Application Industry

Exhaust duct

Elevator Industry

Auto Parts

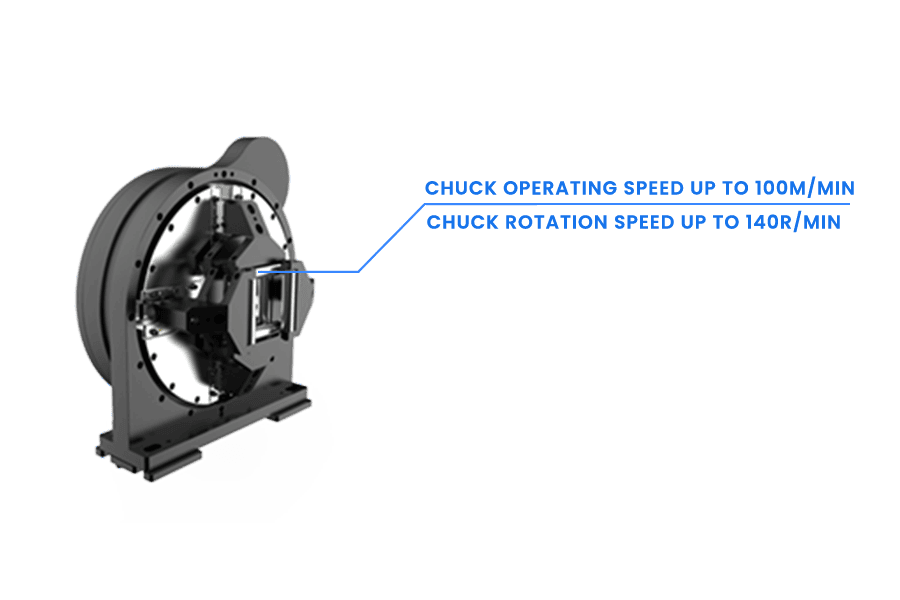

Higher Productivity

The chuck operating speed of K12C can achieve 100m/min and the chuck rotation speed can achieve 140r/min, which play an important role in productivity improvement.

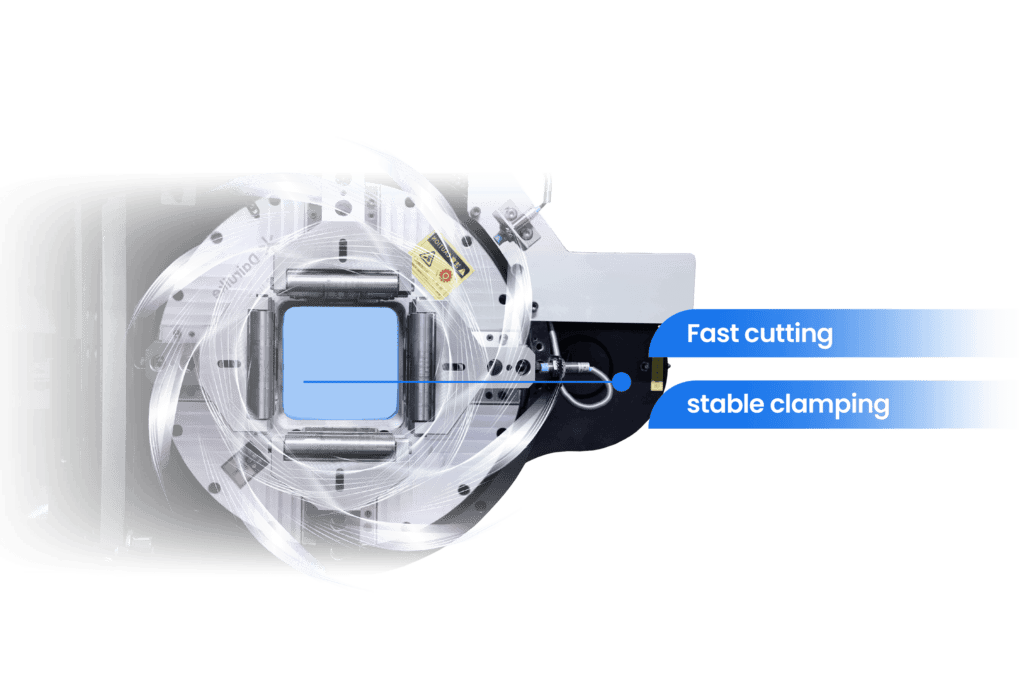

Wide Range of Tube Cutting

Equipped with the industry-leading full stroke precision square hole chucks, it can achieve the single tube weight capacity of 80Kg, supporting various types of tubes.

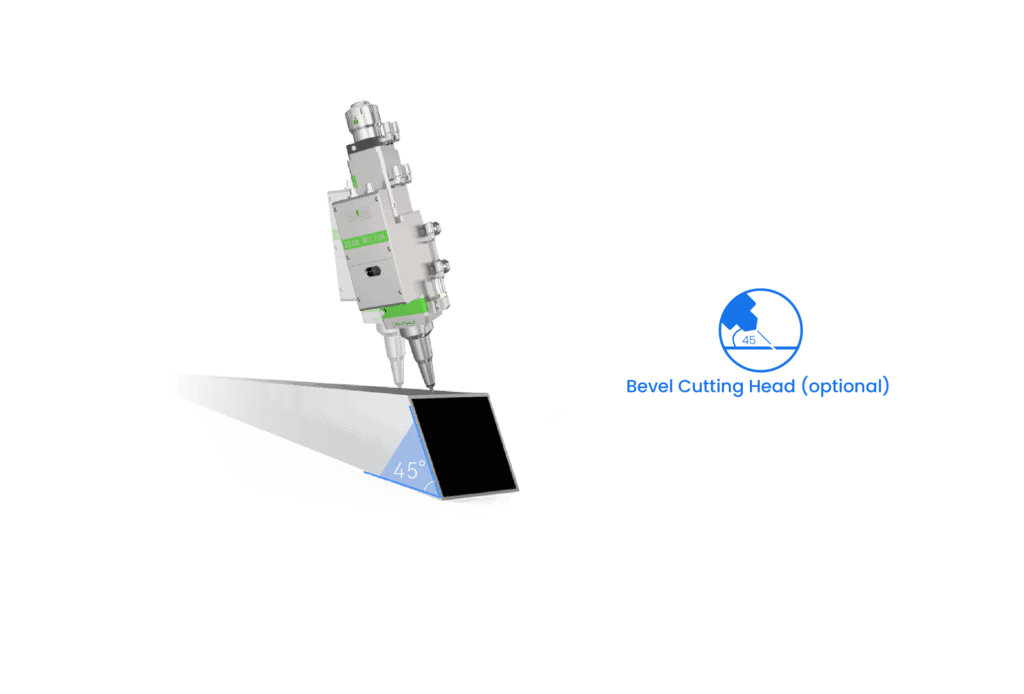

±45° Bevel Cutting(*Optional)

Optional bevel cutting capability can be equipped with bevel cuts from -45° to +45°. Depending on the part geometry, simple V- and X-seams can be cut, as well as more complex V- or K-seams, etc.

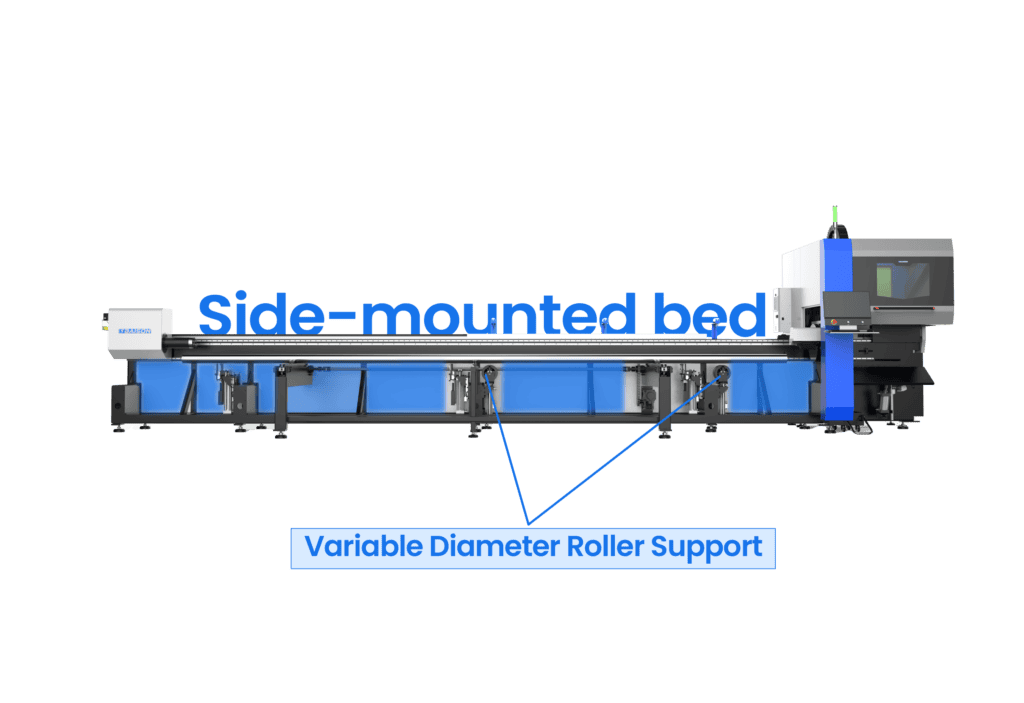

Excellent Process Reliability

The side-hanging machine bed, featuring a triangular structure, provides enhanced stability and facilitates rapid loading and unloading of materials. The variable diameter wheel supports, which are standard on the K12C, significantly enhance the processing accuracy of tube materials.

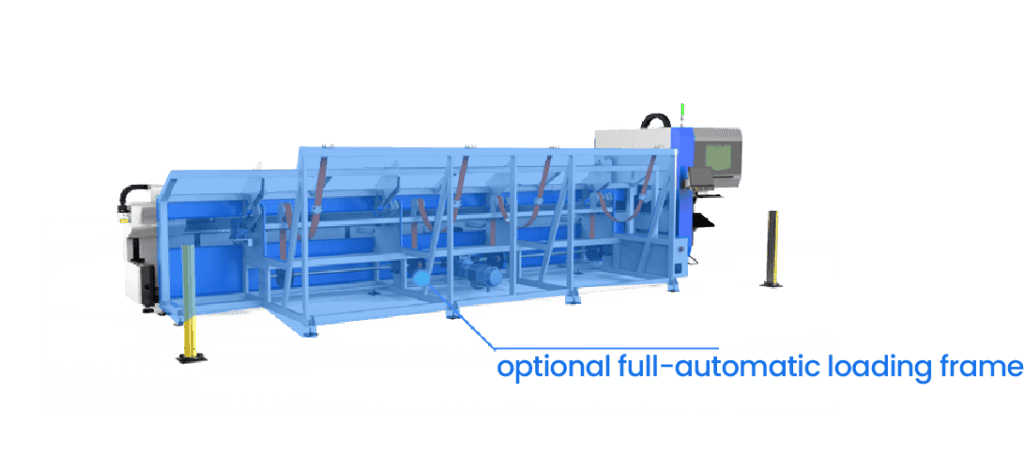

Automation System

Standard with a semi-automatic loading rack and a follow-up unloading rack, allowing one person to operate multiple machines, helping customers solve the problem of pipe cutting efficiency.

Equipment parameters

| K12C | K12CP | |

|---|---|---|

| Laser Power | 1500W~3000W | 1500W~3000W |

| Tubes can be processed | Round tube: φ10~120mm Square tube: 10*10~120*120mm When clamping large square tubes, the chamfer of the tube must be greater than R10mm) Channel steel: 8# (standard clamp, need to add nesting software) Angle iron: 8# (standard clamp, need to add nesting software) | Round tube: φ10~120mm Square tube: 10*10~120*120mm When clamping large square tubes, the chamfer of the tube must be greater than R10mm) Channel steel: 8# (standard clamp, need to add nesting software) Angle iron: 8# (standard clamp, need to add nesting software) |

| Tail length | ≥60mm | ≥60mm |

| Tube processing length | 6500mm | 6500mm |

| Max Speed | 100m/min | 100m/min |

| Max load capacity of single tube | 80kg | 80kg |

| Dimension(L*W*H) | 9550*1850*2135mm |