Application Industry

Exhaust duct

Elevator Industry

Auto Parts

Universal For Various Tubes

G series is applicable to cutting for various shapes of tubes. Whether it’s round,square,or irregular profiles such as H beams, Ι beams,etc.G series has got you covered.

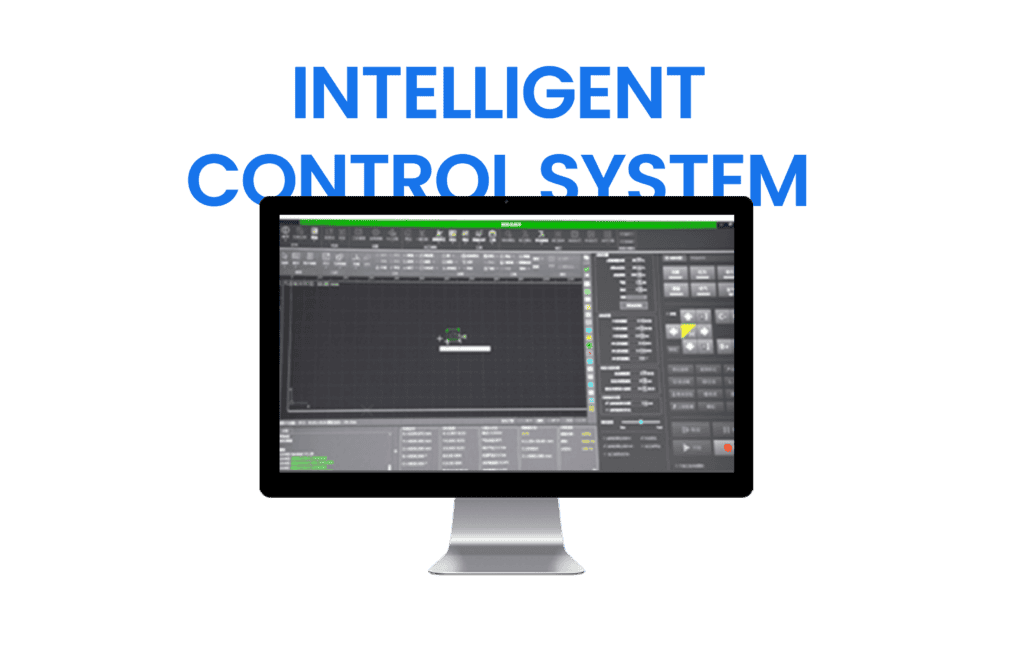

Intelligent Operating System

It comes standard with an extensive cutting technology database, a user-friendly control interface, and flexible operation. It supports and offers modular, personalized, automated, and information-based solutions.

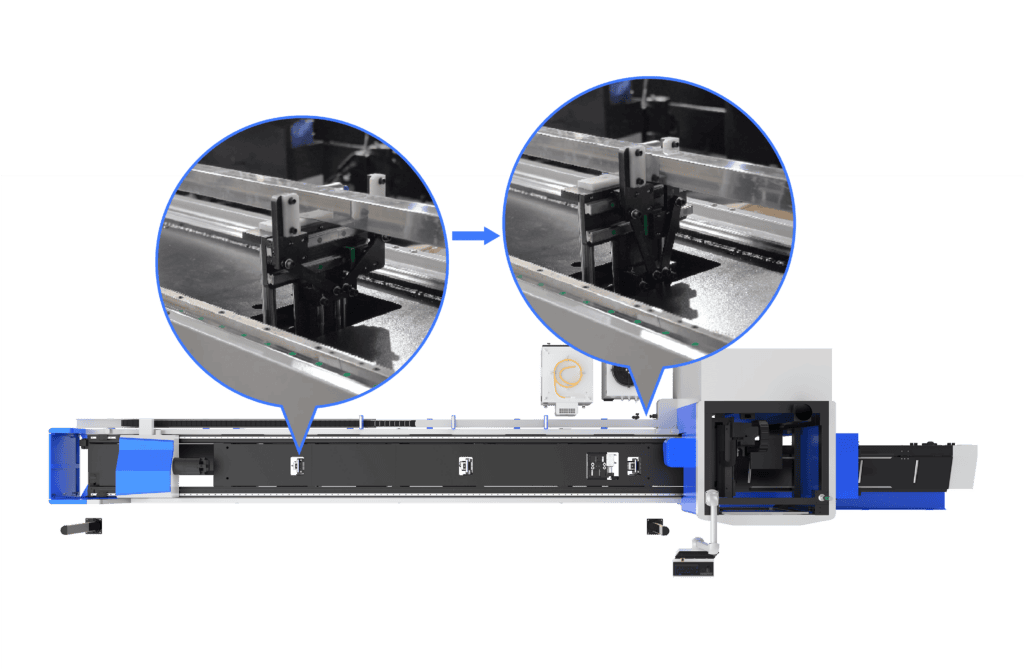

Full-stroke Precision Square-hole Chuck

Innovative processing, the chuck of the same specification has a wider clamping range and stronger load-bearing capacity

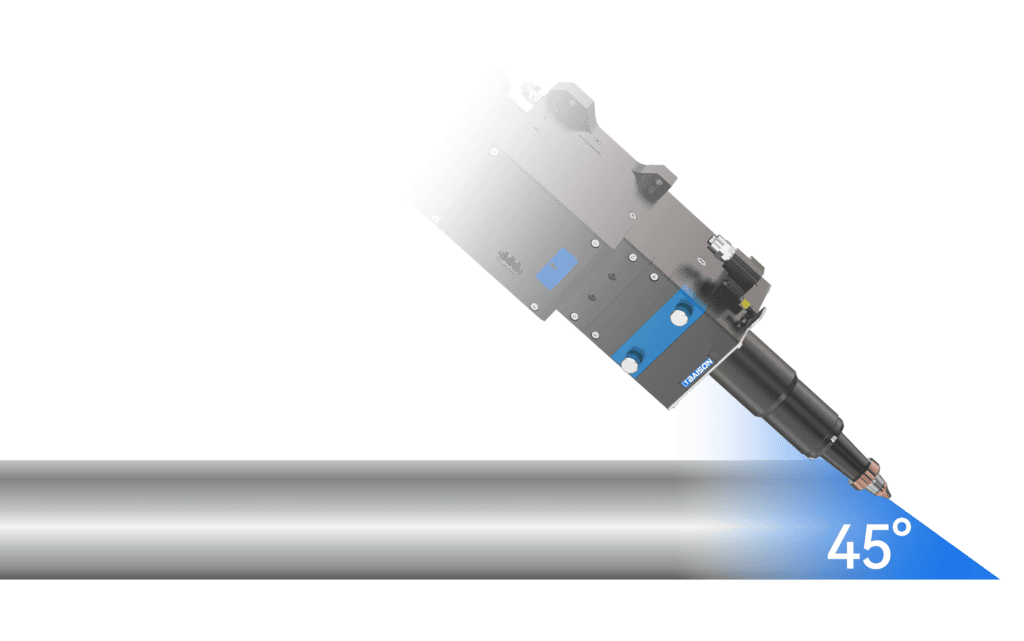

±45° Flexible Cutting (*Optional)

It can achieve ±45° beveling tube processing to bring convenience for following welding technology and reduce costs.

Follow-up Support

It employs high-sensitivity independent servo ollow-up support and follower clamping module, which adjusts the lifting height in real-time, reduces tube swinging, and enhances the linearity of the tube components.

Equipment parameters

| G24X | |

|---|---|

| Laser Power | 1500W~6000W |

| Tubes can be processed | Round tube: φ10~240mm Square tube: 10*10~220*220mm (tube R angle greater than 30mm can be clamped 240mmx240mm) Channel steel: 22# (standard clamp, need to add nesting software) Angle iron: 10# (standard clamp, need to add nesting software) I-beam: 22# (standard clamp, need to add nesting software) H-steel maximum: 22# (standard clamp, need to add nesting software) |

| Tail length | ≥170mm |

| Tube processing length | 6500mm |

| Max Speed | 100m/min |

| Max load capacity of single tube | 400kg |

| Dimension(L*W*H) | 9680*2080*2700mm |