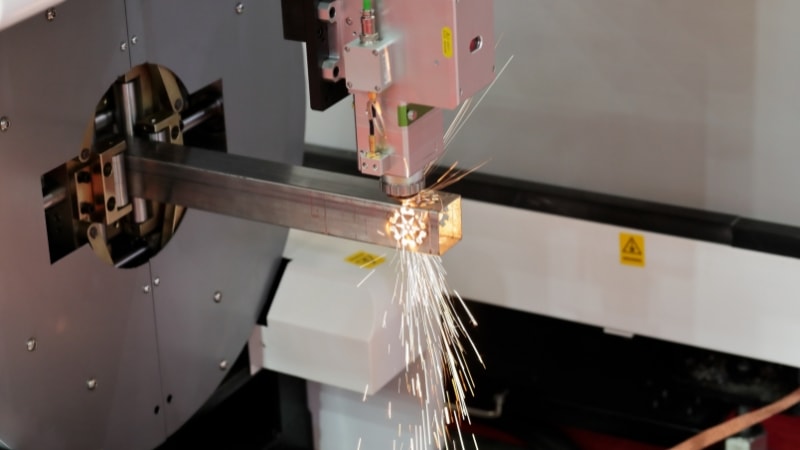

What Maintenance Does a Tube Laser Cutter Require?

Tube laser cutters are high-powered machines capable of making straight cuts on metal tubes or pipes. As with any complicated machine, they require continuous maintenance to operate properly. Proper maintenance will keep your cutter running smoothly and prevent costly repairs. In this article, you will learn everything about the tube laser cutter maintenance.

Why Regular Maintenance Matters for Tube Laser Cutters

Consistent machine maintenance is not only a good idea, but your tube laser cutting machine depends upon it. Once you forgo maintenance, the issues begin to accumulate. Small problems lead to large-scale problems that consume time and money.

Reduces machine wear and unplanned downtime

Machines have a lot of moving components that get older quicker when not taken good care of. When one of the parts malfunctions, you lose production entirely. Periodic upkeep identifies issues at an early stage, when they can still be corrected to avoid breakdowns.

Maintains cutting precision and output quality

Laser cutting machines are well constructed with the ability to cut to high levels of precision in tight tolerances, as long as they are kept operational.

Cut quality is directly connected to dirty optics, loose parts, or worn components. Without frequent cleaning and adjustments, your finished parts may not be compliant with specifications.

Prevents overheating and alignment issues

The heat destroys the costly components, such as laser tubes and control electronics. Repetitive upkeep will make cooling systems effective and avoid the costly procedures of repairing.

Critical for high-volume and automated production lines

Large-scale production lines place more demands on every device and require special care. Automated systems are operated with less human supervision, so proper care of the laser cutting machine helps deal with heavy production work without any sudden breakdowns.

Daily Maintenance Tasks

Quick maintenance only consumes a few minutes per day, but the difference is massive. Most typical problems are avoided by fulfilling these crucial tasks:

Clean the cutting head and nozzle

During cutting, the cutting head becomes full of dust and metal debris. Ensure that the outside is cleaned by using a soft cloth and inspect the nozzle to ensure that it is not damaged or clogged.

The clogged nozzle produces a bad cut and may destroy the cutting head. Clean up any spatter or debris around the nozzle opening with compressed air.

Check and empty the dust collection/slag bin

Metal cutting produces what is known as slag waste, which accumulates in the bins located under the cutting area.

Empty these bins before they are full because the full bins may cause a fire or damage the machine. Ensure that the dust collecting system is functioning correctly and clean the filters accordingly.

Inspect the lens and mirrors for residue:

A laser beam passes through a couple of optical devices that have to be clear to ensure decent cuts. Search the optics to see dust, any metal, or oil films. Make sure to clean using approved cleaning materials and cloths that have no lint.

Monitor the cooling system:

Make sure the reservoir has sufficient coolant and fill it to the top with distilled water, or see to it that the permitted coolant is used. Look at the coolant temperature gauge and watch out for leaks around hoses and fittings.

Lubricate guide rails or moving parts:

Look to your manual to see the lubrication points and schedules. Lubricate properly with the right kind and quantity of lube, as too much entices and attracts dirt, and too little causes wear and damage.

Weekly Maintenance Tasks

Weekly maintenance is more thorough than daily maintenance and can reveal the issues that arise after a few days of use.

Wash the exhaust system or air filters

The exhaust system will take the smoke and fumes out of the cutting area. Dusty filters decrease the flow of air and may lead to overheating. Check and maintain or swap air filters as you see fit. Inspect exhaust ducts and clear out metal dust buildup.

Inspect gas supply lines and fittings for leaks

Tube laser cutters utilize some assist gases such as oxygen or nitrogen, which are kept in high-pressure pipes. Test all connections by using a gas detector or soapy water to check for leaks. Make sure that loose fittings are tightened but not over-tightened, and bad hoses should be replaced as early as possible.

Check the alignment of the laser beam

Laser Beams that are properly aligned make good cuts. Automatic alignment systems are fitted with many modern machines, so run the alignment check program. Of manual systems, employ any alignment instruments to ensure that the beam strikes the center of mirrors and lenses.

Tighten any loose fasteners or connections

Loose fasteners and connections may become loose through the vibration of laser cutting techniques. Inspect significant contacts such as the motor mounts, the guide rail supports, and electrical connections. Fasteners should be tightened using the correct specifications of torque.

Inspect the drive system and belts

When you have belts driving the cutting head, test belt tension and belt condition. Inspect drive belts; be on the lookout to find cracking, fraying, or stretching. Change belts that look worn, and also inspect pulleys.

Monthly and Quarterly Maintenance

More long-term maintenance jobs will involve more time and planning. Prioritize these duties during production breaks to prevent work interruption.

Replace the protective lens or nozzle

Wear items that should be changed and replaced, including protective lenses and nozzles. They break or fade away even after good cleaning. Have some spare parts available, which you can replace quickly.

Check software updates and run diagnostic tools

Modern laser cutters have computer-controlled systems. Software updates describing problem fixes and features are released by the manufacturers. Update it at least on a monthly basis and install it at scheduled maintenance.

Execute diagnostic programs that come with the system (check the health of a system). Such programs check motors, sensors, etc. Fix issues related to diagnosis.

Clean and test the autofocus sensor

Most machines possess autofocus sensors that keep the right cutting height. These sensors will be dirty or may drift. Wipe the sensor as you see in your manual and check the functionality.

Make trial cuts to check that the autofocus system is functioning properly. Improper focus distance leads to a bad cut quality and might damage the laser marking head.

Flush and clean the water chiller

Water cooling systems require regular cleaning, where the scale and the contaminants are removed. Remove the old coolant and wash the system using clean water. Add new coolant to the right concentration. Make sure that the chiller unit is functioning.

Calibrate axes and verify accuracy

As time passes by, mechanical systems may encounter minor positioning mistakes. Positioning accuracy can be verified via the use of calibration fixtures or via test cuts. The control software of most machines has some calibration procedures.

Record document calibration and maintain a record of calibration done.

| Part | Maintenance Step | Frequency | Tools Needed |

|---|---|---|---|

| Protective Lens | Clean and inspect | Daily | Lint-free cloth, lens cleaner |

| Protective Lens | Replace | Monthly | Spare lens, installation tools |

| Nozzle | Clean | Daily | Compressed air, soft brush |

| Nozzle | Replace | Monthly | Spare nozzle, wrench set |

| Coolant | Check level | Daily | Visual inspection |

| Coolant | Replace | Quarterly | Fresh coolant, funnel |

| Air Filters | Clean | Weekly | Compressed air or vacuum |

| Air Filters | Replace | Monthly | Replacement filters |

| Drive Belts | Inspect | Weekly | Visual inspection |

| Drive Belts | Replace | Annually | Replacement belts, tools |

Annual Maintenance Checklist

The most extensive service that your tube laser cutter requires is annual maintenance. This is the time that you take things that may require attention only yearly.

Full inspection and cleaning by a technician

At least once a year schedule professional service. Problems can be detected by trained technicians that may not be seen by the normal operator. Their adjustments are complex, and they have specialized tools and knowledge to do these.

Complete cleaning of internal parts is normally provided in professional service. This extends to parts that cannot be serviced easily.

Replace worn belts, bearings, or linear guides

After one year of operation, it might be necessary to change some of the mechanical wear items. The belt will stretch and wear. The bearing develops the roughness. Linear guides can wear or develop a flat spot.

The technicians will be able to calculate the wear and what should be replaced. This eliminates sudden breakdowns in production.

Clean and service internal fans or motors

The dust gathers in internal cooling fans. This decreases the air flow and may lead to overheating. Yearly service involves fan blade cleaning and motor checking.

Annual inspection is also done on servo motors and stepper motors. Electrical connections are cleaned and inspected by technicians so that they know that they are working.

Perform laser alignment and safety checks

The alignment of the laser is very important to its operation and safety. On yearly checkups, the entire path of the beam is aligned with precision instrumentation. This guarantees optimal performance in laser welding and cutting.

Annual testing is also required of laser safety systems. Emergency brakes, interlocks, and warning lamps should be effective to safeguard operators.

Review usage logs and schedule upgrades

Equipment nowadays has a thorough record of the work and repairs. These logs are reviewed on an annual basis by the service to establish patterns or any issues. Areas that experience high usage might require high maintenance. It is also a good moment to consider upgrading the software or hardware.

Common Maintenance Mistakes to Avoid

Maintenance mistakes are easy to make, even with the best intentions. The following are the most widespread issues to be avoided:

- Neglecting the contamination of the coolant.

- Not replacing protective lenses in a timely manner.

- Tightening up the parts too much during the cleaning.

- Applying cleaning solutions that are not approved.

- Failing to train the operators on the basics of maintenance.

- Failure to conduct regular inspections.

- Postponing the replacement of filters.

Maintenance Tools and Supplies You Should Always Have

Be sure to stock some basic tools and supplies to ensure that maintenance is easy and safe. You will also require lint-free cloths that will clean optical parts without causing any scratches.

Use the glass cleaner recommended by your machine manufacturer, not an ordinary cleaner, which may harm coatings. Maintain the specified oils or greases in your manual, because various components require various oils or greases. Refills and changes of coolant fluid should always be prepared.

When performing maintenance, use your protective gloves and glasses. Lastly, have simple tools to measure amounts, such as gauges and protractors, to verify logic and sizes. Keeping such items at hand makes maintenance time-saving and efficient.

How Often Should You Service a Tube Laser Cutter?

Tube laser cutters are serviced depending on the component and usage:

Daily: Clean the head/nozzle, dump dust, and examine the coolant.

Weekly: Clean exhaust filters, gas line inspection, and simple beam alignment.

Monthly/Quarterly: Change protective lenses, clean auto focus sensor, flush chiller, calibrate axes.

Annually: Major replacement of components, a complete laser alignment, and inspection by the technician and safety inspections.

| Task Category | Light Use | Moderate Use | Heavy Use |

|---|---|---|---|

| Daily Tasks | Daily when operating | Daily when operating | Multiple times daily |

| Weekly Tasks | Weekly | Twice weekly | Every 2-3 days |

| Monthly Tasks | Monthly | Every 3 weeks | Every 2 weeks |

| Annual Service | Annually | Every 8-10 months | Every 6 months |

It should always be noted that the frequency is also dependent on the usage level, environment, and model, and thus, it is important to refer to the manufacturer’s manual of the machine for which specific recommendations are applicable.

Keep a record of your maintenance activity. This will assist you in noting trends and planning your time in the best ways possible.

FAQs

How often should I clean my laser tube cutter?

The cutting head and nozzle should be lubricated daily, and the rest depending on usage, weekly and monthly.

What happens if I don’t maintain the optics?

There will be poor cut quality, slower cutting speed, and damage to costly optical components forever.

Can I do laser maintenance myself, or do I need a technician?

Daily/weekly tasks can be done; however, alignments of various types and annual services cannot be handled without a certified technician.

What’s the lifespan of a well-maintained tube laser cutter?

With proper maintenance, a tube laser cutter may have a lifespan of 10 to 15 years or longer.

Conclusion

The most important thing is utilizing proper maintenance of your tube laser cutter in order to get the best value out of your investment. A machine that is maintained well cuts better, lasts longer and is cheaper in operation.

All maintenance work mentioned in this article might appear to be too much work, but they do eliminate even greater issues in the future.

The thing to remember is that maintenance is not something to follow a schedule. You should monitor how your machine functions and make a change in its maintenance. A 24-hour-a-day machine also requires more attention than one that is used occasionally.

Enhance Your Oil & Gas Operations with Baison Fiber Laser Solutions

With the most demanding requirements in your industry, the Baison advanced fiber laser systems are built to excel. Stop compromising, maximize your production, and work with the lowest waste and the best quality.

Get in touch with Baison to discuss your unique requirements, have all your questions answered, or request a tailor-made quote for your optimal laser solution!