What is Tube Laser Cutting Tolerance? A Detailed Guide

In tube laser cutting, the term accuracy refers to making a cut close to the intended measurement. In contrast, tolerance refers to the allowable deviation. Both accuracy and tolerance are essential in tube cutting. In this guide, we will explain what laser cutting tolerance and accuracy mean. Read on to have a better understanding and to ensure higher accuracy and precision in tube cutting.

What Is Tube Laser Cutting Accuracy and Tolerance?

Before defining why accuracy and tolerance matter, it is essential to understand the meanings of these terms. In simple words, tube laser cutting accuracy refers to the closeness between the cut and the intended dimension.

For instance, if one cut is to be made exactly 50.00 mm after another, and the cut is made at 50.01 mm. The accuracy will be high as the difference is only 0.01 mm.

In contrast, the term tube laser cutting tolerance refers to the allowable limit for deviation. This means that if a cut was intended to be at exactly 50.00 mm but is made at 50.08 mm, the deviation is 0.08 mm and is within the accepted tolerance range.

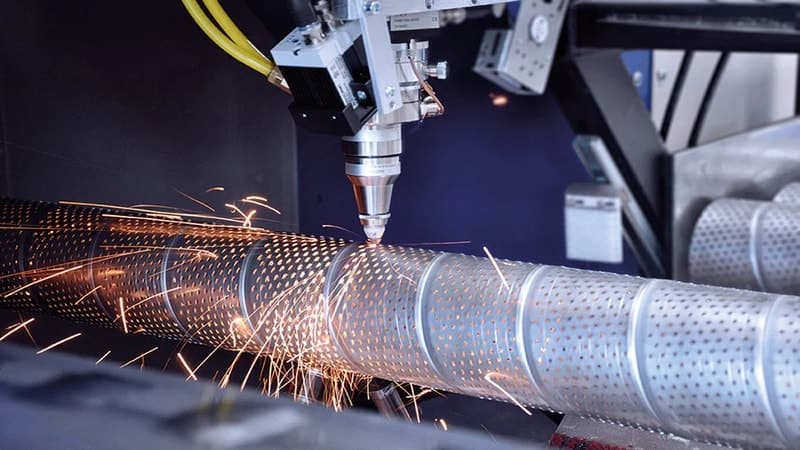

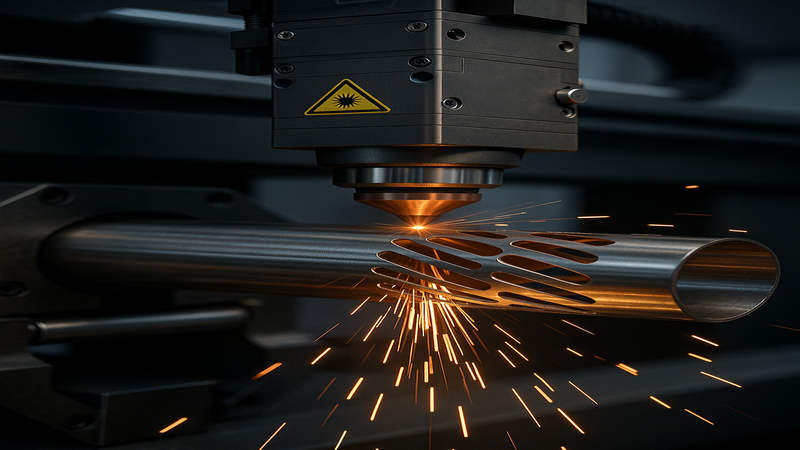

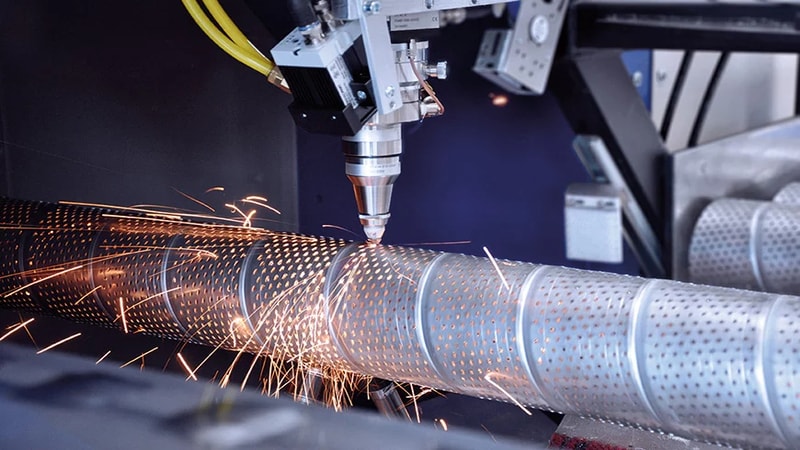

Modern laser CNC machines ensure high accuracy. These machines use a focused laser beam to make cuts only at the intended measurement points.

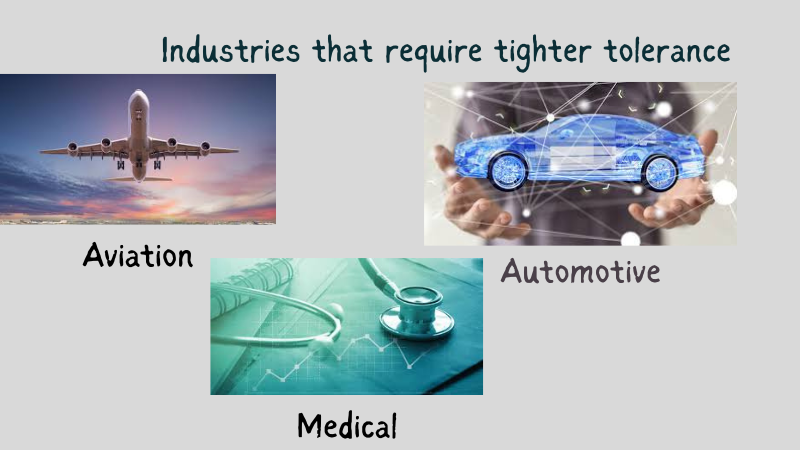

These modern laser machines are specifically designed for use in sectors that require high precision and accuracy. These sectors include the automotive, aviation, and medical industries.

Typical Tolerances in Tube Laser Cutting

The tolerance in tube laser cutting varies from machine to machine. In tube laser cutting, modern CNC tube laser cutting machines typically deliver a tolerance of ±0.1 mm to ±0.3 mm.

The tolerance also depends on many factors. The common ones include machine type and calibration. Some other factors include the tube material, thickness, and the complexity of the cut.

Some modern machines can even deliver a tolerance as tight as ±0.05 mm. This tight tolerance is often required in critical sectors. These sectors include aerospace and medical device manufacturing.

Understanding the Difference Between Tube Laser Cutting Tolerance, Accuracy, and Precision

In tube laser cutting, three terms — precision, accuracy, and tolerance — are widely used. People often use these terms interchangeably, assuming they all mean the same thing. However, it is essential to note that these terms are different.

The term accuracy, as mentioned before, refers to how close a cut is to the intended dimension. For example, in laser cutting, if the drawing specified a 50.00 mm cut, the laser cutting machine delivers 49.95 mm. This indicates that the cut is highly accurate, as the difference is very minimal.

Precision refers to how consistently the machine delivers the same result multiple times. If the machine consistently makes cuts at 49.00 mm, it is considered precise, although not accurate.

Precision is necessary for almost all laser operations, including laser welding and laser marking. In simple terms, precision is about repeatability. High precision is especially crucial in bulk production. In high-volume production, precision ensures that the same result is consistently achieved.

Lastly, tolerance refers to the range of deviation that is acceptable. For example, if the accepted tolerance range is ±0.1 mm, then any cut between 49.90 mm and 50.10 mm is considered acceptable.

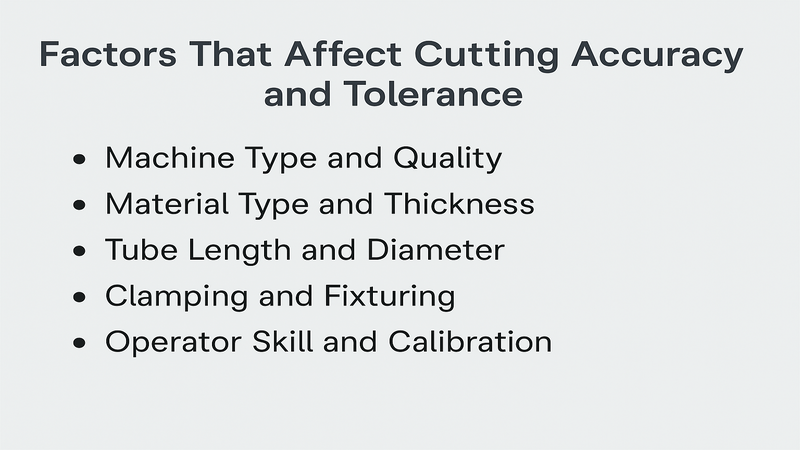

Factors That Affect Cutting Accuracy and Tolerance

High tolerance and accuracy cannot be achieved only by investing in quality machines. Certain factors influence the laser cutting tolerances for tubes.

Below is a detailed analysis of all these factors, along with the measures that should be taken to minimise their effects.

Machine Type and Quality

The first and most important determining factor of accuracy and tolerance is the type and quality of the cutting machine used. Advanced machines utilise fibre laser or CO₂ laser systems to offer higher accuracy and tighter precision.

Fibre lasers are ideal for tube cutting due to their speed. Fibre lasers work best on different metals, including stainless steel, aluminium, and brass. The fibre laser also generates a focused beam, allowing for precise cuts and tighter tolerances.

CO₂ laser systems are used in CO2 laser cutting machines. These machines include dual-chuck, multi-axis support, and automatic centring systems. All of these features ensure stability and precision. Outdated machines produce an inconsistent beam pattern. Thus leading to high tolerance deviations.

Material Type and Thickness

The material type also influences cutting tolerance and accuracy. Different materials react to heat in different ways.

Aluminium reflects laser energy more than other metal types and thus requires high power for cutting. Stainless steel is easier to cut using a fibre laser. In comparison, copper and brass are highly reflective. Also, this material is challenging to cut without a fibre system.

Also, the thicker the tube, the more energy and time are required to cut it. The increased time and power result in a larger heat-affected zone (HAZ). This contributes to thermal expansion and distortion at the edges, thereby reducing accuracy.

Tube Length and Diameter

The size of the tube is another factor that affects the accuracy and tolerance of tubes. Longer and wider tubes are more prone to sagging, bending, and misalignment during the cutting process.

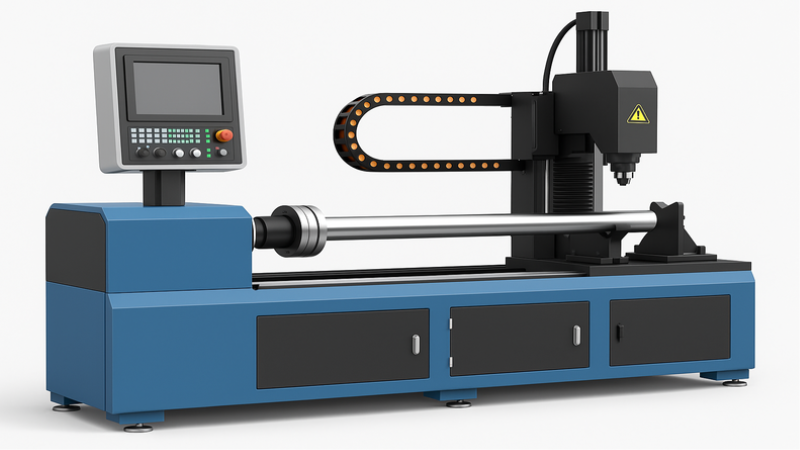

As tubes rotate along the chuck axis during cutting, any deviation from the centerline can increase the likelihood of errors in cutting. To maintain accuracy, modern machines use automated tube supports for long tubes.

In modern machines, self-centering chucks and sensors are used for real-time alignment correction. With all these features, modern machines enhance the tube cutting dimensional accuracy.

Clamping and Fixturing

Clamping and fixturing explain how the tubes are held in place during the laser-cutting process. The clamping and fixturing ensure the tube remains stable and aligned while rotating during the cutting process.

If the clamping is loose, the resulting vibration, movement, or dimensional shift can cause incorrect cutting, uneven edges, and off-angle cuts, thereby impacting precision. To avoid this, machines with well-calibrated fixturing systems should be used.

The machines should have clean and properly maintained chucks, correct clamping pressure, and alignment with the machine’s centerline. Modern machines feature automated or servo-controlled clamping that adjusts in real-time to hold the tube precisely, reducing errors and improving consistency.

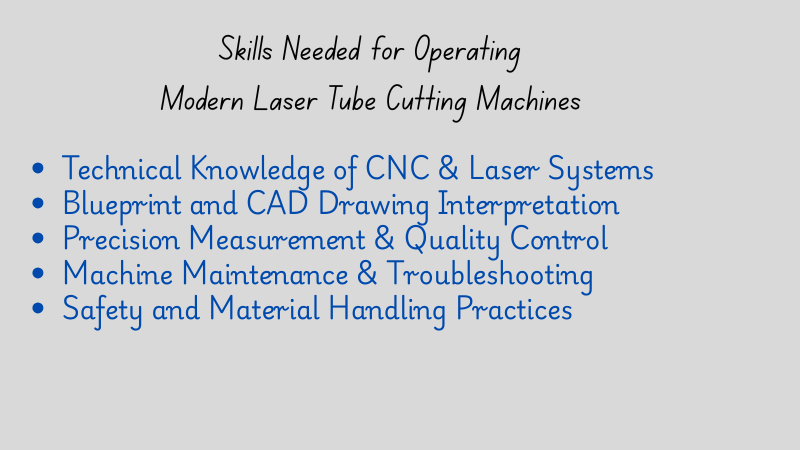

Operator Skill and Calibration

The skills of the operator significantly influence the accuracy of tube laser cutting machines. The machine must be well-maintained and operated by a skilled operator to guarantee higher accuracy and tighter tolerance.

No matter how advanced the machine is, if it’s not appropriately operated or not calibrated, it can contribute to dimensional errors, rough edges, and inconsistent results. Operators should also know how to adjust machine settings according to the material type and thickness.

Some tips that need to be followed to ensure accuracy include:

- The machine should be well-maintained and well-calibrated.

- Nozzle alignment, beam centring, and optics cleaning should be conducted regularly.

- Operators must conduct test cuts before commencing with final production.

All the above-discussed factors influence the accuracy and tolerance of laser tube cutting. However, the good thing is that these factors can be addressed easily.

By investing in a modern cutting machine, hiring a skilled operator to manage it, and regularly maintaining the machine, one can achieve high accuracy and tighter tolerances while cutting tubes.

Using Laser Machines with Advanced Positioning Systems

One way to improve the precision is by using laser machines with advanced positioning systems. This will help you maintain firm control over movement, alignment, and the beam path, ensuring that the cuts stay within the desired tolerance range.

Regular Maintenance and Calibration of Machines

Over time, with usage, the machine system can experience alignment shifts, resulting in reduced accuracy. Regularly maintaining and calibrating the machines will ensure consistent results, extend the machine’s lifespan, and improve its performance.

Automated Material Handling and Centring Systems

Using automated material handling and centring systems is also linked with increasing precision. Automated systems reduce the chance of human errors and improve alignment during loading, especially while working with heavy tubes, thereby increasing accuracy and precision.

Selecting the Proper Equipment

The equipment, including nozzle type, assist gas pressure, and feed rate, should be appropriately selected based on material type and thickness to maintain stability and minimise heat distortion.

Integrate Closed-Loop Feedback

Another way to maximise precision is to integrate closed-loop feedback systems or laser measurement technologies into the cutting process. This will monitor cutting parameters in real time and adjust in the event of any variation.

Post-Cut Quality Inspection

The last thing that will help you in maximising precision is to inspect the post-cut output using tools. This step is crucial in industries where deviations cannot be tolerated, such as in the aerospace, automotive, and medical device sectors.

Why Precision Matters: Applications That Demand Tight Tolerances

For many sectors, precision is not just a feature but a necessity. From performance to safety, the importance of tight tolerance and high accuracy in these sectors cannot be ignored. Below are some of the industries where precision and tight tolerance are an absolute requirement:

Automotive Components

In automotive applications, tube laser cutting is widely used in suspension parts, chassis reinforcements, exhaust systems, and crash protection tubing. All these make tight tolerances important for both safety and performance.

In the automotive industry, even a slight dimensional deviation can pose a safety risk and result in poor fit and vibration issues. This is why we can say that in the automotive industry, tighter tolerance is essential.

Aerospace And Aviation

In the aerospace and aviation industry, tubes are exposed to extreme pressure, stress, and temperature fluctuations. Whether used for structural frames, fluid transportation, engine components, or any other purpose, even a minor deviation can lead to failure.

Tight tolerances reduce the risk of cracking and misalignment, which is why maintaining precision is essential in the aerospace industry.

Medical Devices

In the medical sector, poorly cut edges not only affect the device’s performance but can also increase the risk of contamination and pose a threat to patient safety. Thus, in surgical instruments and diagnostic devices, precision is highly desired.

Laser cutting offers precise and sharp edges, eliminating the need for additional grinding or finishing, making it an ideal choice for medical device manufacturing.

Furniture and Architecture

In furniture and architecture, precision is necessary for getting a clean and appealing design. Structural tubes used in frames, railings, and decorative elements must have a professional appearance.

Misaligned joints, gaps, and uneven edges reduce the quality of the furniture. Thus, designers need tighter tolerances when designing furniture or architectural elements.

Laser Cutting vs. Other Tube Cutting Methods: Precision Comparison

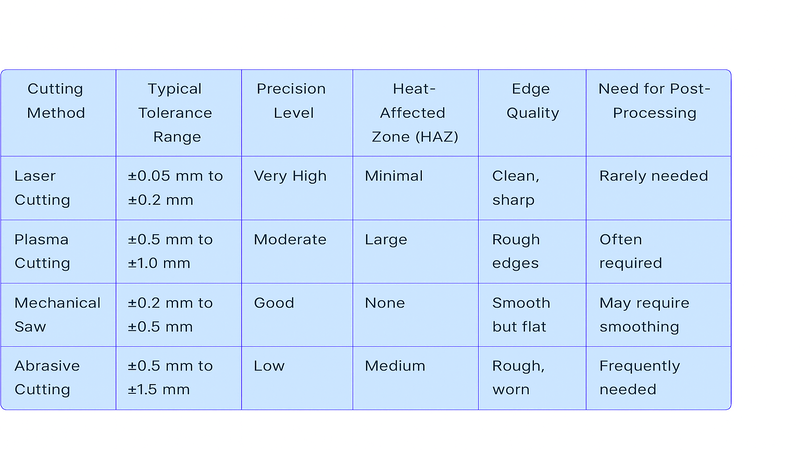

If you are a project engineer or quality specialist, you may have wondered How precise is laser cutting for tubes? Well, this question can be answered easily by looking at the side-by-side comparison of tube-cutting methods given below:

| Cutting Method | Typical Tolerance Range | Precision Level | Heat-Affected Zone (HAZ) | Edge Quality | Need for Post-Processing |

|---|---|---|---|---|---|

| Laser Cutting | ±0.05 mm to ±0.2 mm | Very High | Minimal | Clean, sharp | Rarely needed |

| Plasma Cutting | ±0.5 mm to ±1.0 mm | Moderate | Large | Rough edges | Often required? |

| Mechanical Saw | ±0.2 mm to ±0.5 mm | Good | None | Smooth but flat | May require smoothing |

| Abrasive Cutting | ±0.5 mm to ±1.5 mm | Low | Medium | Rough, worn | Frequently needed |

The laser cutting tolerance chart shows that laser cutting is the most precise method. It offers tight tolerances, minimal heat-affected zones, and clean, burr-free edges. This is why it is ideal for industries where precision is crucial.

Final Verdict

Precision, accuracy, and tolerance are the key factors to be achieved in tube laser cutting. These factors are complex, but they are achievable.

By using high-end modern cutting machines, combined with proper equipment, skilled operators, and regular maintenance, you can easily achieve the desired level of precision and accuracy.

To ensure maximum precision, higher accuracy, and tighter tolerances, invest in modern machines. Most importantly, request a quote only from a reliable laser systems manufacturer.

Baison -Your Reliable Partner For Fiber Laser System Manufacturing

Looking for a reliable and trustworthy manufacturer of fiber laser systems? Well, your search ends here. Baison is a leading manufacturer of fiber laser systems. We have been helping manufacturing firms improve their productivity for over two decades.

With our operations expanding across more than 100 countries and regions, we are well-equipped to meet all your requirements. Contact us today to get answers to all your questions or to receive a quote for your industrial applications.

FAQs

Q. What is the cutting tolerance of a laser tube?

The cutting tolerance of a laser tube ranges between ±0.1 mm to ±0.3 mm. The material type, thickness, and machine quality affect the tolerance range. Advanced CNC fiber laser systems can achieve even tighter tolerances, i.e., ±0.05 mm, easily.

Q. Can you laser cut a tube?

Yes, you can easily cut a tube using a laser. Doing so is one of the most efficient methods of cutting tubes. It results in sharper edges, reduced labour, and highly accurate cutting. Thus, laser cutting is ideal for industries requiring consistent tube fabrication.

Q. Why is my laser cutter not cutting accurately?

Your laser cutter may not cut accurately due to multiple reasons. These reasons include poor calibration, dirty optics, nozzle misalignment, and worn-out mechanical components.

Regular maintenance and proper setup are essential to ensure consistent and precise performance of any cutting machine.

Q. How Long Does a Laser Cutter Tube Last?

There is no fixed answer to this question, as the lifespan of a laser cutter tube depends on its type and its usage. Generally, a CO₂ glass tube lasts 1,000 – 3,000 hours, while ceramic tubes can last 8,000 – 15,000 hours.

With regular inspections, proper cooling, and preventive maintenance, the lifespan of a laser cutter tube can be extended.

Q. Can a Tube Laser Cut a Flat Bar?

Although not initially meant for a flat sheet, but yes, a tube laser can cut a flat bar. If your production frequently involves flat sheets, it is recommended to invest in a dedicated flatbed laser cutter.