service center or distributor nearby.

Inquire about average lead times for spare parts. Also, ask about service response times. Do they provide remote diagnostics? Some companies keep spare consumables, like lenses and nozzles, in regional warehouses. This helps reduce downtime.

Good after-sales service means you won’t lose weeks of production when issues arise.

When you compare suppliers, pick those that:

- Deliver spare parts quickly.

- Offer 24/7 support.

- Have easy warranty terms.

9. Warranty and Maintenance Plans

Laser machines are a long-term investment. A solid warranty is a sign of the manufacturer’s confidence. Typical coverage is 12–24 months, but laser sources may have separate terms.

Ask if warranties cover optics, chillers, and consumables.

Many manufacturers offer maintenance contracts. These contracts include scheduled inspections, replacing wear parts, and priority service. These contracts reduce the risk of unexpected failures.

When negotiating, check the warranty length and what it covers.

A manufacturer that provides clear terms and extended coverage values its customers’ success.

10. Customization and Scalability

No two businesses are alike. Some may need a small handheld welder. Others might need fully automated robotic cells.

Top manufacturers can tailor their systems. They use special nozzles, fixtures, multi-axis motion, or higher laser power.

Scalable solutions let you upgrade your system later. You won’t have to replace it completely.

You might be able to add an automation module or upgrade to a stronger laser as your business expands.

This flexibility keeps your equipment from aging too quickly. It makes sure your investment aligns with future production needs.

11. Quality Certifications and Traceability

Choose manufacturers that meet ISO 9001 standards and provide traceability for key components.

Quality compliance is essential in the aerospace, automotive, and medical fields.

Ask about their quality control steps. Inquire about factory acceptance tests (FATs) and how they track materials.

Certified processes lower the risk of machine variability. They also ensure consistency in different production runs.

Manufacturers who invest in quality management show a long-term commitment to reliability. Always verify certifications and request samples of their QA procedures.

12. Energy Efficiency and Environmental Impact

Laser welding is often more energy-efficient than traditional methods. Yet, efficiency can vary depending on the model. Compare energy consumption at full load and in standby mode.

Think about fume extraction. When welding stainless steel, aluminum, or galvanized steel, it creates hazardous fumes. These fumes need proper filtration.

A good manufacturer helps you choose the right extraction system. They also provide integrated solutions.

Energy-efficient systems save on electricity costs. Eco-friendly features help your company follow environmental regulations. They also support your sustainability goals.

13. Customer References and Case Studies

A trustworthy manufacturer should share real-world case studies. They should also link you to customers in your industry.

See how their machines work in car factories, fabrication shops, or electronics assembly plants.

Customer testimonials often reveal insights into long-term reliability, service responsiveness, and ROI. A manufacturer with repeat clients in competitive industries demonstrates trustworthiness.

Don’t hesitate to ask for references. Great companies love showing off their customers.

14. Lead Time and Installation Support

Delivery delays can disrupt production schedules. Confirm the lead time for manufacturing and shipping before signing a contract.

Check on installation help: Does the manufacturer send technicians to your place for setup and training? Is there an extra cost for this?

A good partner provides turnkey installation, calibration, and operator training. A trusted manufacturer can finish installation and setup in a few days. This helps reduce production delays. Faster installation reduces downtime, allowing you to start generating ROI sooner.

15. Pricing Transparency and Hidden Costs

Don’t just focus on the machine price. Also, look into hidden costs. These could be for shipping, installation, training, consumables, and software licenses.

Some low-cost machines end up more expensive when you add these extras. Reputable manufacturers provide transparent pricing, breaking down what is included in the package.

Compare the total cost of ownership, not just the purchase price. Clear pricing protects you from budget overruns and builds trust with the manufacturer.

16. Training Programs for Operators

Even the best machine is ineffective if your team doesn’t know how to use it.

Determine if the manufacturer offers training that includes both classroom sessions and practical exercises. Training should cover parameter adjustment, safety protocols, basic troubleshooting, and preventive maintenance.

Some manufacturers also offer refresher training or advanced courses for automation. Proper training reduces operator errors, improves productivity, and ensures safe machine usage.

17. Global Presence and Export Experience

Select a manufacturer with a broad reach and strong export capabilities if you want your business to expand globally.

Baison Laser ships to more than 100 countries. They are familiar with the customs, compliance, and installation regulations for each location.

This global reach offers improved support and streamlined logistics. It also assures you that your machine complies with international regulations.

It also shows the manufacturer is stable and financially strong. This lowers the risk of supply chain issues.

18. Innovation and R&D Capabilities

Technology evolves quickly. A savvy manufacturer invests in research and development (R&D). This helps improve laser sources, control systems, and automation.

Check if they release new product lines, software updates, or patented technologies.

An innovative company keeps your investment current. It won’t be outdated in just a few years.

A manufacturer with a strong R&D team adapts quickly to new industry needs. This gives you a competitive edge.

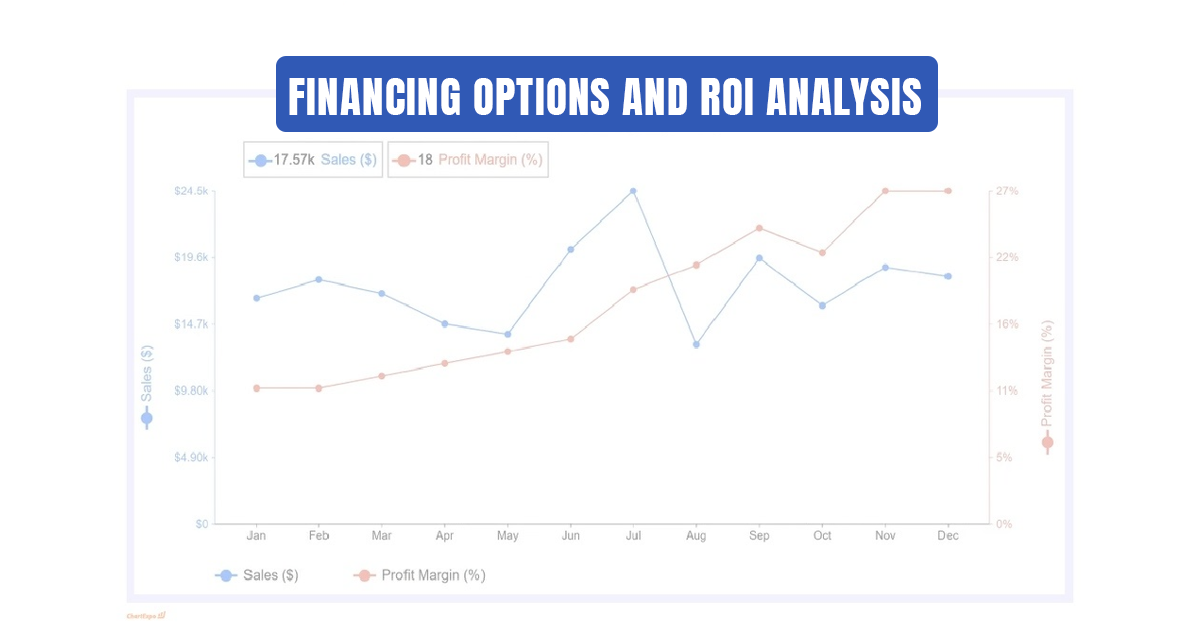

19. Financing Options and ROI Analysis

Laser welding machines can be a large investment. Some manufacturers offer financing options, leasing, or installment plans to ease upfront costs.

Some offer ROI calculators. Faster welding speeds, reduced rework, and lower consumable use can mitigate the impact of the purchase price.

Choosing a manufacturer that aids in financial planning helps you invest wisely. This can result in a shorter payback period.

20. Brand Reputation and Long-Term Reliability

Finally, consider the manufacturer’s reputation in the industry. Established brands with years of proven reliability are safer investments than untested newcomers.

Check online reviews, trade show presence, and the company’s longevity.

Baison Laser has a global customer base and a solid product line. This demonstrates its stability and reliability.

Pick a trusted brand. It protects you from untested technology and unreliable suppliers.

Why Consider Baison Laser?

Baison Laser is a global manufacturer of fibre laser systems. They focus on welding, cutting, marking, and cleaning machines. We offer welding and plasma cutting equipment. These products are designed to meet the diverse needs of various industries.

- Reliable fiber laser sources with flexible power ranges.

- Handheld, benchtop, and automated welding solutions.

- Products engineered for a variety of applications, including welding and plasma cutting.

- Strong after-sales service and technical support worldwide.

- Focus on energy efficiency, precision, and scalability.

- Machines should have a clean and neat work surface. This ensures high welding quality, enhances safety, and maintains proper workpiece alignment.

We offer a wide range of products, allowing customers to find various laser solutions in one convenient location. This makes maintenance and service easier.

Final Thoughts

Choosing the right laser welding machine manufacturer involves much more than comparing prices. It’s about choosing a partner who offers reliable technology, clear pricing, and ongoing support.

Check the 20 factors listed. Request weld samples. Always compare the total cost of ownership, not the upfront costs.

Focus on key elements such as laser source quality and after-sales support. Doing so will help you find a machine that offers reliable welds, raises productivity, and enhances your return on investment.

Get in Touch With Us: https://baisonlaser.com/