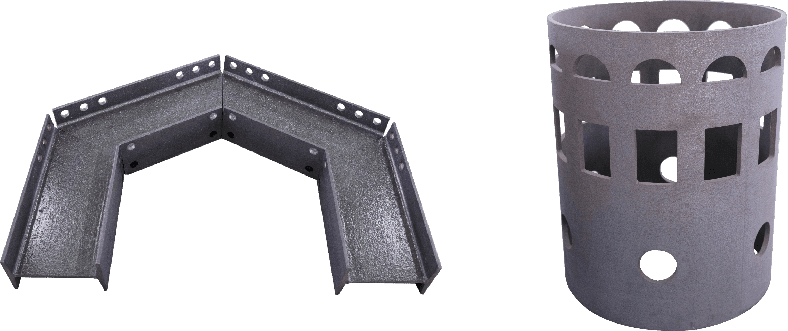

Application Industry

Exhaust duct

Elevator Industry

Auto Parts

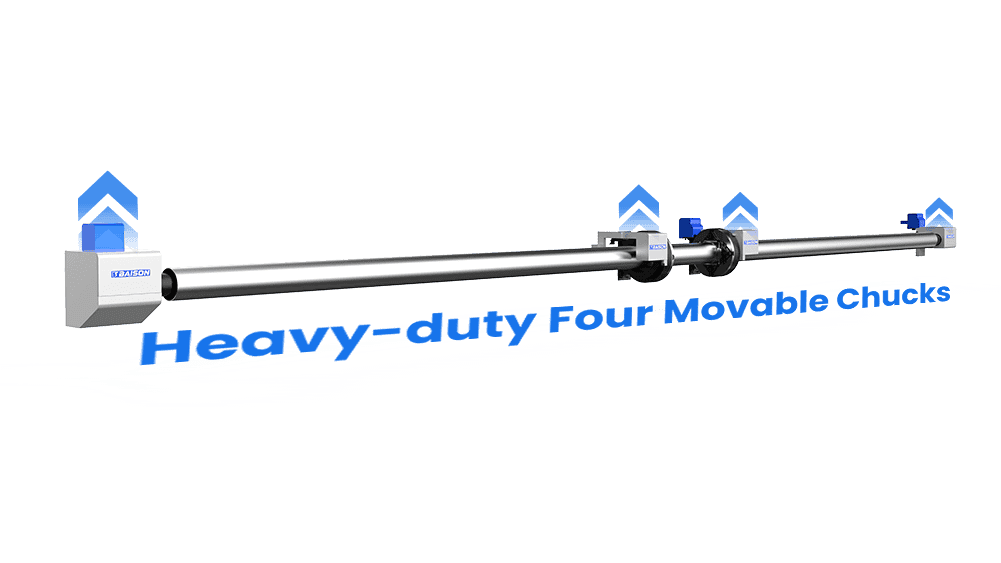

Heavy-duty Four Movable Chucks

Coordinated clamping and support by four chucks effectively addresses the challenges of machining extra-long and extra-heavy pipes.

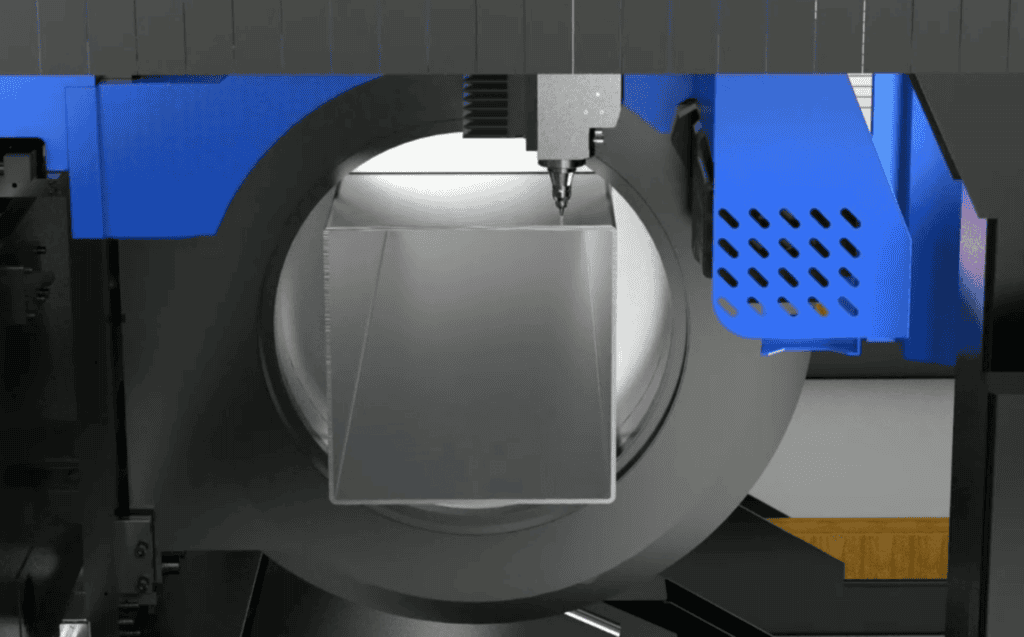

Universal For Various Tubes

The V Series offers an efficient solution for cutting large, heavy, and long pipes, profiles, and beams, incorporating numerous advanced technologies to ensure optimum process results.

Zero Excess Materials Processing

The four-chuck cutting system ensures zero-waste tube processing with versatile, efficient cuts for both heavy and long tubes.

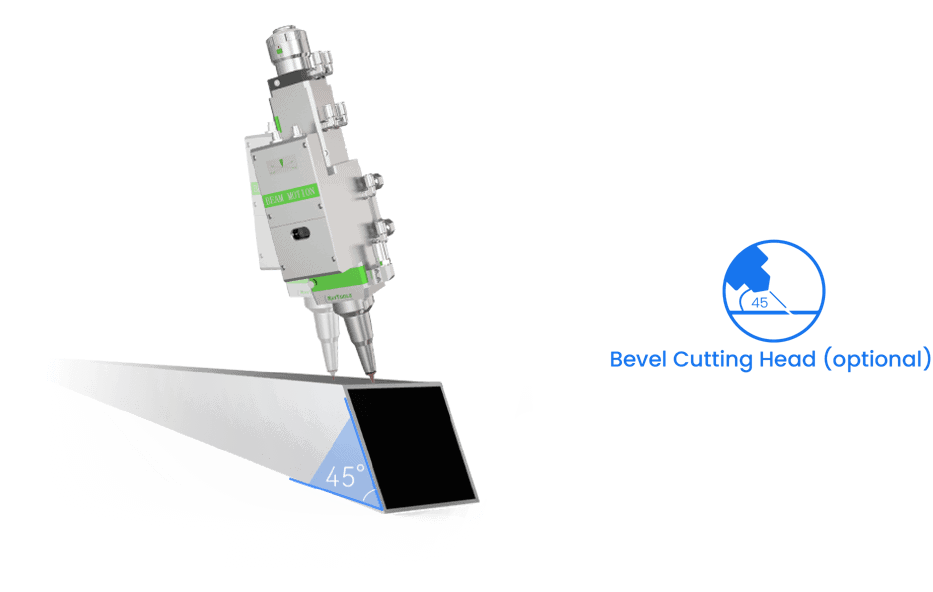

±45° Bevel Cutting(*Optional)

Optional bevel cutting capability can be equipped with bevel cuts from -45° to +45°. Depending on the part geometry, simple V- and X-seams can be cut, as well as more complex V- or K-seams, etc.

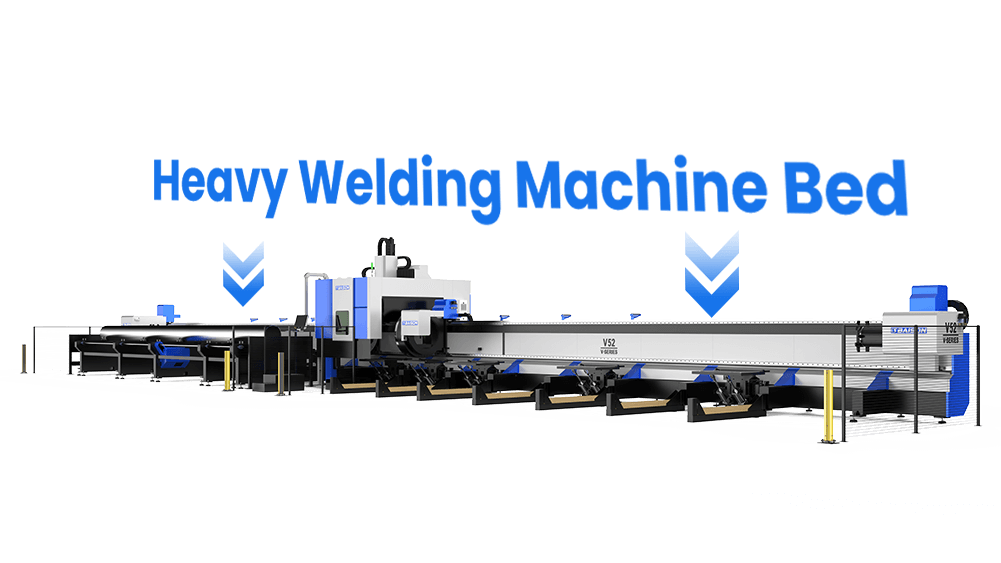

Heavy Welding Machine Bed

The reinforced welded bed frame offers excellent rigidity, capable of withstanding high accelerations, and ensuring long-term operational precision and stability.

Equipment parameters

| V52UTT | |

|---|---|

| Laser Power | 3000W~12000W |

| Tubes can be processed | Round tube: φ450~p500mm Square tube: 50*50mm~500*500mm Channel steel: 5#~50# (standard fixture) Angle steel maximum: 200x200mm (standard fixture) (greater than 20# need to pay for professional tooling fixture) I-beam: 10#~50# (standard fixture) H-beam: 100*100~500*500mm (standard fixture) |

| Tail length | 0 |

| Tube processing length | 12000mm |

| Max Speed | 50m/min |

| Max load capacity of single tube | 2000kg |

| Dimension(L*W*H) | 29080*5000*3250mm |