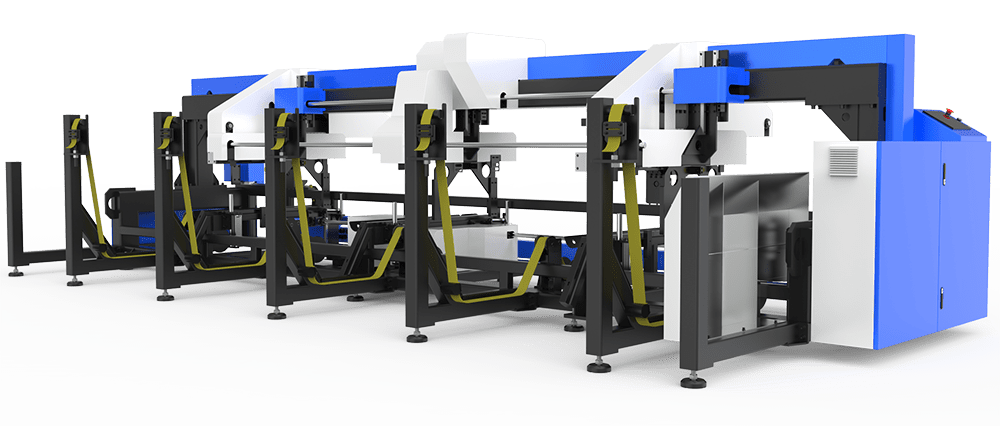

All-round Tube Laser Cutting Machine

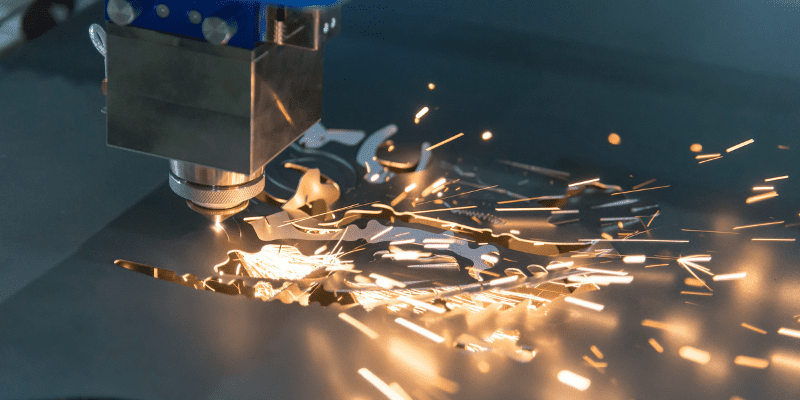

The all-around tube laser cutting machine has been a breakthrough in the industry. It uses solid-state lasers that allow for short processing times and high-volume production, even on heavier tubes or thicker materials, to ensure you can always afford excellent quality!

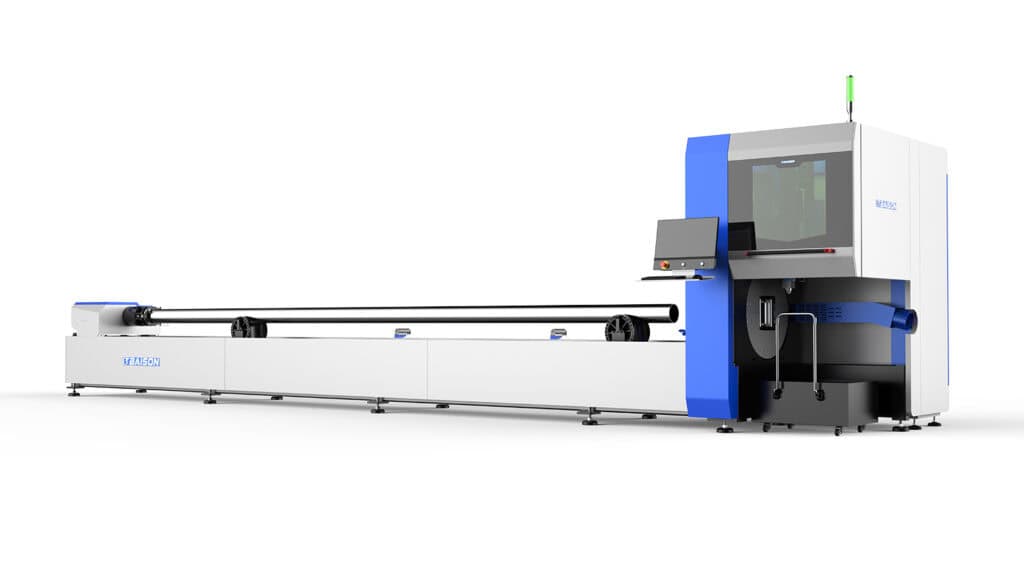

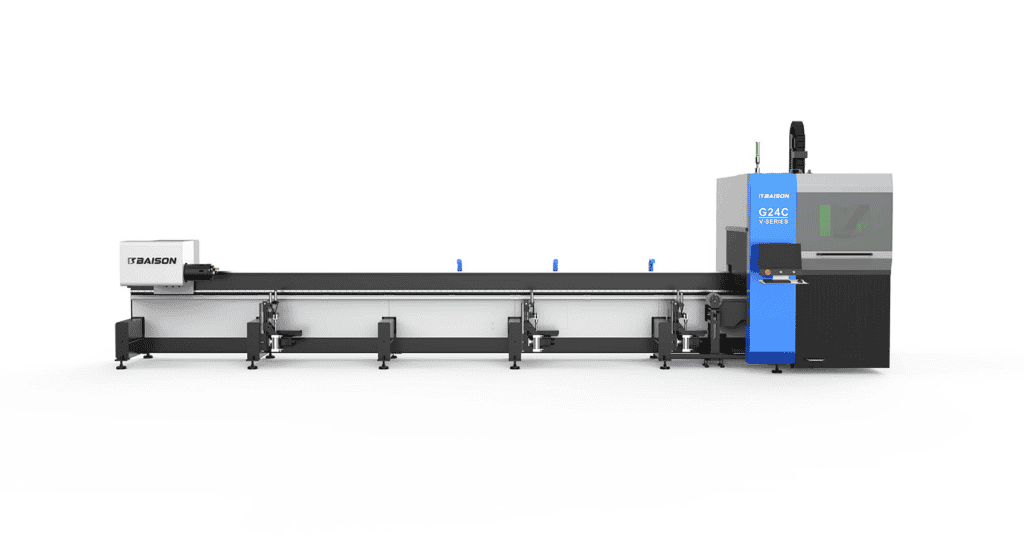

G Series All-round Tube Laser Cutting Machine

G24C

High Degree of Automation

1500W-6000W

Tube Range φ 0.39″ -9.45″ (10-240mm )

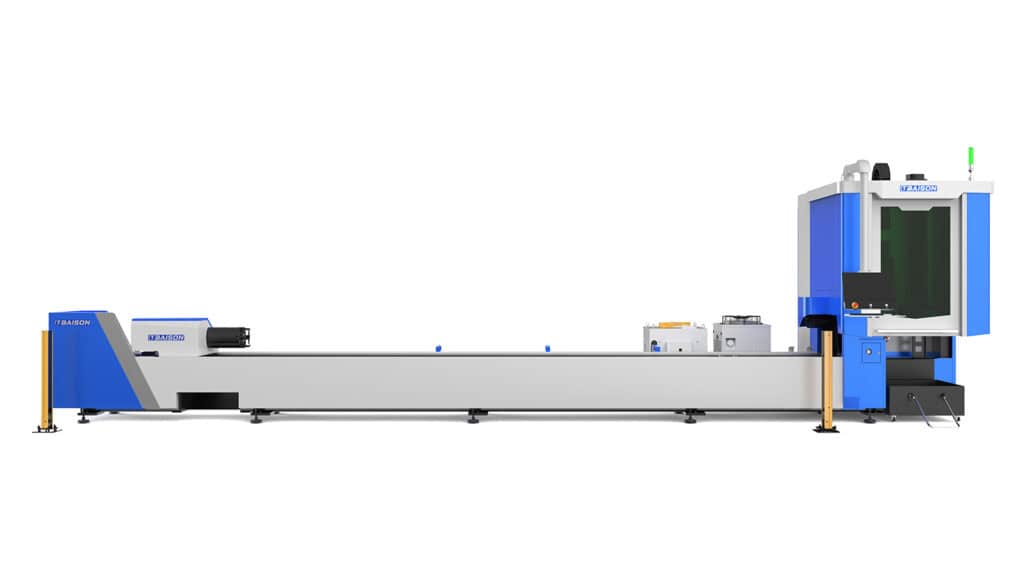

G24CP

Bevel Cutting

1500W-6000W

Tube Range φ 0.39″ -9.45″ (10-240mm )

All Around Tube Cutting Machine Key Features

We are the leading provider of quality tube laser cutting systems, providing global businesses with a cost-effective way to improve their operations.

10-220mm Metal Tube and Pipes

Meet a variety of metal materials in the range of 10-220mm diameter cutting.

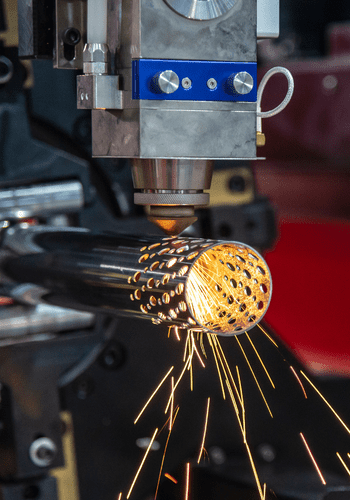

Dynamic and Precise

The dynamic combination of chuck and laser head allows you to cut more flexibly.

Lightning Fast Cutting Speed

High-powered laser generators make your cuts as fast as lightning.

Full Stroke Professional Pneumatic Chuck

The intelligent and stable chucking system makes your cutting more accurate.

Easy Machine Operation

No complicated setup and operation are required to complete your cutting job.

Zero Tail Material to Reduce Waste

Three chuck design allows you not to waste a centimeter of the tube.

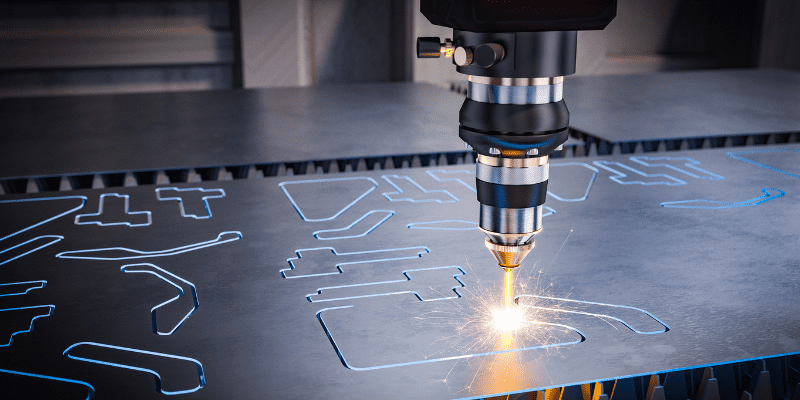

All Around Tube Laser Cutter Applications

The all around tube laser cutting machine can be used to process metal pipes of different sizes and thicknesses as it is used in a wide range of different industries.

Storage Racks

Furniture

Gym Equipment

All Around Tube Cutting Machine Capabilities

With a Baison tube-cutting machine, you can efficiently use your time and resources.

| Model | G24 | G24X | G24C |

|---|---|---|---|

| Laser Power | 1500W-6000W | 1500W-6000W | 1500W-6000W |

| Pipe Processing Range | Round tube: φ20~240mm Square tube: 20*20~220*220mm (tube R angle greater than 30mm can be clamped 240mmx240mm) Channel steel: 20# (need to pay for nesting software and professional fixtures) Angle iron: 20# (need to pay for nesting software and professional fixtures) I-beam: 20# (need to pay for nesting software and professional fixtures) H-steel maximum: 20# (need to pay for nesting software and professional fixtures) | Round tube: φ20~240mm Square tube: 20*20~220*220mm (tube R angle greater than 30mm can clamp 240mmx240mm) Channel steel: 22# (need to pay for professional fixtures) Angle iron: 10# (need to pay for professional fixtures) I-beam: 22# (need to pay for professional fixtures) H-steel maximum: 22# (need to pay for professional fixtures) | Round tube: φ20~240mm Square tube: 20*20~220*220mm (tube R angle greater than 30mm can be clamped 240mmx240mm) Channel steel: 22# (need to pay with matching material software and professional fixtures) Angle iron: 10# (need to pay with nesting software and professional fixtures) I-beam: 22# (need to pay with nesting software and professional fixtures) H-steel maximum: 22# (need to pay with nesting software and professional fixtures) |

| Pipe Processing Length | 6500mm | 6500mm | 6500mm |

| Wall Thickness | 0.8-10mm | 0.8-10mm | 0.8-10mm |

| Max Chuck Speed | 106r/min | 106r/min | 106r/min |

| Max Single Tube Loading Weight | 300KG | 400KG | 300KG |

Configuration for Efficiency

Baison’s laser cutting machines have always insisted on using accessories from the world’s leading brands, which is a significant reason for the powerful performance of our machines. It will continue to help you increase your productivity and competitiveness.

IPG Laser Source

IPG laser sources are considered one of the industry's most stable and highest-performing lasers.

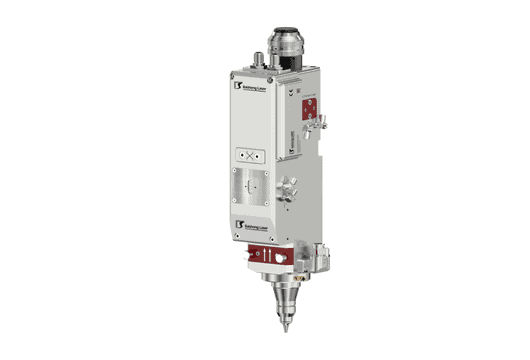

Ospri Cutting Head

Designed with precision cutting technology, Ospri laser heads help you maintain production levels.

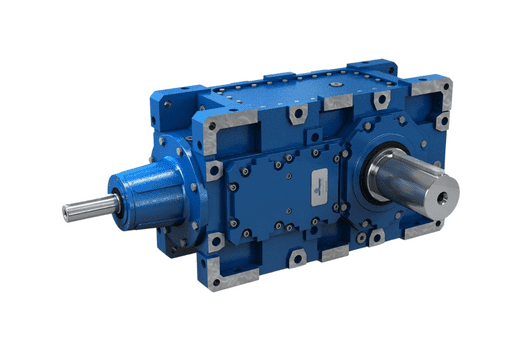

Motovario Motoreducer

Motovario is a leading supplier of high-quality electric motors for all your industrial and civil needs.

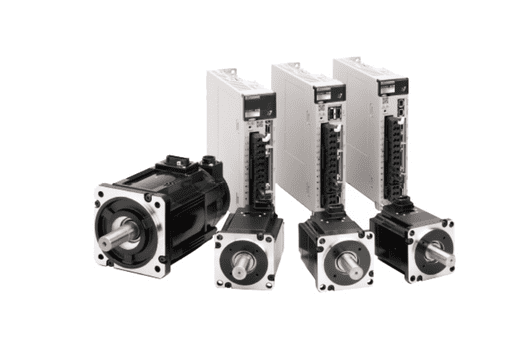

Yaskawa Servo Motor

With Yaskawa Servo motors, you can use mechatronics in your digital operations.

Smart Operating Software

The operating system is the soul of a machine, and an excellent operating system can make the machine play at its maximum performance. That’s why we choose Cypcut TubePro operating system.

TubePro was designed to meet the needs of professionals looking for an efficient, cost-effective way to cut tubes. The software has been made explicitly with tube cutting and profile shapes in mind so that it can be used by any kind or production line without having too many limitations on what they produce – even if you’re working outside standard limits!

- Auto-finding tube centers in production

- Control holders based on chuck position

- Supports 3-chucks of 7-axis linkage machines

Tube Laser Cutting Resources & Knowledge

Our team of engineers and writers is constantly innovating to provide our customers with the best possible solutions. Check out some behind-the-scenes looks at how we do it all in this article!

Which Gas Is Best for Laser Cutting?- An Easy to Follow Guide.

What is Fiber Laser Cutting?

Laser Cutting VS. Plasma Cutting: Which Procedure is Better for You?

Loading Automation

The tube auto-loading system is a practical way to minimize setup times. The space-saving design automatically provides you with the unprocessed material, and it’s also possible (and easy) for one person in control to at least partly set up this machinery before starting work!

Get a Solution for Expanding Your Business Today!

We have the perfect solution for all of your manufacturing needs. Contact us today if you’re looking for a tube laser cutting system!