Application Industry

Exhaust duct

Elevator Industry

Auto Parts

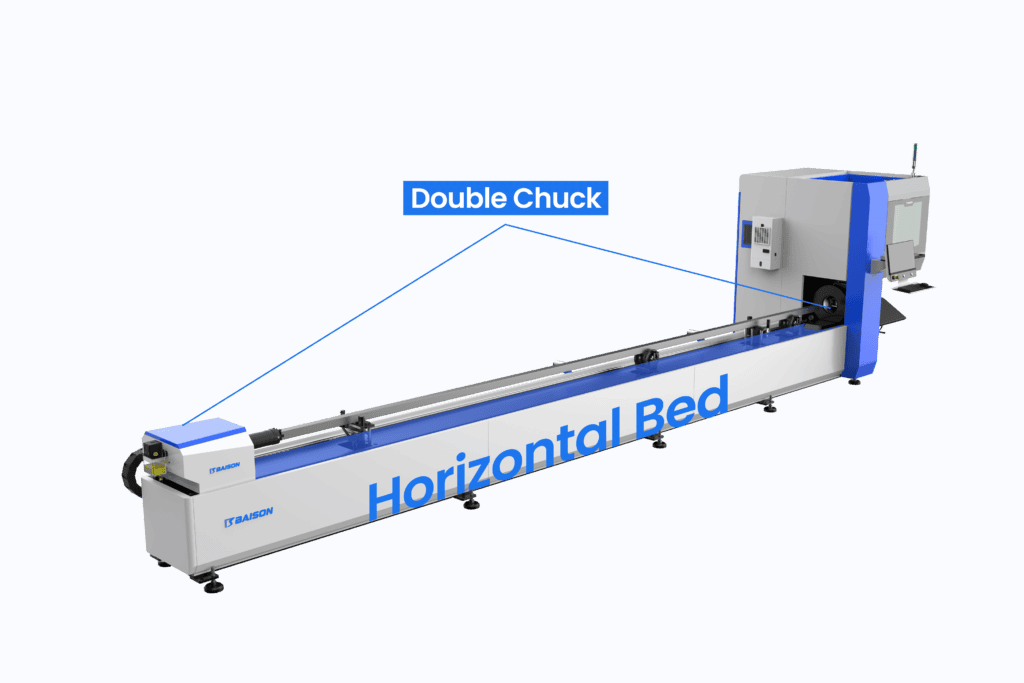

Double Chuck Horizontal Bed

The bed is processed through 12 procedures and has undergone finite element stress analysis using SolidWorks software, ensuring reliable rigidity, strong durability, and guaranteeing the machine tool’s precision and non-deformation for long-term use.

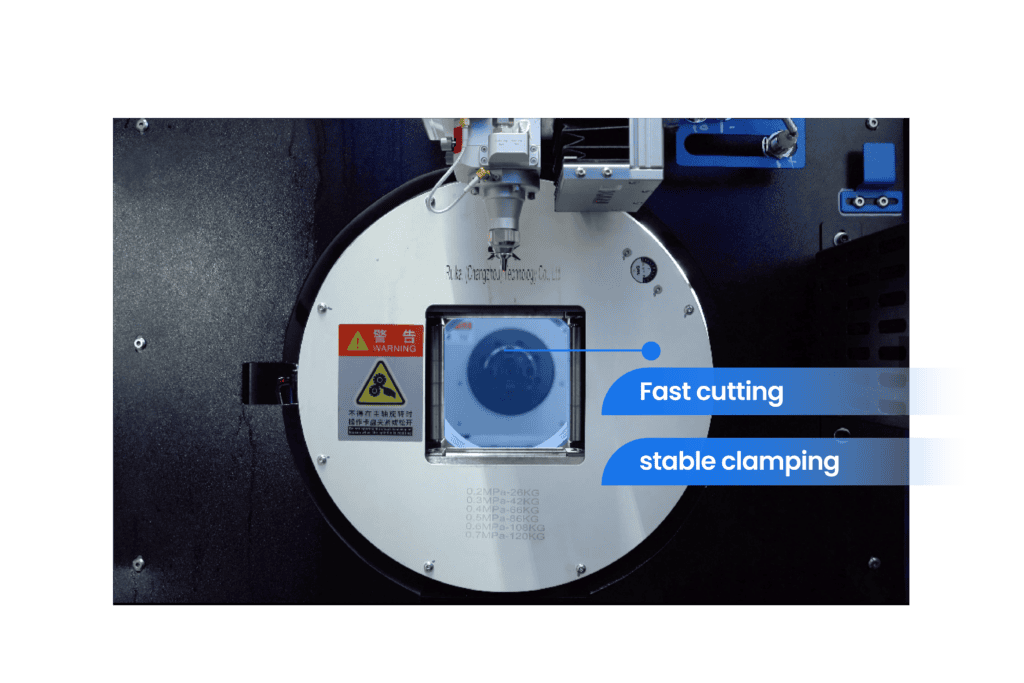

Full Stroke Precision Square Hole Chuck

K series’ precision chucks are well-suited for the rapid cutting in dynamic applications and stable clamp without damaging the workpiece.

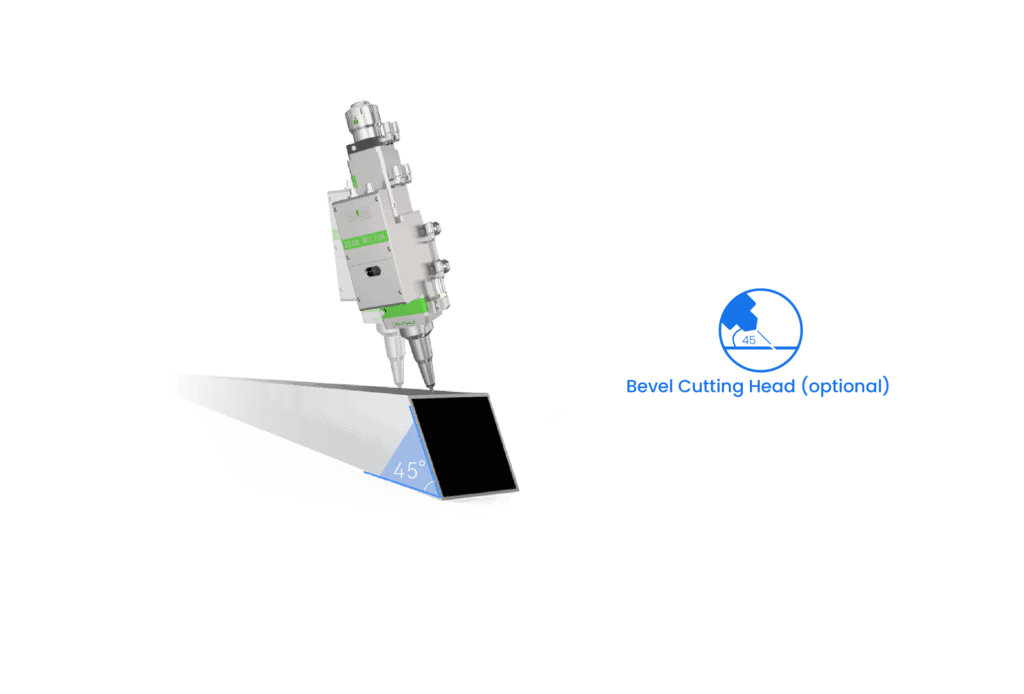

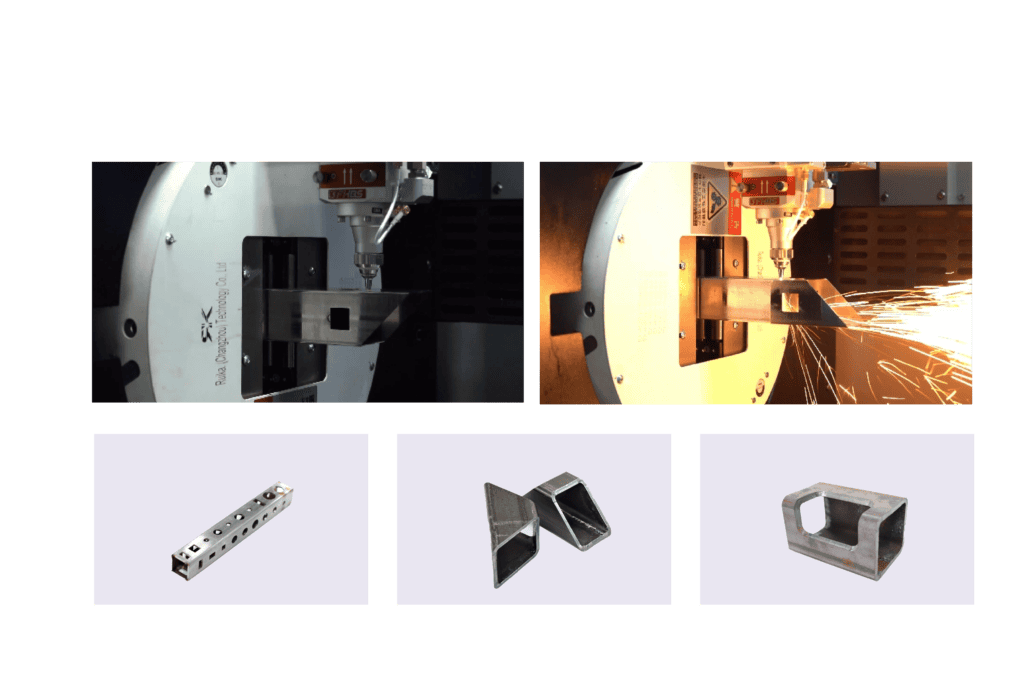

±45° Bevel Cutting(*Optional)

Optional bevel cutting capability can be equipped with bevel cuts from -45° to +45°. Depending on the part geometry, simple V- and X-seams can be cut, as well as more complex V- or K-seams, etc.

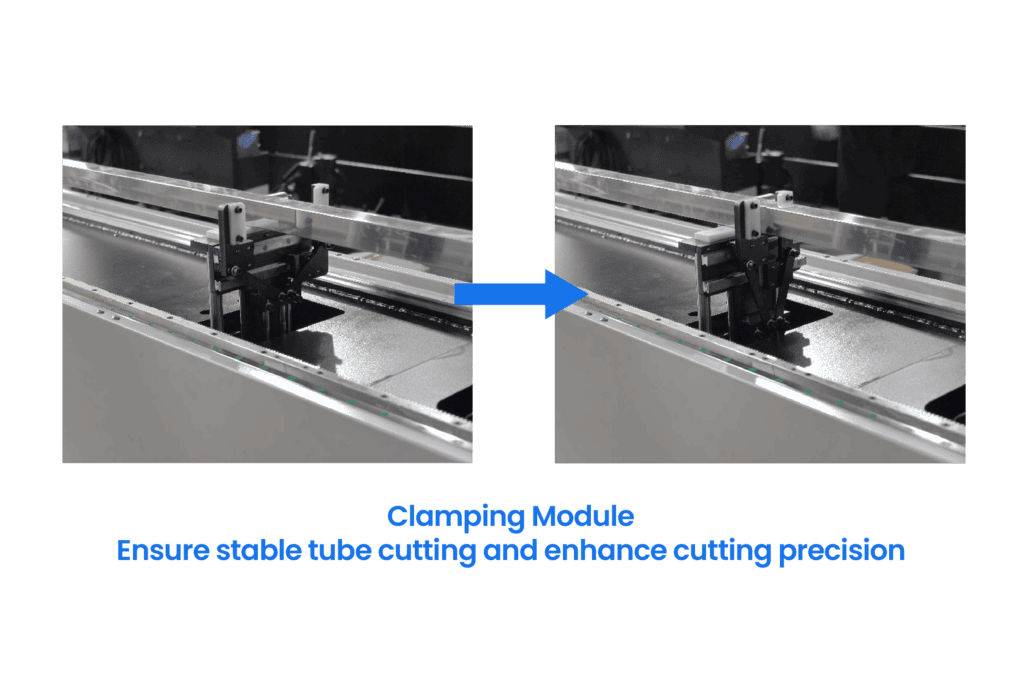

Intelligent Clamping System

The pneumatic cylinder follow-up support function prevents pipe fittings from swinging left and right, improving precision. Higher clamping force, better dynamic performance, and faster response speed.

Ultra-high Processing Capability

The multifunctional integrated solution offers high efficiency in cutting, punching, and grooving, no need for any drawing software, no need for molds, one machine to solve multiple pipe processing procedures.

Equipment parameters

| K12 | |

|---|---|

| Laser Power | 1500W~3000W |

| Tubes can be processed | Round tube: φ10~120mm Square tube: 10*10~120*120mm (when clamping a large square tube, the chamfer of the tube must be greater than R10mm) Channel steel: 8# (standard clamp, need to add nesting software) Angle iron: 8# (standard clamp, need to add nesting software) |

| Tail length | ≥60mm |

| Tube processing length | 6500mm |

| Max Speed | 100m/min |

| Max load capacity of single tube | 100kg |

| Dimension(L*W*H) | 8680*1650*2080mm |